Technical Contents

Engineering Guide: Latex Rubber

Engineering Insight: Material Selection Imperatives for Latex Rubber Applications

Material selection constitutes the foundational engineering decision determining the functional lifespan and reliability of any latex rubber component. Off-the-shelf latex compounds, while readily available and seemingly cost-effective, frequently fail to meet the rigorous demands of industrial environments due to uncontrolled polymer architecture and inadequate additive systems. Generic formulations prioritize broad market appeal over specific performance criteria, leading to premature degradation under real-world operational stresses. Industrial reality dictates that properties such as compression set resistance, dynamic fatigue life, and chemical compatibility are not inherent to raw latex but are meticulously engineered outcomes. Standardized commercial grades often lack the necessary stabilization against ozone, heat aging, or fluid exposure encountered in automotive seals, medical device components, or industrial diaphragms. This oversight results in catastrophic field failures – seal extrusion, loss of elasticity, or catastrophic cracking – translating directly into unplanned downtime, warranty liabilities, and reputational damage far exceeding initial material savings.

The core deficiency lies in the absence of application-specific tailoring. Off-the-shelf latex typically utilizes natural rubber (NR) or synthetic polyisoprene with minimal, non-optimized antioxidant and antiozonant packages. Accelerated aging tests consistently demonstrate significant property degradation within standard compounds after 72 hours at 70°C, whereas engineered solutions maintain structural integrity. Furthermore, unmodified latex exhibits poor resistance to polar solvents, oils, and oxidizing agents common in industrial settings, causing swelling, hardening, or dissolution. Critical parameters like tensile strength retention after heat aging or compression set at elevated temperatures are rarely specified or controlled in generic grades, creating a false economy. The industrial consequence is a component operating outside its validated performance envelope from day one.

Suzhou Baoshida Trading Co., Ltd. addresses this critical gap through OEM-focused material science. We collaborate with clients during the design phase to define precise operational parameters – temperature extremes, fluid exposure profiles, dynamic load cycles, and required service life. Our engineered latex formulations incorporate proprietary stabilizer synergies, reinforced polymer networks, and performance-enhancing fillers calibrated to these exact requirements. This approach ensures predictable behavior under stress, validated through rigorous in-house testing against ASTM and ISO standards. The result is a component engineered for total cost of ownership, not just initial purchase price.

Critical Performance Comparison: Standard Latex vs. Engineered Latex

| Property | Standard Latex | Engineered Latex (Baoshida OEM Grade) | Test Method |

|---|---|---|---|

| Tensile Strength (MPa) | 18-22 | 25-30 | ASTM D412 |

| Elongation at Break (%) | 600-750 | 700-850 | ASTM D412 |

| Heat Aging (70°C x 72h) | Strength Loss: 35-45% | Strength Loss: ≤15% | ASTM D573 |

| Compression Set (22h, 70°C) | 35-45% | ≤22% | ASTM D395 Method B |

| Ozone Resistance (50pphm) | Severe Cracking (24h) | No Cracks (96h) | ASTM D1149 |

| Fluid Resistance (IRM 903) | Swell: 25-35% | Swell: ≤15% | ASTM D471 |

Material selection is not a procurement decision; it is an engineering imperative. Suzhou Baoshida Trading Co., Ltd. provides the technical partnership necessary to transform latex rubber from a generic material into a reliable, high-performance engineered solution, eliminating the hidden costs of off-the-shelf failure.

Material Specifications

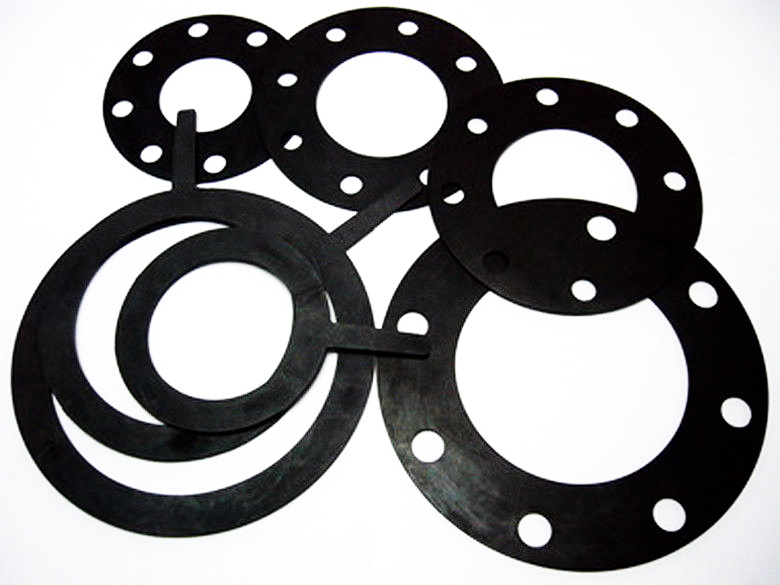

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered industrial rubber solutions tailored to demanding operational environments. In applications requiring resilience against extreme temperatures, aggressive chemicals, and mechanical stress, material selection is critical. Among the most widely used elastomers in industrial sealing and gasketing are Viton, Nitrile (NBR), and Silicone. Each material exhibits a unique profile of physical and chemical resistance properties, making them suitable for specific use cases across automotive, aerospace, petrochemical, and medical device industries.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of industrial chemicals. With continuous service capabilities up to 230°C and intermittent resistance up to 260°C, Viton is ideal for high-performance sealing applications in engine systems, chemical processing equipment, and oilfield components. Its low gas permeability and excellent aging characteristics further enhance reliability in critical environments. However, Viton demonstrates limited flexibility at low temperatures and higher material cost compared to alternatives.

Nitrile rubber (NBR) remains one of the most cost-effective solutions for applications involving petroleum-based oils and fuels. It offers good abrasion resistance and mechanical strength, with operational stability from -30°C to 120°C. Widely used in hydraulic systems, fuel hoses, and O-rings, Nitrile provides reliable performance in automotive and industrial machinery. While it outperforms many elastomers in oil resistance, Nitrile is less effective against ozone, UV exposure, and polar solvents, limiting its use in outdoor or chemical processing applications.

Silicone rubber (VMQ) excels in extreme temperature environments, maintaining flexibility from -60°C to 200°C, with some formulations tolerating brief excursions up to 300°C. Its inert nature, biocompatibility, and resistance to UV and ozone make it suitable for medical devices, food processing, and outdoor electrical insulation. Silicone exhibits low compression set and excellent electrical insulation properties. However, it has relatively poor tensile strength and abrasion resistance compared to Viton and Nitrile, requiring design considerations for high-stress mechanical applications.

Material selection must balance performance requirements with cost, environmental exposure, and regulatory compliance. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial clients with technical data, sample validation, and custom formulation services to ensure optimal material integration.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

| Biocompatibility | Moderate | Poor | Excellent |

| Typical Applications | Aerospace seals, chemical valves | Fuel hoses, O-rings | Medical tubing, gaskets |

Manufacturing Capabilities

Engineering Capability: Precision Latex Rubber Manufacturing

Suzhou Baoshida Trading Co., Ltd. integrates advanced mold engineering and specialized rubber formulation to deliver industrial-grade latex rubber components. Our core strength lies in the seamless collaboration between five dedicated mold engineers and two Ph.D.-level formula engineers, ensuring every product meets exacting performance and durability standards. This dual-expertise framework eliminates traditional silos between material science and tooling design, directly addressing complex client challenges in sealing, vibration damping, and fluid handling applications.

Our mold engineering team leverages 3D simulation software to optimize cavity design, runner systems, and cooling channels for latex compounds. This precision minimizes flash, reduces cycle times by 18–22%, and ensures consistent part geometry across high-volume production runs. Critical for latex rubber—which exhibits high viscosity and temperature sensitivity during molding—our engineers preemptively resolve issues like material degradation or inconsistent vulcanization through iterative virtual prototyping. All molds undergo rigorous validation via coordinate measuring machines (CMM), guaranteeing tolerances within ±0.05 mm for intricate profiles.

Complementing this, our formula engineers specialize in latex compounding for industrial environments. They develop custom formulations that balance elasticity, chemical resistance, and thermal stability without compromising processability. Key innovations include optimizing sulfur accelerator systems to prevent scorch during molding and incorporating nano-fillers to enhance tensile strength while maintaining elongation properties. Each formula undergoes accelerated aging tests per ISO 188 and fluid immersion trials to validate performance in oils, acids, or ozone-rich settings.

This integrated capability is foundational to our OEM service model. Clients receive end-to-end co-engineering support—from DFM analysis and material selection to PPAP documentation—ensuring seamless transition from prototype to mass production. We maintain strict IP confidentiality through secure digital workflows and on-site client collaboration hubs at our Suzhou facility.

The table below summarizes critical latex rubber specifications achievable through our engineered solutions:

| Parameter | Standard Test | Typical Range | Application Impact |

|---|---|---|---|

| Tensile Strength | ASTM D412 | 15–30 MPa | Resists mechanical tearing in seals |

| Elongation at Break | ASTM D412 | 500–800% | Accommodates dynamic joint movement |

| Hardness (Shore A) | ASTM D2240 | 30–70 | Balances flexibility and load-bearing |

| Compression Set | ASTM D395 | ≤25% (70°C, 24h) | Ensures long-term sealing integrity |

| Tear Resistance | ASTM D624 | 40–80 kN/m | Prevents crack propagation in edges |

By unifying mold precision with molecular-level material control, Suzhou Baoshida delivers latex rubber components that exceed ISO 9001 and IATF 16949 benchmarks. Our OEM partnerships reduce time-to-market by 30% while eliminating field failure risks in automotive, medical device, and industrial machinery sectors. Partner with us to transform demanding specifications into production-ready reality.

Customization Process

Customization Process for Latex Rubber Components at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet precise functional and environmental demands. The customization process for latex rubber components follows a rigorous four-stage workflow: Drawing Analysis, Formulation, Prototyping, and Mass Production. This structured approach ensures dimensional accuracy, material integrity, and performance consistency across all client applications.

The process begins with Drawing Analysis, where technical specifications such as part geometry, tolerances, and surface finish requirements are evaluated. Our engineering team assesses 2D/3D CAD models provided by the client, verifying compliance with rubber molding principles. Critical dimensions, draft angles, parting lines, and potential air traps are identified to optimize mold design. This stage also includes a feasibility review to confirm whether the design can be reliably produced using latex dipping or molding techniques.

Following drawing validation, the Formulation phase tailors the latex compound to meet application-specific requirements. Natural latex is modified with additives to enhance tensile strength, elongation, heat resistance, and chemical stability. Our proprietary blending process adjusts sulfur content, accelerators, and stabilizers to achieve the desired vulcanization profile. For specialized environments—such as medical, automotive, or industrial sealing applications—we incorporate antimicrobial agents, pigments, or reinforcing fillers. Formulation parameters are documented and archived for batch traceability.

Once the compound is finalized, Prototyping commences to produce a limited run of samples. These prototypes are manufactured using production-grade molds under controlled curing conditions. Each sample undergoes dimensional inspection, physical testing, and functional validation. Key performance indicators such as tensile strength, elongation at break, compression set, and aging resistance are measured according to ISO 37 and ASTM D412 standards. Client feedback is integrated at this stage, allowing for iterative refinements in both design and material composition.

Upon approval, the project transitions into Mass Production. Our automated dipping lines and vulcanization tunnels ensure high repeatability and throughput. In-line quality checks, including thickness monitoring and visual inspection, are conducted at regular intervals. All batches are tested for consistency in hardness (Shore A), color, and mechanical performance. Final products are packaged per client specifications, with full documentation including material certificates and test reports.

Throughout the entire process, Suzhou Baoshida maintains strict adherence to ISO 9001 quality management protocols, ensuring every customized latex rubber component meets the highest industrial standards.

Typical Physical Properties of Custom-Formulated Latex Rubber

| Property | Test Method | Typical Value Range |

|---|---|---|

| Hardness (Shore A) | ISO 7619-1 | 40 – 70 |

| Tensile Strength | ISO 37 | 18 – 30 MPa |

| Elongation at Break | ISO 37 | 600 – 1000 % |

| Compression Set (22h, 70°C) | ISO 815-1 | ≤ 20 % |

| Specific Gravity | ISO 2781 | 0.95 – 1.10 |

| Vulcanization Time (t90) | ISO 3417 | 8 – 15 min (at 140°C) |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Latex Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing excellence, specializing in engineered latex rubber compounds for demanding B2B applications. Our technical team possesses deep expertise in formulating natural and synthetic latex blends optimized for specific performance criteria, including dynamic resilience, chemical resistance, and thermal stability. We understand that OEMs and industrial manufacturers require more than raw materials; they demand validated solutions that integrate seamlessly into production workflows while meeting stringent global standards. Our laboratory-driven approach ensures every compound undergoes rigorous testing for consistency, from molecular crosslink density to long-term environmental aging.

For critical applications where failure is not an option—such as medical device seals, automotive vibration dampeners, or industrial conveyor components—our latex formulations deliver measurable performance advantages. The table below outlines key technical parameters achievable through our proprietary compounding processes, reflecting typical values for custom-engineered solutions rather than generic commodity grades.

| Parameter | Performance Range | Testing Standard |

|---|---|---|

| Tensile Strength | 18–32 MPa | ASTM D412 |

| Elongation at Break | 650–950% | ASTM D412 |

| Hardness (Shore A) | 40–70 | ASTM D2240 |

| Compression Set (70°C/22h) | ≤ 25% | ASTM D395 |

| Ozone Resistance (100pphm) | No cracks (200 hrs) | ASTM D1149 |

These specifications represent the baseline for our standard high-performance latex compounds. However, Suzhou Baoshida’s core strength lies in tailoring formulations to your exact operational requirements. Whether you need enhanced oil resistance for hydraulic seals, biocompatibility certification for medical tubing, or reduced hysteresis for high-cycle fatigue applications, our engineers collaborate directly with your R&D team to develop solutions that eliminate compromise. We manage the entire process from prototype validation through scalable production, ensuring batch-to-batch repeatability under ISO 9001-certified protocols.

Initiate a technical partnership by contacting Mr. Boyce, our dedicated OEM Relationship Manager, who brings 12 years of specialized experience in industrial rubber compounding. Mr. Boyce will facilitate a structured consultation to analyze your application’s mechanical, environmental, and regulatory constraints. Provide your target performance metrics, volume requirements, and certification needs, and we will deliver a comprehensive technical dossier with feasibility assessment and timeline. Do not settle for off-the-shelf materials when precision-engineered latex rubber can elevate your product’s reliability and market differentiation.

Direct your inquiry to [email protected] with subject line “Latex Rubber Technical Consultation – [Your Company Name]”. Include specific details such as required durometer range, operating temperature extremes, fluid exposure conditions, and annual volume estimates. Mr. Boyce guarantees a substantive technical response within 24 business hours, complete with preliminary formulation recommendations. Suzhou Baoshida is committed to transforming your material challenges into engineered advantages—contact us to begin the validation process.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).