Technical Contents

Engineering Guide: Sticky Strip

Engineering Insight: The Critical Role of Material Selection in Sticky Strip Performance

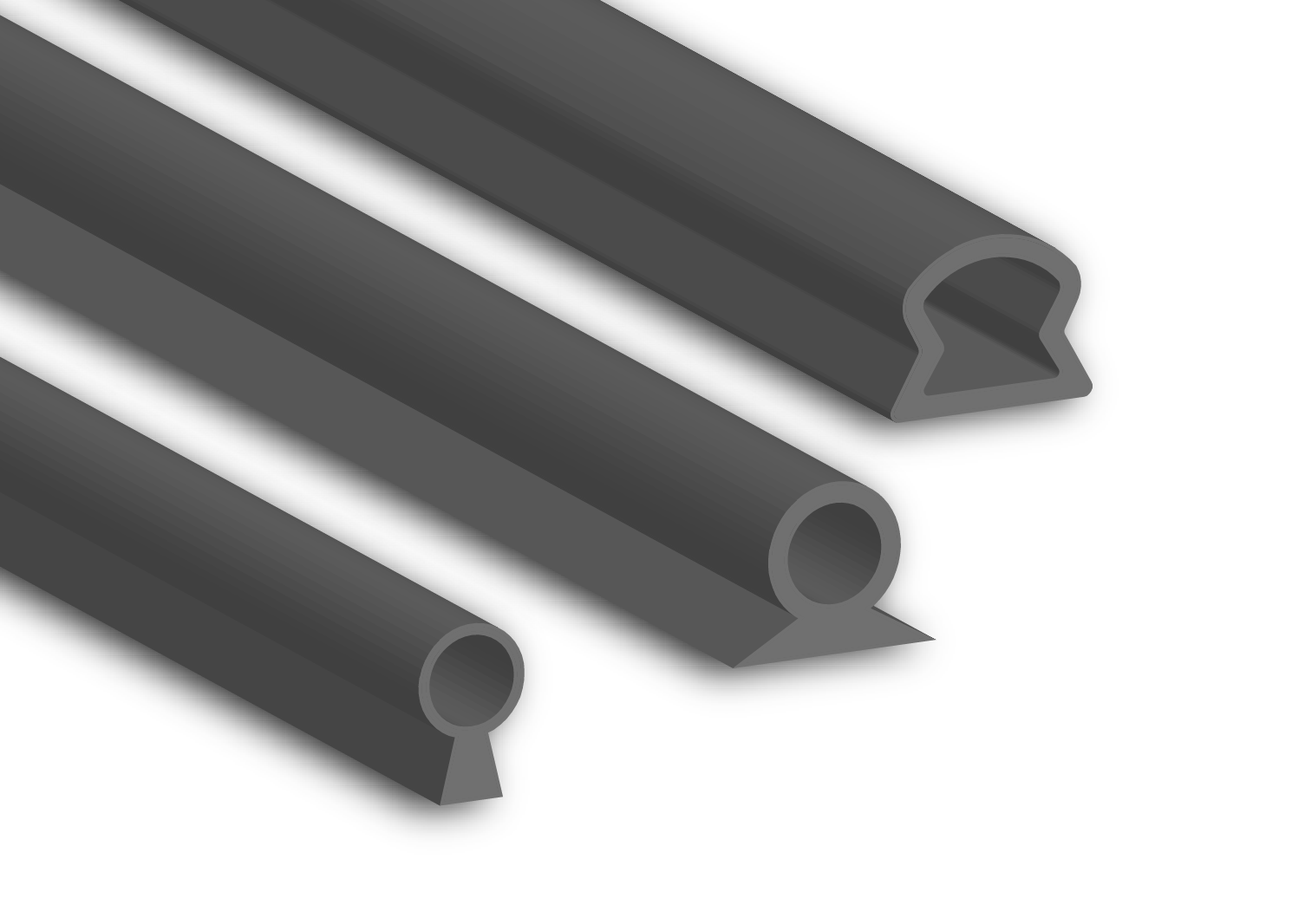

In industrial applications, the term sticky strip often refers to adhesive-coated elastomeric profiles used for sealing, bonding, impact absorption, or surface protection. While these components may appear simple in form, their performance is profoundly influenced by material selection—a factor frequently underestimated when off-the-shelf solutions are deployed without engineering analysis. At Suzhou Baoshida Trading Co., Ltd., we emphasize that successful sticky strip integration begins not with geometry or adhesion strength alone, but with a precise understanding of operational environment and material compatibility.

Off-the-shelf sticky strips are typically formulated for general-purpose use, relying on standardized rubber compounds such as natural rubber (NR) or low-grade EPDM. These materials may provide adequate initial tack and flexibility under benign conditions. However, they often degrade rapidly when exposed to industrial stressors such as UV radiation, ozone, temperature extremes, or chemical exposure. The consequence is premature failure—delamination, hardening, loss of adhesion, or embrittlement—leading to increased maintenance costs and system downtime.

For example, a standard NR-based sticky strip installed in an outdoor automotive assembly line may perform well in the first month. However, prolonged exposure to engine oils and sunlight accelerates oxidative degradation, causing the rubber matrix to crack and the adhesive layer to detach. In contrast, a fluoroelastomer (FKM) or high-saturation nitrile (HSN) formulation—engineered for oil and heat resistance—would maintain integrity over extended service life.

Material selection must also account for substrate compatibility, surface energy, and application pressure. A silicone-based adhesive may offer excellent thermal stability, but if applied to a low-energy polyolefin surface without proper priming, adhesion will fail regardless of bulk material quality. Similarly, soft elastomers like sponge neoprene provide conformability on uneven surfaces but may compress permanently under continuous load unless properly durometer-rated.

At Baoshida, we approach sticky strip design through a systems engineering lens. Each formulation is evaluated against application-specific parameters including temperature range, dynamic vs. static loading, exposure media, and expected service duration. This methodology ensures that the final product is not merely “sticky,” but functionally reliable.

Below is a comparative analysis of common elastomer types used in industrial sticky strips:

| Material | Temperature Range (°C) | Key Resistance Properties | Typical Adhesive Type | Common Industrial Use |

|---|---|---|---|---|

| EPDM | -50 to +150 | Ozone, UV, water | Acrylic | Outdoor enclosures, roofing |

| NBR | -30 to +120 | Oil, fuel, abrasion | Rubber-based | Automotive gaskets, machinery |

| Silicone | -60 to +230 | Heat, cold, electrical | Silicone PSA | Electronics, aerospace |

| FKM | -20 to +250 | Chemicals, oils, high heat | Fluoropolymer | Petrochemical, engine systems |

| HSN | -40 to +130 | Oil, heat (improved NBR) | Modified acrylic | Transmission components |

Material selection is not a secondary consideration—it is the foundation of sticky strip reliability. Generic solutions may reduce initial procurement cost, but they compromise long-term performance. Precision-engineered elastomeric systems, tailored to operational demands, deliver superior return on investment through durability, consistency, and reduced lifecycle cost.

Material Specifications

Material Specifications for Industrial Sticky Strip Applications

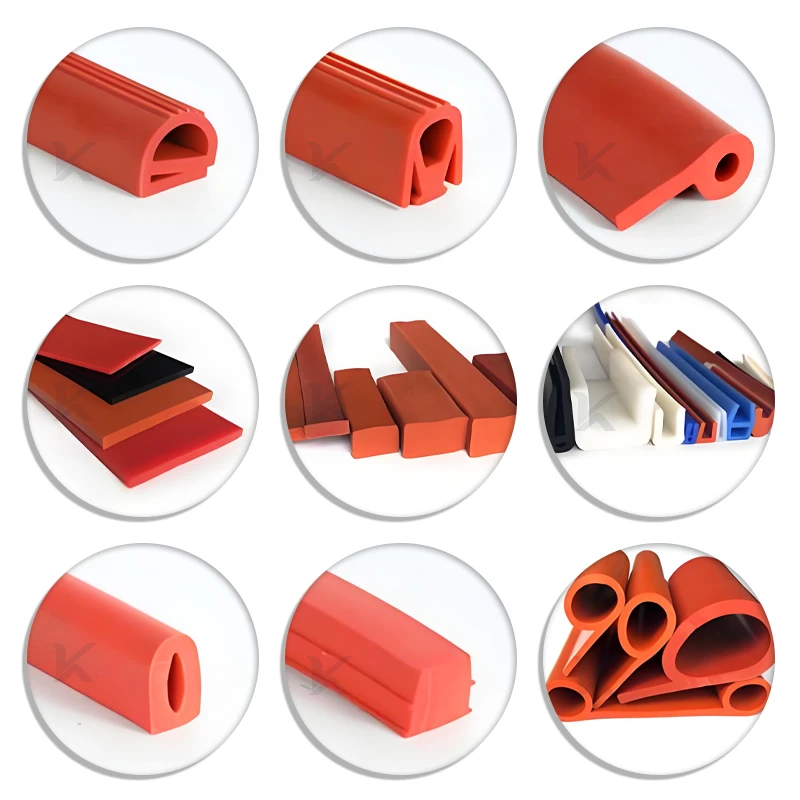

Selecting the optimal elastomer compound is critical for sticky strip performance in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., our OEM-engineered solutions prioritize chemical resistance, thermal stability, and adhesion consistency under operational stress. Viton, Nitrile, and Silicone represent three core material families, each engineered for distinct service conditions. Precision in material selection directly impacts seal integrity, longevity, and compliance with industry-specific regulatory frameworks.

Viton fluoroelastomers deliver exceptional resistance to aggressive chemicals, including fuels, oils, and acids, while maintaining structural integrity across extreme temperatures. Our standard Viton formulations operate reliably from -20°C to 230°C, with short-term exposure tolerance up to 300°C. These compounds exhibit low gas permeability and outstanding resistance to compression set, making them ideal for aerospace hydraulic systems, semiconductor processing equipment, and chemical handling applications where failure is not an option.

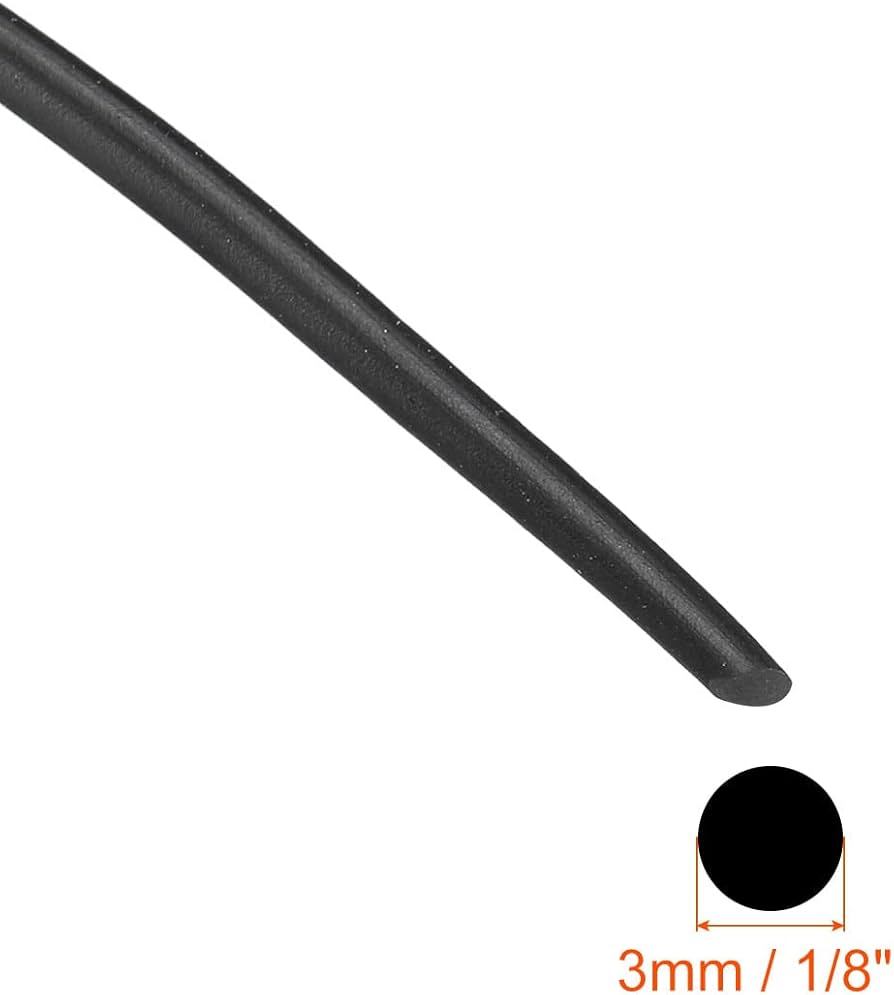

Nitrile rubber (NBR) remains the industry standard for cost-effective oil and fuel resistance in moderate-temperature scenarios. Baoshida’s Nitrile sticky strips feature acrylonitrile content ranging from 34% to 45%, balancing oil resistance with low-temperature flexibility. Standard grades function effectively between -30°C and 120°C, with specialized high-ACN variants extending oil resistance at the expense of cold flexibility. Shore A hardness is precisely controlled at 70±5, ensuring consistent sealing force in automotive fuel systems, hydraulic machinery, and general industrial fluid handling.

Silicone rubber provides unmatched flexibility across broad thermal ranges and superior resistance to ozone and weathering. Our platinum-cured silicone compounds maintain elasticity from -60°C to 200°C, with brief excursions to 230°C. While exhibiting moderate oil resistance, they excel in food-grade, medical, and outdoor applications due to inherent biocompatibility and UV stability. Shore A hardness ranges from 40 to 60, enabling conformability to irregular surfaces in electronic enclosures, pharmaceutical processing, and solar panel sealing.

The following comparative analysis details critical performance parameters for strategic material selection

| Material | Temperature Range (°C) | Key Chemical Resistances | Shore A Hardness | Primary Industrial Applications |

|---|---|---|---|---|

| Viton | -20 to 230 (300 short) | Fuels, oils, acids, solvents | 75±5 | Aerospace hydraulics, semiconductor tools |

| Nitrile | -30 to 120 | Aliphatic hydrocarbons, oils | 70±5 | Automotive fuel systems, hydraulic seals |

| Silicone | -60 to 200 (230 short) | Ozone, UV, water, steam | 40-60 | Medical devices, food processing, solar |

Material selection must account for synergistic factors beyond individual properties. Viton’s superior chemical resistance incurs higher material costs but reduces lifecycle expenses in critical systems. Nitrile offers optimal value for standard oil exposure but degrades rapidly with aromatic hydrocarbons. Silicone’s thermal breadth is unmatched, though mechanical strength diminishes under high-pressure dynamic loads. Baoshida’s OEM engineering team collaborates with clients to validate material performance against real-world operational profiles, ensuring sticky strip formulations meet exacting functional and compliance requirements. This precision-driven approach minimizes field failures and maximizes service life across industrial sealing applications.

Manufacturing Capabilities

Engineering Excellence in Industrial Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation in the industrial rubber manufacturing sector. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver precision-engineered sticky strip solutions tailored to the exacting demands of global OEMs. Our integrated approach ensures that both material science and mechanical design are optimized in parallel, reducing development cycles and enhancing product performance.

Our mould engineers bring over 70 combined years of experience in precision tooling design, utilizing advanced CAD/CAM systems and finite element analysis (FEA) to simulate stress, compression, and adhesion behavior under real-world operating conditions. This enables us to design robust, high-cycle moulds that ensure dimensional accuracy, consistent part quality, and extended tool life. Whether producing simple linear profiles or complex multi-cavity configurations, our tooling team ensures rapid prototyping, tight tolerance control, and seamless scalability from pilot runs to full-volume production.

Complementing our mould expertise is our in-house rubber formulation capability. Our two senior formula engineers specialize in compounding elastomers for targeted performance characteristics, including adhesion strength, temperature resistance, compression set, and aging stability. We work extensively with EPDM, silicone, NBR, and TPE systems, customizing formulations to meet specific OEM requirements for durability, chemical resistance, and surface tack. This vertical integration of material development and tooling design allows us to solve complex application challenges—such as maintaining consistent stickiness across varying environmental conditions—without reliance on external suppliers.

We operate as a full-service OEM partner, providing end-to-end development from concept to certified production. Our clients benefit from IP-protected processes, rigorous quality control (IATF 16949-aligned), and full traceability across batches. We support low-surface-energy substrates, automotive sealing systems, electronic enclosures, and industrial assembly applications where reliable, long-term adhesion is critical.

The following table outlines the key technical capabilities and performance parameters achievable with our sticky strip solutions:

| Parameter | Standard Range | Customizable Up To | Testing Method |

|---|---|---|---|

| Adhesion Strength (Peel) | 1.5–3.0 N/cm | 5.0 N/cm | ASTM D3330 |

| Operating Temperature | -40°C to +120°C | -60°C to +200°C (silicone) | ASTM D1329 / ISO 188 |

| Hardness (Shore A) | 40–80 | 30–90 | ASTM D2240 |

| Compression Set (24h @ 70°C) | ≤20% | ≤10% | ASTM D395 |

| Tensile Strength | 6–12 MPa | 15 MPa | ASTM D412 |

| Elongation at Break | 250–500% | 700% | ASTM D412 |

| Mould Tolerance | ±0.1 mm | ±0.05 mm | CMM Inspection (ZEISS) |

By combining deep materials expertise with precision engineering, Suzhou Baoshida delivers sticky strip solutions that meet the highest standards of reliability and performance in demanding industrial environments.

Customization Process

Customization Process for Industrial Sticky Strip Solutions

At Suzhou Baoshida Trading Co., Ltd., our sticky strip customization process integrates rigorous engineering protocols with OEM manufacturing excellence. This structured workflow ensures precise alignment with client specifications while maintaining industrial scalability. Each phase undergoes stringent validation to eliminate performance deviations in final applications.

Drawing Analysis initiates the process. Our engineering team dissects technical drawings to verify dimensional tolerances, substrate compatibility, and environmental exposure requirements. Critical parameters such as strip width, thickness variance (±0.05 mm), and adhesion geometry are cross-referenced against ISO 3302-1 standards. We identify potential stress points in the design that could compromise peel strength or thermal stability, providing actionable feedback within 72 hours. This phase prevents downstream tooling errors and ensures manufacturability.

Formulation Development follows, leveraging our proprietary rubber compound database. Based on the drawing analysis, we select polymer backbones—typically hydrogenated nitrile rubber (HNBR) or silicone—for optimal balance of tack force and chemical resistance. Key variables include crosslink density adjustments to achieve target Shore A hardness (40–80), controlled filler dispersion for UV stability, and tackifier concentration calibrated to substrate energy. All formulations undergo accelerated aging simulations per ASTM D573 before prototyping.

Prototyping validates the formulation under real-world conditions. Using CNC-machined molds, we produce 50–100 sample units with exact client-specified dimensions. Each prototype undergoes SGS-certified testing: initial tack force (ASTM D2979), peel strength at 180° (ASTM D3330), and thermal cycling from -40°C to 150°C. Client feedback on prototype performance triggers iterative refinements, typically resolved within two cycles. This phase confirms adhesion consistency across substrates like powder-coated steel or polycarbonate.

Mass Production commences only after prototype sign-off. Our Suzhou facility employs automated extrusion lines with laser-guided thickness control (±0.03 mm) and inline IR curing ovens. Every production batch includes real-time rheometry monitoring to ensure cure kinetics match formulation targets. Final inspection uses automated vision systems to detect surface defects at 0.1 mm resolution, with 100% electrical continuity testing for conductive variants. Shipment documentation includes full material traceability certificates and batch-specific performance dossiers.

The table below summarizes critical performance specifications achievable through this process

| Property | Test Method | Range | Tolerance |

|---|---|---|---|

| Initial Tack Force | ASTM D2979 | 1.5–8.0 N/mm | ±0.2 N/mm |

| Peel Strength (180°) | ASTM D3330 | 4.0–22.0 N/mm | ±0.5 N/mm |

| Operating Temperature | ISO 188 | -40°C to +150°C | ±5°C |

| Hardness (Shore A) | ASTM D2240 | 40–80 | ±3 points |

| Elongation at Break | ASTM D412 | 150%–450% | ±20% |

This end-to-end methodology guarantees that every sticky strip shipment meets the exact functional demands of automotive seals, electronics assembly, or construction gasketing applications. Suzhou Baoshida’s integration of material science and precision manufacturing eliminates performance gaps between design intent and field reliability.

Contact Engineering Team

For industrial manufacturers seeking high-performance rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of precision-engineered rubber components. Our expertise in industrial rubber formulations and custom extrusion processes enables us to deliver reliable, durable, and application-specific products, including our advanced sticky strip solutions. Engineered for consistent adhesion, temperature resistance, and long-term durability, our sticky strips are designed to meet the rigorous demands of automotive assembly, construction sealing, electronics manufacturing, and industrial automation.

Our sticky strip products are formulated using proprietary rubber compounds that ensure optimal tackiness without residue, excellent bonding to substrates, and resistance to environmental stressors such as UV exposure, moisture, and thermal cycling. Whether you require EPDM, silicone, neoprene, or custom-blend rubber profiles, we maintain strict quality control throughout the production cycle—from raw material selection to final inspection. Each batch is tested for tensile strength, elongation, adhesion performance, and compression set to guarantee compliance with international standards.

Suzhou Baoshida specializes in OEM collaboration, offering full technical support from concept to volume production. Our engineering team works directly with clients to optimize material selection, cross-sectional design, adhesive backing type, and packaging format. We support low-volume prototyping as well as high-volume continuous extrusion, ensuring scalability without compromise in quality.

Below are representative technical specifications for our standard sticky strip product line:

| Property | Test Method | Value/Range |

|---|---|---|

| Base Material | — | EPDM, Silicone, Neoprene |

| Hardness (Shore A) | ASTM D2240 | 40–80 |

| Tensile Strength | ASTM D412 | 8–15 MPa |

| Elongation at Break | ASTM D412 | 200–500% |

| Operating Temperature Range | — | -40°C to +150°C |

| Adhesion to Steel (Peel) | ASTM D3330 | 0.8–1.5 N/mm |

| Compression Set (24h @ 70°C) | ASTM D395 | ≤25% |

| Color Options | — | Black, White, Gray, Custom |

| Standard Lengths | — | 10m, 25m, 50m, 100m |

To discuss your specific application requirements or request custom formulation data, we invite you to contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over 15 years of experience in industrial elastomer systems, Mr. Boyce leads technical client engagement and ensures that every product solution is grounded in scientific rigor and manufacturing practicality.

Reach out today to initiate a technical consultation. Email Mr. Boyce directly at [email protected] to request material data sheets, sample kits, or a customized quote. Our team responds to all inquiries within 24 business hours and supports communication in English, Mandarin, and technical engineering terminology. At Suzhou Baoshida Trading Co., Ltd., we are committed to delivering not just rubber products—but engineered adhesion solutions that enhance your manufacturing performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).