Technical Contents

Engineering Guide: Styrofoam Acoustic Insulation

Engineering Insight: Material Selection in Styrofoam Acoustic Insulation

In industrial environments where noise control is critical, styrofoam acoustic insulation is frequently deployed for its lightweight structure and cost-effective thermal performance. However, its acoustic efficacy is highly dependent on precise material engineering and application-specific customization. Off-the-shelf styrofoam solutions, while readily available, often fail to meet the rigorous demands of industrial noise attenuation due to inherent limitations in density, cell structure, and mechanical stability under operational stress.

Standard expanded polystyrene (EPS) or extruded polystyrene (XPS) foams are engineered primarily for thermal insulation, not sound absorption. Their closed-cell architecture reflects mid- to high-frequency sound waves rather than absorbing them, resulting in poor Noise Reduction Coefficient (NRC) ratings. In dynamic environments—such as manufacturing floors, HVAC enclosures, or machinery housings—this reflective behavior exacerbates noise pollution rather than mitigating it. Furthermore, these materials lack the viscoelastic damping properties essential for attenuating structure-borne vibrations, a dominant noise transmission path in industrial systems.

Material selection must account for three primary acoustic mechanisms: absorption, transmission loss, and damping. Generic styrofoam performs inadequately across all three. Its low density (typically 15–30 kg/m³) limits mass-based sound blocking, while its brittle nature makes it prone to cracking under thermal cycling or mechanical load. When installed near vibrating surfaces, such as compressor panels or ductwork, standard styrofoam delaminates or compresses unevenly, creating acoustic flanking paths that degrade system performance.

At Suzhou Baoshida Trading Co., Ltd., we address these shortcomings through engineered composite solutions. By integrating modified polystyrene matrices with elastomeric binders and open-cell acoustic facings, we achieve broadband sound absorption without sacrificing structural integrity. Our formulations are tailored to match the vibrational signature and environmental conditions of the target application, ensuring long-term performance under humidity, temperature extremes, and mechanical stress.

The following table compares key properties of standard styrofoam versus engineered acoustic composites:

| Property | Standard Styrofoam (EPS/XPS) | Engineered Acoustic Composite |

|---|---|---|

| Density (kg/m³) | 15–30 | 40–80 |

| Noise Reduction Coefficient | 0.10–0.25 | 0.55–0.85 |

| Sound Transmission Class | 25–30 | 35–45 |

| Compression Set (25%, 24h) | >20% | <8% |

| Temperature Resistance (°C) | -40 to +70 | -60 to +120 |

| Cell Structure | Closed-cell | Hybrid open/closed |

| Damping Loss Factor (100 Hz) | 0.02–0.04 | 0.15–0.25 |

These engineered composites exemplify how precise material science elevates styrofoam from a basic insulator to a high-performance acoustic solution. The failure of off-the-shelf products underscores a broader principle in industrial rubber solutions: acoustic performance cannot be retrofitted—it must be designed in from the molecular level. At Baoshida, we leverage polymer modification, composite layering, and application-specific testing to deliver insulation systems that perform reliably in real-world conditions.

Material Specifications

Material Specifications: Rubber Compounds for Acoustic Insulation Systems

Suzhou Baoshida Trading Co., Ltd. clarifies a critical industry distinction: Styrofoam (expanded polystyrene, EPS) is not a rubber material and falls outside our core expertise in elastomeric solutions. As an OEM partner specializing in industrial rubber formulations, we address the sealing and damping components essential to acoustic insulation assemblies. Rubber elements—such as gaskets, seals, and vibration isolators—complement rigid insulation like EPS/XPS by preventing sound leakage at joints, flanges, and structural interfaces. Our engineered compounds (Viton, Nitrile, Silicone) provide the resilience, density, and damping properties required for effective noise control in demanding environments. Selecting the optimal elastomer ensures long-term acoustic integrity under thermal, chemical, and mechanical stress.

The following table details key specifications for our primary rubber compounds used in acoustic applications. Data reflects standard formulations per ASTM D2000; customizations for enhanced sound absorption or temperature stability are available through our OEM engineering services.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -40 to +120 | -60 to +230 |

| Chemical Resistance | Excellent (fuels, oils, acids) | Good (oils, water) | Poor (fuels, oils) |

| Density (g/cm³) | 1.85 | 1.05 | 1.20 |

| Hardness (Shore A) | 70 ± 5 | 75 ± 5 | 60 ± 5 |

| Compression Set (%)* | ≤ 20 (24h @ 150°C) | ≤ 25 (24h @ 70°C) | ≤ 20 (24h @ 150°C) |

| Acoustic Damping (Loss Factor) | 0.15–0.25 | 0.10–0.20 | 0.08–0.15 |

*Per ASTM D395 Method B. Lower values indicate superior recovery for sustained sealing pressure.

Viton demonstrates unmatched performance in high-temperature acoustic barriers exposed to aggressive chemicals, such as engine compartments or industrial exhaust systems. Its high density (1.85 g/cm³) enhances mass-law sound blocking, while the loss factor of 0.15–0.25 provides effective vibration damping. Nitrile remains the cost-optimized solution for general-purpose acoustic gaskets in HVAC or machinery enclosures, balancing oil resistance and damping capability within moderate thermal ranges. Silicone excels in extreme low-temperature applications (e.g., aerospace or cryogenic insulation) due to its flexibility below -60°C, though its lower density and chemical susceptibility necessitate careful system design.

Critical selection criteria include the operational temperature profile, exposure to fluids, required compressive load, and target frequency range for noise attenuation. Viton’s superior compression set retention ensures consistent sealing force in high-heat scenarios where NBR would permanently deform. Conversely, NBR offers optimal value for water-based environments where chemical aggression is minimal. Silicone’s wide thermal stability suits applications with rapid cycling but requires reinforcement for high-pressure acoustic seals. All compounds undergo rigorous ISO 10534 testing for sound absorption coefficients at Suzhou Baoshida’s R&D facility.

As your OEM partner, we prioritize application-specific formulation. Our engineers collaborate to adjust filler systems (e.g., barium sulfate for increased density) or polymer blends to meet precise acoustic transmission loss (ATL) requirements. Contact our technical team to validate material suitability against your insulation assembly’s performance metrics.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Solutions for Industrial Acoustic Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in a highly specialized team of professionals dedicated to advancing industrial rubber solutions for demanding environments. With five dedicated mould engineers and two expert formula engineers, we bring a synergistic blend of material science and precision manufacturing to every project. This integrated approach ensures that our styrofoam acoustic insulation systems meet exacting performance standards in noise attenuation, thermal stability, and mechanical resilience.

Our formula engineers focus on polymer chemistry optimization, tailoring rubber compounds to achieve superior sound absorption and vibration damping characteristics. By modifying cross-link density, filler dispersion, and elastomer base selection, we engineer materials that perform reliably across a broad temperature range and resist degradation from environmental exposure. These formulations are specifically designed to complement expanded polystyrene (EPS) or extruded polystyrene (XPS) substrates used in acoustic insulation panels, enhancing durability without compromising acoustic transparency.

Simultaneously, our mould engineering team leverages advanced CAD/CAM software and finite element analysis (FEA) to design and validate mould tooling with micron-level accuracy. This precision ensures consistent part geometry, optimal cell structure integrity in foam integration, and seamless bonding between rubber and styrofoam components. The team routinely develops multi-cavity and family moulds to support high-volume production, while maintaining strict dimensional tolerances and surface quality control.

As an OEM manufacturer, Suzhou Baoshida excels in end-to-end product realization. From initial concept and material selection to prototyping, tooling, and serial production, we manage every phase under ISO 9001-certified processes. Our OEM clients benefit from rapid design iteration, DFMEA support, and full traceability throughout the supply chain. This capability is particularly critical in automotive, HVAC, and industrial equipment sectors, where acoustic performance and regulatory compliance are paramount.

We support custom geometries, durometer ranges, and bonding configurations, ensuring compatibility with diverse assembly methods including adhesive lamination, mechanical fastening, and overmoulding techniques. Our facility is equipped with hydraulic presses, CNC mould manufacturing units, and environmental testing chambers to validate product performance under real-world conditions.

The following table outlines key technical parameters supported by our engineering team for styrofoam acoustic insulation components:

| Parameter | Capability Range | Testing Standard |

|---|---|---|

| Durometer (Shore A) | 30–90 | ASTM D2240 |

| Temperature Resistance | -40°C to +120°C (continuous) | ISO 188 |

| Tensile Strength | 5–18 MPa | ASTM D412 |

| Elongation at Break | 200–600% | ASTM D412 |

| Compression Set (24h, 70°C) | ≤25% | ASTM D395 |

| Sound Absorption Coefficient | 0.45–0.85 (1000–4000 Hz) | ASTM C423 |

| Mould Tolerance | ±0.05 mm | ISO 2768 |

This combination of advanced material formulation, precision tooling, and OEM agility positions Suzhou Baoshida as a trusted engineering partner for high-performance acoustic insulation systems.

Customization Process

Customization Process for Rubber-Modified Polystyrene Acoustic Insulation Solutions

Suzhou Baoshida Trading Co., Ltd. implements a rigorous, science-driven customization workflow for industrial acoustic insulation solutions based on rubber-modified expanded polystyrene (EPS) and extruded polystyrene (XPS) composites. This process ensures optimal noise attenuation performance while meeting stringent OEM dimensional, thermal, and durability requirements. Our methodology transitions seamlessly from conceptual design to high-volume manufacturing, prioritizing material science precision at every stage.

The engagement commences with comprehensive Drawing Analysis. Our engineering team conducts a detailed review of client-provided CAD models and acoustic specifications, focusing on critical parameters such as cavity geometry, mounting constraints, and target frequency attenuation ranges. Finite element analysis (FEA) simulates sound wave propagation through the proposed geometry, identifying potential resonance points and material stress concentrations. This phase validates dimensional feasibility against manufacturing tolerances (typically ±0.5mm for critical interfaces) and establishes baseline acoustic performance metrics using industry-standard simulation software. Client feedback on initial modeling outputs is integrated before proceeding.

Subsequent Formulation Development leverages Suzhou Baoshida’s proprietary rubber compound database. Based on the acoustic profile and environmental exposure requirements (e.g., automotive under-hood temperatures up to 150°C or HVAC moisture resistance), our chemists adjust the elastomeric phase within the polystyrene matrix. Key variables include rubber type (EPDM, SBR, or specialty nitrile), crosslink density, filler composition (e.g., barium sulfate for enhanced mass law effects), and cell structure modifiers. This stage optimizes the viscoelastic damping properties critical for broadband noise absorption, particularly in the 500-5000 Hz range relevant to machinery and transportation noise. Formulation targets are validated through small-batch compound testing per ASTM D2240 (hardness) and ISO 1856 (compression set).

Prototyping utilizes precision CNC-machined molds or 3D-printed tooling to produce functional samples within 10-15 business days. Each prototype undergoes rigorous validation against the original acoustic and mechanical specifications. Critical tests include impedance tube measurements per ASTM E1050 for Normal Incidence Sound Absorption Coefficient, reverberation room testing per ASTM C423 for Noise Reduction Coefficient (NRC), and thermal cycling per ISO 1143. Client-side installation trials and performance verification are mandatory before final sign-off. Sample iterations address any deviations in compression recovery, adhesion strength, or spectral absorption characteristics.

Upon prototype approval, Mass Production initiates under our ISO 9001-certified quality management system. Continuous extrusion or molding lines operate with real-time monitoring of critical process parameters: melt temperature (±2°C), die pressure, cooling rates, and vulcanization profiles. In-line quality control includes automated dimensional scanning and periodic destructive testing of production lots for acoustic performance consistency (NRC variance < ±0.05). Suzhou Baoshida maintains dedicated production cells for custom formulations, ensuring batch-to-batch repeatability and traceability from raw material certificates to finished goods inspection reports. Production scaling achieves volumes from 5,000 to 500,000 units monthly with lead times starting at 25 days.

Key Performance Specifications Comparison

| Parameter | Standard Acoustic EPS/XPS | Baoshida Custom Rubber-Modified Composite | Test Standard |

|---|---|---|---|

| Density Range (kg/m³) | 15-30 | 25-60 (adjustable) | ISO 845 |

| Noise Reduction Coefficient (NRC) | 0.20-0.50 | 0.55-0.85 | ASTM C423 |

| Thermal Stability Range | -50°C to 75°C | -60°C to 150°C | ISO 11359-2 |

| Compression Set (25%, 23h) | 15-25% | 8-15% | ISO 1856 |

| Flame Resistance (UL94) | HB | HB to V-0 (customizable) | UL 94 |

| Frequency Range (Optimal) | 1000-4000 Hz | 250-6000 Hz | ASTM E1050 |

This structured customization pathway ensures Suzhou Baoshida delivers acoustically superior, application-specific insulation solutions that directly address OEM noise control challenges while maintaining manufacturing scalability and uncompromised quality.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Rubber-Based Acoustic Insulation Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber solutions, delivering high-performance materials tailored for demanding acoustic and thermal applications. While expanded polystyrene (EPS), commonly referred to as styrofoam, has been traditionally used for basic insulation, its limitations in durability, fire resistance, and long-term acoustic performance make it unsuitable for advanced industrial environments. At Baoshida, we specialize in engineered rubber composites that outperform conventional foam-based materials in noise attenuation, vibration damping, and environmental resilience. Our rubber-based acoustic insulation systems are designed for OEMs, automotive manufacturers, HVAC integrators, and industrial equipment builders who require precision-engineered, long-lasting sound control solutions.

Our technical team, led by Mr. Boyce, brings over a decade of experience in rubber formulation and industrial acoustics. We understand that every application presents unique challenges—whether it’s reducing cabin noise in heavy machinery, isolating vibrations in precision equipment, or meeting stringent fire safety codes in public transport. Through customized compound development, advanced lamination techniques, and rigorous testing protocols, we deliver solutions that meet exact performance criteria. Unlike brittle foam materials that degrade under mechanical stress or extreme temperatures, our rubber composites maintain structural integrity and acoustic efficiency across a wide operational range.

We invite engineering managers, procurement officers, and R&D specialists to contact us for technical consultations, material samples, or collaborative development projects. Whether you are replacing traditional foam insulation or designing a new acoustic enclosure, our team will provide data-driven recommendations backed by material science and real-world validation.

Below is a comparison of key performance characteristics between standard styrofoam (EPS) and Baoshida’s advanced rubber-based acoustic insulation:

| Property | Styrofoam (EPS) | Baoshida Rubber Composite |

|---|---|---|

| Density (kg/m³) | 10–30 | 400–800 |

| Sound Transmission Loss (dB @ 1 kHz) | 15–20 | 28–35 |

| Compression Set (after 24h @ 70°C) | High (poor recovery) | <15% (excellent recovery) |

| Operating Temperature Range (°C) | -40 to +70 | -50 to +120 |

| Flame Resistance (UL94) | HB (slow burn) | V-0 (self-extinguishing) |

| Moisture Absorption (%) | Moderate to high | <1.5% |

| Vibration Damping Coefficient | Low | High (0.15–0.35) |

| Service Life (years) | 3–5 (degrades with UV/moisture) | 10–15+ (UV and ozone resistant) |

Partnering with Suzhou Baoshida means access to not just materials, but engineered solutions. We support global clients with ISO-compliant manufacturing, batch traceability, and technical documentation including RoHS and REACH compliance reports.

For immediate assistance, contact Mr. Boyce at [email protected]. Include your project specifications, target performance metrics, and application environment to receive a tailored technical proposal within 48 hours.

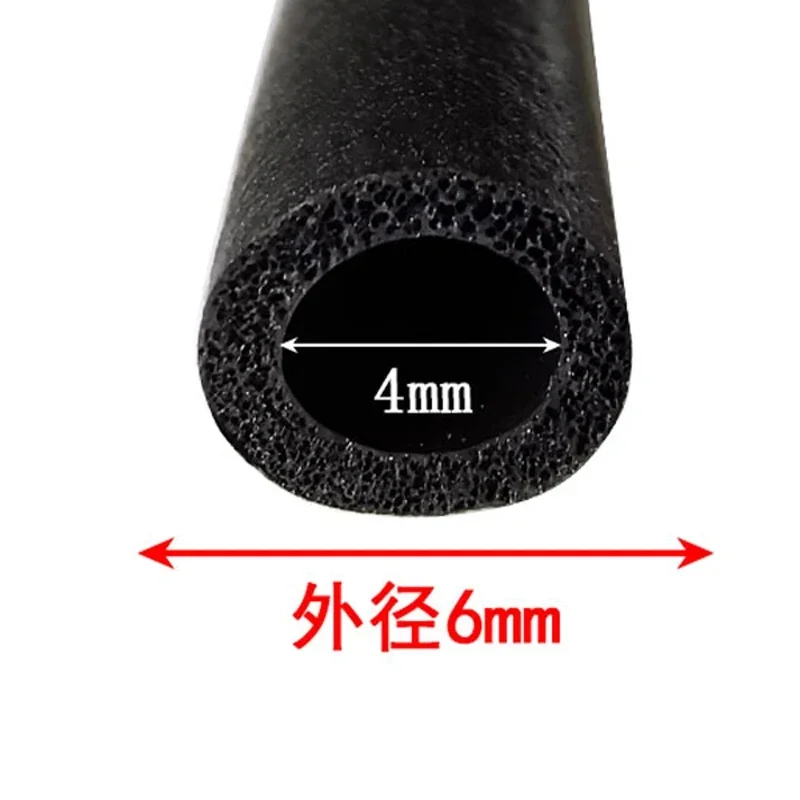

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).