Technical Contents

Engineering Guide: Washable Doormats

Engineering Insight: Material Selection in Washable Doormats

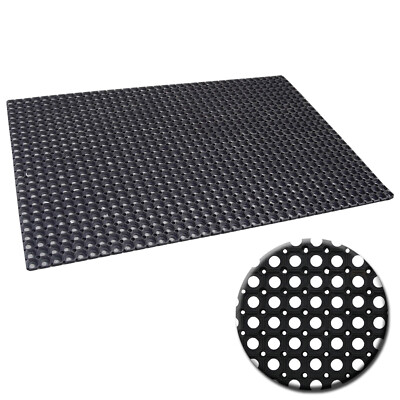

In the industrial rubber manufacturing sector, the performance of washable doormats is directly tied to the precision of material selection. While consumer-grade doormats often prioritize aesthetics and low cost, industrial and commercial applications demand durability, chemical resistance, and long-term structural integrity under repeated washing cycles. Off-the-shelf solutions frequently fail in these environments due to the use of substandard elastomers and inadequate reinforcement, leading to premature degradation, loss of dimensional stability, and compromised functionality.

The core challenge lies in balancing elasticity, abrasion resistance, and water resistance—three properties that are inherently difficult to optimize simultaneously without advanced polymer engineering. Standard PVC or low-grade rubber compounds used in mass-market doormats lack the molecular stability required for frequent exposure to water, detergents, and mechanical agitation. These materials swell, crack, or delaminate after only a few wash cycles, resulting in reduced traction, fiber shedding, and contamination risks in clean environments.

At Suzhou Baoshida Trading Co., Ltd., we utilize high-density styrene-butadiene rubber (SBR) and thermoplastic polyolefin (TPO) blends engineered specifically for repeated laundering. These formulations are cross-linked to enhance hydrolytic stability and incorporate UV stabilizers and anti-oxidants to prevent surface degradation. The base substrate is reinforced with a woven polyester scrim, which maintains dimensional stability during washing and prevents curling or warping—a common failure mode in non-reinforced mats.

Another critical factor is the interaction between the rubber backing and the pile material (typically polyamide or polypropylene). Poor interfacial adhesion leads to delamination under thermal and mechanical stress. Our engineered bonding process uses reactive primers that form covalent bonds between the rubber matrix and fiber tufts, ensuring structural cohesion across 200+ wash cycles at temperatures up to 85°C.

The following table outlines key performance specifications of our industrial-grade washable doormat material compared to standard commercial alternatives:

| Property | Baoshida Industrial Grade (SBR/TPO + Polyester Scrim) | Standard Commercial Grade (PVC/Latex Blend) |

|---|---|---|

| Tensile Strength (MPa) | 18.5 | 8.2 |

| Elongation at Break (%) | 320 | 180 |

| Water Absorption (24h, %) | 0.6 | 4.3 |

| Wash Cycles (85°C, no delamination) | >200 | <50 |

| Abrasion Loss (Taber, mg/1000 rev) | 45 | 120 |

| Temperature Range (°C) | -40 to +100 | -10 to +60 |

| Chemical Resistance (pH 3–11) | Excellent | Moderate to Poor |

This data underscores the performance gap between engineered industrial solutions and generic alternatives. Material selection is not a cost-driven compromise—it is a precision engineering decision that determines service life, safety, and total cost of ownership.

In environments where hygiene, durability, and reliability are non-negotiable, only purpose-built rubber compounds deliver sustained performance. Suzhou Baoshida Trading Co., Ltd. applies industrial rubber science to ensure every washable doormat meets the rigorous demands of commercial laundries, healthcare facilities, and cleanroom applications.

Material Specifications

Material Specifications for Industrial Washable Doormats

Selecting the optimal elastomer for washable industrial doormats requires rigorous evaluation of chemical exposure, thermal cycling, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we prioritize formulations that maintain structural integrity through repeated high-pressure washing, UV exposure, and contact with abrasive contaminants. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent our core solutions, each engineered for distinct operational profiles. Viton excels in extreme chemical resistance, particularly against hydrocarbon-based contaminants common in automotive and manufacturing facilities; its fluoropolymer structure ensures minimal swelling in oils, greases, and solvents, with continuous service temperatures up to 230°C. Nitrile offers a cost-optimized balance for general industrial use, providing robust resistance to aliphatic hydrocarbons, water-based fluids, and moderate ozone exposure; its acrylonitrile content directly correlates with oil resistance, though low-temperature flexibility diminishes below -30°C. Silicone delivers superior flexibility across extreme thermal ranges (-60°C to 200°C) and exceptional resistance to UV degradation and microbial growth, making it ideal for outdoor or healthcare settings, though it exhibits lower abrasion resistance against coarse particulates compared to hydrocarbon elastomers.

Critical to washable mat performance is the retention of tensile strength and elongation after 500+ wash cycles. Our proprietary compounding adjusts filler systems (e.g., reinforcing silica for Silicone, carbon black for NBR) and crosslink density to prevent hardening or cracking. Viton formulations utilize peroxide curing for enhanced thermal stability, while NBR relies on sulfur systems optimized for rapid mold release in high-volume production. Silicone requires platinum-catalyzed addition curing to eliminate volatile byproducts that compromise surface adhesion. All materials undergo ASTM D2000 testing for compression set, ensuring consistent sealing against debris ingress after repeated compression from foot traffic.

Material performance is quantified below for direct OEM comparison:

| Material Type | Key Properties | Temperature Range (°C) | Chemical Resistance Profile | Abrasion Resistance (DIN 53516, mm³) | OEM Processing Notes |

|---|---|---|---|---|---|

| Viton (FKM) | High heat/oil resistance; low gas permeability | -20 to 230 | Excellent: oils, acids, fuels; Poor: ketones, amines | 110 | Requires high-temp molding; post-cure essential |

| Nitrile (NBR) | Balanced oil/water resistance; cost-effective | -30 to 120 | Good: water, aliphatic oils; Poor: ozone, esters | 95 | Fast sulfur cure; standard molding temps |

| Silicone (VMQ) | Extreme temp flexibility; biocompatible | -60 to 200 | Excellent: water, steam, UV; Poor: concentrated acids | 140 | Platinum cure; low shrinkage; cleanroom recommended |

For high-traffic industrial zones with chemical exposure, Viton remains the premium specification despite higher raw material costs, as its longevity reduces total lifecycle replacement expenses. Nitrile is the strategic choice for cost-sensitive applications with moderate fluid exposure, while Silicone dominates environments demanding thermal stability and hygiene compliance. Suzhou Baoshida’s OEM team tailors durometer (60–80 Shore A), pigment stability, and surface texture to your exact wash protocol and end-user requirements, ensuring dimensional stability and contaminant-trapping efficacy across 5,000+ cleaning cycles. Material selection directly dictates mat service life; our engineering data validates performance beyond baseline industry standards.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Industrial Rubber Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering division is the backbone of our industrial rubber solutions, delivering technically advanced, application-specific products for demanding environments. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we maintain full in-house control over product development, from concept to production. This integrated approach ensures precision, repeatability, and compliance with rigorous OEM standards.

Our mould engineers possess extensive experience in designing complex, high-cycle rubber compression and transfer moulds. Utilizing advanced CAD/CAM systems, including SolidWorks and AutoCAD, they develop optimized mould geometries that ensure uniform material flow, minimal flash, and extended tool life. Finite element analysis (FEA) is routinely applied to simulate mould performance under production conditions, enabling preemptive correction of potential defects such as air entrapment or uneven curing.

Complementing this capability are our two senior rubber formula engineers, who specialize in elastomer compounding for functional performance. They formulate custom rubber compounds tailored to specific mechanical, thermal, and environmental requirements. For washable doormats, this includes developing formulations with enhanced abrasion resistance, hydrophobic properties, and accelerated cure profiles to support high-volume manufacturing. Our lab maintains a comprehensive database of polymer systems, including SBR, EPDM, and NBR, allowing rapid prototyping and iterative refinement.

We operate a fully integrated R&D workflow that links formulation development with mould design, ensuring compatibility between material behavior and tooling parameters. This synergy is critical in producing washable doormats with consistent texture definition, dimensional accuracy, and long-term durability under repeated washing cycles. Our engineers collaborate directly with OEM partners to interpret technical drawings, performance specifications, and end-use conditions, enabling co-engineering of products that meet exact functional and aesthetic criteria.

Our OEM capabilities extend beyond design to full-scale production support. We offer DFM (Design for Manufacturability) analysis, material sourcing, prototype validation, and process optimization. All formulations are subjected to rigorous testing, including tensile strength, compression set, Shore A hardness, and water absorption, to ensure compliance with international standards.

The following table outlines key engineering specifications and testing parameters relevant to our washable doormat solutions:

| Parameter | Standard Test Method | Typical Value |

|---|---|---|

| Shore A Hardness | ASTM D2240 | 55–70 |

| Tensile Strength | ASTM D412 | ≥8 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤20% |

| Water Absorption (24 hrs) | ISO 2781 | ≤1.5% |

| Abrasion Loss (DIN) | ISO 4649 | ≤120 mm³ |

| Operating Temperature Range | — | -40°C to +100°C |

Through this engineering-centric approach, Suzhou Baoshida delivers technically robust, manufacturable rubber solutions that meet the exacting demands of global OEM partners.

Customization Process

Customization Process for Industrial Washable Doormats

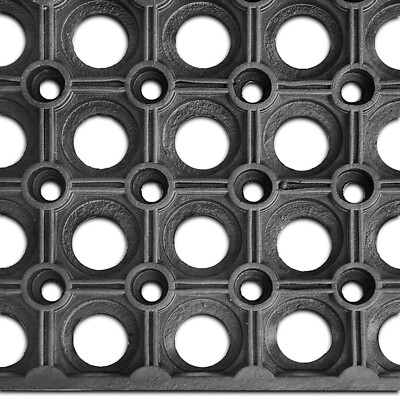

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for industrial washable doormats begins with rigorous Drawing Analysis. Client-provided technical drawings undergo dimensional validation against ISO 10137 standards for rubber product tolerances. We assess critical features including groove depth uniformity, edge sealing integrity, and load-bearing zones. This phase identifies potential manufacturability conflicts, such as undercuts exceeding 3° draft angles or wall thickness deviations beyond ±0.5mm. Material constraints are cross-referenced with the design to prevent warpage during high-temperature washing cycles. Non-compliant elements trigger collaborative engineering revisions prior to formulation.

Formulation development follows, leveraging our proprietary rubber compound database. We select base polymers—typically SBR for cost-sensitive applications or EPDM for superior hydrolysis resistance—based on client durability requirements. Key additives include silica for wet-traction enhancement, zinc oxide for accelerated vulcanization, and proprietary antimicrobial agents to inhibit mold growth during moisture retention. Each compound is optimized for Shore A hardness between 65–75 to balance flexibility and soil-scraping efficacy. Critical washability parameters like water absorption (target: <1.5% per ISO 188) and compression set (<20% after 24h immersion) are simulated computationally before lab validation.

Prototyping employs precision steel molds with micro-textured surfaces to replicate final production fidelity. Three iterative samples undergo accelerated lifecycle testing: 500+ simulated wash cycles at 60°C with alkaline detergents, ISO 4649 abrasion resistance trials, and ISO 1817 fluid resistance checks against common cleaning agents. Performance deviations exceeding 5% from specifications trigger compound recalibration. Client approval requires documented evidence of all test metrics, including dimensional stability reports post-washing.

Mass production initiates only after sign-off on the qualified prototype. We deploy automated rubber injection molding systems with real-time cavity pressure monitoring to maintain ±0.3mm thickness consistency. Every batch undergoes inline spectrometry for polymer composition verification and 100% visual inspection for surface defects. Final quality gates include ISO 37 tensile strength validation and hydrostatic pressure testing to 0.5 bar. Traceability is ensured via laser-etched batch codes linked to raw material certificates and process parameters.

Key Rubber Compound Specifications for Washable Doormats

| Property | Test Standard | Target Value | Industrial Significance |

|---|---|---|---|

| Shore A Hardness | ISO 7619-1 | 65–75 | Optimal debris removal without floor scratching |

| Abrasion Loss | ISO 4649 | ≤120 mm³/1.61km | Sustained performance after 10,000+ foot passes |

| Water Absorption | ISO 188 | ≤1.5% | Prevents warping and microbial growth |

| Compression Set (24h) | ISO 815-1 | ≤20% | Maintains groove depth integrity post-washing |

| Tensile Strength | ISO 37 | ≥15 MPa | Resists tearing during commercial laundering |

Contact Engineering Team

For industrial manufacturers and OEM partners seeking high-performance rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of innovation and precision engineering. Specializing in industrial rubber products, including washable doormats designed for durability, chemical resistance, and long-term performance in high-traffic environments, we deliver engineered materials that meet rigorous commercial and industrial standards. Our expertise spans material formulation, compression molding, and custom finishing processes, ensuring every product aligns with the functional demands of modern facilities, from manufacturing plants to public infrastructure.

Our washable doormat solutions are formulated using advanced synthetic rubber compounds, optimized for abrasion resistance, dimensional stability, and effective debris retention. Unlike standard consumer-grade mats, our industrial-grade products are designed to withstand repeated cleaning cycles, exposure to oils and solvents, and extreme temperature fluctuations. Each mat is manufactured under strict quality control protocols, ensuring consistent thickness, tensile strength, and slip resistance across production batches. Whether you require custom dimensions, branding integration, or specific color coding for safety zoning, Suzhou Baoshida provides end-to-end customization with scalable production capacity.

Partnering with Suzhou Baoshida means accessing a vertically integrated supply chain supported by in-house material science expertise. Our rubber formulations are engineered in alignment with international compliance standards, including RoHS and REACH, and can be tailored to meet fire-retardant (FMVSS), low-emission (VOC), or anti-static requirements as needed. We work directly with OEMs, facility managers, and industrial suppliers to co-develop products that balance performance, cost-efficiency, and sustainability.

To ensure seamless integration into your procurement workflow, we offer technical documentation, material test reports, and sample provisioning upon request. Our engineering team supports clients through every phase—from initial concept and prototyping to mass production and logistics coordination.

For detailed specifications and partnership opportunities, please contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd., via email at [email protected]. Mr. Boyce specializes in industrial rubber applications and will provide technical consultation, pricing structures, and lead time estimates tailored to your project volume and performance criteria.

Below are representative technical specifications for our standard industrial washable doormat formulation:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 10 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1044 | ≤ 80 mg |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤ 20% |

| Operating Temperature Range | — | -30°C to +80°C |

| Specific Gravity | ASTM D792 | 1.25 ± 0.05 |

| Slip Resistance (DIN 51130, R9) | DIN 51130 | Pass |

Reach out to Mr. Boyce today to discuss custom formulations, volume pricing, or technical integration support for your next generation of industrial flooring solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).