Technical Contents

Engineering Guide: Vinyl Floor Tiles Garage

Engineering Insight: Material Selection for Vinyl Floor Tiles in Garage Applications

In industrial and high-traffic garage environments, the performance of vinyl floor tiles is not solely determined by aesthetic appeal or ease of installation. The fundamental determinant of long-term durability lies in precise material selection engineered for mechanical stress, chemical exposure, and thermal cycling. Off-the-shelf vinyl floor tiles, typically formulated for residential or light commercial use, lack the reinforcement and polymer architecture required to withstand the operational demands of garage settings. These environments subject flooring to concentrated point loads from vehicle axles, prolonged exposure to oils, solvents, and brake fluids, and fluctuating temperature gradients due to seasonal changes and engine heat. Standard formulations often utilize plasticized polyvinyl chloride (PVC) with low filler content and minimal cross-linking, resulting in creep deformation, surface crazing, and delamination under sustained stress.

At Suzhou Baoshida Trading Co., Ltd., our engineering approach begins with a granular analysis of service conditions. We classify garage usage into three tiers: light-duty (personal vehicles), medium-duty (service bays), and heavy-duty (fleet maintenance and industrial repair). Each tier demands a tailored compound formulation. For example, heavy-duty applications require a co-polymer matrix incorporating chlorinated polyethylene (CPE) modifiers to enhance oil resistance and reduce swelling in hydrocarbon environments. Additionally, the inclusion of nano-silica fillers improves compressive strength and abrasion resistance, critical for preventing indentation from tire contact and rolling equipment.

Another critical factor is dimensional stability. Standard vinyl tiles exhibit high coefficients of thermal expansion, leading to buckling or gapping at temperature extremes. Our engineered solutions integrate glass-fiber-reinforced backing layers, which reduce linear expansion by up to 60% compared to conventional products. This structural reinforcement ensures long-term flatness and seam integrity, even in unheated or poorly insulated facilities.

The failure of generic vinyl tiles often manifests within 12 to 18 months of installation, with symptoms including surface chalking, edge curling, and permanent indentation. These failures stem not from installation error but from material inadequacy. A true industrial-grade vinyl floor tile must balance flexibility with rigidity, chemical resistance with impact absorption, and cost-effectiveness with lifecycle performance.

The following table outlines key material specifications differentiating standard off-the-shelf tiles from engineered industrial solutions:

| Property | Standard Vinyl Tile | Engineered Industrial Tile |

|---|---|---|

| Shore A Hardness | 65–75 | 80–88 |

| Tensile Strength (MPa) | 8–12 | 16–20 |

| Elongation at Break (%) | 180–250 | 120–150 |

| Oil Resistance (IRHD change after 7 days in ASTM #3 oil) | +25 to +35 | +8 to +12 |

| Thermal Expansion Coefficient (10⁻⁶/°C) | 180–220 | 80–100 |

| Abrasion Loss (Taber, mg/1000 cycles) | 120–160 | 50–70 |

| Compression Set (24h at 70°C, %) | 25–35 | 10–14 |

Material selection is not a commodity decision—it is an engineering imperative. At Suzhou Baoshida Trading Co., Ltd., we apply polymer science and field data to deliver vinyl floor tile systems that perform reliably under real-world industrial stress.

Material Specifications

Material Specifications for Industrial Garage Vinyl Floor Tiles

Selecting the optimal elastomer compound is critical for vinyl floor tiles deployed in demanding garage environments. These tiles must withstand continuous exposure to automotive fluids, heavy point loads, temperature fluctuations, and mechanical abrasion while maintaining dimensional stability and slip resistance. At Suzhou Baoshida Trading Co., Ltd., we engineer formulations using three primary high-performance rubber materials: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each offers distinct chemical and physical properties suited to specific operational challenges inherent in automotive service bays, manufacturing facilities, and high-traffic vehicle storage areas.

Viton fluoroelastomers provide the highest level of chemical resistance among commercial elastomers. This perfluoroelastomer formulation exhibits exceptional stability against hydrocarbons, synthetic lubricants, brake fluids, and aggressive solvents commonly encountered in garages. Viton maintains integrity within an operational temperature range of -20°C to +230°C, making it suitable for environments with extreme thermal cycling. Its inherent hardness (typically 70-90 Shore A) contributes to excellent cut and tear resistance, though material cost is significantly higher than alternatives. Viton is the preferred solution for facilities handling jet fuels, concentrated acids, or where maximum fluid resistance is non-negotiable.

Nitrile rubber (NBR) represents the industry standard for cost-effective oil and fuel resistance in garage flooring. Optimized acrylonitrile content (typically 33-36%) delivers robust performance against petroleum-based oils, greases, and hydraulic fluids per ASTM D471 standards. NBR compounds operate effectively between -30°C and +120°C, balancing flexibility in cold climates with heat resistance during summer months. Standard hardness ranges from 60-80 Shore A, allowing for formulation adjustments to enhance abrasion resistance or impact absorption. Its superior mechanical strength and lower cost make NBR the most prevalent choice for general automotive workshop applications where chemical exposure is moderate to high.

Silicone rubber (VMQ) excels in extreme temperature environments but requires careful application consideration for garage tiles. It maintains flexibility from -60°C to +200°C, outperforming other elastomers at both thermal extremes. Silicone offers good resistance to ozone, UV radiation, and water, but exhibits significantly lower resistance to petroleum-based oils and fuels compared to Viton or NBR. Its inherent lower tensile strength and higher compression set necessitate specialized reinforcement for high-load flooring applications. Silicone is primarily selected for garages requiring exceptional cold-weather flexibility or exposure to non-petroleum chemicals, where fluid resistance is secondary.

The comparative performance characteristics of these materials are detailed below for critical garage flooring parameters.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness Range (Shore A) | 70-90 | 60-80 | 40-80 |

| Temp Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Oil/Fuel Resistance | Excellent (ASTM 1) | Very Good (ASTM 2) | Poor (ASTM 3-4) |

| Tensile Strength (MPa) | 10-18 | 15-25 | 5-12 |

| Abrasion Resistance | Very Good | Excellent | Good |

| Compression Set (%) | 10-25 (24h, 150°C) | 15-30 (70h, 100°C) | 20-40 (22h, 200°C) |

| Primary Garage Use Case | Extreme chemical exposure | Standard automotive fluids | Extreme temp, non-petroleum |

Material selection must align with the specific fluid exposure profile, load requirements, and budget constraints of the garage facility. Suzhou Baoshida Trading Co., Ltd. provides OEM partners with tailored compound recommendations and rigorous validation testing per ISO 48 and ASTM F1913 standards to ensure optimal tile performance and longevity in industrial settings. Consult our engineering team for application-specific formulation support.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering engineered performance materials tailored to demanding environments. Our engineering capability is anchored by a dedicated team of five specialized mould engineers and two advanced formula engineers, enabling end-to-end development and precision manufacturing of rubber-based vinyl floor tiles designed specifically for garage and industrial floor applications. This integrated technical team ensures that every product meets exacting standards for durability, chemical resistance, thermal stability, and mechanical performance under real-world conditions.

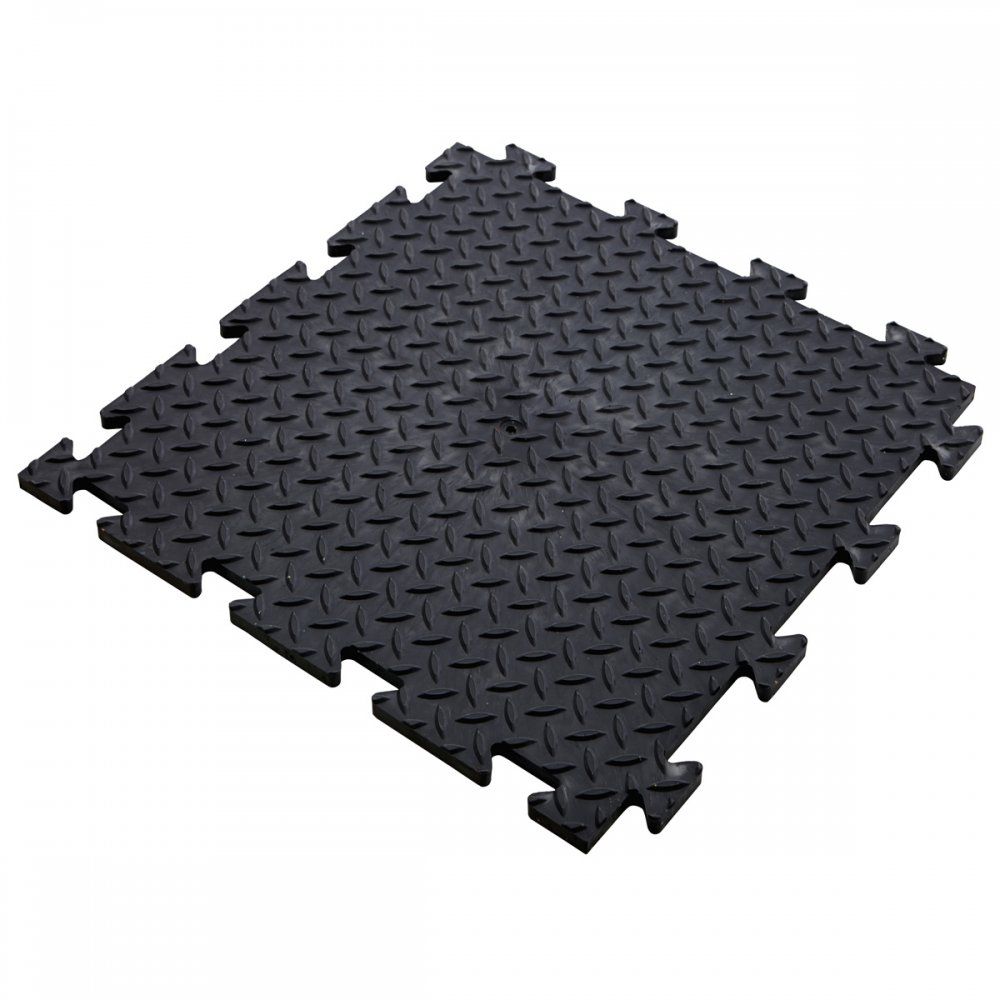

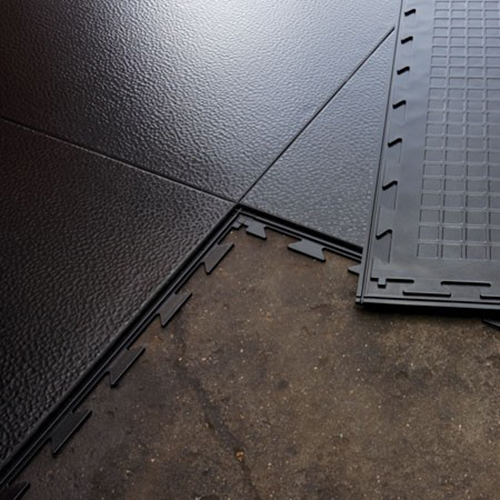

Our mould engineers possess extensive experience in designing high-tolerance, long-cycle-life tooling optimized for consistent replication of complex surface textures and interlocking geometries essential in vinyl floor tiles. Utilizing advanced CAD/CAM software and precision CNC machining, our team develops moulds that support rapid production cycles while maintaining dimensional accuracy across large-volume runs. These capabilities are particularly critical in garage flooring applications where load-bearing stability, edge integrity, and slip resistance are non-negotiable.

Complementing our mould design expertise, our two in-house rubber formula engineers focus on material science innovation to tailor compound formulations for specific environmental and mechanical demands. By adjusting polymer base ratios, filler content, plasticizers, and cross-linking agents, we engineer rubber blends that enhance abrasion resistance, UV stability, and oil/fuel resistance—key performance factors in garage and workshop settings. Our formulation development is supported by in-house testing protocols, including Shore A hardness measurement, tensile strength analysis, compression set evaluation, and accelerated aging cycles, ensuring long-term performance under dynamic stress.

As an OEM manufacturing partner, Suzhou Baoshida provides full-service product development from concept to commercialization. Clients benefit from our ability to customize tile dimensions, surface profiles, color integration, and performance characteristics while maintaining strict process control and scalability. Our facility supports low-volume prototyping and high-volume production, with seamless transition between stages, ensuring time-to-market efficiency and consistent quality.

The following table outlines typical technical specifications achievable for our engineered rubber vinyl floor tiles:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65–85 |

| Tensile Strength | ASTM D412 | ≥ 8.0 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22 hrs, 70°C) | ASTM D395B | ≤ 25% |

| Specific Gravity | ASTM D792 | 1.35–1.45 |

| Operating Temperature Range | — | -30°C to +80°C |

| Resistance to Oils & Greases | ASTM D471 | Excellent |

| Flame Resistance | UL94 | HB Rating |

This technical foundation, combined with our OEM agility, positions Suzhou Baoshida as a trusted partner for industrial flooring solutions requiring engineered resilience and precise manufacturability.

Customization Process

Customization Process for Industrial Garage Vinyl Floor Tiles

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial garage vinyl floor tiles integrates rigorous engineering protocols to ensure optimal performance under demanding vehicular and chemical exposure conditions. This four-phase methodology guarantees alignment with client specifications while adhering to global safety and durability standards.

Drawing Analysis

Initial engagement begins with comprehensive technical drawing review. We dissect substrate compatibility requirements, load-bearing expectations (static/dynamic), and environmental factors including temperature fluctuations (-20°C to 60°C), oil/fuel resistance, and slip coefficients. Critical dimensions, joint tolerances, and surface texture profiles are validated against ISO 10582 and ASTM F1700 standards. This phase identifies potential failure points such as edge curling under thermal stress or compression set in high-traffic zones, enabling preemptive design refinement.

Formulation Engineering

Leveraging 15+ years of polymer science expertise, our R&D team develops bespoke PVC-rubber composite formulations. Key considerations include: plasticizer selection for low-temperature flexibility without migration, calcium carbonate filler ratios to balance cost and impact resistance, and UV stabilizers for fade prevention. Antimicrobial additives are integrated where required for humidity-prone environments. All formulations undergo accelerated aging simulations per ISO 188, targeting Shore A hardness of 75–85 and tensile strength exceeding 12 MPa to withstand forklift tire shear forces.

Prototyping & Validation

Three physical prototypes are produced using client-approved tooling. Each undergoes destructive and non-destructive testing:

ASTM D2240 hardness validation at 23°C and -10°C

ISO 2818 abrasion resistance testing (target: <150 mg loss/100 cycles)

Chemical exposure trials with automotive oils, brake fluids, and battery acid

Slip resistance verification via DIN 51130 ramp tests (R10 minimum)

Client feedback on texture, color consistency, and edge integrity triggers iterative adjustments. Final approval requires ≤5% deviation from target specifications across all test parameters.

Mass Production Oversight

Upon prototype sign-off, production commences under ISO 9001-certified protocols. Extrusion lines operate at 160–180°C with real-time rheometer monitoring to ensure uniform polymer fusion. Each 500m² batch undergoes:

Thickness verification via laser micrometers (±0.1mm tolerance)

Volatile organic compound (VOC) emissions testing per EN 14041

Batch traceability through embedded QR codes linking to raw material certificates

Statistical process control (SPC) charts track critical variables hourly, with automatic line shutdown if hardness or thickness falls outside client-defined control limits.

Material Performance Specifications

Key properties of our standard garage tile formulation are detailed below, with customization ranges available per project requirements.

| Property | Standard Requirement | Baoshida Customization Range |

|---|---|---|

| Shore A Hardness | 75–85 | 65–95 |

| Tensile Strength (MPa) | ≥12.0 | 10.0–18.0 |

| Elongation at Break (%) | ≥250 | 200–350 |

| Abrasion Loss (mg) | ≤150 | 100–200 |

| Slip Resistance (R-value) | R10 | R9–R12 |

| Oil Resistance (Grade) | 3 (ASTM D471) | 2–4 |

This structured workflow ensures garage flooring solutions deliver 15+ years of service life under industrial use, minimizing client lifecycle costs through precision engineering and uncompromised quality control. All stages include transparent documentation for OEM compliance auditing.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Vinyl Floor Tiles for Garage Applications

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber and polymer-based flooring solutions, delivering high-performance vinyl floor tiles engineered specifically for demanding environments such as garages, workshops, and light industrial facilities. Our expertise in material science and manufacturing precision ensures that every product meets rigorous standards for durability, chemical resistance, and long-term dimensional stability. As a trusted OEM partner and technical supplier, we provide tailored solutions that align with both functional requirements and cost-efficiency goals for commercial and industrial clients.

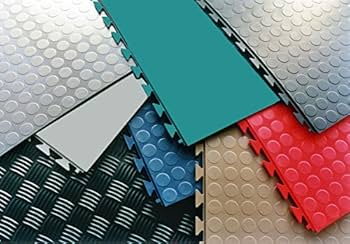

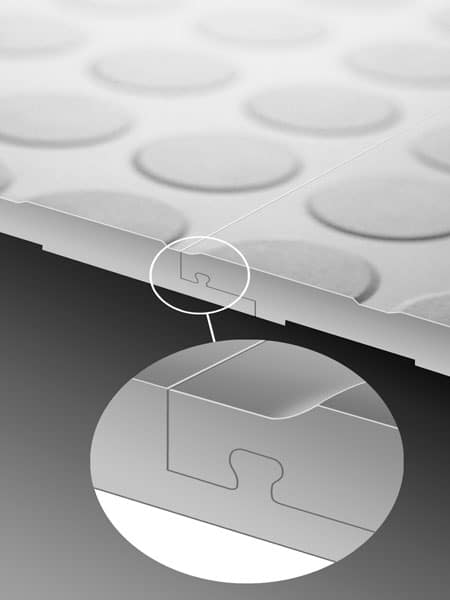

When selecting flooring for garage environments, performance under stress is non-negotiable. Exposure to oils, solvents, temperature fluctuations, and heavy mechanical loads necessitates a flooring system that combines structural integrity with slip resistance and ease of installation. Our vinyl floor tiles are formulated with advanced plasticizers and stabilizers to resist cracking, fading, and deformation over time. Each tile is manufactured under strict quality control protocols to ensure uniform thickness, interlocking precision, and consistent surface texture—critical factors for safety and longevity in high-traffic zones.

We invite architects, contractors, facility managers, and procurement officers to engage directly with our technical team to discuss project-specific needs. Mr. Boyce, our dedicated OEM and industrial solutions manager, brings over 15 years of experience in polymer applications and rubber-based industrial products. He is available to provide technical data sheets, sample kits, and customized formulation advice based on environmental conditions, load requirements, and aesthetic preferences.

Our commitment extends beyond product supply—we offer comprehensive support from initial design consultation through to logistics and after-sales service. Whether you require standard modular tiles or custom-colored, anti-static, or fire-retardant variants, Suzhou Baoshida ensures seamless integration with your operational workflow.

To initiate a technical discussion or request a project quotation, please contact Mr. Boyce directly via email at [email protected]. We respond to all inquiries within 12 business hours and can arrange sample dispatch within 48 hours of request confirmation. For urgent project timelines, expedited manufacturing and shipping options are available upon consultation.

Below are key technical specifications of our standard vinyl floor tile series designed for garage and industrial use:

| Property | Specification |

|---|---|

| Material Composition | PVC with reinforced rubber backing |

| Thickness | 2.0 mm, 3.2 mm, 4.5 mm |

| Tile Size | 600 mm × 600 mm (standard), custom sizes available |

| Surface Finish | Matte texture, anti-slip (R10 rating) |

| Load Capacity | Up to 10 tons/m² |

| Temperature Range | -20°C to +70°C |

| Chemical Resistance | Resistant to motor oil, brake fluid, antifreeze, and mild acids |

| Installation Method | Interlocking tongue-and-groove, adhesive-assisted |

| Fire Rating | B1 (DIN 4102), self-extinguishing |

| Warranty | 10 years against deformation and delamination |

Partner with Suzhou Baoshida Trading Co., Ltd. to secure a reliable, high-performance flooring solution engineered for real-world industrial challenges. Contact Mr. Boyce today to elevate your garage flooring project with scientifically optimized vinyl tile technology.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).