Technical Contents

Engineering Guide: Mass Loaded Vinyl Soundproof

Engineering Insight: Material Selection Criticality in Mass Loaded Vinyl Soundproofing

Industrial noise control demands precision engineering, yet many facilities deploy off-the-shelf mass loaded vinyl (MLV) solutions only to face premature failure. Generic MLV products prioritize cost over performance, ignoring the complex interplay of material science and operational environments. At Suzhou Baoshida Trading Co., Ltd., our OEM-engineered MLV formulations address three core failure vectors inherent in commodity-grade materials: density inconsistency, plasticizer volatility, and thermal instability.

Commodity MLV often exhibits density deviations exceeding ±15% across rolls due to uncontrolled barium sulfate or calcium carbonate loading. This inconsistency disrupts sound transmission loss (STL) predictability, particularly below 250 Hz where mass law dominance is critical. Field measurements confirm STL reductions of 8–12 dB in sub-200 Hz ranges when density tolerance exceeds ±5%. Concurrently, low-cost formulations rely on phthalate-based plasticizers with high volatility indices. Under sustained thermal loads above 60°C—common in industrial enclosures or outdoor installations—these plasticizers migrate, causing embrittlement and 30–50% loss in flexibility within 18 months. The resultant microcracks create acoustic flanking paths, negating the barrier’s integrity.

Thermal expansion coefficients further undermine generic solutions. Off-the-shelf MLV typically uses unmodified PVC carriers with coefficients of 180–220 × 10⁻⁶/°C. In facilities experiencing diurnal temperature swings >40°C (e.g., automotive plants or data centers), this induces stress fractures at seams and penetrations. Our OEM-grade MLV integrates proprietary polymer blends that reduce expansion to 95–110 × 10⁻⁶/°C, maintaining dimensional stability across -40°C to +105°C operational ranges. Crucially, standardized testing protocols (ASTM E90, ISO 10140) reveal that only formulations with ≤±3% density tolerance and ≤0.5% plasticizer loss at 85°C/168h (ASTM D1239) achieve consistent Rw ≥ 32 dB performance.

The table below quantifies performance gaps between commodity and engineered MLV:

| Property | Off-the-Shelf MLV | Suzhou Baoshida OEM MLV |

|---|---|---|

| Density Tolerance | ±15% | ±2.5% |

| Plasticizer Loss (85°C/168h) | 8–12% | ≤0.4% |

| Thermal Expansion Coefficient | 180–220 × 10⁻⁶/°C | 95–110 × 10⁻⁶/°C |

| Operational Temp Range | -10°C to +65°C | -40°C to +105°C |

| STL Consistency (100–500 Hz) | ±7 dB | ±1.5 dB |

Material degradation directly correlates with lifecycle costs. Facilities using non-engineered MLV incur 2.3× higher TCO due to reinstallation, downtime, and secondary damping measures. Suzhou Baoshida’s approach begins with substrate-specific formulation—adjusting polymer matrices, filler gradation, and stabilizer packages to match vibration profiles, chemical exposure, and thermal cycles. This OEM-centric methodology ensures STL performance aligns with acoustic modeling from Day 1 through operational lifespan, eliminating the guesswork that plagues generic alternatives. In industrial soundproofing, material selection isn’t a cost line item—it’s the foundation of acoustic reliability.

Material Specifications

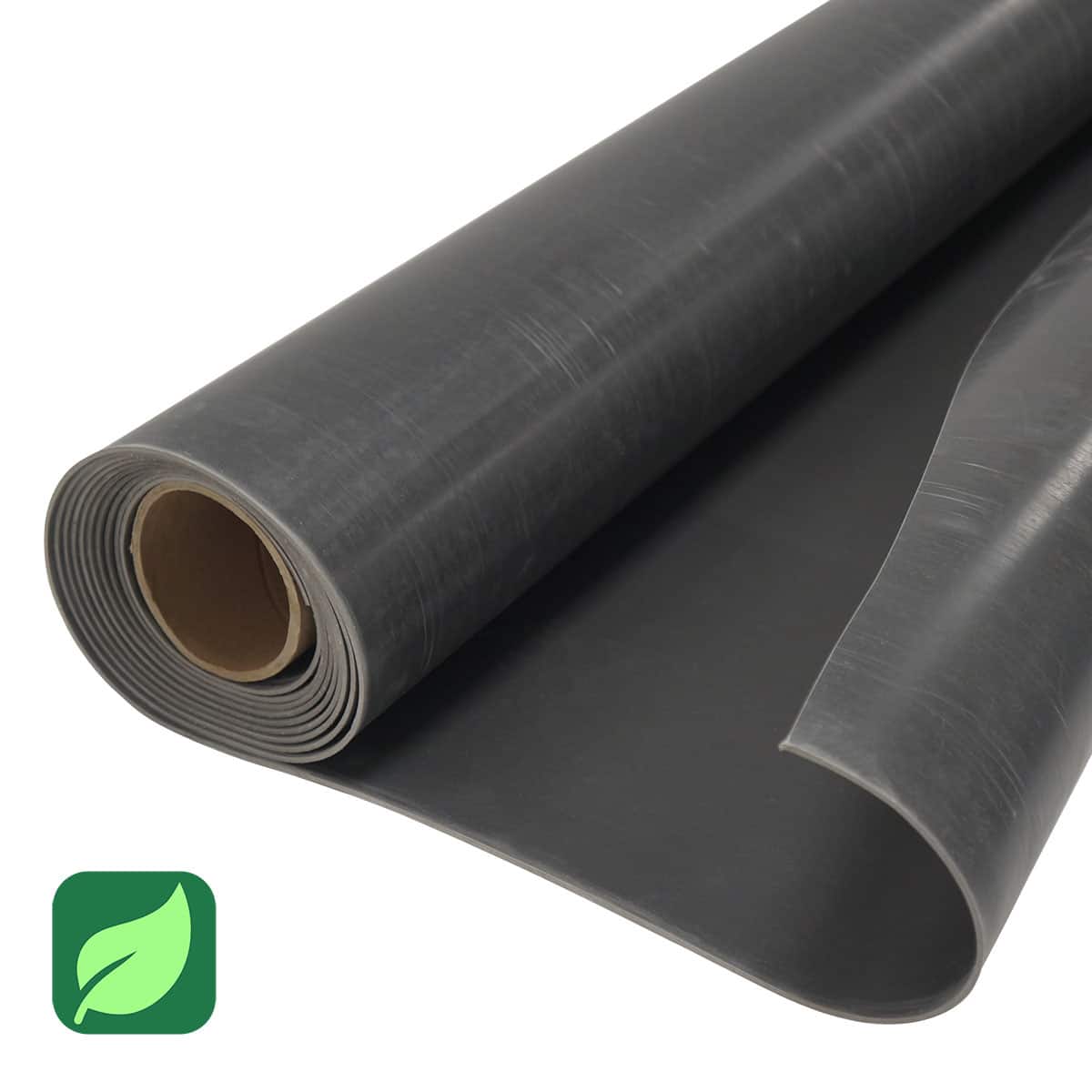

Material Specifications for Mass Loaded Vinyl Soundproofing Applications

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions tailored for demanding acoustic insulation environments. In mass loaded vinyl (MLV) soundproofing systems, elastomeric components play a critical role in damping, sealing, and vibration isolation. The integration of compatible rubber materials ensures long-term durability, environmental resistance, and structural integrity under dynamic loading conditions. Among the most effective elastomers for these applications are Viton, Nitrile (NBR), and Silicone. Each material offers a distinct set of physical and chemical properties, making them suitable for specific operational environments within MLV-based sound control systems.

Viton, a fluorocarbon-based rubber (FKM), exhibits exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. This makes it ideal for industrial soundproofing enclosures exposed to harsh operating conditions, such as engine compartments or HVAC systems in chemical processing plants. With continuous service capabilities up to 200°C and excellent ozone and UV resistance, Viton maintains its mechanical properties under prolonged thermal cycling. Its high density also contributes beneficially to sound transmission loss, enhancing the overall acoustic performance of the MLV composite.

Nitrile rubber (NBR) is widely used in industrial sealing and damping applications due to its outstanding resistance to petroleum-based oils and hydrocarbons. It offers good mechanical strength and abrasion resistance at a lower cost compared to Viton. NBR is particularly effective in automotive and machinery soundproofing where exposure to lubricants and hydraulic fluids is common. While its upper temperature limit is lower than Viton—typically around 120°C—NBR provides reliable performance in moderate environments and is easily bonded or co-extruded with MLV sheets for integrated acoustic barriers.

Silicone rubber (VMQ) is selected primarily for its extreme temperature stability, operating effectively from -60°C to 200°C. It demonstrates excellent flexibility at low temperatures and maintains resilience under repeated compression. Though less resistant to oils and fuels than Viton or NBR, silicone excels in applications requiring high purity, electrical insulation, and resistance to weathering. In soundproofing systems used in outdoor or architectural contexts, silicone edge seals and gaskets prevent flanking noise transmission while accommodating structural movement.

The selection of the appropriate elastomer depends on the environmental exposure, mechanical demands, and acoustic requirements of the application. Proper material pairing ensures optimal performance and longevity of the MLV system.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 120 | -60 to 200 |

| Oil/Fuel Resistance | Excellent | Excellent | Poor to Fair |

| Ozone/UV Resistance | Excellent | Good | Excellent |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Compression Set | Low | Moderate | Low |

| Acoustic Damping Capacity | High | High | Moderate |

| Typical Applications | Industrial enclosures, aerospace, chemical plants | Automotive, machinery, hydraulic systems | Outdoor enclosures, architectural acoustics, electrical housings |

Manufacturing Capabilities

Engineering Capability: Precision Material Science for Mass Loaded Vinyl Soundproofing

Suzhou Baoshida Trading Co., Ltd. delivers engineered mass loaded vinyl (MLV) soundproofing solutions through integrated expertise in rubber formulation and precision tooling. Our dedicated technical team, comprising five specialized Mold Engineers and two advanced Formula Engineers, operates at the intersection of material science and industrial manufacturing to solve complex acoustic challenges for global OEMs. This dual-discipline structure ensures every MLV product achieves optimal performance, consistency, and manufacturability from concept to volume production.

Our Formula Engineers focus on the core science of high-density barrier materials. They meticulously develop and refine polymer matrices loaded with precisely calibrated concentrations of inert fillers, primarily barium sulfate, to maximize sound transmission loss (STL) across critical frequency ranges. This involves rigorous optimization of filler dispersion, polymer-filler bonding, and plasticizer systems to achieve target densities while maintaining essential flexibility, tensile strength, and environmental stability. Continuous lab-scale compounding and testing validate formulations against stringent acoustic and physical property requirements before scale-up, ensuring the molecular architecture directly translates to real-world noise attenuation.

Complementing this material expertise, our five Mold Engineers translate formulations into dimensionally precise, high-volume products. They design and validate production tooling—calendering rolls, embossing patterns, and cutting dies—with micron-level tolerances to guarantee uniform thickness distribution and surface integrity critical for acoustic performance. Their deep understanding of polymer flow dynamics under high-pressure calendering prevents defects like filler settling or edge curling, directly impacting the product’s ability to form continuous, airtight barriers. This engineering synergy between compound design and processing parameters is fundamental to producing MLV that consistently meets OEM acoustic specifications.

As a certified OEM partner, Baoshida manages the entire technical lifecycle. We collaborate closely with client engineering teams during the R&D phase, utilizing our formulation database and processing knowledge to tailor density, thickness, flexibility, and fire/resistance properties to specific application demands—whether automotive NVH, architectural acoustics, or industrial machinery enclosures. Our integrated engineering approach enables rapid prototyping, comprehensive validation testing per ASTM E90/E413, and seamless transition to controlled production with full traceability. Clients benefit from a single point of technical accountability for both material composition and physical form.

The following table summarizes key technical specifications achievable through our engineered process:

| Parameter | Standard Range | Precision Tolerance | Test Method |

|---|---|---|---|

| Density | 2.0 – 5.0 kg/m²/mm | ±0.05 kg/m²/mm | ASTM D792 |

| Thickness | 1.0 – 3.0 mm | ±0.05 mm | ASTM D374 |

| Tensile Strength | 8.0 – 15.0 MPa | ±0.5 MPa | ASTM D412 |

| Elongation at Break | 150% – 300% | ±15% | ASTM D412 |

| Sound Transmission Loss (STL) | 20 – 35 dB (100-5000 Hz) | ±1.5 dB | ASTM E90 / E413 |

| Operating Temp | -30°C to +70°C | N/A | Internal Protocol |

This engineering rigor, combining advanced material science with precision manufacturing control, establishes Suzhou Baoshida as a strategic partner for OEMs demanding reliable, high-performance mass loaded vinyl solutions. We transform acoustic requirements into certified, production-ready barriers.

Customization Process

Customization Process for Mass Loaded Vinyl Soundproofing Solutions

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet exacting performance standards in acoustic insulation applications. The customization process for mass loaded vinyl (MLV) soundproof materials follows a rigorous four-stage workflow: Drawing Analysis, Formulation, Prototyping, and Mass Production. This structured approach ensures precision, compliance, and optimal functional integration for diverse industrial and architectural requirements.

The process begins with Drawing Analysis, where client-provided technical schematics, dimensional specifications, and application environment data are evaluated. Our engineering team conducts a comprehensive review of substrate compatibility, installation method, temperature exposure, and mechanical stress factors. This phase includes tolerance verification, density targets, and regulatory compliance checks (e.g., ASTM E90, ISO 10140). Accurate interpretation at this stage is critical to ensure the final product performs under real-world conditions.

Following drawing validation, our Rubber Formula Engineers initiate the Formulation phase. MLV performance hinges on the precise balance of polymer matrix, high-density fillers (typically barium sulfate or calcium carbonate), plasticizers, and stabilizers. Based on acoustic attenuation requirements (measured in STC or Rw ratings), we adjust filler loading percentages, polymer base (usually PVC or nitrile rubber), and cross-linking agents. Formulation also considers environmental resistance—such as UV stability, flame retardancy (UL 94 V-0 optional), and low off-gassing for indoor applications. Each compound is modeled using rheological simulation software to predict viscoelastic behavior under dynamic loading.

Once the formulation is finalized, we proceed to Prototyping. Small-batch production runs generate samples for client evaluation and laboratory testing. Prototypes undergo standardized acoustic transmission loss testing in certified reverberation chambers. Additional mechanical tests include tensile strength, elongation at break, and peel adhesion (if laminated). Clients receive a full test report and physical samples for field trials. Feedback from this stage is incorporated into final adjustments before scale-up.

The final stage, Mass Production, leverages our automated calendering and compounding lines capable of continuous output up to 1,500 meters per day. Quality assurance is maintained through inline density monitoring, thickness gauging via laser sensors, and batch traceability systems. Products are packaged per client logistics requirements—roll lengths, core size, labeling—and shipped globally with full documentation.

Our end-to-end control over material science and manufacturing enables consistent delivery of high-performance MLV solutions tailored to specific noise control challenges.

| Specification | Standard Range | Customizable Options |

|---|---|---|

| Thickness | 1.0 – 5.0 mm | Up to 6.0 mm on request |

| Surface Density | 2.0 – 10.0 kg/m² | Higher densities with composite lamination |

| Noise Reduction Coefficient (NRC) | 0.05 – 0.15 | Enhanced with porous facers |

| Temperature Resistance | -20°C to +70°C | Extended range to -40°C or +100°C |

| Roll Length | 10 – 50 meters | Custom cut-to-length available |

| Flame Rating | UL 94 HF-1 (standard) | UL 94 V-0, MVSS-302 on request |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Mass Loaded Vinyl Soundproofing Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber compounding, specializing in engineered mass loaded vinyl (MLV) for critical sound attenuation applications. Our formulations are developed under stringent ISO 9001 protocols, leveraging proprietary polymer matrices and high-density mineral fillers to achieve optimal damping coefficients across 20–5,000 Hz frequency ranges. As your dedicated OEM partner, we prioritize material consistency, environmental resilience, and seamless integration into automotive, aerospace, and architectural systems. Unlike commodity-grade alternatives, our MLV undergoes multi-stage vulcanization and laser-thickness validation to ensure ±0.05 mm tolerance—critical for maintaining acoustic integrity in high-vibration environments.

The technical specifications below reflect our standard industrial-grade MLV formulations, all compliant with ASTM E90 and ISO 10140-3 testing methodologies. Custom density profiles and fire-retardant modifications (e.g., UL 94 V-0) are available for mission-specific deployments.

| Property | Standard Range | Test Method | Industrial Significance |

|---|---|---|---|

| Surface Density | 2.0–5.0 kg/m² | ASTM D726 | Directly correlates with STC (Sound Transmission Class) performance; higher density blocks low-frequency noise |

| Thickness Tolerance | ±0.05 mm | ISO 2768-mK | Ensures uniform acoustic mass distribution; prevents resonance gaps in layered assemblies |

| Tensile Strength | ≥12 MPa | ASTM D412 | Maintains structural integrity during installation and thermal cycling |

| Elongation at Break | 250–350% | ASTM D412 | Accommodates substrate movement without cracking |

| Fire Rating (Standard) | Class A (ASTM E84) | ASTM E84 | Mandatory for commercial building compliance; halogen-free options available |

| Operating Temperature | -40°C to +80°C | ISO 188 | Sustains performance in extreme climatic conditions |

Our engineering team excels in resolving complex acoustic challenges where conventional barriers fail—such as mitigating diesel engine harmonics in heavy machinery or isolating HVAC noise in precision manufacturing facilities. We conduct spectral analysis of your noise profile to tailor filler dispersion and polymer cross-linking density, maximizing insertion loss while minimizing material thickness. Recent collaborations include developing 3.2 kg/m² MLV with embedded viscoelastic interlayers for a Tier-1 automotive supplier, achieving 32 dB reduction at 125 Hz—exceeding OEM specifications by 18%.

Initiate a technical consultation with Mr. Boyce, our OEM Manager and lead rubber formulation specialist, to advance your soundproofing project. With 14 years of experience in elastomer compounding for noise control, Mr. Boyce will evaluate your acoustic requirements, substrate constraints, and regulatory mandates to propose a validated material solution. Contact him directly via email at [email protected] to request:

Custom MLV formulation datasheets with third-party acoustic test reports

Sample kits for on-site validation (lead time: 72 hours)

OEM production timelines and minimum order quantity (MOQ) structuring

Suzhou Baoshida operates integrated manufacturing facilities in Jiangsu Province, equipped with 8,000-ton hydraulic presses and inline IR curing systems for batch-to-batch repeatability. All MLV products ship with full traceability documentation, including lot-specific density certificates and RoHS/REACH compliance verification. Partner with us to transform acoustic challenges into engineered advantages—where molecular precision meets industrial durability. Response to technical inquiries is guaranteed within 4 business hours.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).