Technical Contents

Engineering Guide: O-Ring Dash Number Chart

Engineering Insight: The Critical Role of Material Selection in O-Ring Dash Number Applications

In precision sealing applications, the o-ring dash number chart serves as a foundational reference for dimensional standardization, ensuring interchangeability and compliance with AS568 or ISO 3601 standards. However, adherence to size alone does not guarantee performance or longevity. The material selection process is equally, if not more, critical to the functional success of an o-ring in real-world operating environments. Off-the-shelf o-rings, while dimensionally accurate, frequently fail due to inappropriate elastomer choice relative to chemical exposure, temperature extremes, pressure cycles, and dynamic mechanical stress.

Material compatibility is the cornerstone of seal reliability. For example, an NBR (nitrile) o-ring may perform exceptionally in hydraulic systems with mineral oil-based fluids at moderate temperatures, but rapidly degrade when exposed to ozone, ketones, or elevated heat above 120°C. Conversely, a fluorocarbon (FKM) o-ring offers superior resistance to high temperatures and aggressive chemicals but may underperform in low-temperature environments due to increased stiffness and reduced elasticity. Selecting the correct material requires a comprehensive understanding of the service environment, not just dimensional conformity.

Another common failure mode arises from overlooking dynamic application requirements. In reciprocating or rotary shaft seals, friction, compression set, and extrusion resistance become decisive factors. Materials such as silicone (VMQ) exhibit excellent thermal stability but possess poor mechanical strength and wear resistance, making them unsuitable for dynamic sealing despite dimensional compliance. Similarly, ethylene propylene diene monomer (EPDM) excels in water and steam applications but fails in contact with hydrocarbon fuels.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions over generic off-the-shelf offerings. Our technical team evaluates application-specific parameters—fluid media, temperature range, cycle frequency, and surface finish—to recommend optimal elastomer formulations. This proactive approach mitigates premature seal failure, reduces downtime, and enhances system safety.

The following table outlines common o-ring materials, their key properties, and typical limitations:

| Material | Temperature Range (°C) | Key Advantages | Common Limitations |

|---|---|---|---|

| NBR (Nitrile) | -30 to +120 | High resistance to oils, fuels, and hydraulics | Poor ozone and UV resistance; limited heat stability |

| FKM (Fluorocarbon) | -20 to +200 | Excellent chemical and heat resistance | High cost; poor low-temperature flexibility |

| EPDM | -50 to +150 | Superior steam and water resistance | Incompatible with hydrocarbons and oils |

| Silicone (VMQ) | -60 to +180 | Outstanding thermal and cold flexibility | Low tensile strength; poor abrasion resistance |

| Viton® (Specialty FKM) | -15 to +230 | Enhanced chemical resistance and thermal stability | Expensive; limited mechanical durability in dynamic use |

Material selection is not a secondary consideration—it is integral to the engineering integrity of any sealing solution. Relying solely on dash number conformity without evaluating elastomer performance leads to avoidable failures. At Baoshida, we combine dimensional precision with material science expertise to deliver o-rings engineered for reliability, not just fit.

Material Specifications

Material Selection Fundamentals for Precision O-Ring Dash Number Applications

Material specification is a critical engineering decision directly impacting O-ring performance, service life, and system reliability within AS568 dash number frameworks. At Suzhou Baoshida Trading Co., Ltd., our OEM partnerships demand rigorous material science understanding to match seal properties with operational demands. Viton fluorocarbon rubber (FKM) represents the premium solution for extreme environments. Its molecular structure provides exceptional resistance to high temperatures, aggressive chemicals, aerospace fuels, and synthetic lubricants. Continuous service up to 230°C is achievable, with short-term excursions higher. Viton exhibits low gas permeability and excellent resistance to compression set, crucial for dynamic sealing under sustained pressure. However, its cost is significantly higher than alternatives, and it demonstrates limited flexibility at very low temperatures below -20°C. Standard grades offer good resistance to mineral oils, hydraulic fluids, and many acids, but compatibility with ketones, esters, and certain amines requires specific compound formulation.

Nitrile rubber (NBR), a copolymer of butadiene and acrylonitrile, remains the dominant material for general industrial sealing due to its optimal balance of performance and cost. The acrylonitrile content directly governs oil and fuel resistance; higher levels (e.g., 40-50%) enhance resistance to petroleum-based fluids but reduce low-temperature flexibility. NBR effectively seals mineral oils, greases, water, and aliphatic hydrocarbons within a typical range of -40°C to 120°C. Its excellent abrasion resistance and extrusion resistance make it suitable for hydraulic and pneumatic systems. Key limitations include poor resistance to ozone, weathering, polar solvents, and phosphate ester hydraulic fluids. Compression set resistance is moderate compared to FKM or silicone, potentially limiting long-term static sealing performance in demanding applications.

Silicone rubber (VMQ) excels in applications requiring extreme temperature stability and physiological inertness. It maintains flexibility from -60°C up to 200°C continuously, with short-term tolerance to 250°C. Silicone offers outstanding resistance to ozone, UV radiation, and weathering, alongside very low compression set. Its biocompatibility makes it standard for medical and food-grade seals. However, silicone possesses very poor resistance to petroleum-based oils, fuels, and solvents, limiting its use in many industrial fluid power systems. Tensile strength and tear resistance are generally lower than NBR or FKM, requiring careful gland design. It also exhibits higher gas permeability.

Material selection must precede dash number size determination, as the required cross-section and groove dimensions are influenced by material behavior under operational stress. The following table provides a concise technical comparison of these core elastomers for O-ring specification.

| Material | Base Polymer | Temp Range (°C) | Key Fluid Resistances | Key Limitations | Typical Hardness (Shore A) |

|---|---|---|---|---|---|

| Viton (FKM) | Fluorocarbon | -20 to 230 | Jet fuels, synthetic oils, acids, brake fluids | Cost, poor low-temp flex, ketones | 70, 75, 90 |

| Nitrile (NBR) | Acrylonitrile-Butadiene | -40 to 120 | Mineral oils, water, aliphatic hydrocarbons | Ozone, weathering, polar solvents | 60, 70, 80, 90 |

| Silicone (VMQ) | Polysiloxane | -60 to 200 | Water, steam, ozone, UV, some acids | Petroleum oils, fuels, solvents, low tensile | 50, 60, 70 |

Suzhou Baoshida Trading Co., Ltd. provides comprehensive material data sheets and application engineering support to ensure the selected elastomer, precisely matched to the AS568 dash number size, delivers optimal sealing integrity within your specific operational parameters and regulatory requirements. Material choice is foundational to O-ring success.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of precision rubber seal manufacturing, delivering engineered O-ring solutions tailored to exacting industrial standards. Central to our technical leadership is a dedicated team of five specialized mould engineers and two advanced rubber formula engineers. This integrated engineering capability enables us to provide comprehensive OEM support, from concept validation to mass production, ensuring dimensional accuracy, material compatibility, and long-term performance under demanding service conditions.

Our mould engineering team leverages advanced CAD/CAM systems and precision CNC machining to develop high-tolerance moulds for O-rings across all standard and custom dash number sizes. Each design undergoes rigorous simulation for flow dynamics, shrinkage prediction, and parting line optimization, minimizing defects and ensuring consistent replication. With expertise in multi-cavity and family mould configurations, we achieve scalable production efficiency without compromising quality. The team maintains strict adherence to AS568, ISO 3601, and JIS B 2401 standards, enabling seamless interchangeability and global compliance.

Complementing mould precision is our in-house rubber formulation expertise. Our two certified formula engineers specialize in elastomer chemistry, focusing on optimizing compound performance for temperature resistance, compression set, chemical exposure, and dynamic sealing applications. We formulate and validate materials including Nitrile (NBR), Fluorocarbon (FKM), Ethylene Propylene (EPDM), Silicone (VMQ), and specialty blends such as FFKM and ACM. Each formulation is developed to meet or exceed ASTM D2000 specifications and is validated through accelerated aging, fluid immersion, and physical property testing in our on-site laboratory.

This dual-engineering synergy—mould design and material science—positions Suzhou Baoshida as a trusted OEM partner for mission-critical sealing solutions. We support clients across aerospace, automotive, semiconductor, and industrial hydraulics sectors with full documentation, PPAP submissions, and traceable batch records. Our vertical integration reduces lead times and enhances control over quality, enabling rapid prototyping and scalable ramp-up for high-volume programs.

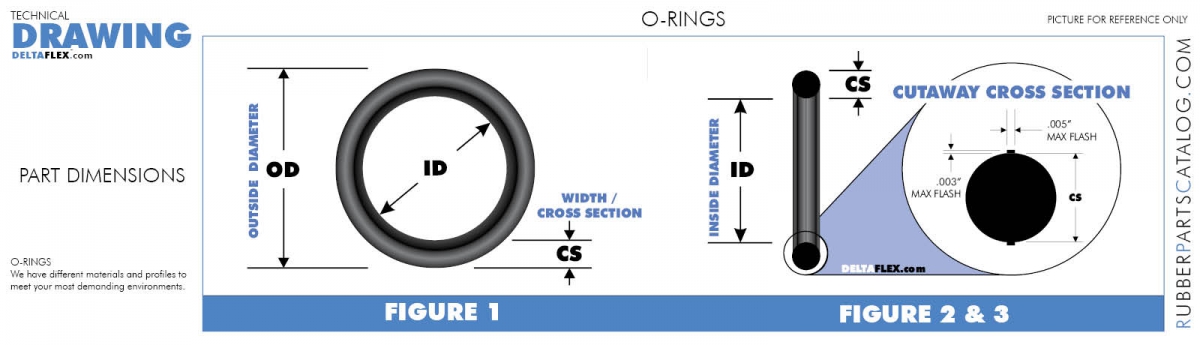

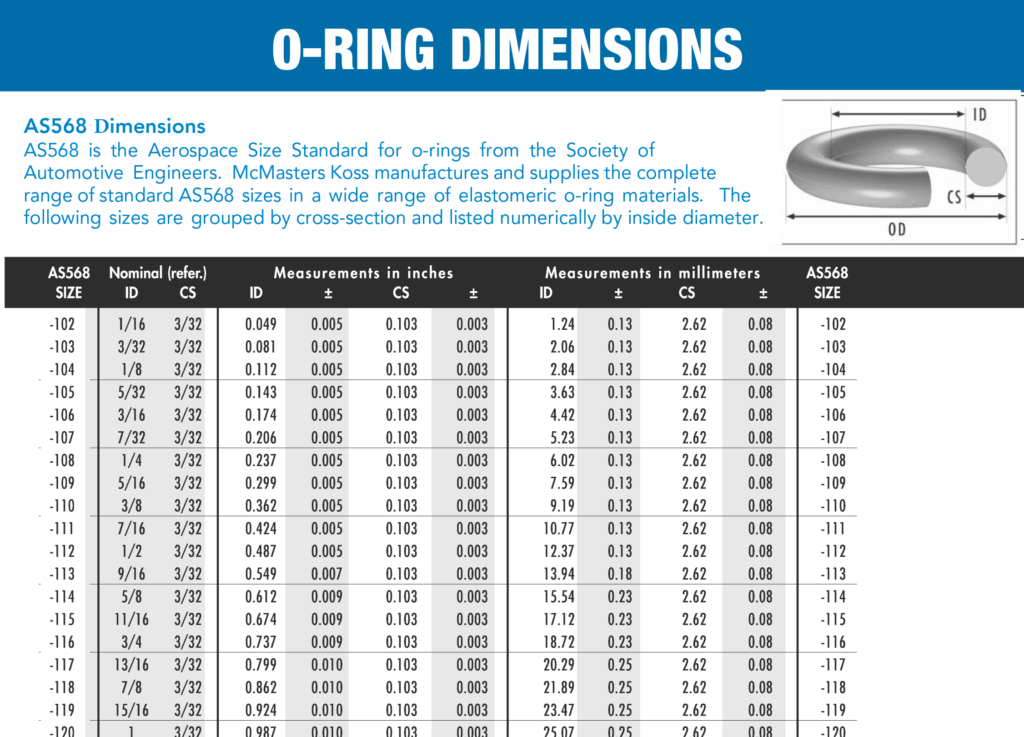

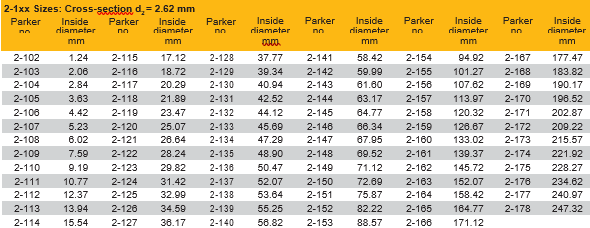

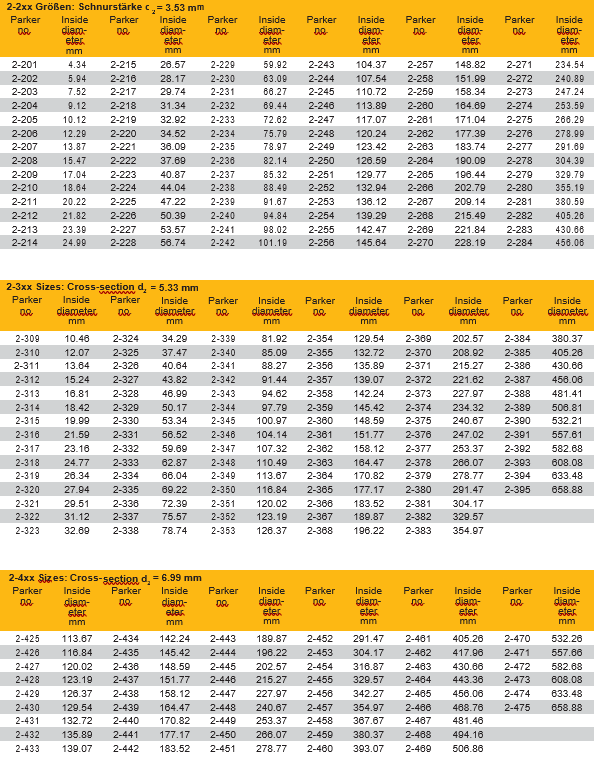

Below is a representative cross-section of standard O-ring dash numbers and corresponding physical dimensions, reflecting the precision achievable through our engineering systems:

| Dash Number | Inside Diameter (inch) | Cross Section (inch) | Inside Diameter (mm) | Cross Section (mm) |

|---|---|---|---|---|

| -001 | 0.040 | 0.040 | 1.02 | 1.02 |

| -012 | 0.120 | 0.070 | 3.05 | 1.78 |

| -104 | 0.254 | 0.104 | 6.45 | 2.64 |

| -214 | 1.260 | 0.139 | 32.00 | 3.53 |

| -326 | 3.414 | 0.210 | 86.72 | 5.33 |

| -434 | 5.620 | 0.275 | 142.75 | 6.99 |

All dimensions are held to ±0.05 mm tolerance as standard, with tighter tolerances available per customer requirement. Our engineering team collaborates directly with clients to select optimal dash numbers, materials, and tolerances, ensuring functional reliability in final assembly.

Customization Process

O-Ring Dash Number Customization Process at Suzhou Baoshida Trading Co. Ltd.

Understanding and accurately applying the AS568 Dash Number standard is fundamental to precision o-ring manufacturing. At Suzhou Baoshida Trading Co. Ltd. our OEM customization process rigorously translates customer drawings referencing dash numbers into high-performance, application-specific seals. This ensures dimensional accuracy, material compatibility, and functional reliability under demanding industrial conditions. Our four-phase methodology guarantees seamless transition from specification to volume production.

Drawing Analysis initiates the process. Our engineering team meticulously deconstructs the provided technical drawing, verifying the specified AS568 dash number (e.g., -214) against the latest AS568-2019 standard. We cross-reference the nominal inside diameter (ID) and cross-section (CS) dimensions, confirming tolerance classes per ISO 3601. Critical attention is paid to application notes regarding media exposure, temperature extremes, pressure cycles, and surface finish requirements. Any ambiguity or potential conflict between the dash number specification and operational demands is flagged immediately for collaborative resolution with the client, preventing downstream errors.

Formulation leverages the validated application parameters. Based on the fluid compatibility, temperature range, and performance criteria identified during analysis, our rubber chemists select the optimal base polymer and compound architecture. Material selection is not arbitrary; it is a science-driven decision. The table below illustrates common material families and their suitability for dash number o-rings in specific environments.

| Material Family | Key Compounds | Temperature Range (°C) | Primary Fluid Resistance | Typical Dash Number Applications |

|---|---|---|---|---|

| Nitrile (NBR) | Standard, High Acrylonitrile | -40 to +120 (+150 intermittent) | Oils, Fuels, Hydraulic Fluids | General industrial, automotive |

| Fluorocarbon (FKM) | Standard, Low Temp, Perfluoroelastomer (FFKM) | -20 to +230 (+300 for FFKM) | Aggressive chemicals, Jet fuels, High-temp oils | Aerospace, semiconductor, chemical processing |

| Ethylene Propylene (EPDM) | Standard, Peroxide cured | -50 to +150 | Water, Steam, Brake fluids, Polar solvents | HVAC, automotive coolant systems |

Compound development targets precise Shore A hardness (typically 70±5 for dash numbers), compression set resistance per ASTM D395, and stringent fluid immersion properties per ASTM D471. Every formulation undergoes rigorous internal validation before prototyping.

Prototyping transforms the engineered compound into physical validation. Utilizing precision molds cut to the exact AS568 dash number dimensions with ISO 3601 Class M tolerances, we produce initial lots. Each prototype o-ring undergoes comprehensive metrology: laser micrometry for ID/CS verification, hardness testing, and visual inspection per MSS-SP-83. Dimensional data is statistically analyzed against the dash number specification. Critical application-specific tests, such as simulated fluid exposure or compression stress relaxation, are conducted. Client approval of prototypes is mandatory before tooling release.

Mass Production implements the validated process at scale. Dedicated production cells run under strict ISO 9001 and IATF 16949 controls. Real-time statistical process control (SPC) monitors key dimensions and compound properties, ensuring Cpk ≥ 1.33 for critical characteristics. Every production lot undergoes 100% visual inspection and抽样 testing per AQL 1.0 for dimensional conformance to the dash number standard. Full material traceability, from raw polymer batch to finished o-ring, is maintained. This disciplined approach guarantees Suzhou Baoshida delivers dash number o-rings that consistently meet the exacting demands of global OEMs, ensuring seal integrity and system longevity.

Contact Engineering Team

Contact Suzhou Baoshida for Precision O-Ring Dash Number Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in the engineering and distribution of high-performance rubber seals tailored to meet the exacting demands of industrial, automotive, aerospace, and fluid power applications. Our expertise in precision rubber formulation and dimensional accuracy ensures that every O-ring we supply adheres to international standards and performs reliably under extreme conditions. As your strategic OEM partner, we go beyond standard catalog offerings—we provide technical consultation, material selection guidance, and custom sealing solutions engineered to your operational requirements.

Understanding the O-ring dash number system is critical for ensuring interchangeability, proper fit, and long-term sealing integrity. Our technical team maintains an in-depth database of AS568, ISO 3601, and JIS B 2401 dash number specifications, enabling rapid cross-referencing and accurate fulfillment of both standard and obsolete sizes. Whether you are designing a new hydraulic system or replacing a legacy seal in industrial machinery, our engineers support you from concept to commissioning.

We recognize that material compatibility, compression set resistance, thermal stability, and fluid exposure are pivotal factors in seal longevity. Our rubber compounds—including Nitrile (NBR), Fluorocarbon (FKM/Viton®), Silicone (VMQ), Ethylene Propylene (EPDM), and Hydrogenated Nitrile (HNBR)—are rigorously tested and certified to ensure compliance with ASTM, SAE, and OEM specifications. Each compound is mapped to specific dash numbers based on cross-sectional diameter and inside diameter tolerances, ensuring dimensional repeatability down to ±0.05 mm.

For your convenience, the table below outlines key dash number dimensions and tolerances per AS568 standards, commonly stocked and available for immediate quotation:

| Dash Number | Inside Diameter (in) | Cross Section (in) | Volume Swell (ASTM D471, 70h @ 100°C) | Standard Material Options |

|---|---|---|---|---|

| -006 | 0.081 ±0.004 | 0.070 ±0.003 | <15% (NBR), <10% (FKM) | NBR, FKM, EPDM |

| -214 | 1.000 ±0.006 | 0.139 ±0.004 | <12% (FKM), <18% (HNBR) | FKM, HNBR, NBR |

| -328 | 3.500 ±0.010 | 0.280 ±0.005 | <8% (FKM), <20% (EPDM) | FKM, EPDM, Silicone |

| -436 | 6.000 ±0.015 | 0.375 ±0.006 | <10% (FKM), <22% (NBR) | FKM, NBR |

All dimensions conform to AS568 Rev D, with traceable certification available upon request. Custom durometer ratings (from 50 to 90 Shore A) and special packaging (kit assembly, labeled reels) are offered to streamline your assembly process.

To obtain a full O-ring dash number cross-reference chart, request material test reports, or discuss application-specific sealing challenges, contact Mr. Boyce directly. As OEM Manager and Technical Rubber Engineer, Mr. Boyce leads our global client integration team and is available to support technical onboarding, sample provisioning, and long-term supply agreements.

Reach out today via email at [email protected] to initiate a precision seal solution engineered for performance, durability, and supply chain efficiency. Suzhou Baoshida Trading Co., Ltd.—your trusted partner in advanced rubber sealing technology.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).