Technical Contents

Engineering Guide: Is Latex And Rubber The Same

Engineering Insight: Are Latex and Rubber the Same?

In industrial manufacturing and precision engineering, the distinction between latex and rubber is not merely semantic—it is a critical technical differentiation that impacts performance, durability, and application suitability. While both materials originate from polymer-based sources, they differ significantly in chemical composition, physical behavior, and engineering applicability. Confusing the two can lead to premature component failure, compromised sealing integrity, and increased maintenance costs—especially in high-stress environments.

Latex, in its raw form, is a natural colloidal suspension derived primarily from the Hevea brasiliensis tree. It consists of cis-1,4-polyisoprene particles dispersed in water and is commonly processed into dipped goods such as gloves, balloons, or foam products. Its high elasticity and biodegradability make it suitable for medical and consumer applications, but its limited resistance to heat, ozone, and petroleum-based fluids renders it unsuitable for most industrial uses.

Rubber, by contrast, encompasses a broader category of elastomeric materials, including both natural rubber (derived from latex but vulcanized) and synthetic variants such as nitrile (NBR), ethylene propylene diene monomer (EPDM), silicone (VMQ), and fluorocarbon (FKM). Industrial rubber compounds are engineered through vulcanization, filler reinforcement, and additive integration to achieve specific mechanical and chemical resistance properties. These modifications enable rubber components to withstand extreme temperatures, aggressive media, and dynamic mechanical loads—conditions where raw latex would rapidly degrade.

A common misconception in procurement is treating off-the-shelf rubber or latex products as interchangeable. Standardized solutions often fail because they do not account for application-specific variables such as compression set, tensile strength, fluid compatibility, or thermal cycling. For example, a generic latex-based seal may swell and disintegrate when exposed to hydraulic oil, whereas a properly specified NBR rubber O-ring maintains integrity under identical conditions.

Material selection must be guided by rigorous engineering analysis. At Suzhou Baoshida Trading Co., Ltd., we emphasize application-driven formulation, leveraging material data sheets, environmental exposure profiles, and finite element analysis to match the elastomer to the operational demands. Custom compounding allows for optimization of hardness, resilience, and aging characteristics—ensuring longevity and reliability in mission-critical systems.

The table below highlights key property differences between common elastomers and natural latex:

| Property | Natural Latex | Nitrile (NBR) | EPDM | FKM (Viton®) |

|---|---|---|---|---|

| Tensile Strength (MPa) | 15–30 | 10–25 | 7–20 | 8–15 |

| Operating Temp Range (°C) | -20 to +60 | -30 to +120 | -50 to +150 | -20 to +200 |

| Oil/Fuel Resistance | Poor | Excellent | Poor | Excellent |

| Ozone Resistance | Low | Moderate | Excellent | Excellent |

| Typical Industrial Use | Gloves, foam | Seals, hoses | Weather seals | High-temp seals |

Understanding these distinctions ensures that material selection is not a cost-driven compromise but a performance-enabling decision. At Baoshida, we partner with OEMs to transition from generic substitutes to engineered rubber solutions—maximizing system efficiency and minimizing lifecycle costs.

Material Specifications

Material Specifications: Clarifying Latex vs. Rubber and Industrial Synthetic Elastomers

Latex and rubber are frequently conflated, yet they represent distinct categories within polymer science. Latex specifically denotes a colloidal suspension of cis-1,4-polyisoprene particles, primarily sourced from the Hevea brasiliensis tree. It constitutes one subset of natural rubber but lacks the performance attributes required for demanding industrial applications. True “rubber” encompasses both natural variants (like latex-derived solid rubber) and synthetics engineered for superior resilience, chemical stability, and thermal endurance. For OEMs in automotive, aerospace, and fluid handling systems, synthetic elastomers—not natural latex—are the standard due to their customizable molecular structures and reliability under extreme conditions.

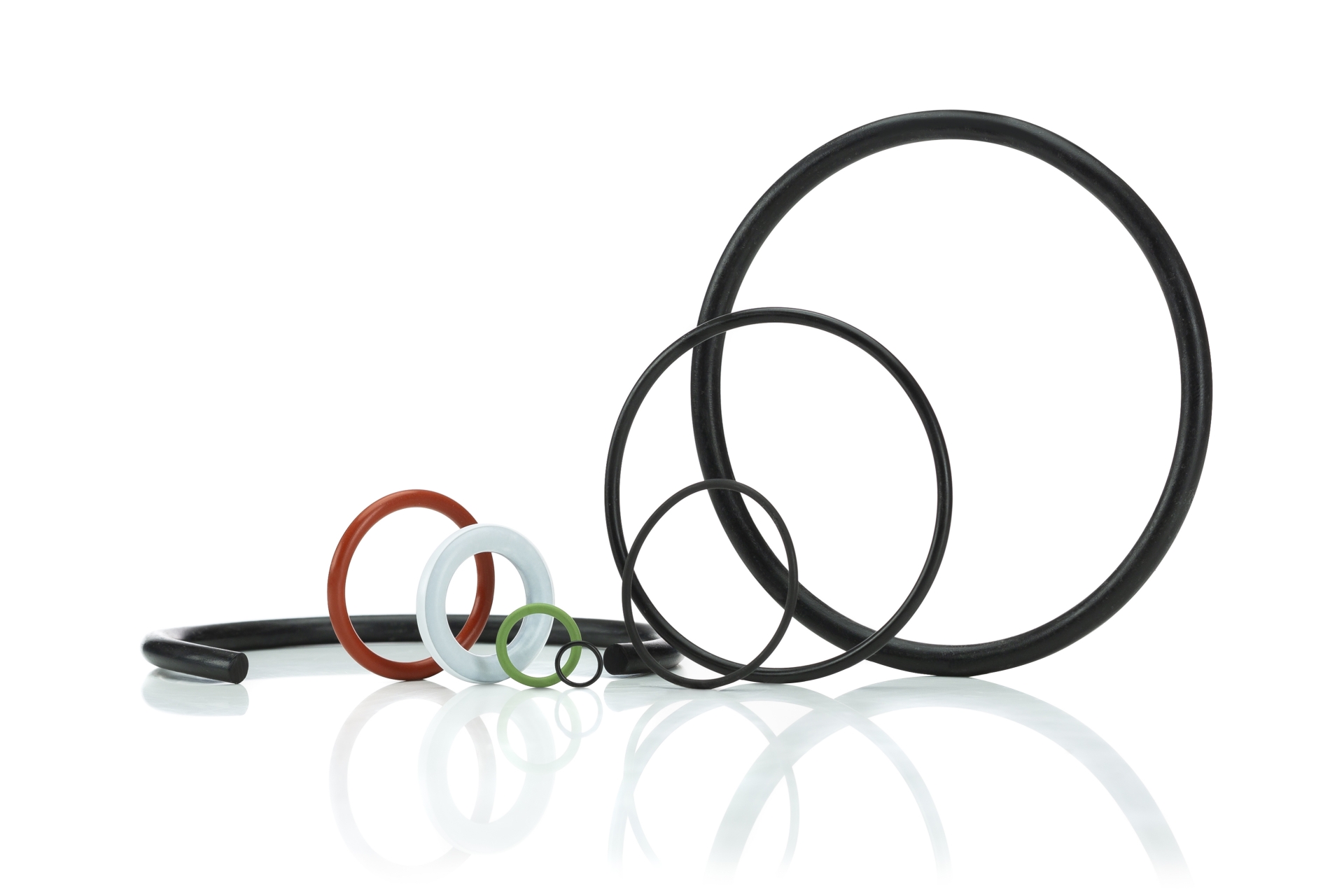

Suzhou Baoshida Trading Co., Ltd. supplies three critical synthetic rubbers for precision engineering: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material exhibits unique chemical compositions and performance thresholds, directly impacting component longevity and safety. Viton, a fluorocarbon elastomer, excels in resisting aggressive chemicals and high temperatures. Nitrile, an acrylonitrile-butadiene copolymer, provides exceptional resistance to oils and fuels. Silicone, a polysiloxane-based polymer, delivers unmatched flexibility across extreme temperature cycles and biocompatibility. Selecting the correct compound prevents premature seal failure, fluid contamination, and costly downtime.

The comparative specifications below adhere to ASTM D2000 and ISO 37 standards, reflecting tested properties for industrial-grade formulations. Hardness values are reported in Shore A scale, tensile strength in MPa, and temperature ranges denote continuous service limits.

| Material | Temperature Range (°C) | Chemical Resistance | Tensile Strength (MPa) | Hardness Range (Shore A) | Primary Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | Exceptional resistance to acids, fuels, hydraulic fluids, and aromatic hydrocarbons. Moderate resistance to steam. | 12–20 | 50–90 | Aerospace fuel systems, chemical plant gaskets, semiconductor manufacturing seals |

| Nitrile (NBR) | -30 to +120 | Superior resistance to aliphatic hydrocarbons, oils, and greases. Poor resistance to ozone, acids, and polar solvents. | 10–30 | 40–90 | Automotive O-rings, fuel hoses, hydraulic seals, printing rolls |

| Silicone (VMQ) | -60 to +200 | Excellent resistance to oxygen, ozone, and water. Limited resistance to concentrated acids, fuels, and steam. | 5–12 | 30–80 | Medical devices, food processing gaskets, high-voltage insulation, cookware seals |

Viton’s fluorine content (66% typical) creates a dense molecular barrier against permeation, critical for handling aggressive media like jet fuel or sulfuric acid. Nitrile’s acrylonitrile percentage (18–50%) directly correlates with oil resistance; higher percentages increase rigidity but reduce low-temperature flexibility. Silicone’s siloxane backbone enables stability from arctic conditions to baking environments, though mechanical strength remains lower than hydrocarbon-based elastomers. Crucially, none of these synthetics share latex’s vulnerability to oxidation, ozone degradation, or protein allergens—making them indispensable for industrial reliability.

OEMs must validate material compatibility against specific media, pressures, and dynamic stresses. Suzhou Baoshida provides full material test reports (MTRs) and application engineering support to ensure optimal compound selection, minimizing field failures and extending service life across global supply chains.

Manufacturing Capabilities

Engineering Capability: Precision in Rubber and Latex Material Science

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise in industrial rubber and elastomer solutions. A common question in the manufacturing sector is whether latex and rubber are the same. While both fall under the broader category of elastomers, they are distinct in composition, performance, and application. Natural rubber, derived primarily from polyisoprene extracted from the Hevea brasiliensis tree, offers superior tensile strength, resilience, and abrasion resistance, making it ideal for industrial seals, gaskets, and mechanical components. Latex, on the other hand, refers to a colloidal dispersion of polymer microparticles in water, often used in dipped goods such as gloves or foam products. Its formulation prioritizes elasticity and thin-film integrity over mechanical durability. Understanding these differences is critical in material selection, and our in-house team ensures precise alignment between application requirements and compound performance.

Our engineering team comprises five dedicated mould designers and two specialized rubber formula engineers. This dual focus enables us to control both the physical geometry of rubber components and the molecular architecture of the compounds used. Our formula engineers develop custom rubber compounds tailored to specific environmental challenges, including resistance to heat, ozone, oils, and dynamic stress. By adjusting polymer types (such as NBR, EPDM, silicone, or FKM), filler systems, vulcanization protocols, and additive packages, we achieve performance characteristics that meet or exceed OEM specifications.

Our mould engineers utilize advanced CAD/CAM software and coordinate closely with the formulation team to ensure dimensional accuracy, optimal flow dynamics during curing, and long-term tooling durability. This integrated approach reduces prototyping cycles and accelerates time-to-market for custom solutions. With full OEM (Original Equipment Manufacturer) service capabilities, we support clients from initial concept and material selection through tooling, validation, and high-volume production. All processes adhere to ISO standards, with rigorous testing protocols for hardness, compression set, tensile strength, and environmental aging.

The table below outlines key performance characteristics of common rubber materials we engineer and manufacture:

| Material | Temperature Range (°C) | Hardness Range (Shore A) | Key Resistance Properties |

|---|---|---|---|

| NBR (Nitrile) | -30 to +100 (up to +120 short-term) | 40–90 | Oil, fuel, abrasion |

| EPDM | -50 to +150 | 50–80 | Ozone, UV, steam, weathering |

| Silicone | -60 to +200 (up to +250 intermittent) | 30–80 | Extreme temperatures, biocompatibility |

| FKM (Viton®) | -20 to +200 (up to +250) | 60–90 | Chemicals, hydrocarbons, high heat |

| Natural Rubber | -50 to +80 | 40–85 | High elasticity, tear strength |

Through this synergy of material science and precision engineering, Suzhou Baoshida delivers reliable, application-specific rubber solutions for automotive, industrial machinery, and fluid handling sectors. Our OEM model is built on collaboration, technical transparency, and consistent quality.

Customization Process

Material Differentiation and Customization Pathway for Industrial Rubber Components

A critical clarification precedes all industrial rubber component development: latex and rubber are not synonymous. Latex refers specifically to the milky colloidal suspension harvested from Hevea brasiliensis trees, serving as the raw feedstock for natural rubber production. Industrial rubber components, however, predominantly utilize vulcanized elastomers—either refined natural rubber (polyisoprene) or synthetics like NBR, EPDM, or silicone. Natural rubber originates from latex but undergoes coagulation, drying, and compounding; synthetics are polymerized from petrochemical derivatives. Confusing these terms risks material misselection for demanding OEM applications where thermal stability, chemical resistance, or mechanical precision are non-negotiable.

At Suzhou Baoshida Trading Co., Ltd., our customization process rigorously bridges this knowledge gap through four sequenced phases. Drawing Analysis initiates the workflow. Our engineering team dissects client CAD files and technical specifications, scrutinizing dimensional tolerances, environmental exposure requirements (e.g., ozone, oils, temperature extremes), and functional stress points. This phase identifies if natural rubber—limited by poor oil resistance and thermal range—is viable or if synthetics better align with performance demands. Misinterpreting “rubber” as universally interchangeable with latex-derived materials here would compromise the entire project.

Formulation follows, leveraging Suzhou Baoshida’s material science expertise. Based on the drawing analysis, our lab engineers design compound recipes using ASTM-standardized base polymers, reinforcing fillers, curatives, and specialty additives. For instance, an automotive seal exposed to engine oil mandates NBR (nitrile) for hydrocarbon resistance, not natural rubber. Each formulation is computationally modeled for cure kinetics and physical property targets before lab-scale mixing. Precision in polymer selection—dictated by the initial material clarification—is paramount; a 5% error in acrylonitrile content within NBR can alter oil swell by 15%.

Prototyping validates the formulation. We produce 3–5 prototype batches via precision molding, subjecting them to client-specified tests: tensile strength, compression set, fluid immersion, and dynamic fatigue. Data is cross-referenced against the original drawing’s performance criteria. If a natural rubber prototype fails at 120°C, we pivot to hydrogenated nitrile (HNBR) without delay. This iterative stage ensures the elastomer—never merely “latex”—meets OEM functional thresholds.

Mass Production commences only after prototype approval. Suzhou Baoshida implements real-time process monitoring: closed-loop control of temperature, pressure, and cure time within ±2°C and ±0.5 MPa tolerances. Every production lot undergoes batch certification per ISO 37 and ISO 2230, with traceability to raw material lot numbers. This guarantees consistency where material identity directly dictates product lifecycle reliability.

The following table underscores why material precision defines industrial success:

| Material Type | Primary Source | Key Properties | Typical Industrial Applications |

|---|---|---|---|

| Natural Rubber | Refined latex | High tensile (15–30 MPa), low hysteresis | Vibration mounts, adhesives |

| NBR (Nitrile) | Petrochemical synthesis | Oil/fuel resistance, -30°C to +100°C range | Automotive seals, hydraulic hoses |

| EPDM | Petrochemical synthesis | Ozone/weather resistance, -60°C to +150°C range | HVAC seals, radiator hoses |

| Silicone | Petrochemical synthesis | Extreme temp range (-100°C to +300°C), inert | Medical devices, aerospace gaskets |

Suzhou Baoshida’s process eliminates material ambiguity through science-led customization. From specification to量产, we ensure the elastomer—whether derived from latex or synthesized—delivers uncompromised performance for your OEM application.

Contact Engineering Team

Understanding the Distinction: Latex vs. Rubber in Industrial Applications

In the field of industrial materials, the terms latex and rubber are often used interchangeably, but they are not the same. Latex refers specifically to a stable dispersion of polymer microparticles in an aqueous medium, typically derived from natural sources such as the Hevea brasiliensis tree or synthesized through petrochemical processes. Natural latex is a raw, liquid form that must undergo coagulation, vulcanization, and further processing to become functional rubber. In contrast, rubber—whether natural or synthetic—is the solid, elastic material resulting from the processing and compounding of latex or other polymer bases. Industrial rubber encompasses a broad category of elastomers engineered for durability, resilience, and performance under extreme conditions.

At Suzhou Baoshida Trading Co., Ltd., we specialize in advanced industrial rubber solutions tailored to meet the rigorous demands of manufacturing, automotive, construction, and specialty equipment sectors. Our expertise lies in transforming raw elastomeric materials into high-performance components, from seals and gaskets to conveyor systems and vibration dampeners. Whether your application requires nitrile (NBR), ethylene propylene diene monomer (EPDM), silicone, or chloroprene (CR), our engineering team ensures precise formulation, consistent quality, and compliance with international standards.

Understanding the chemical and physical differences between latex and rubber is critical when selecting materials for industrial use. Latex, in its raw form, lacks the mechanical strength and thermal stability required for most industrial environments. Rubber, after vulcanization and reinforcement with fillers, additives, and curatives, achieves the tensile strength, abrasion resistance, and temperature tolerance necessary for reliable performance.

Below is a comparative overview of key properties between natural latex and processed industrial rubber:

| Property | Natural Latex (Raw) | Processed Industrial Rubber (e.g., Vulcanized NR) |

|---|---|---|

| Physical State | Liquid dispersion | Solid, elastic material |

| Tensile Strength | Low (1–2 MPa) | High (15–30 MPa) |

| Elongation at Break | High (>300%) | Controlled (400–700%) |

| Thermal Resistance | Poor (<60°C) | Improved (up to 120°C with additives) |

| Chemical Resistance | Low | Moderate to high, depending on compound |

| Applications | Gloves, adhesives, foam | Seals, hoses, industrial rollers, mounts |

For engineers and procurement managers seeking reliable rubber material solutions, partnering with a technically proficient supplier is essential. Suzhou Baoshida Trading Co., Ltd. offers comprehensive support—from material selection and formulation to custom manufacturing and quality assurance.

Contact Mr. Boyce directly at [email protected] to discuss your specific industrial rubber requirements. Our team is ready to provide technical data sheets, sample materials, and engineering consultations to ensure optimal material performance in your application. Let us help you move beyond misconceptions and deliver precision rubber solutions that enhance efficiency, safety, and product longevity.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).