Technical Contents

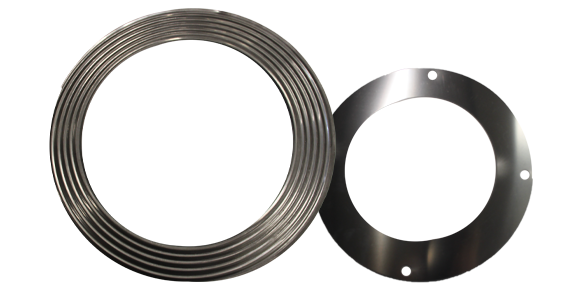

Engineering Guide: Metal Gasket Material

Engineering Insight Metal Gasket Material Selection Criticality

Material selection for metal gaskets represents a non-negotiable engineering decision directly impacting system integrity, safety, and lifecycle cost. While off-the-shelf metal gasket solutions appear cost-effective initially, they frequently precipitate catastrophic field failures due to fundamental mismatches between generic material properties and specific operational demands. This mismatch arises because standardized products inherently neglect the complex interplay of thermal dynamics, chemical exposure, mechanical stress profiles, and environmental variables unique to each application. Precision sealing in critical industrial systems—such as aerospace hydraulics, petrochemical reactors, or semiconductor manufacturing—demands gasket materials engineered at the metallurgical level to withstand exacting service conditions. Failure to conduct rigorous application-specific material qualification inevitably leads to premature degradation modes including stress relaxation, creep, intergranular corrosion, or brittle fracture under cyclic loading.

Generic metal gaskets often fail due to insufficient consideration of thermal expansion differentials between the gasket, flange, and process media. A mismatch here induces uneven stress distribution during thermal cycling, causing loss of sealing force and leakage paths. Similarly, off-the-shelf alloys may exhibit inadequate resistance to specific chemical environments—such as chloride-induced stress corrosion cracking in standard stainless steels within offshore applications or hydrogen embrittlement in high-pressure hydrogen systems. The absence of tailored surface treatments or controlled grain structures in mass-produced gaskets further compromises performance under high vacuum or ultra-pure fluid conditions where outgassing or particle generation becomes critical. These failures translate directly into unplanned downtime, safety hazards, and significantly higher total cost of ownership compared to a precisely engineered solution.

The resolution lies in a systematic material qualification protocol. This requires detailed analysis of maximum/minimum operating temperatures, pressure transients, fluid compatibility, flange surface finish, and required service life. Material properties must be evaluated holistically, not in isolation. Below is a comparative specification guide for common precision metal gasket alloys under extreme conditions:

| Material | Max Continuous Temp (°C) | Pressure Rating (MPa) | Key Chemical Limitation | Primary Failure Risk in Generic Use |

|---|---|---|---|---|

| Inconel 625 | 1000 | 150 | Hydrofluoric acid | Creep relaxation in high-temp flange joints |

| 316L Stainless | 550 | 100 | Chlorides > 50 ppm | Stress corrosion cracking in marine env. |

| Monel 400 | 500 | 80 | Dry chlorine | Rapid oxidation above 500°C in air |

| Elgiloy | 450 | 120 | Strong acids | Work hardening during installation |

Suzhou Baoshida Trading Co., Ltd. implements this precision engineering approach through OEM collaboration. We mandate comprehensive application data sheets prior to material recommendation, utilizing advanced metallurgical testing including ASTM G36 for stress corrosion and ISO 3669 for high-temperature creep verification. Our process ensures the selected alloy—whether specialty nickel-based, precipitation-hardened, or clad composites—possesses the exact grain morphology, hardness profile, and surface integrity required for the operational envelope. This eliminates the false economy of off-the-shelf gaskets by preventing field failures rooted in inadequate material science understanding. Precision sealing demands metallurgical specificity; generic solutions compromise system reliability at every operational extreme.

Material Specifications

Material Specifications for Precision Metal Gasket Applications

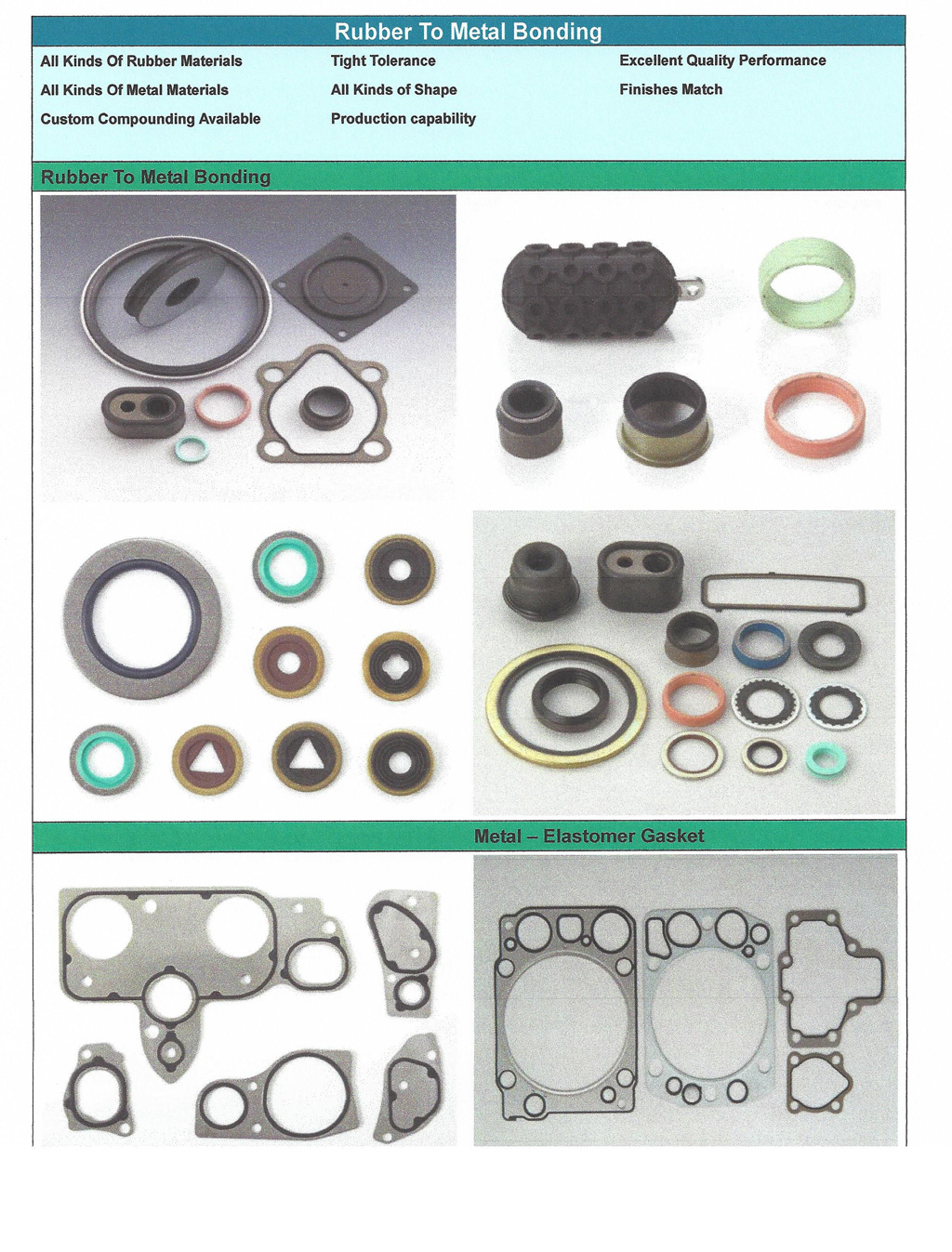

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber-to-metal gasket solutions designed for high-performance sealing in demanding industrial environments. Our precision rubber seals integrate elastomeric compounds such as Viton, Nitrile (NBR), and Silicone, each selected for specific operational requirements including temperature resilience, chemical compatibility, and mechanical durability. These materials are bonded to metal substrates to deliver structural integrity and consistent sealing performance under pressure, vibration, and thermal cycling.

Viton, a fluorocarbon-based elastomer (FKM), offers superior resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It is ideal for applications in the automotive, aerospace, and chemical processing industries where long-term stability in extreme conditions is required. Viton maintains sealing effectiveness from -20°C to +200°C, with intermittent exposure tolerance up to 230°C. Its low compression set and excellent aging characteristics ensure prolonged service life in critical sealing applications.

Nitrile rubber (NBR) is a cost-effective solution for applications involving petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons. With a temperature range of -30°C to +100°C, extendable to +120°C for short durations, NBR provides strong abrasion resistance and mechanical strength. It is widely used in automotive fuel systems, hydraulics, and general industrial machinery. While less resistant to ozone and UV exposure than other elastomers, NBR remains a preferred choice for dynamic and static seals in oil-rich environments.

Silicone rubber (VMQ) excels in extreme temperature applications, functioning reliably from -60°C to +200°C. It demonstrates excellent resistance to ozone, UV radiation, and weathering, making it suitable for outdoor and high-temperature environments. Silicone also meets stringent cleanliness and biocompatibility standards, enabling its use in pharmaceutical, food processing, and medical equipment. However, it has lower tensile strength and abrasion resistance compared to Viton and NBR, requiring careful design consideration in high-stress applications.

The selection of elastomer directly impacts the performance, longevity, and safety of metal-reinforced gaskets. Engineers must evaluate operating conditions including fluid media, temperature profiles, pressure loads, and regulatory requirements when specifying materials.

The following table compares key physical and chemical properties of the three primary elastomers used in our metal gasket solutions.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 (up to 230 intermittently) | -30 to +100 (+120 short term) | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Excellent (aliphatic hydrocarbons, oils) | Fair (poor with oils, good with water, alcohols) |

| Compression Set Resistance | Excellent | Good | Good |

| Ozone & UV Resistance | Excellent | Fair | Excellent |

| Common Applications | Aerospace, chemical processing, automotive | Hydraulics, fuel systems, industrial machinery | Medical, food processing, outdoor seals |

Manufacturing Capabilities

Engineering Capabilities: Precision Metal Gasket Material Development

Suzhou Baoshida Trading Co., Ltd. leverages integrated engineering expertise to deliver mission-critical metal gasket solutions for demanding industrial and automotive applications. Our technical foundation rests on a dedicated team of five Mold Engineers and two specialized Rubber Formula Engineers, operating under a unified OEM management framework. This structure ensures seamless translation of client specifications into high-performance, defect-free sealing components. Unlike commodity suppliers, we prioritize material science and precision tooling in parallel, eliminating iterative delays and reducing time-to-market by up to 30%.

Our Rubber Formula Engineers possess advanced proficiency in elastomer chemistry, focusing on custom compound development for metal-reinforced gaskets. They systematically optimize filler systems, polymer blends, and crosslinking agents to achieve exacting thermal stability, fluid resistance, and compression set performance. Each formulation undergoes rigorous ASTM D2000 and ISO 3601 validation, with traceable batch records ensuring repeatability. Critical parameters such as glass transition temperature (Tg) and Shore A hardness are finetuned to counteract specific operational stresses—whether exposure to biodiesel at 150°C or cyclic fatigue in turbocharger housings. This scientific approach prevents field failures caused by material degradation, a common industry pain point.

Complementing this, our Mold Engineering team executes precision tooling for complex metal-elastomer composites. Utilizing 3D flow simulation (Moldflow) and finite element analysis (FEA), they resolve challenges in insert placement, cavity pressure distribution, and flash control during vulcanization. This expertise is essential for multi-layer gaskets requiring ±0.05mm dimensional accuracy and perfect adhesion between stainless steel cores and rubber compounds. By co-engineering molds and materials, we eliminate interfacial delamination risks and ensure consistent part geometry across production runs exceeding 500,000 units.

Our OEM capabilities extend beyond manufacturing to full technical partnership. Clients receive collaborative support from DFMEA review through PPAP documentation, with real-time data sharing via secure cloud platforms. We maintain dedicated production cells for exclusive client programs, adhering strictly to IATF 16949 protocols. This end-to-end control guarantees zero-defect delivery for safety-critical applications, such as fuel system seals in electric vehicle powertrains or exhaust manifold gaskets for heavy machinery.

The following table illustrates performance advantages of our engineered solutions versus standard materials:

| Performance Parameter | Standard Material | Baoshida Engineered Solution |

|---|---|---|

| Temperature Range | -40°C to +125°C | -55°C to +180°C (continuous) |

| Compression Set (ASTM D395) | ≤ 35% after 70h @ 150°C | ≤ 18% after 168h @ 175°C |

| Fuel Resistance (Biodiesel) | Swell: +25% | Swell: +8% |

| OEM Customization Lead Time | 14-18 weeks | 8-10 weeks |

This synergy of material science and precision engineering enables Suzhou Baoshida to solve complex sealing challenges where conventional suppliers fail. We transform technical specifications into reliable, high-yield production—ensuring your gaskets perform flawlessly under extreme pressure, temperature, and chemical exposure. Partner with us for OEM solutions engineered at the molecular level.

Customization Process

Customization Process for Metal Gasket Material

At Suzhou Baoshida Trading Co., Ltd., our customization process for metal gasket material is engineered to meet the exact performance demands of industrial applications. We specialize in precision rubber seals that integrate with metal substrates to deliver reliable sealing under extreme temperature, pressure, and chemical exposure. Our four-stage workflow—drawing analysis, formulation development, prototyping, and mass production—ensures optimal material behavior and dimensional accuracy.

The process begins with drawing analysis, where we evaluate customer-provided technical blueprints or CAD models. We assess critical dimensions, tolerances, surface finish requirements, and interface conditions. This stage includes reviewing flange types, bolt patterns, and operational parameters such as media type, pressure cycles, and ambient environment. Our engineering team identifies potential stress points, compression set risks, and material compatibility concerns to guide downstream development.

Next, we proceed to formulation development, where our rubber chemists design a compound tailored to the application. For metal gasket applications, this typically involves selecting a high-performance elastomer—such as FKM (Viton®), EPDM, NBR, or silicone—based on chemical resistance, thermal stability, and mechanical resilience. The elastomer is compounded with fillers, curing agents, and modifiers to achieve target hardness (Shore A), tensile strength, elongation, and compression set. When bonded to metal, adhesion promoters and primers are integrated to ensure long-term interface integrity under thermal cycling.

Once the formulation is finalized, we move to prototyping. Using precision tooling and bonding techniques, we fabricate small-batch samples that replicate the final gasket structure. These prototypes undergo rigorous testing, including compression deflection analysis, leak rate measurement, and simulated service condition exposure. We validate dimensional conformity via coordinate measuring machines (CMM) and perform peel tests on metal-rubber interfaces to verify bond strength. Customer feedback is incorporated before final approval.

Approved prototypes transition into mass production, executed in our ISO-certified manufacturing facility. We employ automated mixing, curing presses, and robotic handling to maintain batch consistency and throughput. Every production lot is subject to in-process and final quality inspections, with full traceability of raw materials and process parameters. We support volumes from thousands to millions of units, with JIT delivery options for global OEMs.

The following table outlines typical performance specifications for our metal gasket materials:

| Property | FKM-Based Composite | EPDM-Metal Bonded | NBR-Laminated Steel |

|---|---|---|---|

| Temperature Range | -20°C to +250°C | -50°C to +150°C | -30°C to +120°C |

| Hardness (Shore A) | 70 ±5 | 65 ±5 | 75 ±5 |

| Tensile Strength | ≥15 MPa | ≥10 MPa | ≥12 MPa |

| Elongation at Break | ≥200% | ≥250% | ≥180% |

| Compression Set (22h, 150°C) | ≤25% | ≤30% | ≤20% |

| Adhesion Strength to Metal | ≥4.5 kN/m | ≥4.0 kN/m | ≥5.0 kN/m |

Our structured customization approach ensures that every metal gasket material we produce meets the highest standards of reliability, durability, and performance in critical sealing applications.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Metal Gasket Material Solutions

Selecting the optimal metal gasket material is a critical engineering decision impacting system integrity, longevity, and operational safety across high-pressure, high-temperature industrial applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in scientifically formulated metal-reinforced elastomeric composites engineered to exceed OEM specifications. Our materials undergo rigorous validation under extreme conditions, ensuring consistent performance in aerospace hydraulics, semiconductor manufacturing, and energy sector sealing systems where failure is not an option. Generic solutions often compromise on thermal stability or chemical resistance; our proprietary blends integrate precision-cut metal cores with advanced fluorocarbon or perfluoroelastomer compounds to deliver unmatched resilience. This synergy minimizes creep relaxation while maintaining elastic recovery, directly translating to reduced maintenance cycles and extended service life for your end products.

The following table details core performance parameters for our flagship metal gasket materials, validated per ASTM F37, ISO 3601, and OEM-specific test protocols. These values represent minimum guaranteed thresholds under controlled laboratory conditions; actual performance may vary based on application-specific factors including surface finish, bolt load distribution, and dynamic stress profiles.

| Property | Material Code BD-MG7 | Material Code BD-MG9 | Test Standard |

|---|---|---|---|

| Continuous Service Temperature | -40°C to +260°C | -20°C to +300°C | ASTM D573 |

| Max. Pressure Resistance | 100 MPa (14,500 PSI) | 150 MPa (21,750 PSI) | ISO 3601-3 |

| Hardness (Shore A) | 75 ± 5 | 85 ± 5 | ASTM D2240 |

| Compression Set (22h, 150°C) | ≤ 15% | ≤ 20% | ASTM D395 |

| Fluid Resistance (Jet Fuel A) | Excellent | Excellent | ASTM D471 |

| Metal Core Thickness Tolerance | ±0.02 mm | ±0.015 mm | Internal QA-007 |

Partnering with Suzhou Baoshida means accessing not just materials, but engineered sealing intelligence. Our technical team collaborates directly with your R&D and production engineers to optimize gasket geometry, surface treatment, and material selection for your unique operational envelope. We provide comprehensive documentation packages including material traceability certificates, 3D stress simulation data, and failure mode analysis support—essential for compliance in regulated industries.

Initiate your precision sealing project with confidence by contacting Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over 14 years of experience in elastomer compounding for critical sealing applications, Mr. Boyce will conduct a technical deep-dive into your requirements, from initial concept validation through serial production ramp-up. He will facilitate material sampling, coordinate joint failure analysis, and ensure seamless integration of our solutions into your manufacturing workflow. Do not compromise on sealing performance when system reliability is paramount.

Reach Mr. Boyce directly via email at [email protected] to schedule a technical consultation. Include your application specifications, target performance metrics, and relevant industry standards for immediate, actionable feedback. Suzhou Baoshida Trading Co., Ltd. operates under ISO 9001:2015 certification with dedicated cleanroom production facilities in Suzhou Industrial Park, guaranteeing batch-to-batch consistency for global OEM supply chains. Your next-generation sealing solution begins with an engineered conversation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).