Technical Contents

Engineering Guide: Concrete Expansion Joint Filler Material

Engineering Insight: Concrete Expansion Joint Filler Material Selection Criticality

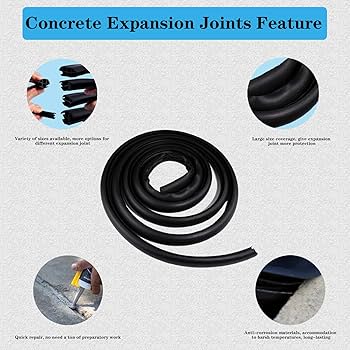

Concrete expansion joints are not passive gaps; they are dynamic, engineered components essential for structural integrity in pavements, bridges, and industrial flooring. The filler material within these joints bears complex, cyclical stresses—thermal expansion/contraction, traffic loading, chemical exposure, and environmental degradation. Material selection is therefore not a commodity decision but a critical engineering parameter. Off-the-shelf generic rubber fillers frequently fail prematurely due to fundamental mismatches between standardized formulations and the specific, demanding service environment. These failures manifest as excessive compression set (permanent deformation), extrusion under load, cracking from UV/ozone degradation, or chemical swelling, ultimately compromising joint functionality and accelerating concrete spalling. The root cause lies in the inherent limitations of mass-produced compounds designed for broad applicability rather than targeted performance.

Generic fillers often utilize basic SBR or low-grade EPDM compounds optimized for cost, not resilience. They lack the tailored polymer architecture, reinforcement systems, and specialized additives required to withstand the unique combination of extreme temperature fluctuations (-40°C to +80°C+), sustained compressive loads, exposure to de-icing salts, oils, or industrial chemicals, and decades of cyclic movement. For instance, inadequate resistance to compression set leads to loss of sealing force, allowing water and debris ingress that erodes sub-base materials. Poor low-temperature flexibility causes brittle fracture during thermal contraction, while insufficient high-temperature stability results in softening and extrusion under wheel loads. Standard formulations also frequently omit critical stabilizers against ozone and UV radiation, accelerating surface cracking in exposed applications. These failures necessitate costly, disruptive repairs and downtime, negating any initial procurement savings.

True performance requires engineered elastomer solutions. Precision-formulated compounds utilize high-purity EPDM or specialty blends with controlled molecular weight distribution, optimized carbon black or silica reinforcement, and synergistic antioxidant/antiozonant packages. Crosslink density is meticulously calibrated to balance recovery force with flexibility. Critical performance metrics must be validated against application-specific ASTM standards, not generic industry minimums. The table below illustrates the stark performance gap between typical off-the-shelf materials and engineered solutions designed for severe service.

| Performance Parameter | Typical Off-the-Shelf Filler | Engineered Solution (e.g., Baoshida PrecisionFill™) | Critical Impact of Deficiency |

|---|---|---|---|

| Compression Set (ASTM D395) | ≤ 40% (70°C, 22h) | ≤ 15% (100°C, 22h) | Loss of sealing force, joint failure |

| Temperature Range | -20°C to +60°C | -50°C to +120°C | Brittle fracture or extrusion at extremes |

| Tensile Strength (ASTM D412) | ≥ 7 MPa | ≥ 15 MPa | Reduced resistance to tearing/extrusion |

| Elongation at Break | ≥ 200% | ≥ 450% | Limited movement accommodation |

| Fluid Resistance (IRM 901) | Volume Swell > 30% | Volume Swell < 10% | Degradation from oils, fuels, de-icers |

| Ozone Resistance (ASTM D1149) | Cracking @ 50 pphm, 20% strain | No Cracking @ 100 pphm, 40% strain | Premature surface cracking and failure |

Material selection must be an OEM-driven engineering process, not a procurement checkbox. Suzhou Baoshida Trading Co., Ltd. partners with infrastructure developers and concrete producers to analyze site-specific load profiles, environmental exposure, and design life requirements. We translate these into precise compound formulations, rigorously validated through accelerated aging and mechanical testing. This scientific approach ensures expansion joint fillers perform as integral structural components, not failure points, delivering decades of reliable service and minimizing lifecycle costs for critical infrastructure. Generic solutions compromise the entire system; engineered elastomers guarantee it.

Material Specifications

Concrete expansion joint filler materials must exhibit dimensional stability, compressive resilience, and long-term resistance to environmental stressors including moisture, temperature cycling, and chemical exposure. At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the rigorous demands of infrastructure, bridge construction, and heavy civil engineering applications. We specialize in high-performance elastomers such as Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each selected for specific operational environments and performance criteria. These materials are compression-molded to precise tolerances and designed to maintain sealing integrity under dynamic joint movement and sustained load conditions.

Viton exhibits exceptional resistance to high temperatures (up to 250°C), ozone, and a broad range of aggressive chemicals including acids, fuels, and hydraulic fluids. This makes it ideal for expansion joints in industrial facilities or transportation infrastructure exposed to harsh chemical environments. Its molecular structure provides low gas permeability and excellent aging characteristics, ensuring long service life in critical applications despite elevated thermal loads.

Nitrile rubber is widely used due to its excellent resistance to oils, greases, and aliphatic hydrocarbons. With an operational temperature range of -30°C to 120°C, NBR offers a balanced combination of mechanical strength and cost efficiency. It demonstrates high abrasion resistance and good tensile properties, making it suitable for joints in parking structures, wastewater treatment plants, and roadways where exposure to automotive fluids is prevalent.

Silicone rubber provides superior flexibility at low temperatures (down to -60°C) and maintains stability up to 200°C. It offers excellent resistance to UV radiation and weathering, making it the preferred choice for outdoor applications subject to extreme climatic variations. While less resistant to petroleum-based fluids than Viton or Nitrile, silicone excels in electrical insulation and maintains elastic recovery over extended compression cycles.

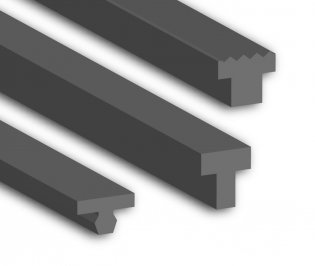

Each material is formulated to meet ASTM C1311 and ISO 10565 standards for expansion joint systems, ensuring compliance with international building codes and durability benchmarks. Custom durometers (ranging from 40 to 90 Shore A) and geometric profiles are available to match project-specific load and deflection requirements.

The following table summarizes key physical and chemical properties of these elastomers for comparative evaluation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 300–700 |

| Hardness (Shore A) | 60–90 | 40–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor to Fair |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Water Resistance | Excellent | Excellent | Excellent |

| Chemical Resistance | Outstanding | Moderate | Moderate |

Selection of the appropriate elastomer requires a comprehensive assessment of the service environment, including thermal exposure, fluid contact, mechanical stress, and expected joint movement. Suzhou Baoshida Trading Co., Ltd. provides technical support and material testing data to ensure optimal performance in diverse construction applications.

Manufacturing Capabilities

Engineering Capability: Precision Formulation and Mold Design for Concrete Expansion Joint Systems

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver mission-critical concrete expansion joint filler materials. Our engineering backbone comprises five dedicated Mold Engineers and two specialized Rubber Formula Engineers, operating within an integrated development framework. This structure ensures rigorous scientific validation of both material composition and physical geometry. Our Formula Engineers optimize polymer matrices—primarily EPDM and SBR compounds—to achieve precise balance between compression recovery, durability, and environmental resistance. Concurrently, Mold Engineers translate these formulations into production-ready tooling, utilizing finite element analysis (FEA) to simulate stress distribution during concrete curing and thermal cycling. This dual-engineering approach eliminates common field failures such as permanent set deformation or joint extrusion under dynamic loads.

OEM partnerships represent a core competency, where we co-develop solutions meeting exact structural specifications. Clients provide dimensional constraints, load profiles, and environmental exposure data; our team responds with tailored compounds and mold designs validated through accelerated aging protocols. For instance, highway bridge applications requiring resilience at -40°C to +85°C undergo iterative formulation adjustments, while high-traffic pedestrian zones demand enhanced abrasion resistance through silica reinforcement strategies. Every OEM project includes comprehensive material traceability, from raw polymer batches to final cured profiles, ensuring compliance with ISO 9001 and ASTM C990 standards.

Critical performance parameters for concrete expansion joint fillers are systematically engineered to exceed industry baselines. The table below outlines key specifications achievable through our formulation and molding precision:

| Property | Test Method | Typical Value | Significance for Concrete Joints |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 40 ± 5 | Balances ease of installation with resistance to aggregate intrusion |

| Compression Set (22h, 70°C) | ASTM D395 | ≤ 15% | Ensures long-term recovery after concrete expansion |

| Tensile Strength | ASTM D412 | ≥ 10 MPa | Prevents tearing during joint movement |

| Temperature Range | ASTM D2137 | -50°C to +100°C | Maintains integrity in extreme climates |

| Water Absorption (7d) | ASTM D570 | ≤ 1.5% | Eliminates swelling-induced joint failure |

This technical rigor extends to mold fabrication, where CNC-machined cavities maintain tolerances within ±0.1mm across 500+ production cycles. Such precision guarantees uniform cross-section density, preventing weak points that compromise seal integrity. Our engineers further validate tooling through real-time cavity pressure monitoring during prototyping, correlating data with final product dimensional stability.

The synergy between formula science and mold engineering enables Suzhou Baoshida to solve complex joint challenges—whether for high-rise foundations requiring sub-1% compression set or seismic zones demanding 50% dynamic deflection. Every OEM collaboration begins with material lifecycle modeling, ensuring fillers perform reliably across 30+ year service lives. This integrated capability, backed by documented DOE (Design of Experiments) protocols, positions us as a strategic engineering partner—not merely a component supplier—for global infrastructure projects. Quality assurance is non-negotiable; all batches undergo third-party verification against the specifications above prior to shipment.

Customization Process

Drawing Analysis: Precision at the Foundation

The customization process for concrete expansion joint filler material begins with rigorous drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering teams evaluate technical blueprints provided by clients, focusing on dimensional tolerances, joint geometry, compression requirements, and site-specific environmental conditions. This stage involves cross-referencing ASTM, GB, and ISO standards to ensure compliance with structural safety and performance benchmarks. Critical parameters such as joint width-to-depth ratio, expected movement range (compression and rebound), and substrate compatibility are validated. Our CAD-integrated review system allows for 3D modeling of the proposed filler profile, enabling early detection of design conflicts or material stress points. Only after full alignment between design intent and manufacturability is confirmed does the process advance.

Formulation: Tailoring Material Performance

Based on the drawing analysis, our rubber formulation engineers develop a compound optimized for the application’s mechanical and environmental demands. The base polymer selection—typically EPDM, neoprene, or SBR—is determined by exposure to UV radiation, temperature extremes, water immersion, or chemical contaminants. Additives such as reinforcing fillers, plasticizers, and vulcanizing agents are precisely metered to achieve target hardness (Shore A), compression set resistance, and elongation at break. For expansion joints in bridges or industrial flooring, low compression set (<20% per ASTM D395) and high resilience are prioritized. Each formulation undergoes simulation testing in our lab to predict long-term aging behavior under cyclic loading. Clients receive a detailed material data sheet outlining compound composition and expected service life.

Prototyping: Validating Design and Material Synergy

A functional prototype is produced using precision extrusion or molding techniques, depending on the joint profile complexity. Prototypes are subjected to simulated installation and service conditions, including repeated compression cycles, water immersion, and thermal cycling from -40°C to +80°C. Dimensional accuracy is verified using coordinate measuring machines (CMM), ensuring conformity within ±0.5 mm tolerance. Performance data is compiled and compared against project specifications. Client feedback is integrated at this stage, allowing for iterative refinement of both geometry and material properties before tooling finalization.

Mass Production: Consistency at Scale

Once prototype approval is obtained, the project transitions to mass production. Our automated rubber processing lines ensure batch-to-batch consistency through real-time rheometry and cure monitoring. Each production run is accompanied by full traceability documentation, including raw material lot numbers and quality control test results. Products are packaged to prevent deformation during transit and labeled per client logistics requirements.

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 40–70 |

| Tensile Strength | ASTM D412 | ≥8 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤20% |

| Operating Temperature Range | — | -40°C to +80°C |

Contact Engineering Team

Technical Consultation for Precision Expansion Joint Solutions

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber compounds specifically formulated for critical concrete expansion joint applications in infrastructure, industrial flooring, and precast construction. Our materials undergo rigorous polymer matrix optimization to ensure dimensional stability under cyclic compression, thermal cycling, and chemical exposure. Unlike generic fillers, our proprietary EPDM and SBR formulations achieve ≤15% compression set after 22 hours at 70°C (ASTM D395 Method B), preventing joint lock-up and maintaining seal integrity for 25+ years. We address field failures caused by inadequate recovery resilience, UV degradation, or poor adhesion—common in substandard products. Partnering with us guarantees compliance with ASTM C1319, EN 13813, and project-specific performance thresholds through material science, not guesswork.

Key technical specifications for our flagship expansion joint filler series are detailed below. All values represent minimum performance after 1,000 hours of accelerated aging (85°C, 85% RH) per ISO 188:

| Property | Test Method | Value | Significance for Joint Performance |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 45 ± 5 | Optimal balance: Prevents extrusion under load while allowing thermal movement |

| Tensile Strength | ASTM D412 | ≥ 10.5 MPa | Resists tearing during installation and seismic events |

| Elongation at Break | ASTM D412 | ≥ 450% | Accommodates joint widening without fracture |

| Compression Deflection | ASTM D575 | 0.8 MPa @ 25% | Ensures consistent pressure against concrete substrates |

| Water Absorption (7d) | ISO 188 | ≤ 1.2% | Eliminates swelling-induced joint displacement |

| Temperature Range | ISO 188 | -40°C to +120°C | Maintains elasticity in extreme climates |

These metrics reflect our commitment to precision engineering. Each formulation is tailored to your substrate chemistry, movement tolerance (±25% to ±50%), and environmental stressors—whether salt-laden marine environments or chemical plant floors. Our OEM process integrates your joint profile dimensions, load requirements, and lifecycle cost targets into compound design. We provide full traceability via batch-specific IR spectroscopy and Mooney viscosity logs, ensuring repeatability across multi-year projects.

Do not compromise joint longevity with off-the-shelf materials lacking validated performance data. Contact Mr. Boyce, our OEM Technical Manager, for a project-specific feasibility assessment. Mr. Boyce holds 14 years of experience in rubber formulation for civil engineering applications and will review your joint specifications, environmental conditions, and volume requirements to propose a solution with documented test reports. Provide your project timeline, joint width/depth dimensions, expected movement range, and substrate type for immediate analysis.

Initiate your technical collaboration by emailing Boyce directly at [email protected] with subject line: Expansion Joint Filler Technical Query – [Your Project Name]. Include relevant drawings or ASTM/EN compliance mandates. Responses include material compatibility matrices, compression set validation data, and lead time projections within 24 business hours. Suzhou Baoshida operates ISO 9001:2015-certified supply chains with 30-day rapid prototyping for qualified OEM partners. Elevate your joint performance from failure-prone to failure-proof—engineer with precision.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).