Technical Contents

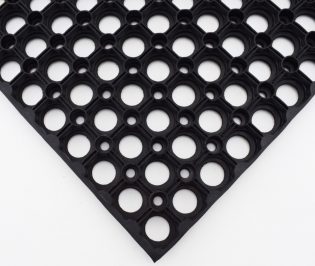

Engineering Guide: Plastic Matting

Engineering Insight: Material Selection Criticality in Industrial Matting Systems

Material selection constitutes the foundational engineering decision determining the operational lifespan and safety efficacy of industrial matting systems. Off-the-shelf plastic matting solutions, frequently marketed as universal, consistently fail under rigorous industrial conditions due to inherent material compromises. These generic products prioritize cost reduction over performance parameters, utilizing base polymers and additive packages incapable of withstanding the complex stressors present in manufacturing, logistics, and processing environments. The consequences manifest as premature degradation, safety hazards, and significant unplanned downtime costs far exceeding initial procurement savings.

Standard plastic matting, predominantly PVC or low-grade polyolefins, suffers from critical limitations. Plasticizer migration in PVC leads to embrittlement and cracking within months under thermal cycling or UV exposure, eliminating impact resistance. Inadequate filler systems and insufficient UV stabilizers accelerate surface degradation, creating slip hazards from micro-cracking and loss of texture integrity. Crucially, these materials lack tailored chemical resistance profiles. Exposure to common industrial agents like hydraulic fluids, cleaning solvents, or mild acids causes swelling, softening, or catastrophic polymer chain scission, compromising structural integrity and dimensional stability. The absence of engineered anti-fatigue properties results in rapid permanent deformation under sustained point loads, rendering mats ineffective for ergonomic purposes. These failures are not anomalies but predictable outcomes of using non-specialized materials in demanding applications.

Suzhou Baoshida Trading Co., Ltd. addresses these systemic failures through precision rubber compound engineering. We collaborate with OEM partners to define exact operational parameters—load profiles, chemical exposures, temperature ranges, and safety requirements—before formulating. Our process utilizes high-purity synthetic rubbers (EPDM, NBR, SBR) or specialized thermoplastic elastomers, incorporating proprietary blends of reinforcing fillers, advanced antioxidant packages, and application-specific plasticizers. Rigorous accelerated aging protocols simulate years of service within weeks, validating performance against real-world failure modes. This OEM-centric approach ensures mats maintain coefficient of friction specifications, tensile strength, and resilience throughout their designed service life, directly reducing total cost of ownership.

The table below illustrates key performance differentiators between standard off-the-shelf plastic matting and engineered rubber solutions specified by Suzhou Baoshida for industrial clients.

| Performance Parameter | Standard PVC Matting | Engineered Rubber Matting (Suzhou Baoshida OEM Specification) |

|---|---|---|

| Tensile Strength (MPa) | 10-15 (degrades >30% in 6mo) | 20-25 (maintains >90% after 18mo accelerated aging) |

| Compression Set (70°C, 22h) % | 45-60 (permanent deformation) | 15-25 (excellent recovery) |

| Hydraulic Fluid Resistance | Severe swelling/cracking | No swelling, <5% weight change |

| Coefficient of Friction (Wet) | 0.35-0.45 (hazardous) | 0.65-0.75 (OSHA compliant) |

| Operating Temperature Range | -10°C to +60°C | -40°C to +120°C |

Material science is non-negotiable in industrial matting. Generic plastic solutions represent a false economy, inevitably succumbing to environmental and mechanical stressors. Suzhou Baoshida’s engineered rubber compounds, developed through rigorous OEM collaboration and validation, deliver the precision performance required for reliable, safe, and cost-effective industrial operations. Selecting the correct material is not a procurement decision—it is a fundamental engineering imperative.

Material Specifications

Material Specifications for Industrial Plastic Matting

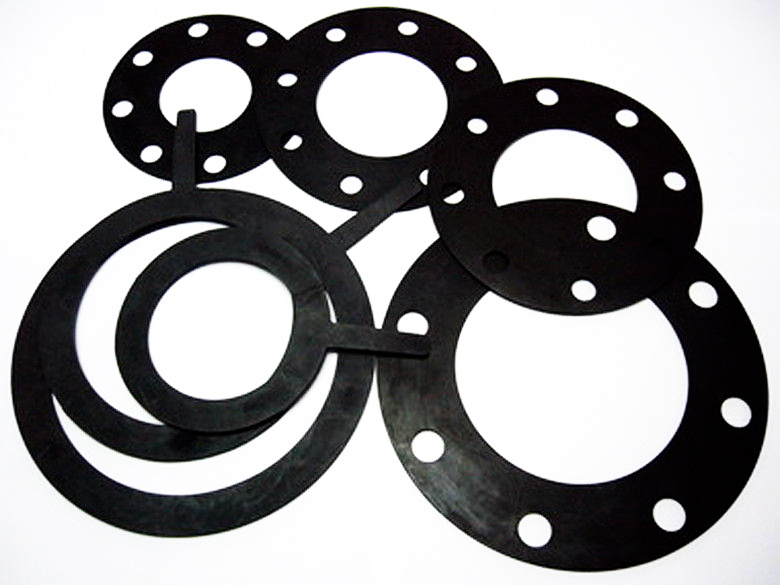

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber matting solutions engineered for critical applications in demanding environments. Our plastic matting systems integrate advanced elastomeric materials tailored to specific operational requirements, including chemical exposure, temperature extremes, and mechanical stress. The selection of base polymer significantly influences performance, durability, and service life. Among the most effective materials for industrial matting applications are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each offers a distinct balance of thermal stability, chemical resistance, and mechanical properties, enabling customization based on end-use conditions.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to high temperatures, aggressive chemicals, oils, and fuels. With continuous service capabilities up to 250°C and intermittent peaks exceeding 300°C, Viton is ideal for extreme environments such as petrochemical processing, aerospace, and high-temperature sealing applications. Its low permeability and outstanding aging characteristics ensure long-term reliability, though it is typically more expensive than other elastomers. Viton-based matting is recommended where maximum chemical inertness and thermal endurance are required.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used for its excellent resistance to petroleum-based oils, greases, and hydraulic fluids. It maintains good mechanical strength and abrasion resistance across a moderate temperature range of -30°C to 120°C. NBR is a cost-effective solution for general industrial flooring, automotive workshops, and fluid-handling environments. While its performance degrades under prolonged UV or ozone exposure, formulations with added stabilizers can mitigate these effects. Nitrile matting offers a practical balance of durability and affordability for medium-duty applications.

Silicone rubber (VMQ) excels in extreme temperature applications, with usable ranges from -60°C to 230°C. It demonstrates excellent resistance to oxidation, UV radiation, and ozone, making it suitable for outdoor or sterilizable environments. Silicone exhibits high flexibility at low temperatures and retains elasticity under thermal cycling. However, it has lower tensile strength and abrasion resistance compared to Viton or Nitrile. Its non-toxic, biocompatible nature makes it ideal for food processing, pharmaceutical, and cleanroom matting applications.

The following table compares key physical and chemical properties of these materials to guide material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor to Fair |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Chemical Resistance | Outstanding | Good | Moderate |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Applications | Petrochemical, Aerospace | Automotive, General Industry | Medical, Food Processing, Outdoor |

Selecting the appropriate elastomer requires a comprehensive assessment of environmental stressors, lifecycle costs, and performance expectations. Suzhou Baoshida Trading Co., Ltd. supports OEM partners with material testing, formulation optimization, and custom compounding to meet exacting industrial standards.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Matting Development at Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. delivers advanced industrial rubber matting solutions through a foundation of rigorous engineering expertise and vertically integrated OEM capabilities. Our dedicated technical team, comprising five specialized Mould Engineers and two certified Rubber Formula Engineers, ensures every matting product meets exacting performance, durability, and application-specific requirements from concept to量产. This integrated approach eliminates design-to-manufacturing gaps, directly translating client specifications into optimized physical products.

Our Formula Engineers possess deep mastery in elastomer science, focusing exclusively on compounding protocols for industrial matting applications. They develop proprietary rubber formulations by precisely manipulating polymer matrices, filler systems, plasticizers, and curatives to achieve targeted physical properties. This includes balancing critical factors such as abrasion resistance, chemical stability, electrical insulation, thermal tolerance, and ergonomic surface characteristics. Each compound undergoes iterative laboratory testing to validate performance against ASTM, ISO, and client-defined standards before scale-up, ensuring molecular architecture aligns perfectly with end-use demands. Concurrently, our Mould Engineering team leverages advanced CAD/CAM software and decades of practical die-casting and compression moulding experience. They design and refine tooling with micron-level precision, optimizing flow dynamics, venting, cooling channels, and ejection systems to guarantee dimensional stability, surface finish consistency, and minimal parting line flash across high-volume production runs. This synergy between material science and precision tooling is non-negotiable for reliable matting performance in demanding environments.

Critical material properties for our standard industrial matting compounds are rigorously controlled as shown below:

| Property | Nitrile Rubber (NBR) | Ethylene Propylene Diene Monomer (EPDM) | Silicone Rubber (VMQ) | Standard Test Method |

|---|---|---|---|---|

| Shore A Hardness Range | 50 – 90 | 40 – 80 | 30 – 80 | ASTM D2240 |

| Tensile Strength (MPa) | 15 – 30 | 10 – 25 | 5 – 12 | ASTM D412 |

| Elongation at Break (%) | 250 – 600 | 200 – 500 | 200 – 800 | ASTM D412 |

| Temperature Range (°C) | -30 to +100 | -50 to +150 | -60 to +230 | ASTM D2240/D573 |

| Specific Gravity | 1.10 – 1.30 | 1.15 – 1.35 | 1.10 – 1.50 | ASTM D297 |

As a full-service OEM partner, Suzhou Baoshida manages the entire product lifecycle under strict confidentiality protocols. We excel in rapid prototyping using client CAD data, material substitution analysis for cost or performance optimization, and implementing robust statistical process control (SPC) during manufacturing. Our facility supports low-volume bespoke matting production through high-volume continuous runs, with integrated quality checkpoints including hardness testing, thickness verification, and visual inspection against AQL standards. Supply chain resilience is maintained through strategic raw material partnerships and in-house compound mixing, ensuring consistent batch-to-batch repeatability. Clients benefit from direct engineering collaboration, reduced time-to-market, and matting solutions engineered not just to specifications, but to exceed the operational realities of industrial floors, walkways, and specialized work zones. This commitment to scientific precision defines our engineering capability and OEM value proposition.

Customization Process

Drawing Analysis: The Foundation of Precision Customization

At Suzhou Baoshida Trading Co., Ltd., the customization process for industrial plastic matting begins with rigorous drawing analysis. This initial phase is critical to ensure dimensional accuracy, functional performance, and compatibility with the client’s operational environment. Our engineering team evaluates technical blueprints, CAD files, and 3D models submitted by the client, focusing on critical parameters such as thickness tolerance, surface texture, load-bearing zones, and edge geometry. We assess not only the geometric specifications but also the intended application—whether for anti-slip flooring, conveyor systems, or industrial walkways—to determine structural integrity requirements. Any ambiguities or potential design inefficiencies are flagged and discussed with the client to optimize manufacturability without compromising performance.

Formulation: Engineering Material Performance

Once the design is validated, our Rubber Formula Engineers develop a tailored compound formulation. This step integrates the mechanical and environmental demands identified during drawing analysis. We select base polymers—such as SBR, NBR, EPDM, or polyolefin blends—based on resistance to oil, UV exposure, temperature extremes, or abrasion. Additives including reinforcing fillers, vulcanizing agents, anti-aging compounds, and flame retardants are precisely metered to meet performance targets. The formulation is documented and archived for full traceability, ensuring consistency across production batches. Clients receive a detailed material data sheet outlining physical properties, hardness (Shore A), tensile strength, elongation at break, and compliance with industry standards such as ISO 48-4 or ASTM D412.

Prototyping: Validation Before Scale-Up

A functional prototype is produced using calibrated extrusion or compression molding techniques, depending on the matting design. Prototyping allows for real-world validation of both material behavior and geometric fidelity. The sample undergoes a battery of in-house tests, including compression set, slip resistance (DIN 51130), and thermal cycling. Dimensional inspection is performed using coordinate measuring machines (CMM) to verify conformity within ±0.5 mm tolerance. Clients are encouraged to conduct field trials under actual operating conditions. Feedback is incorporated into final adjustments before release to mass production.

Mass Production: Consistency at Scale

Upon client approval, the project transitions to mass production. Our manufacturing facilities in Eastern China operate under strict ISO 9001 protocols, with real-time monitoring of extrusion temperature, curing time, and line speed. Each batch is subject to statistical process control (SPC), and random samples are tested for hardness, density, and tensile properties. Packaging and labeling are customized per client logistics requirements.

The following table summarizes key specification ranges available through our customization process:

| Parameter | Standard Range | Custom Capability |

|---|---|---|

| Thickness | 3–20 mm | Up to 50 mm |

| Hardness (Shore A) | 50–85 | 30–95 |

| Temperature Resistance | -30°C to +100°C | -50°C to +150°C (special blends) |

| Color Options | Black, Gray, Blue, Red, Yellow | RAL/ Pantone matching |

| Surface Texture | Smooth, Diamond, Grated, Ribbed | Custom embossing available |

| Compliance Standards | ROHS, REACH, ISO 48-4 | FDA, UL, or CSA upon request |

This structured approach ensures that every custom plastic matting solution from Suzhou Baoshida meets exact functional, regulatory, and aesthetic requirements.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Industrial Matting Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber and polymer solutions for demanding industrial environments. Our expertise in compounding and manufacturing plastic matting systems ensures products that meet rigorous operational standards for durability, chemical resistance, and dimensional stability. We recognize that industrial matting is not a commodity but a critical component in safety, efficiency, and longevity of facility operations. Generic solutions often fail under specific thermal, mechanical, or chemical stresses, leading to premature degradation and operational downtime. Our approach integrates material science with application-specific engineering to deliver matting that performs reliably under your unique conditions.

Below is a comparative overview of our standard and customizable matting specifications, reflecting our commitment to precision engineering. These values represent baseline performance; all parameters are adjustable to meet exact OEM or end-user requirements through our in-house formulation laboratory.

| Property | Standard PVC Matting | Customizable Range (EPDM/NBR/TPU) | Test Method |

|---|---|---|---|

| Hardness (Shore A) | 70 ± 5 | 40 – 90 | ASTM D2240 |

| Tensile Strength (MPa) | 12.0 min | 8.0 – 25.0 | ASTM D412 |

| Elongation at Break (%) | 250 min | 150 – 600 | ASTM D412 |

| Temperature Range (°C) | -20 to +60 | -50 to +150 | ISO 188 |

| Oil Resistance (IRMOG) | Grade B | Grade A (Custom) | ASTM D471 |

| Flame Rating | UL 94 HB | UL 94 V-0 (Optional) | UL 94 |

This technical foundation enables us to address challenges such as hydraulic fluid exposure in manufacturing plants, extreme cold in warehouse settings, or high-traffic abrasion in logistics hubs. Our formulations utilize advanced stabilizers, fillers, and cross-linking systems to optimize performance without compromising recyclability or regulatory compliance (REACH, RoHS). As an OEM partner, we manage full lifecycle development—from initial compound design and prototyping to volume production and quality assurance—ensuring seamless integration with your assembly processes and brand standards.

Partnering with Suzhou Baoshida means accessing direct engineering support to solve complex material challenges. Mr. Boyce, our dedicated OEM Manager, possesses 15 years of experience in translating industrial requirements into validated rubber and polymer solutions. He will collaborate with your technical team to analyze application stressors, define critical performance metrics, and establish rigorous validation protocols. Do not settle for off-the-shelf matting that risks facility safety or operational continuity. Contact Mr. Boyce immediately to initiate a technical consultation:

Specify your application environment, performance requirements, and volume needs in your inquiry. Our team will provide a formal compound proposal with accelerated aging data, cost analysis, and lead-time projections within 72 business hours. For time-sensitive projects, reference “URGENT MATTING SOLUTION” in your subject line to prioritize engineering resource allocation. Suzhou Baoshida delivers not just products, but engineered risk mitigation for your industrial infrastructure. Act now to secure matting performance validated by material science, not marketing claims.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).