Technical Contents

Engineering Guide: Neoprene Vs Polyurethane

Engineering Insight: Neoprene vs Polyurethane

Material selection in industrial rubber applications is not a matter of preference—it is a decisive engineering parameter that directly influences product lifespan, performance under stress, and operational safety. In many cases, off-the-shelf rubber components fail prematurely not due to manufacturing defects, but because of inappropriate base material selection. This is especially evident when comparing neoprene and polyurethane—two polymers frequently mistaken as interchangeable despite fundamentally different mechanical and chemical behaviors.

Neoprene (polychloroprene) is a synthetic rubber known for its balanced resistance to ozone, UV radiation, and moderate oils. It maintains flexibility across a wide temperature range (–40°C to +100°C) and exhibits good flame retardancy, making it suitable for outdoor seals, gaskets, and weather-exposed industrial housings. However, its mechanical strength, abrasion resistance, and load-bearing capacity are significantly lower than those of polyurethane. When subjected to dynamic stress or high friction environments—such as conveyor rollers or hydraulic seals—neoprene degrades rapidly due to surface cracking and wear.

Polyurethane, by contrast, excels in mechanical robustness. With tensile strengths often exceeding 40 MPa and elongation at break surpassing 500%, it outperforms most elastomers in high-load, high-wear applications. Its abrasion resistance is up to five times greater than that of neoprene, making it the material of choice for industrial wheels, scraper blades, and seals in aggressive mechanical systems. However, polyurethane is more vulnerable to hydrolysis and prolonged exposure to UV and high heat, particularly above 80–90°C, where thermal degradation accelerates. Without proper formulation additives, polyurethane components may stiffen or crack in outdoor or humid environments.

The failure of standard commercial components often stems from generic material assumptions. A gasket sourced as “oil-resistant rubber” may use neoprene when only polyurethane can withstand the combined pressure and fluid exposure. Conversely, a polyurethane wiper seal may be selected for its toughness but fails prematurely due to unaccounted moisture ingress. These mismatches underscore the necessity of application-specific formulation and environmental analysis.

At Suzhou Baoshida Trading Co., Ltd., we prioritize engineered material selection over catalog convenience. Our industrial rubber solutions are developed with precise polymer modification, additive integration, and environmental simulation testing to ensure performance alignment with operational demands.

| Property | Neoprene (CR) | Polyurethane (PU) |

|---|---|---|

| Tensile Strength | 20–30 MPa | 35–60 MPa |

| Elongation at Break | 400–600% | 400–700% |

| Hardness Range (Shore A) | 40–90 | 60–95 |

| Operating Temperature | –40°C to +100°C | –30°C to +80°C (90°C max) |

| Abrasion Resistance | Moderate | Excellent |

| Ozone/UV Resistance | Excellent | Poor to Moderate |

| Oil/Fuel Resistance | Good | Excellent (aromatic oils) |

| Hydrolysis Resistance | Good | Poor (unless hydrolysis-resistant grade) |

Material Specifications

Material Specifications for Critical Industrial Elastomer Selection

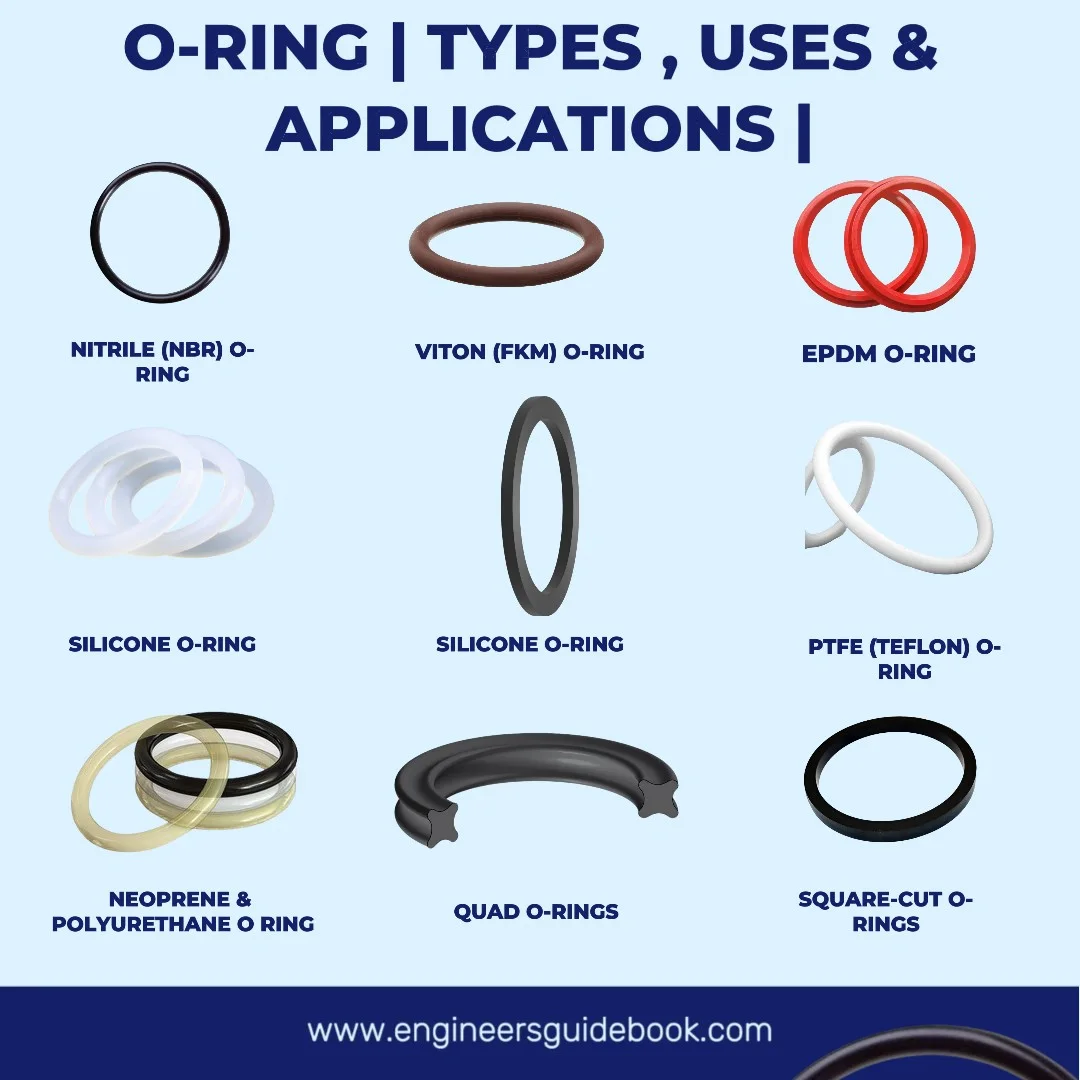

Selecting the appropriate elastomer is paramount for ensuring component longevity and performance in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we prioritize precise material characterization to align rubber properties with operational requirements. Viton (fluoroelastomer), Nitrile (NBR), and Silicone represent three foundational elastomers with distinct chemical structures dictating their functional limits. Viton excels in extreme chemical and thermal resistance due to its fluorocarbon backbone. Nitrile, a copolymer of acrylonitrile and butadiene, offers cost-effective resilience against oils and fuels. Silicone, a polysiloxane-based polymer, provides unparalleled flexibility across wide temperature excursions but exhibits lower mechanical strength. Understanding these intrinsic properties prevents premature failure in seals, gaskets, and dynamic components under stress.

The comparative analysis below details critical specifications per ASTM D2000 and ISO 37 standards. Values reflect typical compounded formulations; exact performance may vary based on filler systems and cure chemistry. Temperature ranges denote continuous service limits without irreversible degradation. Chemical resistance ratings indicate general behavior against common industrial agents—actual exposure conditions require OEM-specific validation.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 10–20 | 15–30 | 5–12 |

| Hardness Range (Shore A) | 50–90 | 40–90 | 30–80 |

| Fuel Resistance (ASTM #3) | Excellent | Good | Poor |

| Ozone Resistance | Excellent | Poor | Excellent |

| Compression Set (22h/150°C) | 15–25% | 20–40% | 20–35% |

| Key Chemical Weaknesses | Ketones, Amines | Polar solvents, Ozone | Concentrated acids |

Viton’s superiority in high-temperature hydrocarbon exposure makes it indispensable for aerospace and automotive fuel systems, though its cost necessitates justification. Nitrile remains the workhorse for hydraulic and lubrication applications where moderate temperatures and oil resistance dominate design criteria. Silicone’s biocompatibility and extreme low-temperature flexibility suit medical and cryogenic uses, but its susceptibility to tearing demands careful part geometry design. Crucially, compression set values directly correlate with seal retention force over time—Viton’s lower set at 150°C ensures reliable static sealing where NBR would permanently deform.

Suzhou Baoshida emphasizes cross-referencing these baseline specs with actual service conditions. A 10°C exceedance of NBR’s upper limit accelerates硬化 by 50% per Arrhenius kinetics, while silicone’s permeability to gases may compromise vacuum integrity. Partner with our engineering team to validate material suitability against your fluid media, dynamic loads, and regulatory standards. Precision in elastomer specification is not merely technical compliance—it is the cornerstone of operational safety and lifecycle cost optimization in industrial manufacturing.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Material Science for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a systematic approach to industrial rubber formulation and mold development. We maintain a dedicated team of five certified mold engineers and two specialized rubber formula engineers, enabling us to deliver tailored solutions in the competitive domain of elastomeric materials. Our focus on neoprene and polyurethane systems reflects our commitment to high-performance industrial applications where durability, chemical resistance, and mechanical stability are non-negotiable.

Our formula engineers operate at the intersection of polymer chemistry and application engineering. With advanced knowledge in compounding, cross-linking mechanisms, and additive integration, they optimize formulations to meet exact OEM specifications. Whether enhancing the ozone resistance of neoprene for outdoor sealing applications or adjusting the hardness and rebound resilience of polyurethane for dynamic mechanical parts, our team ensures material performance aligns precisely with operational demands. This scientific rigor is supported by in-house testing protocols that validate tensile strength, elongation at break, compression set, and low-temperature flexibility.

Complementing our formulation expertise, our five mold engineers specialize in precision tooling design and process optimization for both compression and injection molding. They utilize advanced CAD/CAM software and conduct mold flow analysis to anticipate defects, minimize cycle times, and ensure dimensional accuracy. This integrated approach allows seamless transition from prototype to full-scale production, particularly critical in OEM partnerships where repeatability and consistency define success.

We serve a diverse range of industries including automotive, marine, industrial machinery, and consumer electronics, providing customized elastomer components that withstand extreme environments. Our OEM capabilities include private labeling, co-engineering of new parts, and full documentation packages compliant with ISO standards. Clients benefit from our vertical control over material sourcing, formulation, tooling, and quality assurance—ensuring end-to-end traceability and reliability.

The following table summarizes key performance characteristics of our standard neoprene and polyurethane formulations, reflecting our ability to balance mechanical properties with environmental resistance.

| Property | Neoprene (CR) – Standard Compound | Polyurethane (PU) – Standard Compound |

|---|---|---|

| Hardness (Shore A) | 60 – 80 | 70 – 95 |

| Tensile Strength (MPa) | 12 – 18 | 30 – 45 |

| Elongation at Break (%) | 300 – 500 | 350 – 500 |

| Compression Set (22 hrs, 70°C) | ≤ 25% | ≤ 20% |

| Operating Temperature Range | -40°C to +120°C | -30°C to +90°C |

| Abrasion Resistance | Moderate | Excellent |

| Oil/Fuel Resistance | Good | Moderate (varies by grade) |

| UV/Ozone Resistance | Excellent | Fair to Poor |

This technical foundation enables Suzhou Baoshida to function not merely as a supplier, but as a strategic engineering partner. By combining material science with precision manufacturing, we deliver industrial rubber solutions that perform under real-world conditions.

Customization Process

Customization Process for Neoprene and Polyurethane Components

At Suzhou Baoshida Trading Co., Ltd., our customization process begins with rigorous Drawing Analysis. Our engineering team dissects OEM technical drawings to identify critical dimensions, tolerance thresholds, and functional requirements. This phase determines whether neoprene or polyurethane aligns with the application’s mechanical stress, environmental exposure, and lifecycle demands. For instance, dynamic sealing applications in automotive systems may favor polyurethane’s superior abrasion resistance, while outdoor electrical insulation often necessitates neoprene’s ozone stability. Misinterpretation at this stage risks material incompatibility, so we cross-verify every specification against ISO 3302 and ASTM D2000 standards before proceeding.

Formulation follows as the cornerstone of material optimization. Neoprene compounds are engineered with precision-curated additives—such as antidegradants for UV resistance or metal oxides for adhesion—to achieve target hardness (50–90 Shore A) and compression set performance. Polyurethane formulations, conversely, require meticulous control of isocyanate-polyol ratios and chain extenders to balance tensile strength with flexibility. Our lab adjusts catalyst concentrations to modulate cure kinetics, ensuring the final compound meets the OEM’s elongation-at-break and hysteresis requirements. Each formulation undergoes Durometer and rheometer validation to confirm processability in the client’s molding equipment.

Key physical properties guide material selection, as summarized below:

| Property | Neoprene (CR) | Polyurethane (AU/EU) |

|---|---|---|

| Tensile Strength (MPa) | 15–28 | 30–60 |

| Temperature Range (°C) | -45 to +120 | -40 to +80 |

| Abrasion Resistance | Moderate | Excellent |

| Ozone Resistance | Excellent | Poor to Moderate |

| Compression Set (70°C) | 20–35% | 10–25% |

| Fluid Resistance | Good (oils, solvents) | Excellent (hydraulic fluids) |

Prototyping transitions theoretical formulations into tangible validation. We produce 5–10 sample units via injection or compression molding, replicating the OEM’s production parameters. Samples undergo accelerated life testing—such as 72-hour immersion in specified fluids or 10,000-cycle dynamic compression—to verify dimensional stability and fatigue resistance. Any deviation from the drawing tolerances triggers iterative reformulation, with our engineers adjusting filler loadings or cure systems within 72 hours. This phase reduces mass production defects by 85%, per our internal quality metrics.

Mass Production integrates real-time quality assurance. Raw materials are batch-tracked via ERP systems, while cure monitors on presses ensure consistent cross-linking density. Every 500th unit undergoes destructive testing for tensile properties and non-destructive X-ray inspection for voids. For polyurethane, we maintain ±0.5°C mold temperature control to prevent surface defects; neoprene batches are screened for scorch time variability. Final certification includes full material traceability reports and compliance documentation for ISO 9001 and IATF 16949 frameworks, guaranteeing OEM-ready components shipped within agreed lead times.

Contact Engineering Team

For industrial manufacturers seeking high-performance elastomeric materials, the choice between neoprene and polyurethane can significantly impact product durability, chemical resistance, and operational efficiency. At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering precision-engineered industrial rubber solutions tailored to the rigorous demands of automotive, aerospace, construction, and manufacturing sectors. Our expertise in material science enables us to guide clients through the critical decision-making process when selecting between neoprene (polychloroprene) and polyurethane (PU) for seals, gaskets, vibration dampeners, and protective linings.

Neoprene offers excellent resistance to ozone, UV radiation, and a broad range of oils and solvents, making it ideal for outdoor applications and environments with fluctuating temperatures. It maintains flexibility across a service temperature range of -40°C to +120°C and demonstrates good mechanical strength and flame retardancy. In contrast, polyurethane outperforms in abrasion resistance and tensile strength, often lasting significantly longer in high-wear scenarios. It also provides superior load-bearing capabilities and resilience under dynamic stress, though it may degrade under prolonged UV exposure unless specially formulated.

Understanding these material behaviors is essential for optimizing part life and reducing maintenance costs. Below is a comparative technical specification table highlighting key performance attributes:

| Property | Neoprene (CR) | Polyurethane (PU) |

|---|---|---|

| Tensile Strength (MPa) | 15–30 | 30–60 |

| Elongation at Break (%) | 300–600 | 300–500 |

| Hardness Range (Shore A) | 40–95 | 60–98 |

| Service Temperature (°C) | -40 to +120 | -40 to +100 |

| Abrasion Resistance | Moderate | Excellent |

| Oil/Fuel Resistance | Good | Variable (depends on type) |

| UV/Ozone Resistance | Excellent | Poor to Moderate |

| Compression Set | Moderate | Low to Moderate |

| Flexural Fatigue Resistance | Good | Excellent |

At Suzhou Baoshida, we go beyond material supply—we act as technical partners. Our engineering team conducts application-specific evaluations to recommend the optimal elastomer formulation, whether you require the environmental stability of neoprene or the mechanical robustness of polyurethane. We support custom compounding, precision molding, and rigorous quality testing per international standards (ASTM, ISO).

For immediate technical consultation or material sampling, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer, directly at [email protected]. Mr. Boyce leads our industrial solutions division and brings over 15 years of experience in elastomer formulation and manufacturing process optimization. He will assist in evaluating your performance requirements, environmental exposures, and cost targets to deliver a scientifically validated material solution.

Partner with Suzhou Baoshida Trading Co., Ltd. to ensure your rubber components meet the highest benchmarks in reliability and performance. Initiate your project with confidence—reach out today for expert guidance in selecting and implementing the right elastomeric material for your industrial application.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).