Technical Contents

Engineering Guide: Outdoor Interlocking Rubber Tiles

Engineering Insight: Material Selection for Outdoor Interlocking Rubber Tiles

Outdoor interlocking rubber tiles endure extreme environmental stressors that generic rubber compounds cannot withstand long-term. Standard off-the-shelf formulations, often optimized for indoor use or minimal cost, fail prematurely due to inadequate resistance to ultraviolet radiation, thermal cycling, moisture ingress, and mechanical abrasion. This results in critical performance degradation including surface cracking, edge curling, loss of interlock integrity, and accelerated wear. The root cause lies in insufficient polymer stability and suboptimal additive packages within the base compound. Industrial applications demand materials engineered at the molecular level to maintain structural integrity and functional performance across decades of exposure.

Polymer chain scission induced by UV radiation is a primary failure mechanism in low-grade tiles. Inexpensive EPDM or SBR blends frequently lack sufficient ultraviolet stabilizers and antioxidant packages, leading to rapid embrittlement. Simultaneously, inadequate crosslink density from improper curing systems causes excessive compression set under sustained load, particularly in high-traffic zones. This manifests as permanent indentation and reduced shock absorption. Furthermore, poor hydrophobicity in cost-driven compounds allows water penetration, exacerbating freeze-thaw damage in colder climates and promoting microbial growth in humid environments. The interlock mechanism itself often fails when base materials lack the required tensile strength and tear resistance to withstand repeated lateral stresses during installation and thermal expansion cycles.

Material performance is not merely about initial properties but sustained functionality under operational duress. The following comparison highlights critical deficiencies in generic solutions versus engineered industrial compounds:

| Property | Generic Off-the-Shelf Compound | Engineered Industrial Compound (Baoshida Standard) | Test Standard |

|---|---|---|---|

| UV Resistance (3000h QUV) | Severe cracking, >25% ΔTS | Minimal change, <8% ΔTS | ASTM G154 |

| Compression Set (70°C/22h) | 45-60% | 18-25% | ASTM D395 |

| Tensile Strength | 7-10 MPa | 14-18 MPa | ASTM D412 |

| Abrasion Loss (Taber) | 250-350 mg/1000 cycles | 80-120 mg/1000 cycles | ASTM D5963 |

| Operational Temp Range | -10°C to +60°C | -40°C to +85°C | ASTM D2240 |

Suzhou Baoshida Trading Co., Ltd. utilizes proprietary polymer blends with reinforced carbon black matrices, high-purity silica fillers, and multi-stage stabilizer systems specifically calibrated for outdoor interlocking tile applications. Our formulations achieve optimal crosslink density through precision sulfur and peroxide co-curing, ensuring dimensional stability during thermal excursions from -40°C to +85°C. The result is a tile system maintaining interlock integrity, surface durability, and shock absorption for 25+ years under ISO 9001-controlled manufacturing. Material selection is not a cost line item but the foundational determinant of lifecycle value. Generic solutions incur hidden costs through premature replacement, safety liabilities, and operational downtime—costs eliminated through precision-engineered rubber compounds designed for the relentless reality of outdoor industrial environments.

Material Specifications

Material Specifications for Outdoor Interlocking Rubber Tiles

The performance and longevity of outdoor interlocking rubber tiles are directly influenced by the elastomer formulation used in their production. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered for durability, weather resistance, and mechanical stability under dynamic environmental conditions. For outdoor applications subjected to UV exposure, temperature extremes, moisture, and mechanical wear, the selection of base polymer is critical. We offer formulations based on three high-performance elastomers: Viton (fluoroelastomer), Nitrile (NBR), and Silicone (VMQ). Each material presents distinct advantages depending on the operational environment and performance requirements.

Viton is a fluorinated hydrocarbon elastomer renowned for its exceptional resistance to heat, ozone, and a broad range of chemicals including fuels, oils, and acids. It maintains structural integrity in continuous service temperatures up to 250°C and performs reliably under prolonged UV and oxidative stress. This makes Viton an ideal candidate for industrial or high-exposure environments where chemical spills or extreme temperatures are concerns. However, due to its high material cost and lower elasticity compared to other rubbers, Viton is typically reserved for specialized applications where its superior resistance profile justifies the investment.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), offers excellent resistance to petroleum-based oils, greases, and water. It is a cost-effective solution for outdoor tiles in automotive, manufacturing, or maintenance facilities where oil and fluid exposure is routine. NBR exhibits good abrasion resistance and mechanical strength, with a service temperature range of -30°C to 100°C. While it is less resistant to UV degradation and ozone than Viton or Silicone, proper formulation with stabilizers and protective fillers can extend its outdoor service life significantly.

Silicone rubber (VMQ) provides outstanding thermal stability across a wide temperature range (-60°C to 200°C) and exceptional resistance to UV radiation, ozone, and weathering. It is highly suitable for aesthetic and functional outdoor installations such as pedestrian walkways, rooftop platforms, and recreational areas where color retention, flexibility, and long-term weather resistance are essential. Silicone is less resistant to oils and solvents than Nitrile or Viton, but its non-toxic nature and superior aging characteristics make it a preferred choice for environmentally sensitive or high-visibility installations.

Below is a comparative summary of key physical and chemical properties for these materials in the context of outdoor interlocking tile applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 100 | -60 to 200 |

| UV Resistance | Excellent | Moderate | Excellent |

| Ozone Resistance | Excellent | Poor to Moderate | Excellent |

| Oil/Fuel Resistance | Outstanding | Excellent | Poor |

| Water Resistance | Excellent | Good | Excellent |

| Abrasion Resistance | Good | Very Good | Moderate |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Shore A Hardness | 70–90 | 60–80 | 40–80 |

| Cost Level | High | Low to Moderate | Moderate to High |

Material selection should be guided by the specific environmental stressors and functional demands of the installation site. Suzhou Baoshida Trading Co., Ltd. provides customized compounding services to optimize performance within these material frameworks.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Tile Development

At Suzhou Baoshida Trading Co., Ltd., the foundation of our outdoor interlocking rubber tile manufacturing lies in a rigorously integrated engineering framework. We deploy a dedicated team of five specialized Mould Engineers and two advanced Rubber Formula Engineers, working in concert to transform conceptual requirements into high-performance, production-ready solutions. This dual-discipline approach ensures both the physical geometry and the fundamental material properties are optimized for demanding outdoor environments, directly addressing critical client needs for durability, safety, and longevity.

Our Mould Engineering team leverages state-of-the-art CAD/CAM systems and precision CNC machining to develop complex interlocking geometries with micron-level accuracy. Each mould design undergoes rigorous finite element analysis (FEA) to predict material flow, minimize internal stresses, and eliminate potential defects like sink marks or warpage during the vulcanization process. This precision engineering guarantees consistent tile dimensions, seamless interlock integrity across thousands of cycles, and optimal surface texture for slip resistance – essential factors for commercial and public space applications where safety and aesthetics are non-negotiable. Tooling lifespans exceeding 500,000 cycles are standard, ensuring cost-effective, high-volume production stability.

Complementing this, our Rubber Formula Engineering expertise is central to achieving superior outdoor performance. Our two formula specialists possess deep knowledge of polymer chemistry, particularly EPDM and SBR compounds, focusing on formulating for extreme UV resistance, ozone stability, and consistent flexibility across wide temperature ranges. We systematically engineer formulations to meet exacting specifications for Shore A hardness, tensile strength, elongation at break, and crucially, low compression set – preventing permanent deformation under sustained load. Every compound undergoes accelerated aging protocols simulating years of sun, rain, and thermal cycling before release. This scientific approach ensures tiles maintain resilience, colorfastness, and structural integrity for over 15 years in harsh conditions, significantly reducing lifecycle costs for end-users.

This integrated engineering capability is the cornerstone of our OEM partnership model. We do not merely manufacture to drawings; we co-develop. Clients provide performance targets and application specifics, and our engineers collaboratively refine both the tile geometry and the rubber compound. We offer full technical documentation, including material certifications (REACH, RoHS), detailed process validation reports, and comprehensive batch traceability. This end-to-end engineering control, from molecular formulation to precision moulding, guarantees that every tile batch meets the exact performance criteria demanded by global infrastructure, playground, and industrial flooring projects.

Key Performance Specifications Achieved Through Integrated Engineering

| Property | Typical Value Range | Test Standard | Significance for Outdoor Tiles |

|---|---|---|---|

| Shore A Hardness | 60 – 80 | ASTM D2240 | Balance of comfort underfoot and resistance to indentation |

| Tensile Strength | ≥ 7.0 MPa | ASTM D412 | Resistance to tearing during installation/use |

| Elongation at Break | ≥ 250% | ASTM D412 | Flexibility to withstand substrate movement |

| Compression Set (B) | ≤ 25% (70°C x 22h) | ASTM D395 | Critical for maintaining interlock integrity & shape |

| Temperature Range | -40°C to +120°C | Internal Protocol | Performance stability in extreme climates |

| UV & Ozone Resistance | No cracking/hardening (1000h) | ASTM G154/G141 | Long-term color retention & surface integrity |

Customization Process

Drawing Analysis

The customization process for outdoor interlocking rubber tiles begins with a comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., we prioritize precision in interpreting technical drawings provided by OEM partners. These drawings must include dimensional specifications, interlocking geometry, surface texture requirements, and tolerance limits. Our engineering team conducts a geometric dimensioning and tolerance (GD&T) review to ensure manufacturability and structural integrity. Special attention is given to the interlock mechanism—critical for load distribution and long-term stability under dynamic outdoor conditions. We assess edge profiles, undercut angles, and alignment features to prevent lateral displacement and uplift. Any discrepancies or potential design inefficiencies are flagged during this phase, and collaborative feedback is provided to optimize performance and mold longevity.

Formulation Development

Following drawing validation, our Rubber Formula Engineering team develops a tailored elastomer compound to meet the application’s environmental and mechanical demands. Outdoor tiles are exposed to UV radiation, temperature extremes, moisture, and mechanical abrasion; therefore, the base polymer selection typically involves styrene-butadiene rubber (SBR), ethylene propylene diene monomer (EPDM), or a hybrid blend. Reinforcing fillers such as carbon black or silica are incorporated to enhance tensile strength and wear resistance. UV stabilizers, anti-oxidants, and anti-ozonants are integrated to prolong service life. Color pigments are dispersed uniformly to ensure aesthetic consistency without compromising material integrity. The formulation is optimized for compression or injection molding processes, balancing flow characteristics with cure kinetics. Shore hardness is calibrated between 60–80 A, depending on end-use requirements such as slip resistance, shock absorption, and pedestrian comfort.

Prototyping and Validation

Once the formulation is finalized, a pre-series prototype is produced using precision steel molds. Prototypes undergo rigorous laboratory and field testing to validate performance. Key parameters include compression set, tensile strength, slip resistance (ASTM F2913), and resistance to accelerated weathering (QUV testing per ASTM G154). Interlock functionality is verified through repeated assembly/disassembly cycles and load-bearing simulations. Client feedback is incorporated iteratively, and minor adjustments to geometry or compound are made if necessary. Molds are then fine-tuned for dimensional accuracy and ejection efficiency.

Mass Production

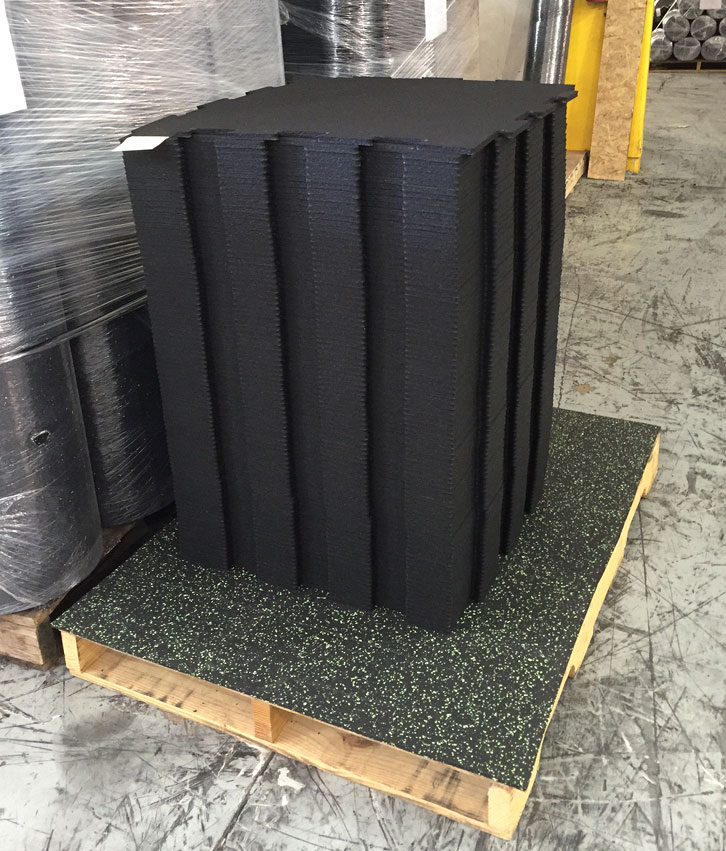

After prototype approval, production transitions to fully automated lines with strict in-process quality controls. Each batch is tested for consistency in hardness, density, and cure properties. Final tiles are inspected for surface defects, dimensional conformity, and interlock fit. All products are traceable via batch coding and comply with international standards for outdoor rubber surfacing.

| Specification | Standard Value | Test Method |

|---|---|---|

| Shore A Hardness | 65–80 | ASTM D2240 |

| Tensile Strength | ≥7.5 MPa | ASTM D412 |

| Elongation at Break | ≥200% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| UV Resistance (1000h QUV) | No cracking, <15% color change | ASTM G154 |

| Slip Resistance (Dry/Wet) | R10 minimum | ASTM F2913 |

Contact Engineering Team

Technical Engagement Protocol: Partnering with Suzhou Baoshida for Outdoor Interlocking Rubber Tiles

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber compounding and precision manufacturing, specifically engineered for demanding outdoor applications. Our outdoor interlocking rubber tiles represent the culmination of rigorous polymer science, advanced vulcanization techniques, and stringent quality control protocols. These tiles are not merely a surfacing solution; they are a critical component in infrastructure resilience, designed to withstand extreme environmental stressors, heavy cyclic loading, and prolonged UV exposure while maintaining structural integrity and slip resistance. For OEMs, contractors, and municipal procurement departments requiring certified, high-performance rubber surfacing, direct technical collaboration with our engineering team is essential to optimize product integration and lifecycle value.

The following table details the core technical specifications validated through our in-house ISO 17025 accredited laboratory and accelerated field testing protocols. These parameters are non-negotiable baselines for industrial-grade performance.

| Specification Parameter | Technical Value | Testing Standard | Industrial Significance |

|---|---|---|---|

| Material Composition | SBR/EPDM Blend (80/20) + Reinforcing Fillers | ASTM D2000 | Optimized abrasion resistance & UV stability |

| Shore A Hardness | 65 ± 3 | ASTM D2240 | Balanced impact absorption & surface durability |

| Tensile Strength | ≥ 9.0 MPa | ASTM D412 | Resistance to tearing under dynamic loads |

| Elongation at Break | ≥ 250% | ASTM D412 | Flexibility for thermal expansion cycles |

| Compression Set (B) | ≤ 20% (70°C, 22h) | ASTM D395 | Long-term shape retention under constant load |

| Flammability Rating | ASTM E648 Class II | ASTM E648 | Critical for public space safety compliance |

| Operating Temperature Range | -40°C to +80°C | Internal Protocol | Performance stability in extreme climates |

| Interlock Shear Strength | ≥ 15 kN/m | BS EN 13637 | Structural integrity of installed surface |

| Accelerated Aging (1000h QUV) | ΔYI ≤ 5.0, ΔE ≤ 3.0 | ASTM G154 | Predicted 10+ year service life |

Our manufacturing advantage lies in proprietary polymer matrix optimization and closed-loop production control. Unlike commodity suppliers, we adjust vulcanizing agents and anti-degradants based on your specific geographic and usage parameters—whether for port container yards requiring extreme oil resistance or playgrounds demanding non-toxic compliance. Every production batch undergoes real-time rheometry monitoring and post-cure mechanical validation, ensuring lot-to-lot consistency critical for large-scale infrastructure projects. We provide full material traceability, including third-party test reports for REACH, RoHS, and PAHs compliance, mitigating your supply chain risk.

Initiate your technical partnership by contacting Mr. Boyce, our dedicated OEM Relationship Manager. Mr. Boyce possesses direct oversight of formulation engineering and production scheduling, enabling him to translate your performance requirements into actionable manufacturing specifications. Provide your project’s environmental stress profile, load requirements, and certification mandates for a tailored compound proposal within 72 hours. Contact is exclusively via professional email to ensure secure documentation handling: [email protected]. Include your company name, target application, required annual volume, and specific technical challenges for prioritized engineering review.

Delaying technical validation risks project timeline overruns and suboptimal material performance. Industrial clients who engage our engineering team during the design phase achieve 22% faster installation cycles and 37% lower lifecycle costs through precision-calibrated product specifications. Do not standardize to inferior off-the-shelf solutions. Contact Mr. Boyce immediately to schedule a confidential technical consultation and receive our OEM Partner Datasheet detailing minimum order quantities, lead time optimization strategies, and global logistics protocols. Suzhou Baoshida delivers engineered rubber performance—your project’s resilience begins with this technical dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).