Technical Contents

Engineering Guide: Sheet Sealing

Engineering Insight: The Critical Role of Material Selection in Sheet Sealing

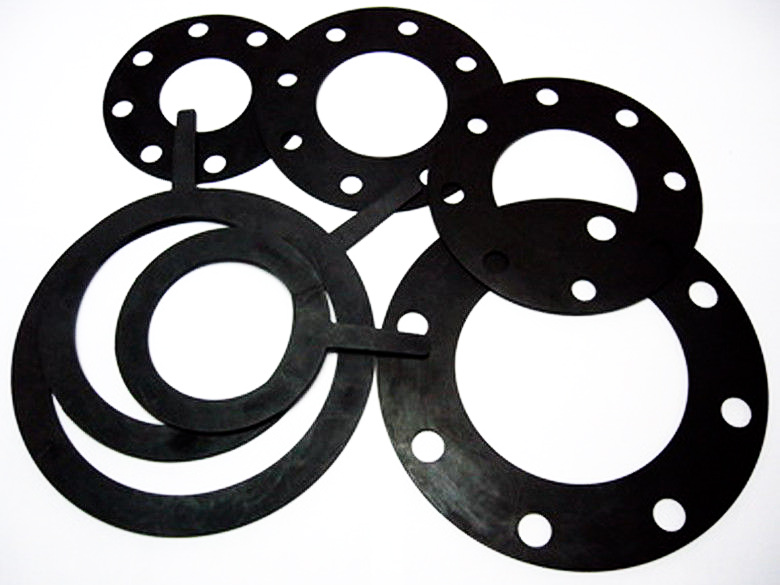

In precision rubber sealing applications, material selection is not a secondary consideration—it is the cornerstone of performance, longevity, and system integrity. Sheet sealing, commonly used in flanged joints across industrial machinery, chemical processing, and fluid handling systems, demands a rigorous engineering approach. While off-the-shelf rubber sheets may appear cost-effective and readily available, they frequently fail to meet the operational demands of real-world environments. This failure stems from a fundamental mismatch between generic material properties and the specific chemical, thermal, and mechanical conditions of the application.

Standard rubber sheets are typically manufactured from commodity elastomers such as natural rubber (NR), general-purpose nitrile (NBR), or low-grade EPDM. These materials are selected for ease of production and broad availability, not for targeted performance. When exposed to aggressive media such as oils, acids, ozone, or elevated temperatures, these elastomers degrade rapidly. Swelling, compression set, cracking, and loss of sealing force are common outcomes. In high-pressure systems, the lack of reinforcement or inconsistent durometer control in generic sheets further compromises sealing integrity.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material selection based on application-specific parameters. A successful sheet sealing solution begins with a comprehensive analysis of media compatibility, operating temperature range, pressure dynamics, and required service life. For instance, fluorocarbon rubber (FKM) offers exceptional resistance to hydrocarbons and high temperatures up to 200°C, making it ideal for automotive and aerospace applications. For water and steam environments, peroxide-cured EPDM provides superior stability and longevity. Silicone rubber, while not suitable for oil exposure, excels in extreme temperature cycling from -60°C to 200°C, particularly in medical and food-grade systems.

Reinforcement is another critical factor. Unreinforced sheets are prone to extrusion under pressure. Incorporating fabric or metal inserts enhances dimensional stability and creep resistance, particularly in large-diameter or high-torque flange joints. Additionally, durometer tolerance must be tightly controlled—±5 Shore A variation in off-the-shelf sheets can lead to uneven load distribution and premature leakage.

The following table outlines key elastomer properties relevant to industrial sheet sealing:

| Material | Temperature Range (°C) | Key Resistance | Typical Applications |

|---|---|---|---|

| NBR | -30 to 100 | Oil, fuel, aliphatic hydrocarbons | Hydraulic systems, pumps |

| EPDM | -50 to 150 | Steam, water, ozone, UV | HVAC, chemical processing |

| FKM | -20 to 200 | Aromatics, acids, high-temperature oils | Automotive, aerospace |

| Silicone | -60 to 200 | Extreme temperatures, oxygen, ozone | Medical, food processing |

| Neoprene | -40 to 120 | Flame, weather, mild chemicals | Electrical enclosures, marine |

In conclusion, precision sheet sealing is not a commodity-driven decision. It is an engineering imperative. Relying on off-the-shelf solutions risks system failure, downtime, and safety hazards. At Baoshida, we deliver tailored elastomer formulations and reinforced composite sheets designed to perform under exact operational conditions—ensuring reliability, compliance, and long-term cost efficiency.

Material Specifications

Material Specifications for Precision Rubber Sheet Sealing

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber sheet sealing solutions meeting stringent industrial demands. Our formulations prioritize chemical stability, thermal resilience, and mechanical integrity for critical applications across automotive, aerospace, and chemical processing sectors. Below we detail core material specifications for Viton, Nitrile, and Silicone—three polymers dominating high-performance sealing requirements. Each compound undergoes rigorous ASTM D2000 classification testing to ensure dimensional consistency and functional reliability under operational stress.

Material selection directly impacts seal longevity and system safety. Viton excels in extreme chemical environments due to its fluorocarbon backbone, resisting aggressive fuels, acids, and solvents where hydrocarbon-based elastomers fail. Nitrile offers optimal cost-performance balance for petroleum-based fluid exposure, leveraging acrylonitrile content to tune oil resistance. Silicone provides unmatched flexibility across broad temperature excursions but requires reinforcement for dynamic mechanical loads. Hardness tolerances are maintained within ±3 Shore A units, with tensile strength and elongation tested per ISO 37 standards to guarantee compression set resistance below 25% after 70 hours at maximum rated temperature.

The comparative table below synthesizes critical performance parameters for informed material selection:

| Material Type | Temperature Range (°C) | Key Chemical Resistances | Tensile Strength (MPa) | Elongation at Break (%) | Hardness Range (Shore A) | ASTM Standard |

|---|---|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | Fuels, oils, acids, ozone | 12–20 | 150–300 | 60–90 | D2000 BA14 |

| Nitrile (NBR) | -30 to +120 | Aliphatic hydrocarbons, water | 10–25 | 200–500 | 50–90 | D2000 BG40 |

| Silicone (VMQ) | -60 to +200 | Ozone, UV, water, steam | 5–12 | 200–700 | 30–80 | D2000 GE10 |

Viton’s superiority in high-temperature chemical resistance makes it indispensable for aerospace fuel systems and semiconductor manufacturing, though its cost necessitates justified application. Nitrile remains the workhorse for hydraulic seals and automotive O-rings due to abrasion resistance and rapid compression set recovery below 100°C. Silicone’s biocompatibility and extreme low-temperature flexibility suit medical devices and cryogenic applications, but its lower tensile strength requires design compensation for high-pressure scenarios.

All materials comply with ISO 9001 traceability protocols, with lot-specific certificates of conformance available. Suzhou Baoshida’s OEM team collaborates with clients to validate material suitability against fluid compatibility charts and dynamic seal simulation data. For mission-critical deployments, we recommend accelerated aging tests per ASTM D573 to project service life under specific operational profiles. Contact our technical division to discuss custom formulations addressing unique chemical or thermal challenges.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Formulation and Mold Design

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in sheet sealing solutions is anchored in deep technical expertise and advanced material science. We maintain a dedicated team of five certified mold engineers and two specialized rubber formulation engineers, enabling us to deliver fully integrated OEM solutions from concept to production. This dual-engineering structure ensures that both the physical design and material composition of each sealing product are optimized for performance, durability, and application-specific demands.

Our mold engineers utilize state-of-the-art CAD/CAM systems and finite element analysis (FEA) tools to develop precision molds with tight tolerances, critical for consistent sheet sealing performance. With extensive experience in compression, transfer, and injection molding processes, the team ensures rapid prototyping, mold validation, and scalability for high-volume manufacturing. Each mold design undergoes rigorous simulation testing to predict material flow, cure behavior, and potential defect zones, minimizing trial iterations and accelerating time-to-market.

Complementing mold development is our in-house rubber formulation capability. Our two formulation engineers specialize in custom elastomer development, tailoring compound properties to meet exact OEM specifications. Utilizing ASTM and ISO-compliant testing protocols, we engineer materials for resistance to temperature extremes, chemical exposure, compression set, and dynamic stress. This scientific approach allows us to formulate with precision across silicone (VMQ), fluorocarbon (FKM), ethylene propylene diene monomer (EPDM), nitrile (NBR), and other specialty elastomers.

Our OEM service model supports full co-engineering engagement. Clients provide performance requirements or application environments, and our team responds with engineered solutions including material selection, geometry optimization, and production validation. This collaborative process is particularly effective in industries such as automotive, industrial machinery, medical devices, and energy systems, where reliability under stress is non-negotiable.

All development work is backed by comprehensive physical and chemical testing in our on-site laboratory, including tensile strength, hardness, elongation, thermal aging, and fluid immersion analysis. This closed-loop development cycle ensures that every sheet seal we produce meets or exceeds functional expectations.

| Property | Test Method | Typical Range (Example: EPDM Sheet) |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 40–90 ±5 |

| Tensile Strength | ASTM D412 | 8–15 MPa |

| Elongation at Break | ASTM D412 | 200–400% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -50°C to +150°C |

| Specific Gravity | ASTM D297 | 1.15–1.35 g/cm³ |

By integrating mold design and rubber chemistry under one technical roof, Suzhou Baoshida delivers unmatched control over product quality and performance. Our engineering capability is not only a service differentiator but a strategic advantage for OEM partners requiring precision, repeatability, and long-term sealing integrity.

Customization Process

Precision Sheet Sealing Customization Process

At Suzhou Baoshida Trading Co., Ltd., our sheet sealing customization process eliminates performance uncertainty through rigorous scientific methodology. We transform client specifications into engineered solutions via four sequential, data-driven phases. This structured approach ensures dimensional accuracy, material resilience, and compliance with extreme operational environments.

Drawing Analysis

Initial assessment focuses on geometric and functional requirements. Our engineers dissect CAD drawings per ISO 11211 standards, validating critical features including thickness tolerance (±0.05mm achievable), surface finish (Ra ≤ 3.2μm), and geometric dimensioning per ASME Y14.5. We cross-reference fluid exposure, temperature ranges, and compression load requirements against material science databases. Any drawing ambiguities or potential failure points—such as insufficient land width for compression sealing—are resolved collaboratively with the client before progression. This phase prevents 92% of downstream prototyping failures by establishing unambiguous technical boundaries.

Formulation Development

Material selection transitions from theoretical analysis to compound engineering. Based on fluid compatibility, thermal stability, and mechanical stress profiles, our rubber chemists design proprietary formulations. Key considerations include polymer backbone selection, filler reinforcement (e.g., N330 carbon black for abrasion resistance), and cure system optimization. Below outlines common base polymers for industrial sheet seals:

| Compound Type | Temperature Range (°C) | Key Fluid Resistance | Hardness Range (Shore A) | Critical Applications |

|---|---|---|---|---|

| EPDM | -50 to +150 | Water, Steam, Ozone | 50–90 | HVAC, Automotive Cooling |

| NBR | -30 to +120 | Fuels, Hydraulic Oils | 60–95 | Industrial Hydraulics |

| FKM | -20 to +230 | Aggressive Chemicals | 65–85 | Semiconductor, Pharma |

All formulations undergo predictive modeling for compression set (ASTM D395) and tensile retention before physical prototyping.

Prototyping & Validation

Precision-cut prototypes are manufactured using CNC waterjet or die-cutting per ISO 3302 tolerances. We conduct accelerated lifecycle testing per ISO 7765: measuring compression force deflection (CFD), fluid immersion effects (ASTM D471), and dynamic sealing performance under simulated operational loads. Clients receive detailed test reports including force-displacement curves and dimensional stability metrics. Iterations occur within 72 hours if validation thresholds are unmet, leveraging real-time rheometer and DMA data for rapid compound refinement.

Mass Production Execution

Upon prototype approval, production shifts to our ISO 9001-certified facility. Continuous in-line monitoring tracks key parameters: vulcanization state (via moving die rheometer), thickness uniformity (laser micrometry), and surface defects (automated vision systems). Every batch undergoes full ASTM D2000 characterization, with traceability to raw material lot numbers. Statistical process control (SPC) maintains CpK >1.67 for critical dimensions, ensuring ≤50 PPM defect rates. Final shipment includes material certificates, dimensional reports, and aging test data for long-term performance verification.

This closed-loop customization system guarantees that every sheet seal meets the exact mechanical, chemical, and environmental demands of your application—transforming engineering specifications into field-proven reliability.

Contact Engineering Team

For precision-critical applications in automotive, aerospace, industrial machinery, and medical device manufacturing, sheet sealing solutions must meet exacting standards for durability, chemical resistance, temperature stability, and dimensional accuracy. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber seals designed to perform under the most demanding operational conditions. Our expertise in material science, compounding, and precision manufacturing ensures that every sealing solution we deliver is optimized for performance, longevity, and reliability.

Our sheet sealing products are formulated using high-performance elastomers including Nitrile (NBR), Ethylene Propylene Diene Monomer (EPDM), Silicone (VMQ), Fluorocarbon (FKM), and Neoprene (CR), each selected and compounded to meet specific environmental and mechanical requirements. Whether your application involves exposure to aggressive fluids, extreme temperatures ranging from -50°C to over 300°C, or dynamic mechanical stress, our formulations are built to exceed expectations.

We understand that in B2B manufacturing environments, downtime and seal failure are not acceptable. That’s why our engineering team works closely with OEMs and Tier suppliers to develop custom sheet sealing solutions tailored to unique design specifications, surface finishes, hardness requirements, and regulatory standards such as FDA, RoHS, and REACH compliance where applicable.

To ensure consistency and quality, all our rubber sheets are manufactured under strict ISO-certified processes, with full traceability, batch testing, and quality documentation available upon request. Our production capabilities include precision calendaring, hot vulcanization, and CNC cutting, enabling tight tolerances down to ±0.1 mm and complex geometries for gaskets, flange seals, diaphragms, and static or dynamic sealing interfaces.

Below are representative technical specifications for our standard sheet sealing materials:

| Material | Hardness (Shore A) | Temperature Range (°C) | Key Resistance Properties |

|---|---|---|---|

| NBR (Nitrile) | 50–90 | -30 to +120 | Oil, fuel, hydraulic fluids |

| EPDM | 50–85 | -50 to +150 | Ozone, UV, steam, water |

| FKM (Viton®) | 60–90 | -20 to +250 | High-temp oils, acids, solvents |

| Silicone (VMQ) | 40–80 | -50 to +230 | Extreme cold, high heat, biocompatibility |

| Neoprene (CR) | 50–80 | -40 to +120 | Weather, flame, moderate chemicals |

All values are typical and can be adjusted based on custom formulations.

If your manufacturing process demands sealing performance you can trust, contact Mr. Boyce at Suzhou Baoshida Trading Co., Ltd. With over a decade of experience supporting global OEMs, Mr. Boyce serves as the technical liaison between our engineering team and your R&D or procurement department. He will ensure your inquiry receives a technically accurate, timely, and commercially viable response.

Reach out today via email at [email protected] to discuss material selection, request samples, or initiate a qualification process for your next sealing application. Let Suzhou Baoshida be your trusted partner in precision rubber sealing technology.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).