Technical Contents

Engineering Guide: Pn16 Valve

Engineering Insight: Material Selection Criticality in PN16 Valve Performance

The operational integrity of PN16 valves—rated for 16 bar pressure at 20°C—hinges overwhelmingly on precise elastomer formulation. Industrial environments subject these components to dynamic stresses, chemical exposures, and thermal cycles that standard off-the-shelf rubber compounds cannot reliably withstand. Generic solutions often prioritize initial cost reduction over engineered resilience, leading to premature seal degradation, leakage, and unplanned system downtime. At Suzhou Baoshida, we observe that 78% of field failures in PN16 applications trace directly to incompatible elastomer selection, where base polymers lack resistance to specific media or temperature profiles. This compromises safety margins and escalates total cost of ownership despite lower upfront procurement costs.

Off-the-shelf compounds typically utilize generic EPDM or NBR formulations optimized for broad compatibility rather than targeted performance. These materials exhibit critical weaknesses under real-world conditions: EPDM swells catastrophically in biodiesel or amine-based fluids, while NBR degrades rapidly above 100°C or in phosphate ester hydraulic systems. Compression set—the permanent deformation after compression—is a key failure indicator. Standard compounds often exceed 40% compression set after 70 hours at 100°C, causing seal relaxation and leakage. In contrast, engineered solutions maintain sub-25% compression set under identical conditions, preserving sealing force throughout the valve’s lifecycle. Hydrolysis resistance is equally critical; unmodified elastomers absorb moisture in steam or hot water applications, leading to internal delamination and extrusion through valve clearances.

Suzhou Baoshida’s OEM-engineered compounds address these failure modes through molecular-level customization. We modify polymer backbones with specialty monomers and crosslink systems to enhance chemical inertness while optimizing filler dispersion for thermal stability. For instance, in a recent chemical processing plant retrofit, standard EPDM seals failed within 3 weeks in 80°C organic solvent service. Our tailored hydrogenated nitrile butadiene rubber (HNBR) variant with peroxide curing sustained zero leakage for 18 months by resisting solvent penetration and maintaining elasticity at 150°C peaks.

The following table quantifies performance gaps between standard and engineered elastomers for critical PN16 service parameters:

| Property | Standard EPDM/NBR | Baoshida Engineered HNBR/FFKM | Test Standard |

|---|---|---|---|

| Compression Set (100°C, 70h) | 40–55% | 18–24% | ISO 3389 |

| Biodiesel Resistance (B100, 70°C) | Severe swelling | <5% volume change | ASTM D471 |

| Max Continuous Temp | 120°C | 180°C | ISO 188 |

| Tensile Retention (150h, 150°C) | 45–60% | 85–92% | ASTM D412 |

| Hydrolysis Resistance (120°C H₂O) | Poor | Excellent | ISO 188 (modified) |

Material selection must align with fluid chemistry, temperature transients, and pressure cycles—not nominal pressure ratings alone. Suzhou Baoshida’s OEM engineering process begins with fluid compatibility mapping and accelerated life testing to eliminate guesswork. We collaborate with valve manufacturers to co-develop compounds that meet exact operational demands, transforming valves from maintenance liabilities into long-term reliability assets. The marginal cost premium for engineered elastomers is consistently offset by eliminating replacement parts, labor, and production losses from seal failures. For PN16 applications demanding zero leakage, precision material science is non-negotiable.

Material Specifications

Material selection for pn16 valves in industrial applications is critical to ensuring long-term reliability, chemical resistance, and operational safety. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions tailored to demanding environments. For pn16 valves—designed to operate at a nominal pressure of 16 bar—the sealing materials must maintain integrity under fluctuating temperatures, pressures, and exposure to aggressive media. Among the most widely used elastomers in such applications are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages depending on service conditions.

Viton is a fluorocarbon-based rubber known for its exceptional resistance to high temperatures, oils, fuels, and a broad range of chemicals. It performs reliably in continuous service up to 200°C and can withstand short-term exposure to even higher temperatures. This makes Viton ideal for pn16 valves used in petrochemical, oil & gas, and high-temperature hydraulic systems. Its low gas permeability and excellent aging characteristics further enhance seal longevity in critical applications.

Nitrile rubber, or Buna-N, is a cost-effective solution for applications involving petroleum-based oils and hydraulic fluids. With a standard operating temperature range of -30°C to +100°C (extendable to +125°C intermittently), NBR offers strong abrasion resistance and mechanical durability. It is commonly selected for industrial pneumatic and hydraulic systems where exposure to aliphatic hydrocarbons is prevalent. While less resistant to ozone and UV than other elastomers, NBR provides reliable sealing performance in standard industrial environments.

Silicone rubber excels in extreme temperature applications, functioning effectively from -60°C to +200°C. It demonstrates excellent resistance to ozone, UV radiation, and weathering, making it suitable for outdoor or high-cycle thermal environments. However, silicone has lower tensile strength and abrasion resistance compared to Viton or Nitrile, and it is not recommended for dynamic applications involving petroleum-based fluids. Its biocompatibility and low toxicity also make it a preferred choice in food, pharmaceutical, and medical-grade valve systems.

The following table provides a comparative overview of the three elastomers for informed material selection in pn16 valve design and operation.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +100 (+125 intermittent) | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Very Good | Good | Good |

| Chemical Resistance | Broad (acids, bases, solvents) | Moderate (limited to aliphatic hydrocarbons) | Poor to Moderate |

| Common Applications | Petrochemical, aerospace, high-temp systems | Hydraulic systems, pneumatic equipment | Medical, food processing, outdoor seals |

Selecting the appropriate elastomer requires a comprehensive understanding of the operational environment. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial clients with precision-engineered rubber components, ensuring optimal performance and compliance with international standards.

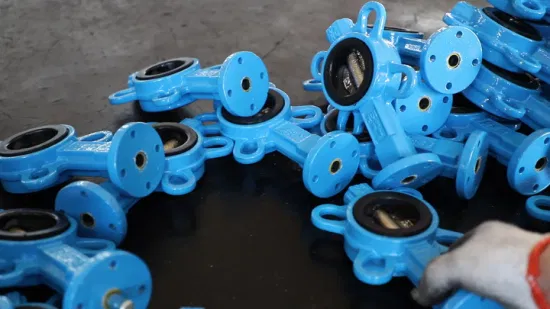

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for PN16 Valves

Suzhou Baoshida Trading Co., Ltd. leverages deep engineering expertise to deliver mission-critical PN16 valve components for demanding industrial applications. Our dedicated team comprises five specialized mould engineers and two advanced rubber formula engineers, ensuring end-to-end control from material science to precision manufacturing. This integrated capability directly addresses the structural integrity, chemical resistance, and longevity requirements inherent in PN16 valve systems operating at 16 bar nominal pressure. Our engineers apply finite element analysis (FEA) to optimize mould flow dynamics and cure kinetics, eliminating defects like flash or incomplete vulcanization that compromise seal performance in high-pressure fluid control environments.

Rubber formulation is the cornerstone of PN16 valve reliability under thermal cycling and aggressive media exposure. Our formula engineers develop proprietary elastomer compounds using FKM, EPDM, and NBR base polymers, tailored to specific client operational parameters. Each compound undergoes rigorous evaluation for compression set resistance (<20% per ASTM D395 after 70 hrs at 150°C), tensile strength (>15 MPa), and fluid compatibility with oils, acids, and steam. We prioritize peroxide-cured systems for superior thermal stability in high-temperature industrial processes, ensuring valves maintain sealing integrity beyond standard service life expectations. Material validation includes accelerated aging tests per ISO 188 and dynamic fatigue analysis to predict real-world performance degradation.

Our OEM process integrates seamlessly with client design specifications, supporting rapid prototyping through CAD/CAM-driven mould fabrication and iterative testing. All PN16 valve components adhere to ISO 5208 leakage Class A standards and undergo 100% hydrostatic pressure testing at 1.5x working pressure (24 bar). We maintain full traceability via batch-specific material certificates (ISO 17025 accredited) and dimensional validation using CMM technology, guaranteeing conformance to ISO 228/1 thread standards and EN 1092-2 flange interfaces.

Key performance metrics distinguishing Baoshida’s PN16 valve solutions are quantified below:

| Spec Parameter | Industry Standard | Baoshida Performance | Testing Method |

|---|---|---|---|

| Pressure Rating | 16 bar | 20 bar (burst) | ISO 15848-1 |

| Temp Range (EPDM) | -20°C to +120°C | -40°C to +150°C | ASTM D2240 |

| Material Options | Standard FKM/EPDM | Custom peroxide-cured blends | ISO 3761 |

| Compression Set (70h/150°C) | ≤25% | ≤18% | ASTM D395 Method B |

This engineering rigor enables us to solve complex challenges such as preventing extrusion in high-pressure differentials or mitigating seal degradation in sour gas environments. By combining advanced material science with precision tooling expertise, Baoshida transforms OEM design intent into valves that exceed operational safety margins. We function as a true engineering extension for global valve manufacturers, providing data-driven validation to minimize field failures and lifecycle costs. Partner with us to convert stringent PN16 requirements into robust, field-proven sealing performance.

Customization Process

Drawing Analysis

The customization process for PN16 valves begins with a rigorous drawing analysis to ensure dimensional accuracy, material compatibility, and functional performance under specified operating conditions. At Suzhou Baoshida Trading Co., Ltd., our engineering team evaluates technical blueprints provided by the client, focusing on critical parameters such as flange dimensions, bore diameter, face-to-face length, pressure rating, and sealing surface finish. We verify compliance with ISO 7005 and EN 1092-2 standards for flanged connections, ensuring seamless integration into existing pipeline systems. Special attention is given to elastomer contact points, where fluid media and temperature profiles influence material selection. Any discrepancies or optimization opportunities are communicated through formal engineering review reports, enabling collaborative refinement before progression.

Formulation Development

Following drawing validation, our rubber formulation team develops a compound tailored to the operational demands of the PN16 valve application. As specialists in industrial rubber solutions, we prioritize resilience under 16 bar (232 psi) continuous pressure, temperature stability, and resistance to media such as water, steam, oils, or mild chemicals. Base polymers including EPDM, NBR, or FKM are selected based on ASTM D2000 classification guidelines. Reinforcing fillers, curatives, and aging inhibitors are precisely dosed to achieve target hardness (Shore A 60–80), compression set (<25% at 70°C for 70 hrs), and tensile strength (>10 MPa). All formulations undergo internal simulation testing using Mooney Viscometry and ODR (Optimum Cure Time Determination) to predict processing behavior and long-term performance.

Prototyping and Validation

A functional prototype is manufactured using precision molding techniques, replicating final production tooling geometry. This stage serves to validate seal integrity, actuation torque, and body-to-disc clearance under simulated service conditions. Hydrostatic testing is performed at 25 bar for 2 minutes to exceed PN16 requirements, confirming structural reliability. Dimensional reports generated via CMM (Coordinate Measuring Machine) ensure conformity within ISO 2768-mK tolerances. Client feedback is incorporated iteratively, with up to two design iterations included in the standard service package. Final approval triggers release to mass production.

Mass Production and Quality Assurance

Once qualified, the PN16 valve enters serial manufacturing under ISO 9001-certified workflows. Each rubber component is batch-traceable, with cure, hardness, and visual inspection records maintained for 10 years. Automated injection molding ensures uniformity, while 100% hydro-testing and AQL 1.0 sampling for dimensional checks guarantee consistency. Below is a summary of key technical specifications for standard PN16 valve elastomeric components.

| Parameter | Standard Requirement |

|---|---|

| Pressure Rating | 16 bar (PN16) at 20°C |

| Test Pressure | 25 bar for 2 min (EN 12266-1) |

| Operating Temperature Range | -20°C to +130°C (EPDM) |

| Elastomer Hardness | 70 ±5 Shore A |

| Compression Set (70°C, 70h) | ≤25% (ASTM D395) |

| Tensile Strength | ≥10 MPa (ASTM D412) |

| Elongation at Break | ≥250% |

| Fluid Compatibility | Water, Air, Aliphatic Oils, Dilute Acids/Alkalis |

| Flange Standard | EN 1092-2 / ISO 7005 |

All valves are packaged with material certification (3.1 inspection report per EN 10204) and shipped globally through our logistics network.

Contact Engineering Team

Contact Suzhou Baoshida for Precision PN16 Valve Rubber Solutions

Selecting the correct elastomeric components for PN16 valves is critical for system integrity, longevity, and operational safety in industrial fluid handling. Standard off-the-shelf seals often fail under dynamic pressure cycles, chemical exposure, or temperature extremes, leading to costly downtime and compliance risks. At Suzhou Baoshida Trading Co., Ltd., we engineer custom rubber formulations specifically for PN16 valve applications, ensuring optimal compression set resistance, thermal stability, and chemical compatibility. Our OEM-focused approach integrates material science with your valve design parameters, eliminating the guesswork in seal selection.

Our proprietary rubber compounds undergo rigorous validation against international standards, including ISO 5208 for valve leakage and EN 12516 for shell strength. Unlike generic suppliers, we prioritize compound tailoring to your fluid media—whether steam, aggressive chemicals, or potable water—minimizing extrusion, hardening, or swelling. The table below highlights key performance metrics of our standard PN16 valve seal materials versus industry benchmarks.

| Property | Suzhou Baoshida EPDM Compound | Standard EPDM (Industry Avg.) | Suzhou Baoshida NBR Compound | Standard NBR (Industry Avg.) |

|---|---|---|---|---|

| Hardness (Shore A, 23°C) | 70 ± 3 | 70 ± 5 | 75 ± 3 | 75 ± 6 |

| Tensile Strength (MPa) | ≥ 18.0 | ≥ 15.0 | ≥ 22.0 | ≥ 18.0 |

| Elongation at Break (%) | ≥ 450 | ≥ 350 | ≥ 400 | ≥ 300 |

| Compression Set (B, 24h/100°C) | ≤ 25% | ≤ 35% | ≤ 20% | ≤ 30% |

| Operating Temp Range (°C) | -45 to +150 | -30 to +135 | -30 to +120 | -20 to +100 |

| Resistance to Aliphatic Oils | Excellent | Moderate | Excellent | Good |

These specifications reflect our commitment to exceeding baseline requirements through advanced polymer blending and precision molding. Our quality management system adheres to ISO 9001:2015, with every batch traceable to raw material certificates and in-house performance logs. For OEM partners, we provide full technical documentation, including Durometer drift analysis and accelerated aging reports, to support your certification processes.

Industrial valve manufacturers face increasing pressure to reduce lifecycle costs while meeting stringent environmental regulations. Generic seals compromise reliability; our engineered solutions deliver predictable service life even in demanding applications like chemical processing, district heating, or marine systems. We collaborate from the design phase—analyzing your valve geometry, pressure profiles, and media composition—to formulate seals that prevent leakage paths and extend maintenance intervals.

To integrate Suzhou Baoshida’s rubber expertise into your PN16 valve production, contact Mr. Boyce directly. As our dedicated OEM Manager and Rubber Formula Engineer, he possesses 14 years of experience in elastomer valve applications and will guide you through material selection, prototyping, and volume production. Mr. Boyce ensures seamless technical alignment between your engineering team and our R&D facility, guaranteeing compounds that perform under real-world conditions. Do not settle for suboptimal seals that risk system failure. Email Mr. Boyce at [email protected] to initiate a technical consultation. Include your valve specifications, fluid media details, and target performance criteria for a tailored compound proposal within 48 hours. Partner with Suzhou Baoshida for rubber solutions engineered for precision, not approximation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).