Technical Contents

Engineering Guide: Aramid Gasket Material

Engineering Insight: Aramid Gasket Material Selection Criticality

Material selection for aramid gasket applications transcends mere specification matching; it is a fundamental engineering decision dictating system integrity, longevity, and operational safety. Off-the-shelf aramid gasket materials frequently fail in demanding industrial environments due to a critical oversight: the inherent variability of aramid fiber performance when integrated into composite matrices without precise formulation control. Generic solutions often utilize standardized resin systems and fiber treatments optimized for cost, not for the specific thermal, chemical, and mechanical stress profiles encountered in high-performance sealing applications. This results in premature degradation modes including excessive compression set, chemical attack at the fiber-resin interface, and catastrophic loss of sealing force under cyclic loading. The consequence is unplanned downtime, environmental compliance breaches, and significant repair costs far exceeding the initial gasket investment.

Aramid fibers themselves possess exceptional inherent properties—high tensile strength, thermal stability exceeding 400°C, and chemical inertness. However, their effectiveness in a gasket is entirely dependent on the compatibility and performance of the binder system and the precision of the manufacturing process. Standard commercial aramid gaskets frequently employ phenolic or nitrile-based binders with inadequate thermal resistance or chemical compatibility for the target application. Furthermore, inconsistent fiber orientation, insufficient resin penetration, or improper curing kinetics create micro-voids and weak interfacial bonds. Under operational stress, these micro-structural flaws become initiation points for creep, extrusion, or chemical permeation, leading to seal failure long before the aramid fibers themselves are compromised. The failure is not of the aramid, but of the engineered composite system surrounding it.

True reliability demands application-specific formulation. This requires rigorous analysis of the operating environment—peak temperature excursions, pressure cycles, fluid compatibility spectrum, and flange dynamics—to tailor the resin chemistry, fiber treatment, and consolidation parameters. Suzhou Baoshida Trading Co., Ltd. leverages proprietary compounding expertise and OEM collaboration to develop aramid gasket materials where the binder system actively complements the fiber, enhancing interfacial adhesion and thermal stability. The result is a cohesive composite that maintains structural integrity and sealing force under extreme conditions where generic alternatives degrade rapidly. Material selection must be an engineered solution, not a catalog number.

The following table illustrates critical performance differentiators between generic and engineered aramid gasket materials under standardized test conditions (ASTM F36, F146):

| Material Type | Compression Set @ 200°C (24h) | Chemical Resistance (Conc. H₂SO₄, 150°C) | Tensile Strength (MPa) | Key Failure Mechanism in Service |

|---|---|---|---|---|

| Standard Nitrile Gasket | >60% | Poor (Severe Swelling) | 12-18 | Extrusion, Rapid Compression Set |

| Generic Aramid Blend | 25-35% | Moderate (Surface Degradation) | 20-25 | Fiber-Resin Debonding, Creep |

| Baoshida Custom Formulated | <15% | Excellent (Minimal Change) | 32-38 | Sustained Seal Integrity |

This data underscores that off-the-shelf aramid gaskets, while superior to basic elastomers, lack the tailored material science required for critical sealing. Only through precise engineering of the composite system can the full potential of aramid fibers be realized, preventing costly field failures and ensuring operational continuity. Material selection is the cornerstone of reliable sealing performance.

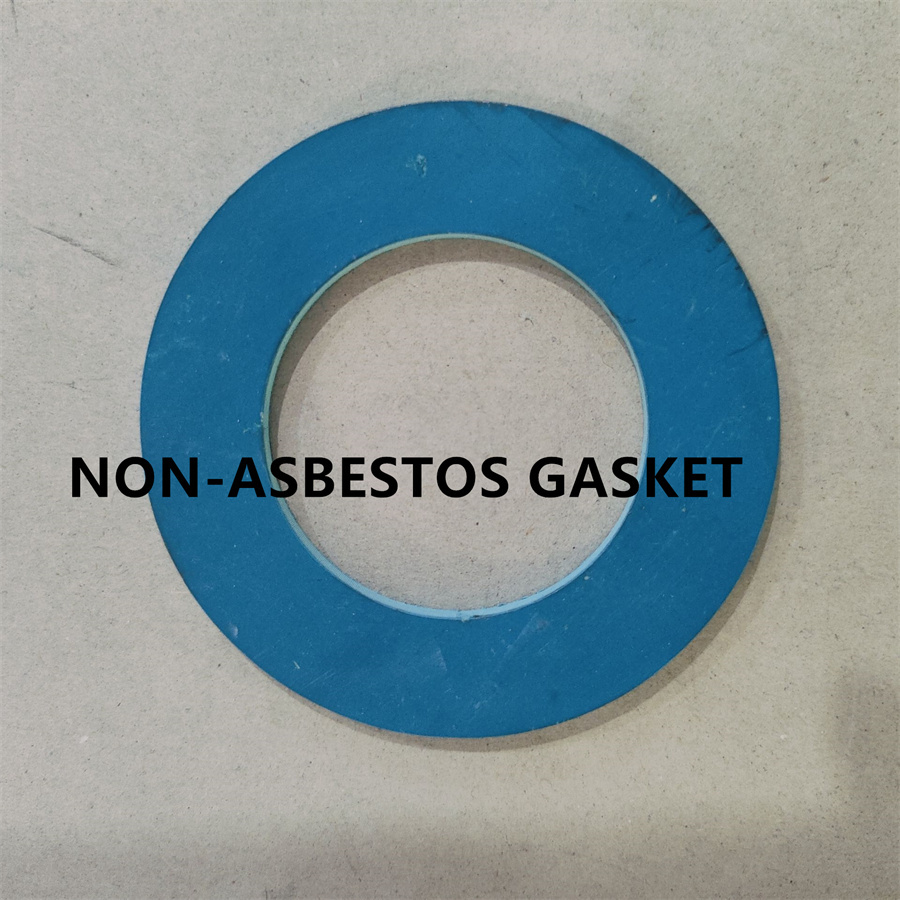

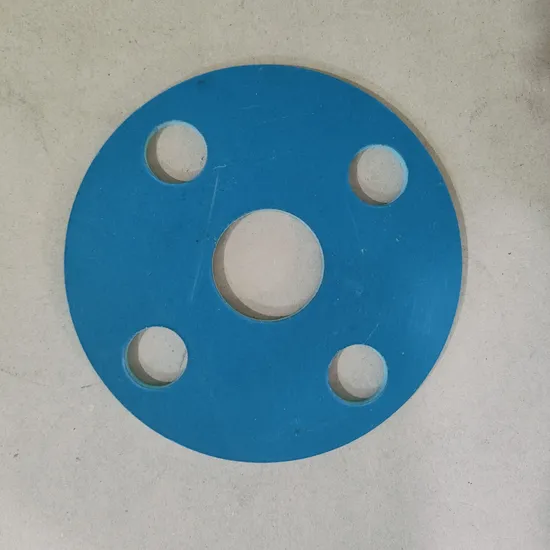

Material Specifications

Aramid gasket materials are engineered composites designed to deliver exceptional mechanical strength, thermal stability, and chemical resistance in demanding industrial sealing applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals that integrate high-performance aramid fibers with advanced elastomeric matrices. Our formulations combine aramid reinforcement with Viton, Nitrile (NBR), and Silicone rubber systems to produce gasket materials tailored for extreme environments in automotive, aerospace, petrochemical, and power generation sectors.

Aramid fibers, known for their high tensile strength and thermal degradation resistance above 500°C, serve as the structural backbone of these composites. When combined with elastomers such as Viton, Nitrile, or Silicone, the resulting gasket materials exhibit superior compression resistance, creep stability, and long-term sealing integrity. The elastomer phase determines the chemical compatibility and operational temperature range, while the aramid reinforcement enhances durability under high stress and cyclic loading.

Viton-based aramid gasket materials offer the broadest chemical resistance, particularly against hydrocarbons, chlorinated solvents, and strong acids. They perform reliably across a temperature range of -20°C to +250°C, with intermittent exposure up to 300°C. These materials are ideal for refinery, chemical processing, and high-temperature engine applications.

Nitrile aramid composites provide excellent resistance to oils, fuels, and hydraulic fluids, making them suitable for automotive and industrial hydraulic systems. With an operating range of -30°C to +120°C (up to +150°C intermittently), NBR-based gaskets balance cost-efficiency with robust performance in oil-rich environments.

Silicone aramid gasket materials excel in extreme temperature applications, functioning from -60°C to +230°C. While offering moderate resistance to oils and solvents, they provide outstanding performance in HVAC, food processing, and medical equipment where thermal stability and low toxicity are critical.

All three material systems are manufactured under strict quality control standards, ensuring consistent fiber dispersion, density, and thickness tolerance (±0.1 mm). Our aramid gasket materials are available in sheets, rolls, and die-cut forms, compliant with ASTM F104, F152, and ISO 2230 standards.

The following table summarizes key technical specifications for aramid gasket materials using Viton, Nitrile, and Silicone elastomers.

| Property | Viton-Aramid | Nitrile-Aramid | Silicone-Aramid |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 (300 intermittent) | -30 to +120 (+150 intermittent) | -60 to +230 |

| Tensile Strength (MPa) | ≥25 | ≥20 | ≥12 |

| Hardness (Shore A) | 85 ± 5 | 80 ± 5 | 75 ± 5 |

| Compression Set (%) @22h, 200°C | ≤25 | ≤30 | ≤20 |

| Specific Gravity | 1.75 | 1.60 | 1.55 |

| Fluid Resistance | Excellent (acids, oils, solvents) | Excellent (oils, fuels) | Good (water, ozone) |

| Applications | Petrochemical, refineries, engines | Automotive, hydraulics | HVAC, medical, food |

Each formulation is optimized for targeted performance metrics, enabling OEMs and industrial clients to select the ideal aramid gasket material based on operational stressors and regulatory requirements.

Manufacturing Capabilities

Engineering Excellence in Aramid-Reinforced Gasket Material Development

Suzhou Baoshida Trading Co., Ltd. leverages deep scientific expertise in polymer science and precision manufacturing to deliver mission-critical aramid fiber-reinforced rubber gasket materials. Our core strength resides in the integrated capabilities of our dedicated engineering teams, specifically structured to address the complex demands of high-performance sealing applications. We maintain a specialized unit comprising five certified Mold Engineers and two advanced Formula Engineers, operating synergistically within our Precision Rubber Seals division. This configuration ensures rigorous control from molecular compound design through to final part production.

Our Formula Engineers possess extensive experience in elastomer chemistry, focusing exclusively on optimizing aramid fiber dispersion, polymer matrix selection, and crosslinking systems for extreme environments. They meticulously formulate compounds balancing critical properties: thermal stability, chemical resistance, compressive recovery, and creep resistance. This molecular-level control is non-negotiable for gaskets operating under high pressure, aggressive media, or wide temperature excursions. Concurrently, our Mold Engineering team applies precision tooling science to translate these advanced compounds into flawless physical components. They manage cavity design, flow dynamics, cure kinetics, and dimensional tolerancing to exacting OEM specifications, eliminating defects like flash, voids, or inconsistent density that compromise seal integrity.

This dual-engineer framework is fundamental to our OEM partnership model. We do not merely manufacture to drawings; we co-engineer solutions. Clients provide application parameters – media, temperature, pressure cycles, flange type – and our teams collaboratively develop the optimal material formulation and production process. This integrated approach minimizes prototyping iterations, accelerates time-to-market, and guarantees the final gasket performs reliably under real-world stress. Our facility supports full-scale OEM production with stringent in-process quality control, including continuous monitoring of rheological properties, hardness, and dimensional conformance per ISO 3301 and customer-specific PPAP requirements.

The resulting aramid-reinforced gasket materials exhibit superior performance characteristics essential for demanding industrial sectors. Key technical specifications consistently achieved include:

| Property | Typical Value Range | Test Standard |

|---|---|---|

| Temperature Resistance | -50°C to +300°C | ASTM D2240 |

| Maximum Operating Pressure | 70 MPa (10,000 PSI) | ASTM F38 |

| Hardness (Shore A) | 65 – 90 | ASTM D1414 |

| Tensile Strength | ≥ 15 MPa | ASTM D412 |

| Elongation at Break | ≥ 200% | ASTM D412 |

| Compression Set (22h/200°C) | ≤ 35% | ASTM D395 Method B |

| Fluid Resistance (IRM 903) | Volume Swell ≤ 25% | ASTM D471 |

Suzhou Baoshida’s engineering capability transcends standard manufacturing. It represents a closed-loop system where material science insight directly informs precision production, ensuring every aramid gasket material shipment meets the uncompromising reliability standards demanded by global industrial leaders. Partner with us for engineered sealing solutions where failure is not an option.

Customization Process

Customization Process for Aramid Gasket Material at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., the customization of aramid gasket materials follows a systematic engineering approach designed to meet the stringent demands of industrial sealing applications. Our process ensures material integrity, dimensional accuracy, and long-term performance under extreme thermal, chemical, and mechanical conditions. The workflow begins with drawing analysis and progresses through formulation development, prototyping, and final mass production.

The first phase, drawing analysis, involves a detailed technical review of customer-supplied engineering drawings or CAD models. Our engineering team evaluates critical dimensions, surface finish requirements, flange compatibility, and operational environment parameters. This stage includes tolerance verification, joint configuration assessment, and identification of potential stress points. Accurate interpretation of these inputs ensures that the final gasket will perform reliably under compression, vibration, and cyclic loading.

Following drawing validation, our Rubber Formula Engineers initiate the formulation phase. Aramid fibers are combined with high-performance elastomers such as nitrile (NBR), hydrogenated nitrile (HNBR), or fluorocarbon (FKM), depending on the required resistance to temperature, oil, or aggressive chemicals. The fiber loading, crosslink density, and filler composition are precisely adjusted to achieve optimal tensile strength, compression set resistance, and thermal stability. Each formulation is documented and archived for traceability and batch consistency.

Once the compound is finalized, we proceed to prototyping. Small-batch samples are manufactured using precision die-cutting or waterjet cutting methods, depending on geometry complexity. Prototypes undergo rigorous in-house testing, including compression deformation, seal integrity under pressure, and exposure to simulated service environments. Dimensional inspection is performed using calibrated measuring instruments to confirm conformance to drawing specifications. Customer feedback is integrated at this stage to refine design or material choices before full-scale production.

The final phase is mass production, executed in our ISO-certified manufacturing facility with strict quality control protocols. Raw material batches are tested upon receipt, and process parameters—such as mixing time, curing temperature, and pressure—are continuously monitored. Every production batch is subjected to final inspection, including visual checks, thickness measurement, and hardness testing. All gaskets are packaged to prevent deformation and labeled with batch numbers for full traceability.

The following table outlines typical physical and mechanical properties of our standard aramid-reinforced gasket compounds:

| Property | Test Method | NBR/Aramid | HNBR/Aramid | FKM/Aramid |

|---|---|---|---|---|

| Tensile Strength (MPa) | ASTM D412 | ≥18 | ≥20 | ≥15 |

| Elongation at Break (%) | ASTM D412 | ≥200 | ≥180 | ≥150 |

| Hardness (Shore A) | ASTM D2240 | 60–90 | 70–90 | 70–90 |

| Compression Set (22h, 150°C) | ASTM D395 | ≤35% | ≤30% | ≤25% |

| Operating Temperature Range (°C) | — | -40 to +150 | -40 to +180 | -20 to +230 |

| Fluid Resistance | ASTM D471 | Excellent (oil/fuel) | Superior (hot oil) | Outstanding (chemicals) |

This structured customization process enables Suzhou Baoshida to deliver aramid gasket solutions tailored to the exact needs of OEMs and industrial clients, ensuring reliability, repeatability, and compliance with international sealing standards.

Contact Engineering Team

Optimizing Sealing Performance with Advanced Aramid Gasket Solutions

Industrial sealing applications operating under extreme thermal cycling, aggressive chemical exposure, or high-pressure differentials demand materials engineered beyond conventional elastomers. Aramid fiber-reinforced gasket composites deliver exceptional dimensional stability, tensile strength, and resistance to compression set—critical factors in maintaining leak-tight integrity across refinery hydrocrackers, chemical reactor vessels, and power generation turbine systems. At Suzhou Baoshida Trading Co., Ltd., we specialize in formulating precision aramid gasket materials tailored to your operational parameters, leveraging proprietary resin matrices and fiber orientation techniques to eliminate premature failure modes. Our ISO 9001-certified manufacturing process ensures batch-to-batch consistency, with raw material traceability from polymer synthesis through final sheet calendaring.

The following technical specifications represent our standard high-performance aramid gasket formulation. Custom modifications for specialized media compatibility or mechanical load profiles are developed through our application engineering workflow:

| Property | Test Method | Value |

|---|---|---|

| Base Material Composition | ASTM D2000 | Aramid fiber/PTFE/nitrile blend |

| Continuous Service Temperature | ASTM D573 | -54°C to +260°C |

| Maximum Pressure Rating | EN 1514-1 | 250 bar @ 200°C |

| Tensile Strength | ASTM D412 | ≥ 18 MPa |

| Compression Recovery (25% def.) | ASTM F36 | ≥ 65% |

| Fluid Resistance (10% H₂SO₄) | ASTM D471 | < 8% volume swell |

| Thickness Tolerance | ISO 2768 | ±0.05 mm |

These metrics reflect our commitment to exceeding OEM sealing requirements where carbonization, extrusion, or chemical degradation compromise standard alternatives. Our R&D team collaborates directly with client engineering departments to validate material performance against actual service conditions—conducting accelerated aging tests in simulated process streams and finite element analysis for flange stress distribution. This proactive validation prevents field failures and extends maintenance intervals, directly impacting your total cost of ownership.

Suzhou Baoshida operates as your strategic OEM partner for mission-critical sealing systems, not merely a component supplier. We integrate seamlessly into your supply chain with JIT delivery protocols, co-branded packaging options, and dedicated technical support for installation troubleshooting. Our global logistics network ensures 15-day lead times for custom formulations while maintaining rigorous QC checkpoints at our Suzhou production facility.

Initiate your sealing optimization project by contacting Mr. Boyce, our Lead Application Engineer, who will coordinate material sampling, performance benchmarking, and joint development agreements. Provide your flange specifications, media composition, and thermal profile to receive a tailored technical proposal within 72 hours. Direct all engineering inquiries and purchase requisitions to [email protected] with subject line “Aramid Gasket Technical Query – [Your Company Name]”. Mr. Boyce will facilitate cross-functional alignment between your design team and our compounding specialists, ensuring seamless transition from prototype validation to serial production. For urgent field failure analysis, include “EMERGENCY SUPPORT” in your email subject to trigger our 4-hour response protocol. Partner with Suzhou Baoshida to transform sealing reliability from a maintenance cost center into a competitive advantage.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).