Technical Contents

Engineering Guide: Metro Mold

Engineering Insight: Material Selection in Custom Molded Rubber Parts for metro mold Applications

In the precision-driven world of custom molded rubber components, particularly within metro mold manufacturing, material selection is not merely a design consideration—it is a foundational engineering decision that directly impacts performance, durability, and total cost of ownership. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf rubber solutions frequently fail in demanding metro mold environments due to their generic formulation, which lacks the tailored response to thermal, chemical, and mechanical stressors inherent in industrial applications.

Metro mold systems operate under rigorous conditions: high cycle rates, exposure to oils and solvents, fluctuating temperatures, and stringent dimensional tolerances. Standard elastomers such as generic NBR or SBR may appear cost-effective initially but often degrade prematurely when subjected to these conditions. For instance, a standard nitrile compound might exhibit adequate tensile strength at room temperature but suffer rapid compression set and hardening when exposed to continuous heat above 100°C—a common scenario in molding cycles. This degradation leads to part failure, increased downtime, and higher replacement costs, ultimately negating any initial savings.

The failure of off-the-shelf materials stems from their one-size-fits-all approach. These compounds are optimized for broad market appeal, not for the specific dynamic loads, media exposure, or longevity requirements of metro mold tooling. In contrast, engineered rubber compounds—such as hydrogenated nitrile (HNBR), fluorocarbon (FKM), or specially formulated silicone blends—are selected and compounded to meet exact operational parameters. For example, FKM offers exceptional resistance to high temperatures and aggressive chemicals, making it ideal for sealing elements in hot-runner systems, while HNBR provides superior mechanical strength and ozone resistance for dynamic molding components.

At Suzhou Baoshida, we collaborate with OEMs to analyze the complete application environment—temperature profile, media exposure, cycle frequency, and mechanical stress—before recommending a material. This data-driven approach ensures that the selected elastomer not only performs under peak load but also maintains integrity over thousands of cycles.

Below is a comparison of common elastomers used in metro mold applications, highlighting key performance characteristics:

| Material | Temperature Range (°C) | Hardness (Shore A) | Tensile Strength (MPa) | Key Resistance Properties |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +100 | 60–90 | 15–20 | Oil, fuel, water |

| HNBR (Hydrogenated Nitrile) | -40 to +150 | 70–90 | 25–35 | Heat, oil, ozone, abrasion |

| FKM (Fluorocarbon) | -20 to +200 | 60–90 | 12–18 | High heat, chemicals, oils |

| Silicone (VMQ) | -60 to +180 | 40–80 | 6–10 | Extreme temperature, UV |

| EPDM | -50 to +135 | 50–80 | 14–22 | Steam, water, ozone |

Material selection is not a compromise between cost and performance—it is a strategic alignment of chemistry, physics, and application engineering. Choosing the right elastomer ensures metro mold systems operate with maximum efficiency, minimal maintenance, and extended service life.

Material Specifications

Material Specifications for Precision Metro Mold Applications

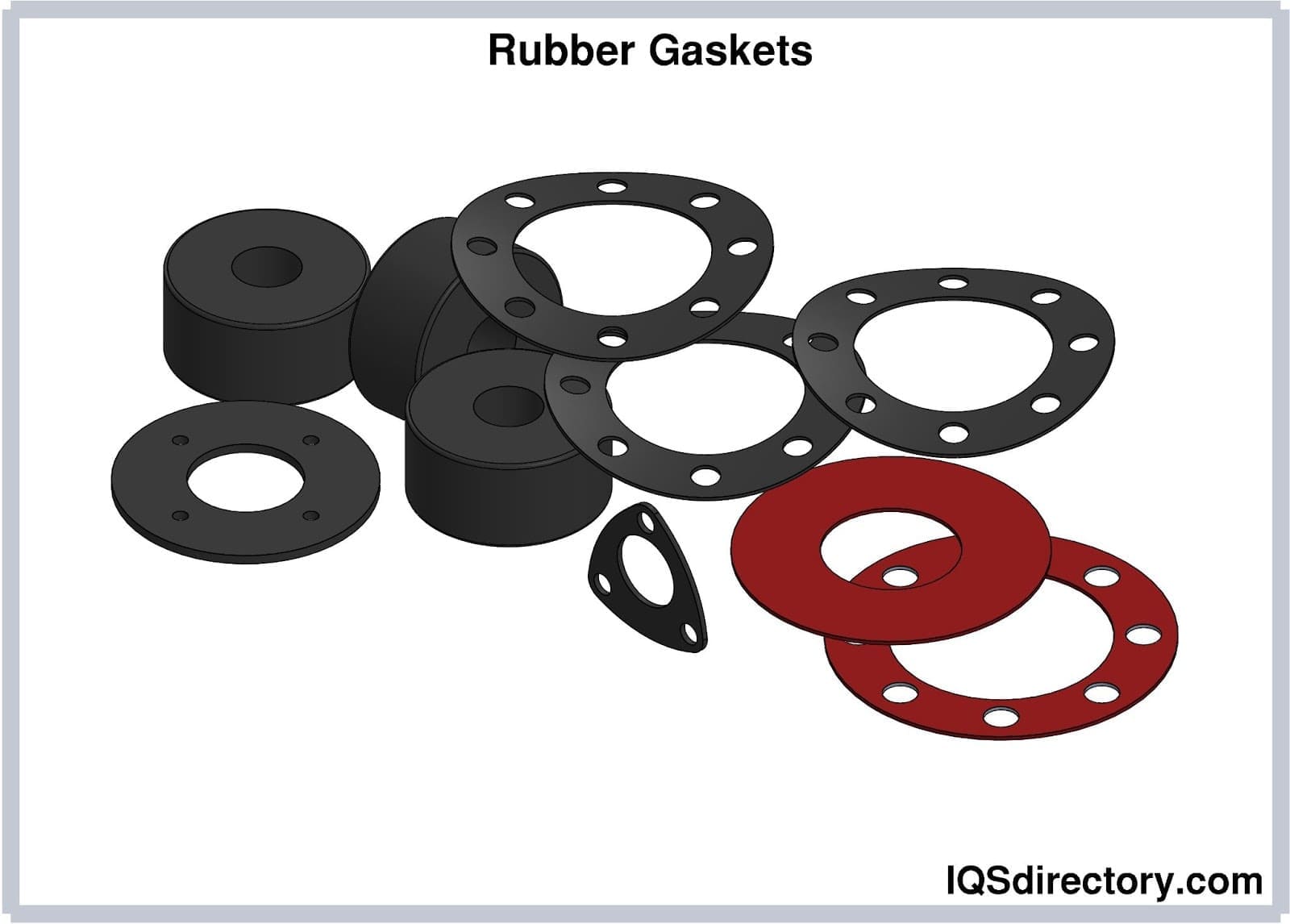

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions for metro mold manufacturing, where dimensional accuracy, chemical resistance, and thermal stability are non-negotiable. Metro molds demand materials that maintain integrity under repeated cycling, stringent tolerances, and exposure to aggressive media. Our formulations for Viton, Nitrile, and Silicone are rigorously validated per ASTM D2000 and ISO 37 standards to ensure zero-defect performance in critical sealing, gasketing, and component applications.

Viton fluorocarbon rubber (FKM) excels in extreme environments requiring resistance to high temperatures, fuels, and corrosive chemicals. With a fluorine content of 66%, it withstands continuous exposure up to 230°C and intermittent peaks of 300°C. Its low gas permeability and exceptional resistance to aromatic hydrocarbons, acids, and steam make it ideal for aerospace fuel systems, semiconductor processing seals, and automotive turbocharger gaskets. Compression set values remain below 20% after 70 hours at 200°C, ensuring long-term sealing force retention.

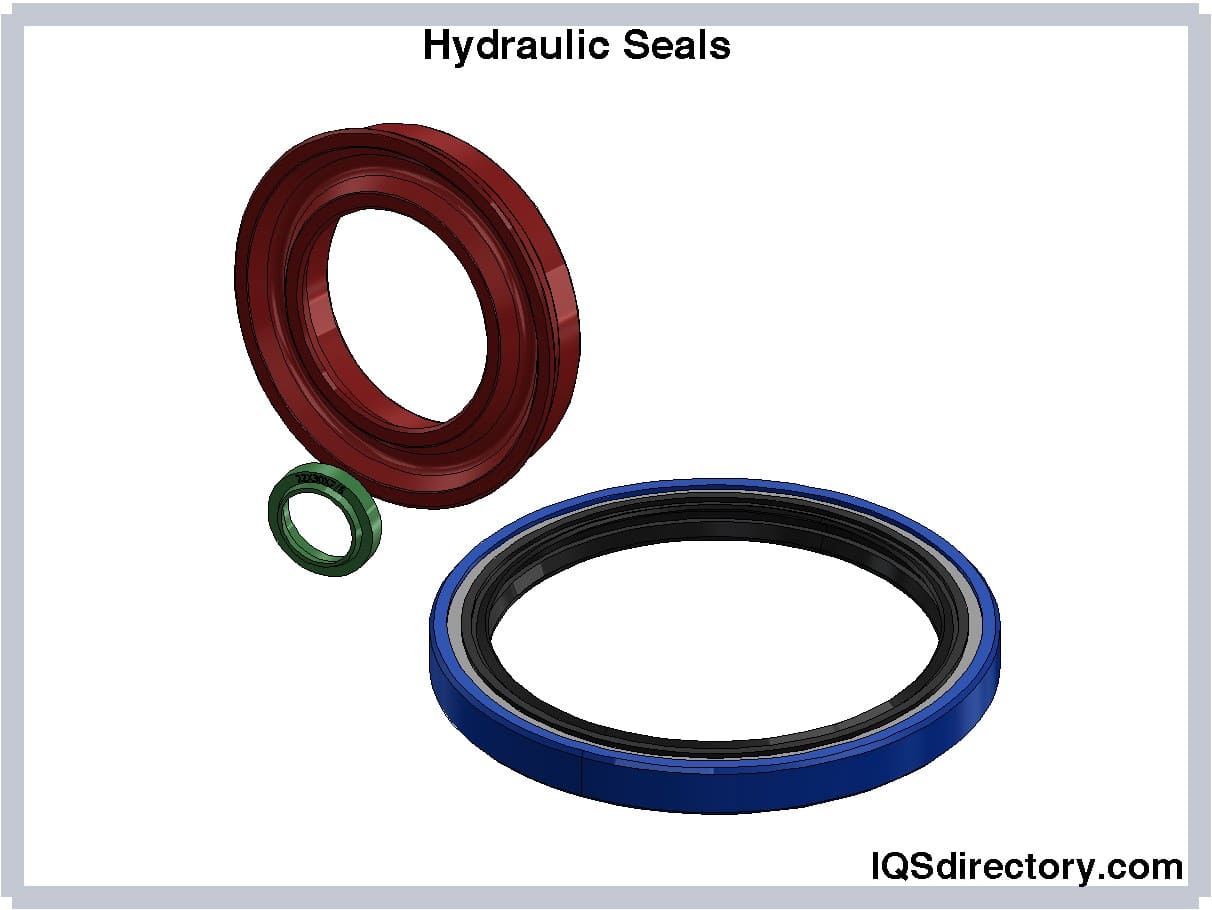

Nitrile butadiene rubber (NBR) offers optimal cost-performance balance for oil and fuel resistance in moderate-temperature settings. Hardness ranges from 40 to 90 Shore A, with formulations achieving 100% tensile elongation at -30°C. Standard grades resist aliphatic hydrocarbons, hydraulic fluids, and greases up to 120°C, while hydrogenated NBR (HNBR) extends this to 150°C with superior ozone and abrasion resistance. This material is preferred for automotive O-rings, fuel injector seals, and industrial hydraulic components where swelling in mineral oils must not exceed 15% per ASTM D471.

Silicone rubber (VMQ) provides unmatched flexibility across -60°C to 200°C, with specialty grades functioning at 230°C. Its inertness, biocompatibility per USP Class VI, and resistance to UV/ozone degradation suit medical device molding, food processing seals, and high-voltage insulation. Compression set is maintained below 25% after 22 hours at 150°C, critical for reusable medical connectors. Platinum-cured variants eliminate peroxide residues, meeting FDA 21 CFR 177.2600 for direct food contact.

The comparative specifications below guide material selection based on operational parameters:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness Range (Shore A) | 50–90 | 40–90 | 30–80 |

| Continuous Temp Range | -20°C to +230°C | -40°C to +120°C | -60°C to +200°C |

| Key Chemical Resistance | Aromatics, acids, steam | Aliphatic oils, fuels | Water, ozone, UV |

| Critical Limitation | Poor ketone resistance | Limited high-temp stability | Low tear strength |

| Primary Metro Mold Use | Semiconductor seals, jet engine gaskets | Fuel system O-rings, hydraulic seals | Medical tubing, food-grade gaskets |

Material selection directly impacts metro mold cycle life and part consistency. Suzhou Baoshida’s OEM engineering team conducts fluid immersion testing per SAE AS5528 and thermal aging per ISO 188 to validate compound suitability. We recommend Viton for >150°C chemical exposure, NBR for cost-sensitive oil applications below 120°C, and Silicone for biocompatible or extreme low-temperature requirements. All formulations undergo 100% lot traceability and dimensional validation to ISO 3302-1 M1 tolerances, ensuring seamless integration into your precision manufacturing process.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our custom molded rubber parts manufacturing, ensuring precision, reliability, and full compliance with OEM specifications. Our technical team comprises five dedicated mold engineers and two specialized rubber formula engineers, enabling end-to-end control from concept to production. This integrated engineering approach allows us to deliver high-performance rubber components tailored to the exact mechanical, thermal, and chemical requirements of diverse industrial applications.

Our mold engineers bring extensive experience in designing and optimizing rubber compression, transfer, and injection molds. Utilizing advanced CAD/CAM software including SolidWorks, AutoCAD, and UG NX, they develop robust mold designs that ensure dimensional accuracy, part consistency, and extended tool life. Finite Element Analysis (FEA) is routinely applied to simulate mold flow, predict part deformation, and optimize gating and venting systems—minimizing defects such as flash, incomplete fill, or internal voids. With a focus on manufacturability, our engineers collaborate closely with clients during the Design for Manufacturability (DFM) phase to refine part geometry, material selection, and tolerance specifications.

Complementing our mold design expertise, our two in-house rubber formulation engineers possess deep knowledge of elastomer chemistry and compounding. They develop custom rubber formulations tailored to specific performance demands, including resistance to oil, ozone, high temperatures, and dynamic stress. By formulating and testing proprietary compounds in our on-site lab, we ensure consistent material behavior across batches and full traceability of raw ingredients. This capability is critical for industries such as automotive, aerospace, medical devices, and industrial sealing, where material performance directly impacts product reliability.

Our OEM capabilities are built on a foundation of technical agility and strict quality control. We support low-volume prototyping through high-volume production, maintaining full documentation in accordance with ISO 9001 standards. All molds are manufactured using hardened tool steels with precision machining to ±0.02 mm tolerances, ensuring long service life and repeatable part quality. Secondary operations such as trimming, surface treatment, and assembly are integrated into our production workflow, reducing lead times and logistics complexity for our clients.

Through the synergy of mold design and material science, Suzhou Baoshida delivers engineered rubber solutions that meet the most demanding OEM requirements.

| Specification | Detail |

|---|---|

| Mold Engineers | 5 (specialized in rubber molding processes) |

| Formula Engineers | 2 (elastomer chemistry and compounding) |

| Design Software | SolidWorks, AutoCAD, UG NX |

| Mold Tolerance | ±0.02 mm |

| Mold Materials | H13, P20, 420SS, SKD61 |

| Molding Processes | Compression, Transfer, Injection |

| Material Testing | Hardness, Tensile Strength, Compression Set, Aging Resistance |

| Quality Standards | ISO 9001 compliant, full batch traceability |

| Secondary Operations | Automated trimming, surface coating, assembly |

Customization Process

Customization Process for Metro Mold Rubber Components

Suzhou Baoshida Trading Co., Ltd. executes a rigorous four-phase customization workflow for metro rail rubber components, ensuring precision alignment with OEM operational demands and safety standards. This structured approach mitigates risk while optimizing performance in high-stress transit environments.

Drawing Analysis initiates the process, where our engineering team conducts comprehensive GD&T validation against ISO 2768-mK tolerances. Critical dimensions, surface finishes, and material callouts undergo cross-referencing with metro-specific requirements such as EN 45545 fire resistance and UIC 606-2 vibration damping criteria. Finite element analysis (FEA) simulations predict deformation under dynamic loads, while mold flow studies identify potential knit lines or air traps. This phase culminates in a formal Drawing Compliance Report, resolving ambiguities before material selection.

Formulation leverages Suzhou Baoshida’s proprietary compound database, tailoring elastomer chemistry to metro operational extremes. Base polymers are engineered for specific failure modes: EPDM for ozone resistance in exterior seals, NBR for oil exposure in undercarriage components, and silicone for fire-retardant interior gaskets. Key properties like Shore A hardness (55–85 range), tensile strength (≥12 MPa), and compression set (<25% at 70°C) are precisely controlled through filler dispersion and cure kinetics optimization. The table below illustrates critical material-performance relationships:

| Material Type | Key Properties | Metro Application Fit |

|---|---|---|

| Peroxide-Cured EPDM | -45°C low-temp flexibility, 120°C continuous service, UL94 V-0 flame rating | Door seals, window gaskets requiring weather/ozone resistance |

| Hydrogenated NBR (HNBR) | 150°C heat resistance, 80% oil swell resistance, 20 MPa tensile strength | Coupling boots, suspension bushings in engine compartments |

| Silicone Rubber | -60°C flexibility, 200°C intermittent service, low smoke toxicity | Emergency exit seals, interior trim meeting EN 45545-2 HL3 |

Prototyping employs rapid steel molds with conformal cooling channels, producing ISO 37 test specimens and functional assemblies for OEM validation. Parts undergo accelerated life testing per ASTM D2240 (hardness), ISO 3384 (compression set), and SAE J2236 (dynamic fatigue). Dimensional verification via CMM (0.005mm accuracy) ensures geometric conformity, while material certificates trace raw batch origins. Iterative adjustments occur within 72 hours of test failure identification.

Mass Production transitions validated prototypes into high-volume manufacturing under ISO 9001 and IATF 16949 controls. Statistical Process Control (SPC) monitors critical parameters: cure time (±5 seconds), mold temperature (±2°C), and press tonnage (±1%). Each batch receives full material retest documentation, with traceability to polymer lot numbers and operator IDs. Final inspection includes 100% visual checks per AQL 1.0 and random destructive testing, guaranteeing zero-defect delivery for metro assembly lines. This end-to-end discipline ensures Suzhou Baoshida’s rubber components withstand 30+ years of cyclic stress in global transit networks.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Custom Molded Rubber Parts

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance, custom molded rubber components engineered to meet the exacting standards of industrial and manufacturing applications. Our expertise in rubber formulation, mold design, and precision manufacturing ensures that every part we produce aligns with your technical specifications and performance requirements. Whether you are sourcing seals, gaskets, diaphragms, or complex elastomeric components, our team is equipped to support your project from concept to completion.

For direct access to our engineering and OEM solutions team, we invite you to contact Mr. Boyce, our dedicated point of contact for custom rubber molding projects. With extensive experience in serving global industrial clients, Mr. Boyce provides technical guidance, material selection support, and rapid prototyping coordination to streamline your development cycle. Reach out via email at [email protected] to initiate a consultation, request a quote, or discuss your application-specific challenges.

Our facility integrates advanced metro mold techniques with rigorous quality control systems to ensure dimensional accuracy, repeatability, and material consistency across production runs. We support both low-volume prototyping and high-volume manufacturing, with the flexibility to accommodate fast turnaround times without compromising on precision.

To assist in your evaluation, the table below outlines our core technical capabilities and material processing parameters:

| Parameter | Specification |

|---|---|

| Material Types | Nitrile (NBR), EPDM, Silicone (VMQ), Fluorocarbon (FKM), Natural Rubber (NR), Neoprene (CR), SBR, HNBR |

| Hardness Range (Shore A) | 30 to 90 |

| Tolerance Standards | ±0.1 mm (critical dimensions), ISO 3302 Class M2 |

| Maximum Mold Size | 600 mm × 600 mm × 300 mm |

| Maximum Part Weight | 2.5 kg |

| Production Processes | Compression Molding, Transfer Molding, Injection Molding |

| Secondary Operations | Flash Trimming, Surface Treatment, Assembly, Packaging |

| Quality Certifications | ISO 9001:2015 compliant processes |

| Lead Time (Prototype) | 15–20 days after design approval |

| Lead Time (Mass Production) | 25–35 days after sample confirmation |

We understand that reliability, consistency, and technical precision are non-negotiable in industrial environments. That’s why Suzhou Baoshida maintains strict process controls, in-house tooling design, and material traceability throughout production. Our engineering team collaborates closely with clients to optimize part geometry, select the most suitable elastomer compound, and validate performance under real-world conditions.

Initiate your next custom rubber molding project with confidence. Contact Mr. Boyce today at [email protected] to leverage Suzhou Baoshida’s technical expertise, advanced manufacturing infrastructure, and commitment to industrial excellence.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).