Technical Contents

Engineering Guide: Fridge Door Gasket Seal

Engineering Insight: Material Selection in Refrigerator Door Gasket Seals

The refrigerator door gasket seal is a deceptively simple component with a complex engineering mandate. Its primary function—maintaining an airtight thermal barrier between the refrigerated compartment and ambient environment—is critical to energy efficiency, temperature stability, and overall appliance longevity. Despite its unassuming appearance, the performance of this elastomeric component is heavily dependent on precise material selection. Off-the-shelf rubber profiles, while economically attractive in the short term, often fail to meet the multifaceted demands of modern refrigeration systems, leading to premature degradation, increased energy consumption, and customer dissatisfaction.

Material failure in gasket seals typically stems from inadequate resistance to environmental stressors. Refrigerator doors undergo repeated compression cycles, exposure to wide temperature fluctuations (from -30°C to +70°C), contact with food-grade surfaces, and prolonged UV exposure in display units. Standard rubber compounds such as generic EPDM or low-grade silicone lack the tailored formulation required to endure these conditions. For instance, improper durometer (hardness) can result in insufficient sealing force or excessive door closing effort. Likewise, poor compression set resistance leads to permanent deformation, creating micro-gaps that compromise thermal integrity.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered elastomer solutions specifically formulated for refrigeration applications. Our preferred base polymer is high-purity, peroxide-cured EPDM, selected for its superior ozone resistance, thermal stability, and low-temperature flexibility. This compound maintains elasticity over extended service life and resists hardening or cracking—a common failure mode in acetal-rich environments. Additionally, we incorporate FDA-compliant additives to ensure safety in food storage applications and optimize surface finish to reduce friction during door closure.

A critical differentiator lies in the customization of physical properties. Unlike mass-produced gaskets, our formulations are adjusted based on OEM specifications, including door weight, frequency of operation, and target climate class (e.g., SN, N, ST, T). This precision engineering ensures optimal sealing performance across diverse operational conditions.

The following table outlines key material specifications for high-performance refrigerator door gaskets compared to standard off-the-shelf alternatives:

| Property | High-Performance EPDM (Baoshida) | Standard Off-the-Shelf EPDM |

|---|---|---|

| Hardness (Shore A) | 60 ± 5 | 50–70 (inconsistent) |

| Tensile Strength (MPa) | ≥ 9.0 | 5.0–7.0 |

| Elongation at Break (%) | ≥ 400 | 250–350 |

| Compression Set (22 hrs, 70°C) | ≤ 20% | 30–50% |

| Low-Temperature Flexibility | -50°C (no cracking) | -30°C (cracking observed) |

| Ozone Resistance (200 pphm) | No cracks after 96 hrs | Cracking within 48 hrs |

| FDA/NSF Compliance | Yes | Often unverified |

In conclusion, the refrigerator door gasket is not a commodity item but a precision-engineered component. Material selection directly impacts reliability, regulatory compliance, and end-user satisfaction. Off-the-shelf solutions, lacking in consistency and performance tailoring, are ill-suited for high-demand refrigeration environments. At Baoshida, we deliver application-specific rubber seals that meet the rigorous standards of global OEMs, ensuring long-term performance and energy efficiency.

Material Specifications

Material Specifications for Refrigerator Door Gasket Seals

Precise material selection is critical for refrigerator door gasket seals, directly impacting energy efficiency, longevity, and compliance with food safety standards. The seal must maintain consistent compression force across operational temperatures (-40°C to 60°C ambient), resist degradation from refrigerants and cleaning agents, and exhibit minimal compression set to prevent air leakage. At Suzhou Baoshida Trading Co., Ltd., we rigorously qualify three elastomers for OEM applications: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct performance profiles aligned with specific use cases, from household units to commercial walk-in coolers.

Viton (FKM) delivers exceptional chemical and thermal stability, making it ideal for seals exposed to aggressive refrigerants like R134a or commercial environments with frequent sanitizer contact. Its fluorocarbon structure resists swelling in oils and hydrocarbons, with continuous service up to 230°C. However, its high cost and limited low-temperature flexibility (-20°C minimum) restrict use to premium or specialized units. Viton formulations require precise peroxide curing to achieve optimal compression set resistance below 20% (ASTM D395).

Nitrile (NBR) remains the industry standard for cost-optimized household refrigerator seals. It provides balanced resistance to water, fats, and aliphatic hydrocarbons at temperatures ranging from -40°C to 120°C. Standard NBR compounds (70 Shore A hardness) achieve 15–25 MPa tensile strength and 200–300% elongation, ensuring reliable door closure force retention. Limitations include vulnerability to ozone cracking and reduced performance with aromatic refrigerants. Baoshida’s hydrogenated NBR (HNBR) variants extend service life by improving heat and ozone resistance.

Silicone (VMQ) excels in extreme low-temperature applications (-60°C) and offers unmatched biocompatibility for medical-grade refrigeration. Its wide thermal range (-60°C to 200°C) and inherent flame resistance suit specialized units but come with trade-offs: lower tensile strength (4–12 MPa), poor tear resistance, and susceptibility to compression set in dynamic sealing scenarios. Silicone’s hydrophobic nature minimizes mold adhesion but requires reinforcement for high-cycle door mechanisms.

Material Performance Comparison for Refrigerator Gasket Seals

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -40 to 120 | -60 to 200 |

| Hardness Range (Shore A) | 70–80 | 60–75 | 50–70 |

| Tensile Strength (MPa) | 10–18 | 15–25 | 4–12 |

| Elongation at Break (%) | 150–300 | 200–350 | 200–600 |

| Key Resistance | Refrigerants, Oils | Water, Fats | Low Temp, Biocompatibility |

OEM selection must balance operational demands against lifecycle costs. Viton suits high-exposure commercial systems despite premium pricing. NBR dominates mass-market production due to its robust cost-performance ratio. Silicone addresses niche ultra-low-temperature or medical requirements but demands design adaptations for mechanical durability. Suzhou Baoshida Trading Co., Ltd. provides material-specific compression set data (per ISO 815) and accelerated aging reports to validate seal integrity over 10+ years of service. Partner with our engineering team to optimize compound formulations for your specific refrigerant, door torque, and regulatory requirements.

Manufacturing Capabilities

Engineering Capability: Precision Design and Material Science for Refrigerator Door Gasket Seals

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation in the precision rubber seals industry. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver technically advanced, performance-optimized refrigerator door gasket seals tailored to OEM requirements. Our integrated approach combines material science, precision tooling, and rigorous testing to ensure every product meets exacting standards for durability, sealing efficiency, and long-term performance under variable thermal and mechanical conditions.

Our rubber formula engineers possess deep expertise in elastomer chemistry, focusing specifically on thermoset materials such as EPDM and silicone—both widely used in refrigeration applications due to their excellent heat resistance, low compression set, and resilience across temperature ranges from -40°C to +120°C. These engineers formulate custom rubber compounds that balance hardness (typically 55–70 Shore A), tensile strength, and elastic recovery to ensure optimal sealing force without excessive door closure effort. Additive integration—including UV stabilizers, anti-aging agents, and antimicrobial modifiers—further enhances product longevity and hygiene compliance, critical in food storage environments.

Parallel to material development, our five mould engineers specialize in the design and optimization of complex multi-cavity compression, transfer, and injection moulds. Utilizing CAD/CAM software (SolidWorks, AutoCAD, and Moldflow), they develop precision tooling that ensures dimensional accuracy, uniform material flow, and minimal flash formation. This enables consistent production of gaskets with tight tolerances (±0.2 mm), critical for achieving airtight seals on refrigerator doors. Our in-house tooling capability reduces lead times and allows rapid prototyping, supporting clients through NPI (New Product Introduction) phases with agility.

We operate as a full-service OEM partner, offering end-to-end solutions from concept validation to mass production. Our engineering team collaborates directly with OEMs to interpret performance specifications, conduct DFM (Design for Manufacturability) reviews, and perform iterative prototyping. Each design is validated through environmental cycling tests, compression set analysis, and leak testing under simulated real-world conditions.

The table below summarizes key technical parameters we routinely achieve in refrigerator door gasket production:

| Parameter | Typical Value / Range | Test Standard |

|---|---|---|

| Material Type | EPDM, Silicone, Custom Compounds | ASTM D2000 |

| Hardness (Shore A) | 55–70 | ASTM D2240 |

| Tensile Strength | ≥7 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (22 hrs, 70°C) | ≤20% | ASTM D395 |

| Operating Temperature Range | -40°C to +120°C | ISO 1817 |

| Dimensional Tolerance | ±0.2 mm | ISO 2768 |

| Cycle Life (Dynamic Testing) | >50,000 cycles | Internal Specification |

This synergy of material innovation and precision engineering enables Suzhou Baoshida to deliver refrigerator door gasket seals that exceed industry benchmarks. Our OEM-focused model ensures scalability, consistency, and technical alignment with global appliance manufacturers’ quality and sustainability goals.

Customization Process

Customization Process for Refrigeration Door Gasket Seals

At Suzhou Baoshida Trading Co., Ltd., our customization process for refrigerator door gasket seals integrates rigorous engineering protocols to ensure optimal performance, longevity, and regulatory compliance. This systematic approach minimizes prototyping iterations and accelerates time-to-market for OEM partners.

Drawing Analysis

The process initiates with comprehensive technical drawing evaluation. Our engineering team scrutinizes dimensional tolerances per ISO 2768-mK, sealing surface geometry, and critical stress points such as corner radii and hinge zones. Finite Element Analysis (FEA) simulates compression behavior under operational loads (typically 0.8–1.2 N/mm linear force) to preempt deformation risks. Material compatibility with refrigerants (R-600a, R-134a) and surface contaminants (oils, sanitizers) is cross-referenced against ASTM D2000 standards. Any deviations from manufacturable tolerances (e.g., ±0.15 mm for extrusion profiles) are flagged for collaborative redesign.

Formulation Development

Based on thermal, chemical, and mechanical requirements, our rubber chemists formulate proprietary EPDM or fluorosilicone compounds. Key parameters include:

| Specification | Standard Requirement | Baoshida Performance Target | Test Method |

|---|---|---|---|

| Hardness (Shore A) | 55–65 | 60 ± 2 | ISO 7619-1 |

| Compression Set (70°C/24h) | ≤35% | ≤22% | ISO 3384 |

| Low-Temperature Flex | -40°C | -50°C | ISO 1432 |

| Tensile Strength | ≥7.5 MPa | ≥9.0 MPa | ISO 37 |

| Fluid Resistance (R600a) | Volume Swell ≤25% | Volume Swell ≤15% | ISO 1817 |

Accelerated aging tests (1000h at 100°C) validate ozone resistance and thermal stability. Formulations are optimized for extrusion efficiency, targeting 0.5 phr peroxide cure systems to eliminate scorch risks during high-speed production.

Prototyping & Validation

Precision extruded prototypes undergo multi-stage validation. Dimensional conformity is verified via CMM (Coordinate Measuring Machine) against 3D CAD models. Functional testing includes:

Seal force measurement using calibrated load cells to ensure consistent door closure energy (3–5 J/m)

Vacuum retention tests simulating 10,000 open/close cycles per ISO 10137

Climate chamber exposure (-30°C to +70°C) with infrared thermography to detect micro-leaks

Adhesion strength validation between rubber and metal insert (≥1.5 kN/m)

Client feedback on prototype performance triggers iterative compound or profile adjustments within 15 working days.

Mass Production

Approved designs transition to ISO/TS 16949-certified production lines. Continuous inline monitoring tracks extrusion temperature (±2°C tolerance), cure state (Mooney viscosity stability), and dimensional drift via laser micrometers. Each batch undergoes first-article inspection and quarterly full-material certification. Statistical Process Control (SPC) with CpK ≥1.33 guarantees batch-to-batch consistency, while automated vision systems reject defects exceeding 0.3 mm surface irregularities. Final gaskets are packaged in humidity-controlled environments to prevent pre-installation degradation.

This end-to-end workflow ensures gaskets achieve >15-year service life with <0.5% field failure rates, directly supporting OEMs’ energy efficiency targets and warranty cost reduction. Suzhou Baoshida’s engineering-led customization eliminates guesswork, transforming technical specifications into precision-engineered sealing solutions.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Refrigerator Door Gasket Seals

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of precision rubber engineering, specializing in high-performance sealing solutions for the home appliance industry. As a trusted OEM partner for global manufacturers, we deliver engineered rubber gasket seals that meet exact thermal, mechanical, and durability requirements. Our expertise in EPDM, silicone, and thermoplastic vulcanizate (TPV) formulations ensures consistent performance across millions of refrigerator door cycles under real-world refrigeration conditions.

For technical collaboration on refrigerator door gasket seals, we invite direct engagement with our lead Rubber Formula Engineer and OEM Manager, Mr. Boyce. With over 15 years of experience in elastomer development and industrial sealing applications, Mr. Boyce leads material selection, compression set optimization, low-temperature flexibility tuning, and aging resistance protocols tailored to your appliance specifications. Whether you require custom durometer ratings, enhanced ozone resistance, or compliance with food-grade safety standards such as FDA 21 CFR 177.2600 and RoHS, our team delivers validated rubber formulations backed by rigorous quality control.

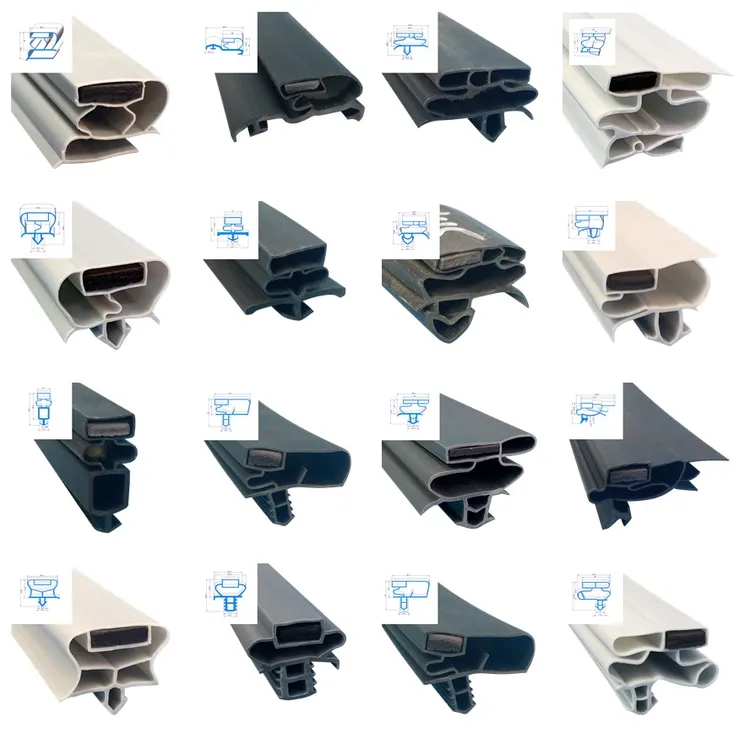

Our manufacturing process integrates precision extrusion, continuous vulcanization (CV), and automated splicing techniques to produce seamless, dimensionally stable gaskets with repeatable performance. Every batch undergoes dynamic compression testing, thermal cycling analysis (-40°C to +80°C), and leak rate validation to ensure airtight integrity over extended service life. We support both standard and custom cross-sectional profiles, including D-shape, hollow bulb, and multi-rib designs, optimized for energy efficiency and door closure torque.

To initiate a technical consultation or request sample submissions, contact Mr. Boyce directly at [email protected]. Include your product specifications, volume requirements, and performance targets to receive a tailored material proposal within 48 hours. We support NDA-protected development cycles and offer on-site technical audits upon request.

Below are key technical specifications for our standard refrigerator door gasket materials:

| Property | EPDM 70 Shore A | Silicone 60 Shore A | TPV 55 Shore A |

|---|---|---|---|

| Hardness (Shore A) | 70 ± 5 | 60 ± 5 | 55 ± 5 |

| Tensile Strength | ≥ 9.5 MPa | ≥ 6.0 MPa | ≥ 8.0 MPa |

| Elongation at Break | ≥ 350% | ≥ 400% | ≥ 380% |

| Compression Set (22h, 70°C) | ≤ 25% | ≤ 20% | ≤ 30% |

| Low-Temp Flexibility | -45°C (pass) | -60°C (pass) | -40°C (pass) |

| Heat Aging (150°C, 72h) | Retains >80% properties | Retains >85% properties | Retains >75% properties |

| Ozone Resistance | Excellent | Excellent | Good |

| FDA Compliant | Yes (on request) | Yes | Yes (on request) |

Partner with Suzhou Baoshida to elevate your refrigeration sealing performance through science-driven elastomer solutions. Reach out today to begin engineering with precision.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).