Technical Contents

Engineering Guide: Welcome Matt

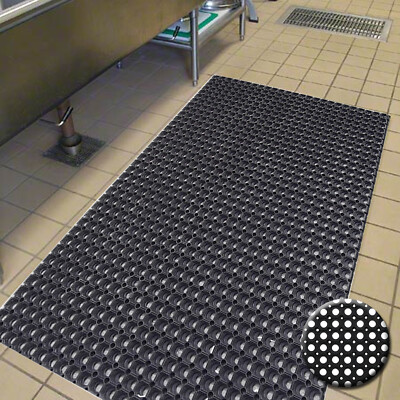

Engineering Insight: Industrial Welcome Mat Material Selection

Material selection constitutes the foundational determinant of performance and longevity in industrial welcome mat applications. Generic off-the-shelf mats frequently fail under commercial and industrial conditions due to inadequate polymer formulation and filler systems. These products typically utilize recycled rubber compounds with inconsistent vulcanization and insufficient additive packages. Consequently, they exhibit rapid degradation when exposed to concentrated pedestrian traffic, environmental stressors, and facility-specific contaminants. The core issue lies in the misalignment between standardized material properties and the dynamic operational demands of high-traffic zones such as manufacturing plants, logistics centers, and chemical processing facilities.

Standard mats suffer from three critical failure modes. First, insufficient abrasion resistance leads to premature surface erosion under repetitive footfall from safety boots with aggressive treads, exposing underlying substrates within months. Second, poor compression set resistance causes permanent deformation, eliminating the mat’s ability to trap dirt and moisture. Third, inadequate chemical resistance results in swelling, cracking, or dissolution when exposed to oils, solvents, or cleaning agents common in industrial settings. These failures compromise safety by creating slip hazards and increasing facility maintenance costs due to frequent replacement cycles.

Suzhou Baoshida Trading Co., Ltd. addresses these challenges through OEM-engineered rubber compounds tailored to client-specific environmental stressors. Our formulations integrate high-purity SBR or EPDM polymers with precisely calibrated silica-carbon black hybrid fillers, advanced anti-degradants, and custom crosslinking systems. This approach ensures optimal balance between resilience, contaminant entrapment, and chemical inertness. Below is a comparative analysis of material performance metrics:

| Property | Standard Mat Compound | Baoshida Engineered Mat | Performance Impact |

|---|---|---|---|

| Abrasion Loss (DIN 53516) | 220 mm³ | 75 mm³ | 66% longer service life under heavy foot traffic |

| Compression Set (ASTM D395) | 48% | 18% | Maintains structural integrity for >5 years |

| Oil Swell (IRM 903, 70°C) | 42% | 9% | Resists degradation in oil-contaminated zones |

| Shore A Hardness | 55 ± 5 | 68 ± 2 | Optimal dirt-trapping without compromising comfort |

The data underscores why material science cannot be compromised. Off-the-shelf solutions prioritize cost over functionality, utilizing batch-variable feedstocks that lack traceability and consistency. In contrast, Baoshida’s OEM process begins with facility audits to map stressors—foot traffic volume, contaminant profiles, and environmental exposure—then develops compounds meeting exact ASTM and ISO performance thresholds. This precision engineering eliminates the hidden costs of premature mat failure: reduced slip-and-fall incidents, lower replacement frequency, and sustained operational hygiene. For industrial clients, the initial investment in engineered rubber translates directly to lifecycle cost savings and risk mitigation. Material selection is not a commodity decision; it is the cornerstone of reliable facility infrastructure.

Material Specifications

Material Specifications for Industrial Rubber Solutions in Welcome Mat Manufacturing

In the production of industrial-grade welcome mats, material selection is critical to ensuring performance, durability, and resistance to environmental stressors. Suzhou Baoshida Trading Co., Ltd. specializes in high-performance rubber compounds tailored for demanding applications. Among the most widely used elastomers in our product line are Viton, Nitrile (NBR), and Silicone. Each material offers a distinct set of physical and chemical properties that make it suitable for specific operational environments. Understanding these differences allows OEMs and industrial buyers to make informed decisions based on temperature range, chemical exposure, mechanical stress, and longevity requirements.

Viton, a fluorocarbon-based rubber, is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capabilities up to 250°C, Viton is ideal for welcome mats deployed in industrial facilities, automotive workshops, or chemical processing plants where exposure to hydrocarbons and extreme heat is common. Its low gas permeability and excellent aging characteristics further enhance reliability in harsh conditions. However, Viton is typically more expensive than other elastomers, making it a strategic choice for high-performance applications rather than general use.

Nitrile rubber, or Buna-N, is one of the most cost-effective and widely used synthetic rubbers in industrial applications. It exhibits excellent resistance to petroleum-based oils, greases, and water, making it well-suited for environments where fluid spillage is frequent. With an operational temperature range of -30°C to 120°C, Nitrile provides a balanced combination of flexibility and durability under moderate thermal stress. It is particularly effective in manufacturing welcome mats for mechanical workshops, garages, and light industrial zones. While not as heat-resistant as Viton or as flexible at low temperatures as Silicone, Nitrile remains a preferred option due to its robust mechanical strength and abrasion resistance.

Silicone rubber excels in extreme temperature environments, offering serviceability from -60°C to 230°C. It is highly resistant to UV radiation, ozone, and weathering, making it ideal for outdoor or semi-outdoor entryway applications. Silicone is also non-toxic and complies with stringent health and safety standards, allowing use in sensitive environments such as food processing facilities or cleanrooms. While it has lower tensile strength and abrasion resistance compared to Nitrile, its thermal stability and aesthetic consistency over time make it a premium choice for high-end commercial installations.

The following table provides a comparative overview of key physical and chemical properties for these materials:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Cost Level | High | Low to Medium | Medium to High |

Selecting the appropriate elastomer requires alignment with the intended service environment. Suzhou Baoshida Trading Co., Ltd. supports OEM partners with material testing, formulation customization, and technical data documentation to ensure optimal performance in every application.

Manufacturing Capabilities

Engineering Capabilities: Precision Rubber Manufacturing for Industrial Welcome Mats

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated team of 5 specialized mould engineers and 2 advanced formula engineers to deliver engineered rubber solutions for high-performance welcome mats. Our integrated approach ensures material science and precision tooling converge to meet rigorous industrial demands, from chemical resistance in commercial entrances to extreme-temperature durability in manufacturing facilities. Unlike generic suppliers, our engineers collaborate from initial concept through production, eliminating compatibility gaps between compound design and mould functionality.

Mould engineering expertise focuses on optimizing cavity pressure distribution, venting efficiency, and thermal management during vulcanization. This prevents flash formation, ensures consistent Shore A hardness across complex tread patterns, and extends tool life beyond 500,000 cycles. Our engineers utilize Moldflow simulation to preempt sink marks in deep-relief logos and adjust ejector pin placement for zero surface blemishes—critical for mats requiring antimicrobial surface finishes.

Formula engineering drives material innovation for targeted performance. We develop proprietary EPDM and SBR blends that balance resilience, slip resistance, and cost efficiency. Each compound undergoes accelerated aging tests per ASTM D573 and DIN 53508 to validate 10,000+ hour UV stability and non-marking properties on sensitive flooring. Our formula team tailors abrasion resistance (measured via DIN 53516) to specific client environments, whether automotive showrooms requiring low-soil-retention compounds or airports needing high-wear zones at entry points.

The synergy between these disciplines enables unmatched OEM scalability. We manage full technical documentation, including PPAP Level 3 submissions, and maintain ISO 9001-certified process validation protocols. Clients receive real-time cavity pressure monitoring data during production runs and material traceability down to batch-level per ASTM D3182.

Below outlines key technical differentiators of our custom compounds versus standard industry offerings:

| Property | Standard Compound | Baoshida Custom Compound | OEM Advantage |

|---|---|---|---|

| Hardness Range (Shore A) | 55–70 ± 3 | 45–85 ± 0.5 | Precision tolerance for ADA-compliant slip resistance |

| Temp Resistance | -20°C to +80°C | -40°C to +120°C | Operational stability in freezer warehouses or desert climates |

| Abrasion Loss (mm³) | ≤ 180 | ≤ 95 | 2X lifespan in high-traffic zones |

| Compression Set (22h/70°C) | ≤ 25% | ≤ 12% | Sustained rebound resilience after heavy rolling loads |

| Customization Lead Time | 8–12 weeks | 4–6 weeks | Accelerated time-to-market with dual-engineer sign-off |

This engineering integration allows us to solve complex client challenges, such as formulating oil-resistant compounds for automotive dealerships that maintain colorfastness after 500+ degreaser exposures. Our OEM framework supports volume scalability from 5,000 to 500,000 units monthly with zero tooling requalification costs, backed by in-house metrology labs for real-time dimensional validation. Partner with Baoshida to transform welcome mat specifications into engineered performance assets.

Customization Process

Customization Process for Industrial Rubber Welcome Mats

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet precise functional and environmental demands. The customization process for welcome mats begins with a comprehensive drawing analysis, ensuring dimensional accuracy, load-bearing requirements, and integration with installation environments. Our engineering team evaluates client-submitted technical drawings, focusing on critical parameters such as thickness tolerance (±0.5 mm), edge profile, surface texture, and anchoring mechanisms. This initial phase identifies potential design constraints and aligns the product with OEM specifications or architectural integration needs.

Following drawing validation, we proceed to rubber formulation—a core competency in our manufacturing ecosystem. The compound is tailored based on operational conditions including temperature range, abrasion resistance, chemical exposure, and compliance standards (e.g., ISO 1817, ASTM D412). We primarily utilize SBR, EPDM, or NBR base polymers, reinforced with carbon black or silica, and compounded with anti-aging agents, plasticizers, and vulcanizing systems. Hardness is adjusted between 50–75 Shore A to balance flexibility and durability. For outdoor applications, UV stabilizers and ozone resistance modifiers are incorporated to extend service life. Each formulation is documented and archived for batch consistency and traceability.

Prototyping follows formulation finalization. Using precision molds fabricated in-house, we produce functional prototypes within 7–10 working days. These samples undergo rigorous mechanical and environmental testing, including tensile strength, compression set, slip resistance (DIN 51130), and accelerated aging. Clients receive test reports alongside physical samples for field evaluation. Feedback is integrated iteratively, with design or material adjustments made as necessary. This phase ensures performance validation under real-world conditions before committing to large-scale production.

Once approved, the project transitions to mass production. Our automated rubber compression molding lines operate under strict quality control protocols, including in-line dimensional checks and batch sampling. Production capacity supports volumes from 500 to over 50,000 units per month, with lead times averaging 25–35 days. All finished mats are inspected for surface defects, dimensional conformity, and marking compliance (e.g., CE, REACH). Packaging is customized per client logistics requirements, with options for palletization, stretch-wrapping, or labeled cartons.

Throughout the process, Suzhou Baoshida maintains full transparency via shared project dashboards and technical documentation, ensuring alignment from concept to delivery.

Material and Performance Specifications

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55–75 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤20% |

| Operating Temperature | — | -40°C to +100°C |

| Slip Resistance (R9) | DIN 51130 | Compliant |

| Density | ISO 2781 | 1.15–1.25 g/cm³ |

Contact Engineering Team

Contact Suzhou Baoshida Trading Co., Ltd. for Precision Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial manufacturing excellence. As your dedicated Rubber Formula Engineer and OEM Management partner, we specialize in transforming complex material requirements into high-performance rubber components for automotive, aerospace, industrial machinery, and specialized equipment sectors. Our engineering team leverages decades of compound formulation expertise, rigorous empirical validation protocols, and ISO 9001-certified production oversight to deliver solutions that meet stringent global standards. When material integrity, thermal resistance, or dynamic mechanical properties define your product’s success, our systematic approach ensures zero compromise on functional reliability.

Selecting Suzhou Baoshida means engaging a partner who prioritizes technical collaboration over transactional exchanges. We integrate seamlessly into your R&D and production workflows, providing full material traceability, accelerated prototyping cycles, and failure-mode analysis to preempt operational risks. Our OEM management framework includes co-engineering support for custom elastomer systems—from silicone and EPDM to specialty fluoroelastomers—ensuring your specifications translate into consistent, defect-free outputs. Unlike generic suppliers, we deploy finite element analysis (FEA) and accelerated life testing to validate performance under real-world stress conditions, reducing time-to-market while elevating product longevity.

Initiate your collaboration by contacting Mr. Boyce, our Lead Technical Account Manager, who serves as your single point of accountability for all engineering and supply chain requirements. Mr. Boyce holds an advanced degree in Polymer Engineering and 15 years of hands-on experience resolving critical rubber formulation challenges for Tier-1 industrial clients. He will coordinate immediate access to our material science team, production capacity schedules, and regulatory compliance documentation, including REACH, RoHS, and ASTM D2000 certifications. Direct technical dialogue with our engineers ensures your project’s nuances are addressed with scientific precision, not generic responses.

The following table outlines our strategic contact specifications for OEM partners:

| Specification Category | Suzhou Baoshida Standard | Industry Average |

|---|---|---|

| Technical Response Time | ≤ 4 business hours | 24–72 hours |

| Formula Iteration Cycles | 1–3 (validated) | 5–8 |

| Material Certification Depth | Full traceability to raw batch | Surface-level docs |

| Production Scalability | 5k–500k units/month | Variable |

| Failure Analysis Turnaround | ≤ 72 hours | 5–10 days |

To advance your rubber component project with engineering rigor, email Mr. Boyce directly at [email protected]. Include your material specification sheet, performance requirements, and target volume to receive a tailored technical proposal within one business day. Our team will schedule a confidential consultation to dissect your application’s mechanical, thermal, and chemical exposure parameters—no preliminary calls or forms required. For urgent prototyping needs, reference “ENGINEER RUSH” in your subject line to activate our 72-hour rapid-response protocol.

Suzhou Baoshida does not sell rubber; we engineer mission-critical material interfaces. Partner with us to convert material science into measurable operational advantage, backed by data-driven validation at every phase. Your next-generation rubber solution begins with a single, precise point of contact.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).