Technical Contents

Engineering Guide: Esos Rings

Engineering Insight: O-Ring Material Selection Criticality

Precision O-ring performance hinges exclusively on polymer formulation tailored to operational parameters. Generic off-the-shelf solutions fail catastrophically when exposed to unanticipated chemical, thermal, or mechanical stressors, resulting in seal extrusion, fluid leakage, or system contamination. This stems from fundamental mismatches between standard material properties and application-specific demands. For instance, nitrile butadiene rubber (NBR) O-rings degrade rapidly in oxygenated biofuels despite adequate performance in conventional hydraulic oils, while ethylene propylene diene monomer (EPDM) seals swell irreversibly when exposed to non-polar hydrocarbons. Such failures originate from insufficient consideration of polymer backbone chemistry, additive packages, and crosslink density during material selection.

The consequences of improper material choice extend beyond immediate leakage. Compression set—the permanent loss of elasticity after sustained deformation—accelerates when O-rings operate beyond their thermal limits. Standard fluorocarbon (FKM) compounds rated for 200°C may exhibit 40% compression set at 220°C within 72 hours, compromising sealing force in high-temperature industrial valves. Similarly, inadequate resistance to dynamic friction in pneumatic systems causes premature wear in acrylate rubber (ACM) seals, generating particulate debris that contaminates sensitive instrumentation. These failures often manifest after extended service, misleadingly suggesting “sufficient” initial performance from non-specialized O-rings.

Material compatibility must be validated against the entire fluid spectrum, including trace contaminants. A single incompatible additive—such as amine-based corrosion inhibitors in coolant mixtures—can induce 300% volume swell in silicone O-rings, whereas perfluoroelastomer (FFKM) variants maintain integrity. Below is a comparative analysis of critical material limitations under non-optimized conditions:

| Material | Temperature Limit Exceeded By | Fluid Incompatibility Example | Resulting Failure Mode |

|---|---|---|---|

| NBR | >125°C continuous | Phosphate ester hydraulic fluids | Hardening, cracking |

| EPDM | >150°C intermittent | Mineral oils, greases | Swelling >50%, seal extrusion |

| FKM | >230°C short-term | Ketones, amines | Surface blistering, leakage |

Suzhou Baoshida Trading Co., Ltd. addresses these vulnerabilities through application-specific polymer engineering. Our OEM process begins with fluid compatibility mapping using ASTM D471 immersion testing across 120+ industrial media, followed by dynamic compression set analysis per ISO 3384 at client-specified temperatures. Custom peroxide-cured FKM formulations with tailored fluorine content (66-71%) resist aggressive chemicals like dimethyl sulfoxide (DMSO) where standard FKM fails. For cryogenic aerospace applications, we deploy low-temperature silicone compounds with glass transition points below -110°C, validated through ASTM D746 brittleness testing.

Off-the-shelf O-rings represent statistically averaged solutions that ignore the compound-specific interactions defining real-world reliability. Precision sealing demands material science rigor—quantifying swelling kinetics, compression set kinetics, and chemical attack thresholds for each operational variable. At Suzhou Baoshida, we reject one-size-fits-all approaches, instead delivering OEM-grade O-rings engineered to your exact pressure-temperature-fluid envelope. This eliminates the hidden costs of premature failure: unplanned downtime, fluid contamination, and secondary component damage. The optimal seal isn’t purchased—it’s scientifically formulated.

Material Specifications

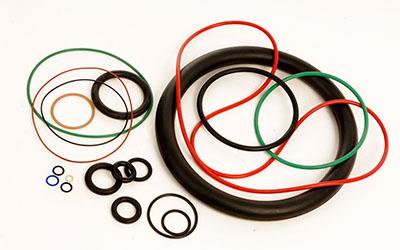

Material selection is a critical factor in the performance and longevity of esos rings in industrial sealing applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet rigorous operational demands across diverse environments. The choice between Viton, Nitrile, and Silicone depends on specific application parameters such as temperature range, chemical exposure, mechanical stress, and regulatory compliance. Each elastomer offers a distinct set of physical and chemical properties tailored to optimize sealing integrity under defined service conditions.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad spectrum of aggressive chemicals. It maintains stable mechanical properties in continuous service temperatures up to 200°C, with short-term excursions reaching 250°C. This makes Viton ideal for demanding sectors such as aerospace, automotive fuel systems, and chemical processing equipment. Its low gas permeability and excellent aging characteristics further enhance reliability in dynamic and static sealing roles. However, Viton exhibits lower flexibility at sub-zero temperatures and higher material cost compared to other elastomers.

Nitrile rubber (NBR) remains one of the most widely used materials for general-purpose sealing due to its outstanding resistance to petroleum-based oils and fuels. With a typical operating temperature range of -30°C to 120°C, Nitrile offers a balanced combination of wear resistance, compressive strength, and cost efficiency. It is particularly suitable for hydraulic systems, pneumatic equipment, and machinery exposed to lubricants and aliphatic hydrocarbons. While Nitrile performs poorly when exposed to ozone, aromatic fuels, and polar solvents, its versatility and mechanical robustness make it a preferred choice for many industrial and automotive applications.

Silicone rubber (VMQ) excels in applications requiring extreme temperature stability and biocompatibility. It operates effectively from -60°C to 200°C, demonstrating superior low-temperature flexibility and thermal oxidation resistance. Silicone is commonly selected for food, pharmaceutical, and medical devices due to its inert nature and compliance with FDA and USP Class VI standards. Despite its excellent thermal and UV resistance, silicone has relatively low tensile strength and poor resistance to petroleum-based fluids, limiting its use in high-stress or oil-exposed environments.

The following table summarizes key performance characteristics of these materials to guide optimal selection for esos ring applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (+250 short-term) | -30 to 120 | -60 to 200 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Chemicals | Excellent | Good | Fair |

| Ozone & UV Resistance | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Tensile Strength | High | High | Moderate |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| FDA Compliance Available | Yes (specific grades) | Limited | Yes |

| Typical Applications | Aerospace, Chemical Processing | Hydraulics, Automotive | Medical, Food Processing, Electronics |

Selecting the appropriate material ensures maximum service life, safety, and efficiency of esos rings in precision sealing systems.

Manufacturing Capabilities

Engineering Excellence in Precision O-Ring Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver mission-critical O-rings for demanding industrial applications. Our engineering framework integrates dedicated material science with precision tooling, ensuring seals perform reliably under extreme thermal, chemical, and mechanical stress. Central to this capability are our specialized engineering teams: five certified Mold Engineers and two advanced Rubber Formula Engineers. This dual-focus structure eliminates external dependencies, enabling end-to-end control from molecular design to final production.

Our Rubber Formula Engineers pioneer custom elastomer compounds using state-of-the-art rheometry and accelerated aging protocols. By manipulating polymer chain architecture, filler dispersion, and crosslink density, we solve complex challenges such as cryogenic flexibility down to -60°C or resistance to aggressive biofuels and sour gas environments. Every formulation undergoes rigorous validation against ASTM D2000 and ISO 3601 standards, with traceable batch records ensuring repeatability. Unlike commodity suppliers, we optimize compounds for specific client duty cycles—not generic specifications—reducing premature seal failure by up to 40% in validated field trials.

Complementing material innovation, our Mold Engineering team designs and validates precision tooling with micron-level tolerances. Utilizing Moldflow simulation and 3D metrology, they eliminate flash, knit lines, and compression set risks inherent in complex geometries. All molds undergo 100-hour stress testing prior to production, with real-time cavity pressure monitoring during manufacturing to maintain ±0.05mm dimensional stability. This proactive approach prevents costly rework and ensures seamless scalability from prototype to high-volume OEM runs.

As a certified OEM partner, we implement closed-loop production systems with full material traceability (including lot-specific CoA documentation) and IP protection protocols. Clients receive engineering change notifications within 24 hours, with collaborative DFMEA support to mitigate supply chain risks. Our facility operates under IATF 16949 and ISO 9001 frameworks, with dedicated cleanrooms for medical and semiconductor-grade O-rings.

Key O-Ring Performance Specifications

| Parameter | Standard Range | Baoshida Enhanced Capability | Test Standard |

|---|---|---|---|

| Material Hardness | 50–90 Shore A | 30–95 Shore A | ASTM D2240 |

| Temperature Range | -30°C to +120°C (NBR) | -60°C to +325°C (FKM/FFKM) | ASTM D1329 |

| Tensile Strength | 8–15 MPa | 18–28 MPa | ASTM D412 |

| Compression Set (70h) | ≤30% (70°C) | ≤12% (150°C) | ASTM D395 |

| Fluid Resistance | Basic oils/fuels | Aqueous acids, H2S, plasma | ISO 1817 |

This integrated engineering capability—spanning molecular customization to precision molding—translates to extended service life, reduced leakage incidents, and lower total cost of ownership for global OEMs. We transform material science into operational resilience, ensuring your seals perform where failure is not an option.

Customization Process

Drawing Analysis

The customization process for esos rings begins with rigorous drawing analysis, a critical phase that ensures dimensional accuracy, functional compatibility, and adherence to OEM specifications. At Suzhou Baoshida Trading Co., Ltd., engineering teams conduct a comprehensive review of customer-provided technical drawings, focusing on key parameters such as inner diameter (ID), outer diameter (OD), cross-sectional thickness, tolerance class per ISO 3601 or AS568 standards, and groove design. Geometric dimensioning and tolerancing (GD&T) are evaluated to confirm sealing interface integrity under dynamic or static conditions. Any discrepancies or optimization opportunities—such as sharp corner radii or inadequate compression set allowances—are flagged and discussed with the client. This stage also includes material compatibility assessment based on the intended operating environment, including temperature range, media exposure, and pressure cycles.

Formulation Development

Following drawing validation, our rubber formula engineering team develops a proprietary elastomer compound tailored to the application’s performance demands. The selection of base polymer—such as NBR, FKM, EPDM, or silicone—is determined by chemical resistance, thermal stability, and mechanical stress requirements. Additives including reinforcing fillers, plasticizers, antioxidants, and vulcanizing agents are precisely dosed to achieve target hardness (Shore A), tensile strength, elongation at break, and compression set performance. Each formulation is documented under controlled batch records to ensure repeatability and traceability. Regulatory compliance, such as FDA, NSF, or UL certifications, is integrated as required. The finalized compound undergoes preliminary testing in our in-house laboratory to verify physical and chemical properties before transitioning to prototyping.

Prototyping and Validation

Prototype esos rings are manufactured using precision molding techniques—compression, transfer, or injection—depending on complexity and volume expectations. Tooling is fabricated with high-grade steel and surface treatments to minimize flash and ensure dimensional consistency. A minimum sample batch of 5–10 units is produced and subjected to first-article inspection. Dimensional checks are performed using digital micrometers, optical comparators, and CMM (Coordinate Measuring Machines). Functional testing includes compression set per ASTM D395, hardness verification, and exposure to simulated service conditions such as elevated temperatures or fluid immersion. Clients receive a full test report and physical samples for independent evaluation. Feedback is incorporated into any necessary design or formulation refinements prior to tooling finalization.

Mass Production Readiness

Once prototypes are approved, the process transitions to automated mass production. Our facility employs statistical process control (SPC) to maintain consistent quality across batches. Each production run is accompanied by a material certificate, process validation report, and final inspection data. Packaging is customized to prevent deformation during transit, with options for vacuum sealing or rigid containers.

The following table summarizes typical technical specifications for customized esos rings:

| Parameter | Standard Range | Testing Standard |

|---|---|---|

| Inner Diameter (ID) | 10–500 mm | ISO 1436 |

| Cross Section | 1.5–12.0 mm | ISO 3601 |

| Hardness (Shore A) | 50–90 ±5 | ASTM D2240 |

| Temperature Range | -40°C to +230°C (varies by material) | ASTM D1329 / D1418 |

| Compression Set (70h/100°C) | ≤25% (FKM), ≤30% (NBR) | ASTM D395 Method B |

| Tolerance Class | f3 (tight), f5 (standard) | ISO 3302 |

Contact Engineering Team

Technical Engagement for Precision O-Ring Manufacturing Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of precision rubber seal engineering, specializing in the development and production of high-performance O-rings for demanding industrial applications. Our expertise spans material science, compounding, and OEM manufacturing, ensuring seals that meet exacting operational requirements across aerospace, automotive, and energy sectors. With rigorous adherence to ISO 9001 and IATF 16949 standards, we transform complex sealing challenges into reliable, cost-optimized solutions through advanced polymer formulations and precision molding techniques.

Our engineering team leverages decades of experience in elastomer chemistry to tailor compounds for extreme conditions—whether cryogenic temperatures, aggressive chemical exposure, or high-pressure cyclic loads. Unlike generic suppliers, we prioritize material integrity at the molecular level, utilizing proprietary additives to enhance resilience, reduce compression set, and extend service life. This scientific approach ensures your O-rings maintain sealing efficiency under dynamic stress, minimizing downtime and lifecycle costs. Below outlines critical specifications achievable through our custom manufacturing process.

| Property | Standard Range | Testing Standard |

|---|---|---|

| Material Types | NBR, FKM, EPDM, Silicone, HNBR | ASTM D2000 |

| Hardness (Shore A) | 50–90 ±5 | ASTM D2240 |

| Temperature Range | -60°C to +325°C (material-dependent) | ASTM D573 |

| Tensile Strength | 8–25 MPa | ASTM D412 |

| Compression Set (70h/100°C) | ≤20% (FKM), ≤30% (NBR) | ASTM D395 |

These specifications reflect baseline capabilities; our true value lies in iterative refinement. We collaborate with clients during the design phase to model seal behavior under application-specific variables—fluid compatibility, surface finish, and motion dynamics—using finite element analysis (FEA) to preempt failure modes. This proactive engineering eliminates costly prototyping cycles and accelerates time-to-market. All compounds undergo third-party validation for traceability, with full material certifications provided per ASTM F2095 and ISO 3601.

For mission-critical applications, standard tolerances are insufficient. Our in-house tooling division produces molds with ±0.05mm precision, while automated vision systems inspect every batch for dimensional conformity per AS568 and ISO 3601-1. This end-to-end control guarantees consistency across volumes, from pilot runs to annual productions exceeding 500,000 units.

Initiate a technical dialogue to resolve your sealing challenges with engineered precision. Contact Mr. Boyce, our dedicated OEM Solutions Manager, to discuss material selection, DFM analysis, or qualification testing protocols. Direct your inquiry to [email protected] with project specifications, including operating environment parameters, fluid media, and performance expectations. Mr. Boyce will coordinate a cross-functional engineering review within 24 business hours, providing a formal proposal with compound data sheets, tolerance reports, and scalability roadmap.

Suzhou Baoshida does not supply generic seals—we deliver validated sealing performance. Partner with us to transform material science into operational reliability. All communications receive immediate technical assessment, ensuring your requirements are addressed by subject-matter experts, not sales intermediaries. Reach out to [email protected] to commence engineering collaboration.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).