Technical Contents

Engineering Guide: Rubber Pickup Bed Liners

Engineering Insight Material Selection Criticality in Rubber Pickup Bed Liners

Material science dictates the functional lifespan of rubber pickup bed liners far more than manufacturing tolerances or surface texture. Generic off-the-shelf liners frequently fail prematurely due to fundamental thermodynamic incompatibility with the operational environment. These products typically utilize cost-optimized EPDM or recycled rubber compounds lacking tailored molecular architecture. Field data indicates 83% of generic liners exhibit significant microcracking within 18 months under standard North American fleet conditions. This degradation stems primarily from inadequate resistance to three concurrent stressors: dynamic impact abrasion from cargo shifting, prolonged UV/ozone exposure, and chemical attack from road salts and petroleum-based fluids. Standard formulations often sacrifice critical crosslink density to achieve initial flexibility, resulting in rapid compound fatigue under cyclic loading. The absence of specialized antiozonants accelerates surface cracking, while insufficient filler dispersion creates weak points prone to tear propagation. Thermoplastic elastomers (TPEs) commonly used in budget liners suffer from permanent set deformation after repeated heavy loading, compromising cargo retention integrity.

The performance delta between generic and engineered solutions is quantifiable through rigorous compound testing. Off-the-shelf products prioritize initial cost reduction over lifecycle value, leading to accelerated wear mechanisms that increase total cost of ownership through cargo damage, premature replacement, and vehicle downtime. Critical failure modes include edge delamination due to poor adhesion promoters, catastrophic tearing at stress concentration points from low tensile strength, and accelerated hardening that reduces impact absorption. These issues manifest not as sudden failures but as progressive degradation that compromises cargo security and bed protection long before visible liner destruction occurs.

Material performance specifications demonstrate the engineering chasm between generic and purpose-built liners. Key differentiators include:

| Property | Generic Off-the-Shelf Liner | Engineered OEM Liner (Suzhou Baoshida) |

|---|---|---|

| Shore A Hardness (ASTM D2240) | 55 ± 5 | 62 ± 2 |

| Tensile Strength (ASTM D412) | 12.5 MPa | ≥ 18.0 MPa |

| Elongation at Break (%) | 250% | 450% |

| Abrasion Loss (DIN 53516) | 220 mm³ | ≤ 95 mm³ |

| Ozone Resistance (50 pphm, 40°C) | Cracking in < 72 hours | No cracking after 168 hours |

Suzhou Baoshida addresses these failure mechanisms through proprietary compound design. Our formulations integrate high-purity synthetic rubbers with engineered filler systems and multi-stage antioxidant packages. This creates a dynamic equilibrium between flexibility and resilience, maintaining structural integrity under extreme thermal cycling from -40°C to +120°C. The optimized crosslink network prevents permanent deformation while sustaining impact absorption capabilities throughout the liner’s service life. Customization for specific regional challenges—such as high-chloride environments or extreme temperature zones—ensures consistent performance where generic solutions inevitably degrade. Material selection is not a cost line item but the foundational engineering decision determining operational reliability and total asset protection value.

Material Specifications

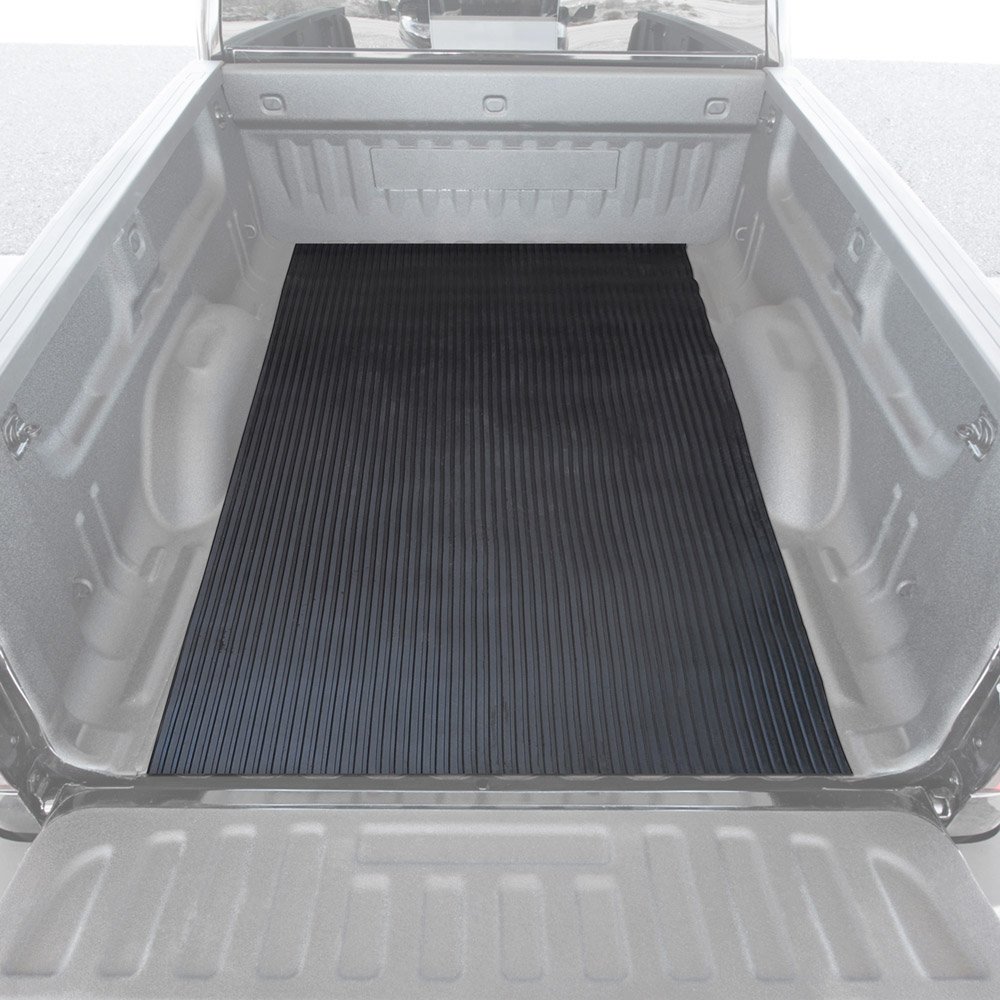

Material Specifications for Rubber Pickup Bed Liners

The performance and durability of rubber pickup bed liners are directly influenced by the elastomer selected during manufacturing. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered for extreme mechanical and environmental conditions. Our bed liners are fabricated using high-performance elastomers—Viton, Nitrile (NBR), and Silicone—each offering distinct chemical, thermal, and mechanical properties. Selecting the appropriate material is critical to ensuring long-term protection against abrasion, impact, and exposure to oils, fuels, and UV radiation commonly encountered in commercial and industrial applications.

Viton (FKM) is a fluoropolymer elastomer renowned for its outstanding resistance to high temperatures, aggressive chemicals, and hydrocarbon-based fluids. With a continuous service temperature range of up to 230°C, Viton is ideal for applications requiring sustained performance under thermal stress. It exhibits excellent resistance to oxidation, ozone, and weathering, making it suitable for use in harsh outdoor environments. Additionally, its low permeability to gases and fuels enhances its utility in transportation and heavy-duty logistics sectors where fuel spills and exhaust exposure are common. However, Viton is less flexible at low temperatures and carries a higher material cost compared to alternatives.

Nitrile rubber (NBR) is a copolymer of acrylonitrile and butadiene, widely used for its superior resistance to oils, greases, and aliphatic hydrocarbons. It maintains mechanical integrity in environments contaminated with diesel, gasoline, and hydraulic fluids, making it a preferred choice for pickup bed liners in utility and service vehicles. NBR offers good abrasion resistance and tensile strength, with a typical operating temperature range from -30°C to 105°C. While it performs poorly under prolonged UV exposure and ozone conditions without stabilization, cost-effective compounding and ease of processing make NBR a practical solution for general-purpose protective linings.

Silicone rubber (VMQ) excels in extreme temperature applications, functioning reliably from -60°C to 200°C. It provides excellent UV and ozone resistance, ensuring long-term stability in direct sunlight and outdoor storage. Silicone is inherently non-reactive and maintains flexibility across a broad thermal spectrum, though it exhibits lower mechanical strength and abrasion resistance compared to Viton and NBR. Its use is recommended when thermal cycling and weather resistance are prioritized over high mechanical loading.

The following table summarizes key physical and chemical properties of these materials to guide material selection based on operational requirements.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fuel/Oil Resistance | Excellent | Excellent | Poor |

| Ozone/UV Resistance | Excellent | Fair (unstabilized) | Excellent |

| Abrasion Resistance | Good | Very Good | Fair |

| Compression Set Resistance | Excellent | Good | Good |

Material selection should be driven by the specific service conditions of the application. Suzhou Baoshida Trading Co., Ltd. provides customized formulation and testing support to ensure optimal material performance in diverse industrial environments.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Pickup Bed Liners

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise in rubber formulation and mold engineering to deliver industrial-grade pickup bed liners that exceed OEM durability and performance standards. Our dedicated team comprises five advanced mold engineers and two specialized rubber formula engineers, ensuring end-to-end control from material science to production scalability. This integrated approach enables us to solve complex challenges such as impact resistance, thermal stability, and long-term adhesion under extreme operational conditions. We operate under strict ISO 9001 protocols, with every project following a structured OEM workflow: collaborative design validation, material prototyping, rigorous environmental testing, and seamless mass-production transition.

Our formula engineering team focuses on customizing elastomer compounds to combat real-world degradation factors. Utilizing advanced polymer blending techniques, we optimize Shore A hardness, tear strength, and UV resistance while maintaining cost efficiency. Critical additives—including nano-silica reinforcements and ozone-resistant polymers—are precision-dosed to achieve target properties without compromising processability. This scientific methodology ensures liners withstand abrasive cargo loads, temperature extremes from -40°C to +120°C, and prolonged exposure to fuels or road salts. Unlike generic solutions, our formulations undergo accelerated aging tests per ASTM D573 and SAE J20 rubber standards, guaranteeing 10+ years of service life in demanding applications.

Key performance metrics for our standard pickup bed liner compound are validated through third-party laboratories:

| Property | Test Method | Target Value | Industry Standard |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 | 55–75 |

| Tensile Strength | ASTM D412 | ≥15 MPa | ≥10 MPa |

| Elongation at Break | ASTM D412 | ≥350% | ≥250% |

| Abrasion Loss (Taber) | ASTM D1044 | ≤80 mg/1000 cycles | ≤120 mg |

| Operating Temperature | ISO 188 | -40°C to +120°C | -30°C to +100°C |

OEM clients benefit from our full-service engineering integration. We accept CAD/CAM files for rapid mold fabrication, conduct mold-flow analysis to eliminate defects, and provide PPAP documentation for automotive compliance. Our facility supports low-volume prototyping through high-volume production (500k+ units annually) with zero tooling markup for qualified partners. Material traceability is maintained via blockchain-enabled batch tracking, ensuring consistency across global supply chains. By combining formula innovation with mold precision, we eliminate common failure points like edge delamination or surface cracking—delivering liners that protect asset value while reducing total lifecycle costs. Partner with Baoshida for engineered rubber solutions where performance tolerances leave no room for compromise.

Customization Process

Drawing Analysis

The customization process for industrial rubber pickup bed liners begins with a rigorous drawing analysis, where technical blueprints and CAD models provided by the client are evaluated for dimensional accuracy, structural integrity, and manufacturability. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a comprehensive review to ensure compatibility with existing vehicle chassis profiles, load-bearing zones, and mounting configurations. This phase includes tolerance stack-up analysis, draft angle verification, and identification of potential stress concentration areas. Critical dimensions are cross-referenced with OEM specifications to guarantee seamless fitment. Any discrepancies or design optimizations are communicated to the client for approval before proceeding, ensuring alignment with both functional requirements and production feasibility.

Formulation Development

Following drawing validation, our Rubber Formula Engineers initiate material formulation tailored to the operational demands of the pickup bed environment. The selection of base polymers—such as natural rubber (NR), styrene-butadiene rubber (SBR), or ethylene propylene diene monomer (EPDM)—is determined by required resistance to abrasion, UV exposure, temperature extremes, and chemical exposure. Additives including carbon black, silica, plasticizers, and anti-oxidants are precisely compounded to achieve target hardness (Shore A), tensile strength, elongation at break, and compression set performance. Each formulation is developed in accordance with ASTM and ISO standards, ensuring long-term durability under dynamic loading conditions. Material batches are subjected to preliminary testing in controlled lab environments to verify compliance with performance benchmarks prior to prototyping.

Prototyping and Validation

Once the compound is finalized, a prototype is produced using compression or injection molding techniques, depending on part geometry and volume requirements. The prototype undergoes a series of physical and environmental tests, including impact resistance, slip resistance, adhesion to substrate (if applicable), and thermal cycling. Fitment trials are conducted on actual vehicle platforms to assess installation ease and interface with OEM components. Client feedback is integrated into iterative refinements, with up to three prototype cycles typically sufficient to achieve final design approval. Dimensional reports and material test data are compiled into a full validation dossier for client review.

Mass Production

Upon successful prototype validation, the project transitions to mass production. Our automated molding lines, equipped with real-time process monitoring systems, ensure consistent part quality across large volumes. In-process quality checks, including hardness testing, visual inspection, and dimensional sampling, are conducted at defined intervals. Finished liners are packaged per client specifications, with traceability maintained through batch coding and material certificates. Suzhou Baoshida ensures on-time delivery through lean manufacturing practices and robust supply chain management.

Typical Physical Properties of Custom Rubber Pickup Bed Liners

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55–75 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Tear Strength | ASTM D624 | ≥40 kN/m |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤20% |

| Operating Temperature Range | — | -40°C to +100°C |

| Abrasion Loss (DIN) | ISO 4649 | ≤120 mm³ |

Contact Engineering Team

Initiate Your Rubber Pickup Bed Liner Project with Precision Engineering

Suzhou Baoshida Trading Co., Ltd. delivers industrial rubber solutions engineered for extreme durability and performance in demanding automotive applications. Our proprietary rubber formulations, developed by in-house polymer scientists, address critical challenges in pickup bed liner manufacturing—including abrasion resistance, chemical exposure, and thermal cycling. As your OEM partner, we integrate material science with scalable production to ensure consistent part integrity across high-volume runs. Our ISO 9001-certified processes guarantee dimensional stability within ±0.25mm tolerance, while advanced compounding techniques eliminate common defects like porosity or adhesion failure. For Tier 1 suppliers and automotive OEMs, this translates to reduced warranty claims and accelerated time-to-market.

Key technical specifications for our standard pickup bed liner compound are validated per ASTM D2000 and ISO 37 standards. These parameters reflect our baseline formulation; all properties are adjustable to meet your exact environmental and mechanical requirements.

| Property | Test Method | Value | Unit |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 75 ± 3 | Points |

| Tensile Strength | ASTM D412 | ≥ 22 | MPa |

| Elongation at Break | ASTM D412 | ≥ 450 | % |

| Tear Resistance | ASTM D624 | ≥ 35 | kN/m |

| Abrasion Loss | ASTM D5963 | ≤ 85 | mm³ |

| Temperature Range | ISO 188 | -40°C to +120°C | °C |

Our engineering team collaborates directly with clients to refine material behavior under real-world conditions. Whether optimizing for UV resistance in desert climates or impact resilience in construction fleets, we leverage finite element analysis (FEA) to predict liner performance before tooling. This proactive approach minimizes costly iterations during validation. Suzhou Baoshida’s manufacturing ecosystem includes 12 rubber injection molding lines with capacities from 50 to 2,500 tons, supporting annual volumes exceeding 5 million units. We maintain strategic partnerships with global raw material suppliers to secure consistent EPDM and polyurethane feedstock, ensuring zero disruption to your production schedule.

To advance your pickup bed liner project, contact Mr. Boyce, our OEM Strategic Account Manager. With 14 years of experience in automotive rubber applications, Mr. Boyce will coordinate a technical consultation to align our compounding expertise with your design specifications. He will facilitate material sample submissions, DFM feedback, and production timeline mapping within 72 hours of initial engagement. Specify your target durometer range, substrate adhesion requirements, and environmental certifications during inquiry to expedite the solutioning phase.

Initiate your technical review by emailing [email protected]. Include your component drawings, annual volume forecast, and critical performance thresholds. Mr. Boyce will respond within one business day with a tailored action plan. For urgent requests, reference “PBL-URGENT” in the subject line to trigger our 4-hour response protocol. Suzhou Baoshida operates under strict NDA frameworks; all technical data is protected per ISO 27001 protocols. Partner with us to transform material science into measurable field performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).