Technical Contents

Engineering Guide: Fridge Sealing Rubber

Engineering Insight: Material Selection in Refrigerator Sealing Rubber

The performance and longevity of refrigerator door seals hinge critically on precise material selection. While off-the-shelf rubber profiles may appear cost-effective, they frequently fail to meet the demanding thermal, chemical, and mechanical requirements of modern refrigeration systems. These generic solutions are often formulated for broad industrial applications, lacking the tailored compound design necessary for consistent sealing integrity under fluctuating temperature cycles, exposure to refrigerants, and repeated mechanical compression.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered elastomer solutions designed specifically for refrigeration environments. Standard rubber materials such as general-purpose EPDM or low-grade silicone may exhibit initial flexibility and adhesion but degrade prematurely due to thermal aging, compression set, or ozone exposure. In contrast, high-purity, peroxide-cured EPDM formulations offer superior resistance to weathering, UV radiation, and temperature extremes ranging from -40°C to +120°C. This ensures dimensional stability and elastic recovery over thousands of door cycles—critical for maintaining energy efficiency and preventing condensation ingress.

Another often-overlooked factor is compatibility with refrigerants and cleaning agents. Many OEMs now use low-global-warming-potential (GWP) refrigerants such as R-600a or R-290, which can interact adversely with non-resistant elastomers, causing swelling, softening, or embrittlement. Our sealing compounds are rigorously tested against common refrigerants and sanitizing chemicals to ensure long-term compatibility. Furthermore, food-grade compliance (e.g., FDA 21 CFR 177.2600) is integrated into formulations where seals contact food storage zones, ensuring safety and regulatory adherence.

Compression set resistance is a key performance metric in refrigerator seals. A seal that fails to rebound after prolonged closure compromises the airtight barrier, increasing energy consumption and frost accumulation. High-quality formulations incorporate optimized cross-link density and reinforcing fillers to minimize permanent deformation. Additionally, precise durometer control (typically 55–65 Shore A) balances sealing force with ease of door operation.

Below is a comparative specification table highlighting critical properties of standard versus engineered sealing materials:

| Property | Off-the-Shelf EPDM | Engineered Refrigeration-Grade EPDM | Test Standard |

|---|---|---|---|

| Temperature Range | -30°C to +100°C | -40°C to +120°C | ASTM D1329 |

| Compression Set (22h at 100°C) | ≤35% | ≤15% | ASTM D395 |

| Tensile Strength | ≥7 MPa | ≥10 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ≥350% | ASTM D412 |

| Ozone Resistance (100 pphm, 20% strain) | Cracking after 24h | No cracking after 96h | ASTM D1149 |

| Refrigerant Resistance (R-600a) | Moderate swelling | Negligible volume change | ISO 1817 |

| Food Contact Compliance | Not certified | FDA, EU 1935/2004 | – |

In summary, the failure of generic sealing solutions in refrigeration applications stems from inadequate material science alignment with operational demands. Precision-engineered rubber compounds, developed through rigorous testing and application-specific formulation, deliver the reliability, safety, and efficiency required by OEMs and end users alike. At Suzhou Baoshida, we prioritize performance-driven elastomer design to ensure every seal functions as a critical component of system integrity.

Material Specifications

Material Specifications for Refrigeration Door Seals

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber seals meeting stringent OEM requirements for refrigeration systems. Material selection directly impacts seal longevity, energy efficiency, and compliance with food safety standards. Below we detail critical specifications for Viton (FKM), Nitrile (NBR), and Silicone (VMQ) compounds, optimized for freezer and refrigerator door applications. Each material undergoes rigorous testing per ASTM D2000 and ISO 3601 standards to ensure performance under cyclic compression, temperature extremes, and exposure to refrigerants.

Nitrile rubber remains the industry standard for cost-sensitive commercial refrigeration units due to its exceptional resistance to hydrocarbon-based compressor oils and moderate refrigerant exposure. Its glass transition temperature of -40°C ensures flexibility in standard freezer compartments (-18°C). However, NBR exhibits vulnerability to ozone degradation and limited high-temperature resilience beyond 100°C, restricting use in high-efficiency systems employing aggressive refrigerants like R600a. Typical formulations achieve 20-30 Shore A hardness with 15-25% compression set after 22 hours at 70°C.

Silicone offers superior low-temperature flexibility down to -60°C, making it ideal for ultra-low-temperature medical freezers. Its inert composition complies with FDA 21 CFR 177.2600 for food contact surfaces, though tensile strength (5.5-7.0 MPa) remains lower than NBR. Silicone maintains stability across -60°C to 200°C but demonstrates higher gas permeability, potentially compromising energy efficiency in vapor-sealed environments. Compression set values typically range from 20-35% under standard testing conditions.

Viton fluorocarbon elastomers deliver unparalleled chemical resistance against modern HFC/HFO refrigerants and cleaning solvents, with continuous service capability up to 200°C. This material is essential for premium commercial refrigeration where seal failure risks catastrophic system contamination. Viton’s high cost is justified by its <10% compression set after 70 hours at 150°C and exceptional ozone/weathering resistance. Hardness ranges from 60-80 Shore A, requiring precise molding parameters to avoid flash defects in thin-profile seals.

The comparative analysis below outlines key performance metrics for OEM validation:

| Property | Nitrile (NBR) | Silicone (VMQ) | Viton (FKM) |

|---|---|---|---|

| Hardness Range (Shore A) | 50-80 | 40-70 | 60-80 |

| Tensile Strength (MPa) | 10-20 | 5.5-7.0 | 8-15 |

| Elongation at Break (%) | 200-400 | 200-400 | 150-300 |

| Compression Set (%) | 15-25 (70°C/22h) | 20-35 (70°C/22h) | <10 (150°C/70h) |

| Temp Range (°C) | -40 to +100 | -60 to +200 | -20 to +200 |

| Refrigerant Resistance | Moderate (R134a) | Poor | Excellent (R600a) |

| Ozone Resistance | Poor | Excellent | Excellent |

OEMs must prioritize material compatibility with specific refrigerant types and cabinet operating profiles. Baoshida’s technical team provides customized compound formulations with accelerated aging data to validate seal lifetime projections exceeding 15 years under simulated use conditions. All materials undergo extractables testing per ISO 10993-17 to eliminate contamination risks in food storage environments.

Manufacturing Capabilities

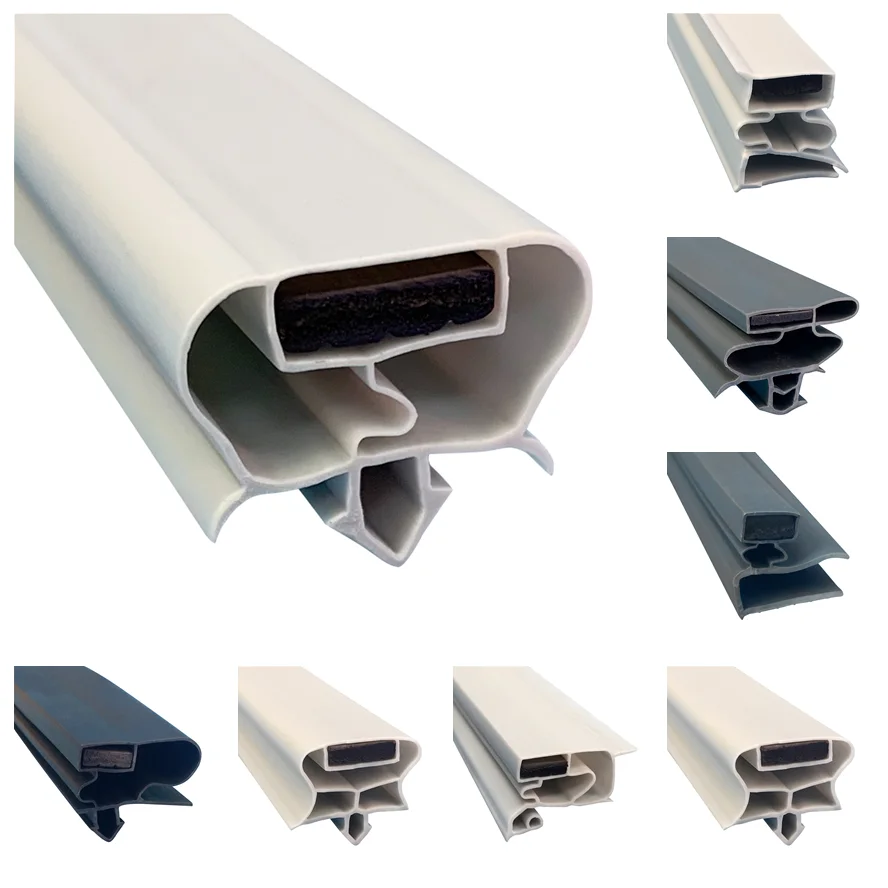

Engineering Capability: Precision-Driven Rubber Seal Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation in the precision rubber seals industry. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we deliver technically advanced, application-specific sealing solutions for critical environments—particularly in refrigerator and cold chain appliances. Our integrated engineering approach ensures that every seal meets stringent performance criteria for durability, compression set resistance, thermal stability, and long-term sealing integrity.

Our mould engineers bring over a decade of cumulative experience in precision tooling design for EPDM, silicone, and thermoplastic rubber (TPR) compounds. Utilizing advanced CAD/CAM software and CNC machining protocols, they develop moulds with tight tolerances (±0.1 mm) and optimized flow channels to ensure uniform curing and minimal flash. This precision directly translates into consistent part geometry, dimensional accuracy, and extended service life—critical factors in refrigerator door and drawer seal applications where energy efficiency and air-tightness are paramount.

Complementing our tooling expertise, our two in-house rubber formula engineers specialize in compound development tailored to OEM performance requirements. They formulate custom elastomer blends that balance flexibility at low temperatures (down to -40°C), resistance to UV and ozone exposure, and compliance with food safety standards (FDA, RoHS, REACH). By controlling the polymer base, filler content, cross-linking agents, and additives, we achieve targeted hardness (45–75 Shore A), compression set values below 25% after 22 hours at 70°C, and exceptional resilience over 100,000 opening cycles.

Our OEM development process follows a structured workflow: from initial technical consultation and 3D sealing analysis to prototype validation and mass production. We support clients from concept to commercialization, offering DFM (Design for Manufacturing) feedback, rapid tooling iterations, and material certification dossiers. Our engineering team collaborates directly with appliance OEMs to align seal performance with cabinet design, energy efficiency targets, and assembly line compatibility.

This vertically integrated engineering model—combining advanced tooling with proprietary material science—enables Suzhou Baoshida to deliver refrigerator seals that exceed industry benchmarks. We do not outsource critical development stages; instead, we maintain full in-house control over both formulation and mould design, ensuring consistency, traceability, and rapid response to technical challenges.

Key Technical Specifications of Standard Refrigerator Sealing Rubber

| Property | Test Method | Typical Value |

|---|---|---|

| Material | — | EPDM, TPR, Silicone |

| Hardness (Shore A) | ASTM D2240 | 50–75 |

| Tensile Strength | ASTM D412 | ≥8 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +100°C |

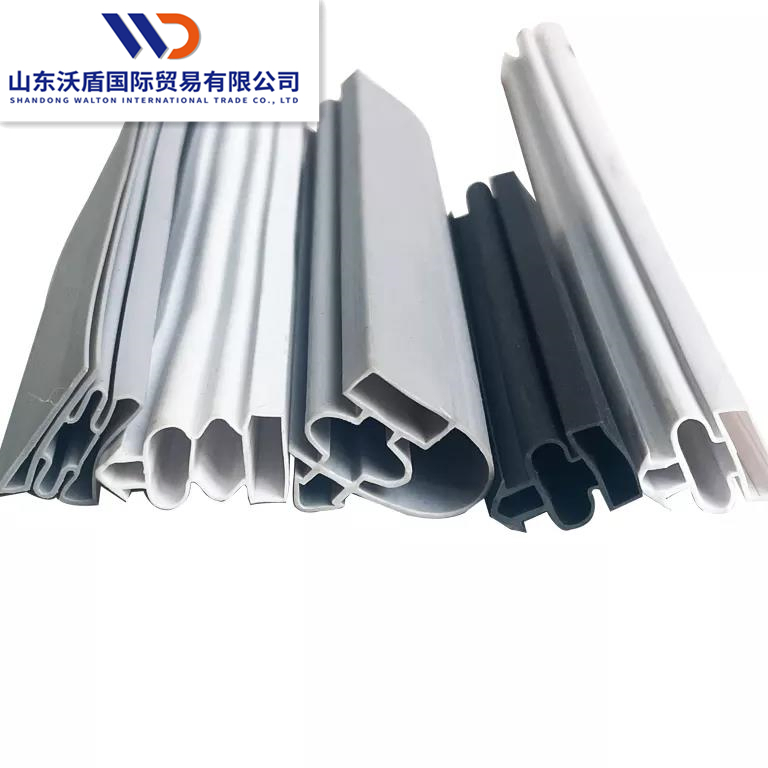

| Color Options | — | Black, White, Gray, Custom |

| Certifications | — | RoHS, REACH, FDA compliant |

Suzhou Baoshida Trading Co., Ltd. leverages its dual-engineering expertise to provide technically superior, OEM-qualified sealing solutions that enhance appliance performance and reliability.

Customization Process

Fridge Sealing Rubber Customization Process: Engineering Precision from Concept to Production

At Suzhou Baoshida Trading Co., Ltd., our customization process for refrigerator sealing rubber integrates rigorous material science with precision manufacturing to deliver seals meeting exact OEM thermal and durability requirements. This four-phase methodology ensures optimal performance in demanding refrigeration environments while adhering to global quality standards.

Drawing Analysis

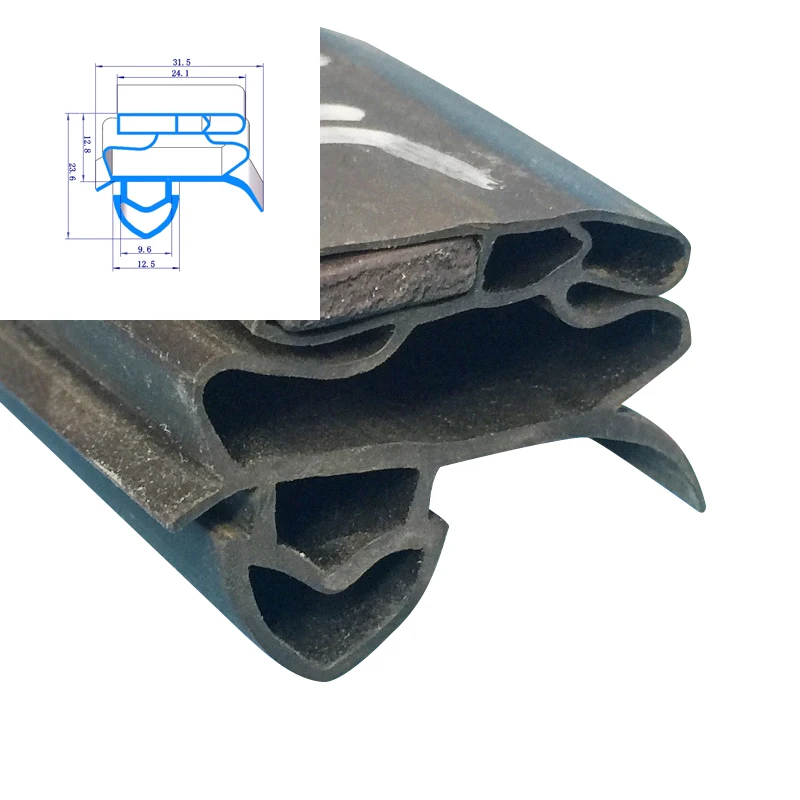

Initial engagement commences with comprehensive technical drawing review against ISO 1101 geometric dimensioning and tolerancing (GD&T) standards. We validate critical parameters including cross-section tolerance (±0.05mm), sealing lip geometry, and installation groove compatibility. Finite element analysis (FEA) simulates compression behavior under operational loads (typically 15–25% compression set) to preempt stress concentration points. Any deviations from manufacturability thresholds trigger collaborative engineering feedback within 72 hours, ensuring design integrity prior to material selection.

Formulation Development

Material science drives our proprietary EPDM compound design. Leveraging ASTM D2000 classification, we engineer formulations balancing low-temperature flexibility (-50°C brittleness point), ozone resistance (50 pphm, 40°C, 96h), and compression set (<25% per ASTM D395). Key variables include:

Polymer backbone saturation for weathering resistance

Peroxide curing systems to minimize compression set

Reinforcing silica fillers enhancing tear strength (>25 kN/m)

Each formulation undergoes Durometer stability testing (Shore A 60±5) across -40°C to +80°C cycles, with viscosity profiles optimized for extrusion precision.

Prototyping & Validation

Prototypes are produced using production-intent tooling under controlled ISO 9001 conditions. Critical validation includes:

Seal force measurement via tensile testing (ASTM D412)

Accelerated aging (72h at 100°C per IEC 60068-2-1) tracking hardness drift

Dynamic compression testing simulating 100,000 door cycles

Performance data is benchmarked against OEM leakage rate specifications (typically ≤0.5 L/min at 200 Pa pressure differential). Iterations conclude only when all metrics achieve statistical process control (SPC) capability (Cpk ≥1.33).

Mass Production Execution

Approved compounds enter high-volume production with real-time monitoring of 12 critical process parameters, including extrusion temperature variance (±2°C) and cure press timing (±0.5s). Every batch undergoes:

100% visual inspection for surface defects (ISO 3302)

In-line Shore A hardness verification (per ASTM D2240)

Lot traceability via blockchain-enabled material passports

Final shipment includes comprehensive test certificates aligned with IATF 16949, with dimensional reports certified to ASME Y14.5.

Critical Material Specifications Comparison

| Property | Standard Grade | Baoshida Enhanced Grade | Test Standard |

|---|---|---|---|

| Compression Set (70h/100°C) | ≤30% | ≤18% | ASTM D395 |

| Tensile Strength | ≥8.0 MPa | ≥11.5 MPa | ASTM D412 |

| Ozone Resistance | 100 pphm, 48h pass | 50 pphm, 200h pass | ASTM D1149 |

| Low-Temp Flexibility | -45°C | -55°C | ISO 1432 |

| Shore A Hardness Range | 55–65 | 58–63 | ASTM D2240 |

This systematic approach guarantees fridge seals achieving 15+ year service life under continuous thermal cycling, directly supporting OEM energy efficiency targets and warranty performance. All processes are documented per customer-specific APQP frameworks, with engineering change control managed through Suzhou Baoshida’s PLM system.

Contact Engineering Team

For manufacturers and OEMs requiring high-performance refrigerator sealing rubber, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in precision rubber engineering. Our expertise lies in the development and supply of advanced elastomeric sealing solutions tailored specifically for refrigeration applications. With rigorous quality control, material science innovation, and deep industry experience, we ensure every seal meets exact thermal, mechanical, and durability specifications critical for long-term performance in cold environments.

Our refrigerator sealing rubbers are engineered to deliver consistent compression set resistance, low-temperature flexibility, and excellent resilience across thousands of door cycles. Whether you are designing household refrigerators, commercial cold storage units, or specialized medical cooling systems, our formulations comply with international food safety and environmental standards, including FDA, RoHS, and REACH compliance where applicable. We specialize in EPDM, silicone, and thermoplastic vulcanizate (TPV) compounds optimized for sealing integrity, energy efficiency, and longevity.

To support global clients, Suzhou Baoshida offers full technical collaboration—from material selection and prototype development to tooling design and volume production. Our engineering team works directly with OEMs to match sealing performance with operational demands, including temperature range, compression load, aging resistance, and surface adhesion requirements.

The following table outlines typical technical specifications for our standard refrigerator sealing rubber profiles:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 8.0 MPa |

| Elongation at Break | ASTM D412 | ≥ 300% |

| Compression Set (22 hrs, 70°C) | ASTM D395B | ≤ 25% |

| Low-Temperature Flexibility | ASTM D1329 | Pass at -40°C |

| Operating Temperature Range | — | -50°C to +100°C |

| Specific Gravity | ASTM D792 | 1.25 ± 0.05 |

| Color Options | — | Black, White, Gray (custom colors available) |

All materials are subject to client-specific validation and can be modified to meet unique design or regulatory needs. We maintain strict process controls through ISO 9001-certified workflows and provide full traceability for every production batch.

For technical consultation, sample requests, or partnership discussions, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Direct communication ensures rapid response to engineering inquiries, quoting, and project scoping. Reach Mr. Boyce via email at [email protected] to initiate a precision-driven collaboration focused on performance, reliability, and cost-effective scalability in refrigeration sealing solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).