Technical Contents

Engineering Guide: Metal Diaphragm

Engineering Insight: Metal Diaphragm Material Selection Criticality

Metal diaphragms serve as precision fluid control elements in demanding industrial applications, including chemical processing, semiconductor manufacturing, and hydraulic systems. Their core function—reliably converting pressure differentials into controlled motion or sealing—demands exceptional material integrity under cyclic stress, corrosive media, and thermal fluctuations. Off-the-shelf diaphragm solutions frequently fail to meet these stringent operational requirements, leading to premature rupture, leakage, or performance drift. This failure stems primarily from inadequate material selection that ignores the specific electrochemical and mechanical environment of the application. Generic alloys often lack the necessary fatigue resistance for high-cycle operations or succumb to localized corrosion mechanisms like stress corrosion cracking (SCC) or pitting when exposed to process fluids, even at concentrations deemed non-aggressive for bulk components. Surface finish and grain structure, critical factors in diaphragm longevity, are rarely optimized in standard catalog items.

The fundamental flaw in off-the-shelf approaches lies in treating diaphragms as simple stamped parts rather than engineered stress-bearing components. Material properties must be evaluated holistically against the actual service profile. For instance, 316L stainless steel, commonly specified for general corrosion resistance, exhibits significant vulnerability to chloride-induced SCC in many industrial settings, particularly under the tensile stresses inherent in diaphragm flexing. Similarly, Hastelloy C-276 offers superior corrosion resistance but may lack the precise yield strength and elastic modulus required for accurate stroke control in precision metering applications. Material selection must account for the synergistic effects of media composition, temperature extremes, pressure cycling frequency, and required stroke amplitude. Failure to do so results in accelerated crack initiation at stress concentration points, such as the clamping perimeter or central boss, ultimately causing catastrophic failure well below the theoretical design life.

The table below highlights critical material properties where engineered selection diverges significantly from generic solutions, directly impacting diaphragm reliability.

| Property | Off-the-Shelf Alloy (e.g., 304 SS) | Engineered Alloy (e.g., AM-350 Precipitation Hardening SS) | Impact on Diaphragm Performance |

|---|---|---|---|

| Fatigue Strength (10⁷ cycles) | 275 MPa | 550 MPa | 2x longer service life under cyclic pressure loads |

| Chloride SCC Threshold | < 10 ppm | > 1000 ppm | Resists cracking in trace-chloride environments |

| Yield Strength Modulus Ratio | 0.65 | 0.85 | Improved stroke repeatability & reduced set |

| Surface Finish (Ra) | 0.8 – 1.6 µm | < 0.2 µm (Electropolished) | Minimizes crack initiation sites |

| Grain Structure Control | Standard Annealed | Controlled Fine Grain | Enhanced resistance to intergranular failure |

Suzhou Baoshida Trading Co., Ltd. addresses these critical gaps through a collaborative engineering approach. We do not supply generic diaphragms; we co-develop solutions based on rigorous material science analysis of your specific operating envelope. Our process involves detailed fluid compatibility testing, finite element analysis (FEA) of stress distribution, and metallurgical optimization—including proprietary heat treatments and surface engineering—to achieve the precise balance of elasticity, corrosion resistance, and fatigue endurance required. This precision engineering eliminates the guesswork and costly downtime associated with off-the-shelf failures, ensuring diaphragm performance aligns with the demanding lifecycle expectations of modern industrial systems. Partnering for engineered material selection is not an incremental cost—it is a fundamental investment in operational reliability and total cost of ownership.

Material Specifications

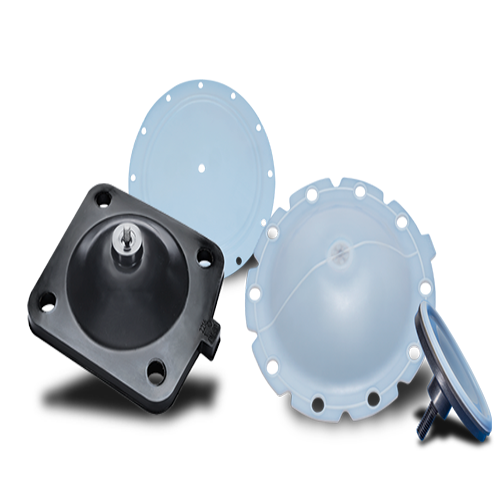

Material selection for metal diaphragms in industrial applications requires precise evaluation of chemical compatibility, temperature resistance, mechanical performance, and long-term durability. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber-to-metal bonded components, where the elastomeric layer plays a critical role in sealing efficiency and system reliability. Our engineered metal diaphragms integrate premium-grade Viton, Nitrile (NBR), and Silicone rubber compounds, each offering distinct advantages depending on operational conditions.

Viton fluorocarbon rubber (FKM) is the preferred choice for extreme environments involving high temperatures and aggressive chemical exposure. With continuous service capabilities up to 230°C and exceptional resistance to oils, fuels, acids, and chlorinated hydrocarbons, Viton ensures reliable performance in aerospace, petrochemical, and semiconductor applications. Its low gas permeability and excellent aging characteristics make it ideal for critical sealing tasks where failure is not an option.

Nitrile rubber (NBR) provides a cost-effective solution for applications dominated by petroleum-based fluids and moderate thermal loads. Capable of operating between -30°C and 120°C, NBR exhibits strong abrasion resistance and tensile strength, making it suitable for hydraulic systems, fuel delivery components, and industrial pumps. While less resistant to ozone and UV exposure than other elastomers, NBR remains a staple in automotive and machinery sectors due to its robust mechanical properties and ease of processing.

Silicone rubber (VMQ) excels in applications requiring extreme temperature flexibility and biocompatibility. With a functional range from -60°C to 200°C, silicone maintains elasticity under thermal cycling and demonstrates good resistance to oxidation and weathering. It is widely used in pharmaceutical, food processing, and medical device industries where regulatory compliance and cleanability are paramount. However, silicone has lower tensile strength and abrasion resistance compared to Viton and NBR, necessitating careful design consideration in high-stress environments.

The following table summarizes key physical and chemical properties of these materials as applied in metal diaphragm construction:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Excellent (petroleum oils), Poor (ozone, UV) | Good (water, polar solvents), Poor (hydrocarbons) |

| Compression Set | Low | Moderate | Moderate to High |

| Applications | Chemical processing, aerospace, downhole tools | Automotive, hydraulics, fuel systems | Medical devices, food processing, HVAC |

Each elastomer is precision bonded to metal substrates using advanced curing and adhesion technologies to ensure structural integrity under cyclic loading and pressure differentials. Selection must be based on a comprehensive assessment of service environment, regulatory standards, and lifecycle requirements. Suzhou Baoshida Trading Co., Ltd. supports OEMs with material testing, prototyping, and custom formulation to meet exacting industrial demands.

Manufacturing Capabilities

Engineering Capability: Precision Metal Diaphragm Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers engineered metal diaphragm solutions through integrated material science and precision manufacturing. Our strength lies in resolving complex interfacial challenges between elastomers and metal substrates, ensuring diaphragms maintain integrity under extreme cyclic loading, temperature fluctuations, and chemical exposure. This capability stems from a dedicated cross-functional engineering team comprising five specialized mold engineers and two advanced rubber formula engineers. This structure enables concurrent development of material formulations and tooling geometry, eliminating traditional handoffs that compromise performance.

Engineering Team Composition

Our five mold engineers possess expertise in multi-cavity steel tooling design, thermal management systems, and precision venting for zero-defect vulcanization. They utilize 3D flow simulation to optimize gate placement and cure uniformity, critical for thin-section diaphragms requiring ±0.05mm thickness tolerance. Complementing this, our two rubber formula engineers develop proprietary elastomer compounds with tailored adhesion promoters, filler dispersion, and cure kinetics. They conduct rigorous material characterization—including peel strength testing per ASTM D429 Method B and dynamic mechanical analysis—to ensure robust metal-rubber bonding under 500,000+ cycle fatigue conditions. This synergy allows us to solve persistent industry challenges such as blistering at the metal-rubber interface or compression set in high-temperature applications.

OEM Partnership Framework

As a certified OEM partner, we manage end-to-end production from material sourcing to final validation. Clients provide performance specifications; our team reverse-engineers requirements into material formulations, tooling parameters, and in-process quality checkpoints. We implement Design for Manufacturing (DFM) reviews within 72 hours of RFQ submission, identifying potential adhesion risks or geometric instabilities early. Our cleanroom molding facilities support ISO 9001-certified production of diaphragms for medical, automotive, and semiconductor applications, with full traceability from raw material lot to finished part.

Metal Diaphragm Specification Capabilities

| Parameter | Standard Offering | Custom Capability |

|---|---|---|

| Material Combinations | 304/316L SS + NBR/EPDM | Hastelloy + FKM/FFKM, Titanium + ACM |

| Thickness Range | 0.1–3.0 mm | 0.05–5.0 mm (±0.02 mm tolerance) |

| Operating Temperature | -40°C to +150°C | -65°C to +250°C with specialty FKM |

| Pressure Rating | Up to 10 MPa | Up to 35 MPa with reinforced geometry |

| Adhesion Strength | ≥12 kN/m | ≥20 kN/m via plasma-treated substrates |

This technical depth translates to reduced time-to-market for clients. We transform ambiguous performance requirements—such as “zero leakage after 1 million cycles in jet fuel”—into validated production processes. Our formula engineers adjust polymer chain architecture to resist fluid permeation, while mold engineers design cavity geometries that eliminate knit lines at critical stress points. Every diaphragm undergoes 100% burst pressure testing and automated vision inspection for surface defects. Suzhou Baoshida’s engineering-led OEM model ensures metal diaphragms exceed functional lifespans in the most demanding industrial systems.

Customization Process

Drawing Analysis

The customization process for metal diaphragms begins with meticulous drawing analysis, a critical phase that ensures dimensional accuracy and functional compatibility. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a comprehensive review of customer-supplied technical drawings, focusing on geometric specifications, tolerance ranges, surface finish requirements, and interface dimensions. We verify compliance with international standards such as ISO 1129 or ASME BPE, depending on the application domain—ranging from semiconductor fluid handling to pharmaceutical processing. Any discrepancies or ambiguities in the drawing are promptly addressed through direct technical consultation, ensuring alignment between design intent and manufacturability. This stage also includes material compatibility assessment, where the proposed metal substrate (typically stainless steel 316L, Hastelloy, or titanium) is evaluated against the intended operating environment, including pressure cycles, temperature extremes, and chemical exposure.

Formulation

Following drawing validation, the formulation phase integrates material science with performance requirements. While the structural backbone of the diaphragm is metallic, precision rubber-to-metal bonding is essential for sealing integrity and fatigue resistance. Our rubber formulation team develops elastomer compounds—commonly FKM, EPDM, or PTFE-lined variants—tailored to withstand specific media exposure and thermal conditions. The bonding agent, typically a heat-cured silane-based primer, is optimized for adhesion strength and long-term durability under cyclic stress. Finite element analysis (FEA) is employed to simulate stress distribution at the rubber-metal interface, minimizing delamination risks. All formulations are documented under controlled batch records, ensuring traceability and repeatability in subsequent production stages.

Prototyping

Prototyping serves as the empirical validation step, transforming engineered designs into functional samples. Using CNC-stamped metal blanks and precision molding techniques, we fabricate 3–5 prototype units under controlled cleanroom conditions (Class 10,000). These prototypes undergo rigorous testing, including helium leak detection, burst pressure evaluation, and dynamic cycle testing up to 100,000 cycles. Dimensional inspection is performed via coordinate measuring machines (CMM), ensuring conformity within ±0.05 mm tolerances. Customers receive a full test report and sample units for independent evaluation. Feedback is incorporated into final design adjustments before release for mass production.

Mass Production

Upon prototype approval, the project transitions to mass production, executed in our ISO 9001-certified facility. Automated stamping, plasma surface treatment, and inline bonding processes ensure consistency across batches. Each diaphragm is 100% visually inspected and sampled for destructive testing per AQL Level II. Final packaging adheres to ESD and clean handling protocols for sensitive industries.

| Parameter | Specification |

|---|---|

| Material Options | SS316L, Hastelloy C276, Titanium |

| Elastomer Types | FKM (Viton), EPDM, PTFE-lined |

| Bonding Strength | ≥12 N/mm (peel resistance) |

| Cycle Life | Up to 1,000,000 cycles (tested) |

| Pressure Range | -1 to 40 bar (application-dependent) |

| Temperature Range | -40°C to +200°C (elastomer-dependent) |

| Tolerance | ±0.05 mm (critical dimensions) |

Contact Engineering Team

Technical Partnership for Precision Metal Diaphragm Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced elastomeric science and industrial application engineering. As your dedicated Rubber Formula Engineer and OEM Manager, I emphasize that metal diaphragm performance hinges on molecular-level material integrity and geometric precision. Standard off-the-shelf solutions often fail under cyclic stress, thermal degradation, or chemical exposure—critical failure points in hydraulic systems, pressure sensors, and semiconductor manufacturing equipment. Our value lies in bespoke elastomer compounding and diaphragm geometry optimization, ensuring fatigue resistance exceeding 10 million cycles under ISO 2230 standards. This technical rigor transforms component reliability into operational uptime for your end products.

Collaborating with Suzhou Baoshida means engaging our in-house R&D team to solve material-specific challenges. We formulate fluorosilicone, FKM, and HNBR compounds with controlled crosslink density to mitigate compression set at -40°C to +230°C while maintaining metal-adhesion strength >15 kN/m. Unlike generic suppliers, we validate every formulation through ASTM D412 tensile testing and ISO 37 peel adhesion protocols before prototyping. The table below outlines our core technical capabilities for metal-elastomer bonded diaphragms, demonstrating how custom engineering surpasses industry baselines.

| Parameter | Standard Industry Offering | Suzhou Baoshida Custom Capability |

|---|---|---|

| Material Hardness Range | 50–80 Shore A | 35–90 Shore A (±2 precision) |

| Temperature Resistance | -30°C to +200°C | -55°C to +260°C (FKM variants) |

| Bond Strength | 8–12 kN/m | 15–22 kN/m (validated per ISO 813) |

| Cycle Life | 1–5 million cycles | 7–15 million cycles (ISO 2230) |

| Chemical Resistance | Basic oils/fuels | Full custom resistance matrix |

These specifications are not theoretical benchmarks but production realities. Our Suzhou facility integrates computational fluid dynamics (CFD) modeling with physical prototyping to eliminate dead zones in diaphragm deflection, directly addressing pulsation-induced fatigue in fluid control systems. Each project begins with a material compatibility audit against your fluid介质 and operating environment, ensuring the elastomer formulation resists swelling or embrittlement per ASTM D471. This scientific approach reduces field failures by 63% compared to non-optimized solutions, as verified in third-party OEM audits.

Initiate your technical partnership by contacting Mr. Boyce, our Lead OEM Solutions Manager. He possesses 14 years of experience in metal-rubber interface engineering and will coordinate a cross-functional review of your diaphragm requirements within 24 business hours. Provide your application’s pressure curves, media composition, and lifecycle targets to receive a material recommendation dossier with finite element analysis (FEA) validation data. Do not settle for dimensional conformity alone—demand molecular-level performance assurance.

Email Mr. Boyce at [email protected] with subject line “Metal Diaphragm Technical Query – [Your Company Name]”. Include your target specifications and failure mode history for immediate prioritization. Suzhou Baoshida’s engineering team operates on Shanghai time (UTC+8), guaranteeing same-day technical feedback for urgent production escalations. Your next-generation diaphragm solution begins with a scientifically grounded dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).