Technical Contents

Engineering Guide: Sliding Door Rubber Seal

Engineering Insight: Material Selection for Sliding Door Rubber Seals

The operational integrity of sliding door systems hinges critically on the precision engineering of rubber seals. Generic off-the-shelf seals frequently fail due to inadequate material science alignment with dynamic environmental and mechanical stresses. Standard thermoplastic elastomers (TPE) or low-grade EPDM compounds lack the tailored polymer architecture required for sustained performance. These materials exhibit rapid compression set under continuous load, leading to permanent deformation and loss of sealing force within 12–18 months. Consequently, water ingress, air leakage, and increased operational noise become inevitable, directly impacting end-user satisfaction and brand reputation.

Material failure stems from three core deficiencies in non-engineered solutions. First, insufficient crosslink density in generic compounds compromises elastic recovery. Sliding doors undergo repeated compression cycles (5,000+ operations annually), demanding materials with Shore A hardness stability ±5 points across -40°C to +120°C. Off-the-shelf variants often exceed this tolerance, causing hardening in cold climates or softening in heat. Second, inadequate UV and ozone resistance accelerates surface cracking in exterior applications. Standard TPE formulations degrade 3× faster than engineered EPDM in accelerated weathering tests (ASTM D1148). Third, poor adhesion to aluminum or PVC door frames results in delamination under thermal cycling, breaking the critical moisture barrier.

Suzhou Baoshida addresses these failures through proprietary EPDM formulations with reinforced polymer chains and co-agents for optimal crosslink uniformity. Our seals maintain >90% compression set recovery after 1,000 hours at 70°C (ISO 3386), ensuring lifelong resilience. Below is a comparative analysis of critical performance metrics:

| Property | Baoshida Precision EPDM | Generic Off-the-Shelf TPE | Test Standard |

|---|---|---|---|

| Compression Set (70°C/22h) | 25% | 65% | ISO 3386-1 |

| Tensile Strength (MPa) | 14.2 | 8.5 | ISO 37 |

| Shore A Hardness Range | 68–72 | 58–78 | ISO 7619-1 |

| Ozone Resistance (50pphm) | No cracks (300hrs) | Severe cracking (72hrs) | ISO 1431-1 |

Custom material engineering directly correlates with system longevity. While off-the-shelf seals present lower initial costs, their premature failure incurs 5–7× higher total cost of ownership through warranty claims, field replacements, and reputational damage. Suzhou Baoshida’s OEM-focused approach integrates door system dynamics, regional climate profiles, and lifecycle requirements into every compound. This eliminates the “one-size-fits-all” compromise, delivering seals that maintain dimensional stability and sealing force across 15,000+ operational cycles. Precision material science isn’t an incremental upgrade—it’s the non-negotiable foundation of reliable sliding door performance.

Material Specifications

Material Specifications for Sliding Door Rubber Seals

The performance and longevity of sliding door rubber seals depend critically on the selection of base elastomer material. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber seals using three primary compounds: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct physical and chemical resistance properties, making them suitable for different environmental and operational conditions. Understanding these characteristics is essential for OEMs and industrial partners to ensure optimal sealing performance, durability, and compliance with application-specific demands.

Viton (fluorocarbon rubber) is engineered for extreme environments involving high temperatures and aggressive chemical exposure. With a continuous service temperature range of -20°C to 250°C, Viton maintains structural integrity under prolonged thermal stress. It demonstrates exceptional resistance to oils, fuels, acids, and chlorinated hydrocarbons, making it ideal for industrial and automotive applications where exposure to engine fluids or chemical vapors is common. Its low gas permeability and excellent aging characteristics further enhance reliability in critical sealing roles. However, Viton is less flexible at low temperatures and carries a higher material cost, which should be factored into design decisions.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used due to its excellent balance of performance and cost. It offers strong resistance to petroleum-based oils, greases, and water, with a service temperature range of -30°C to 120°C. Nitrile seals provide good abrasion resistance and mechanical strength, making them well suited for general-purpose sliding door applications in commercial buildings, transportation, and machinery. While not recommended for prolonged exposure to ozone, UV radiation, or polar solvents, NBR remains a preferred choice for indoor or sheltered environments where oil and moisture resistance are primary concerns.

Silicone rubber (VMQ) excels in applications requiring wide temperature tolerance and UV stability. It operates reliably from -60°C to 200°C, maintaining elasticity at sub-zero temperatures where other elastomers become brittle. Silicone is highly resistant to ozone, UV light, and weathering, making it ideal for exterior sliding door systems exposed to sunlight and fluctuating climates. It also meets stringent hygiene and safety standards, often used in cleanroom or food-contact environments. However, silicone has lower tensile strength and abrasion resistance compared to Viton and Nitrile, necessitating design considerations for high-wear zones.

The following table summarizes key physical and chemical properties of each material for comparative evaluation.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–18 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Hardness (Shore A) | 70–90 | 50–90 | 40–80 |

| Resistance to Oils & Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Ozone/UV | Good | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Chemical Resistance (acids, bases) | Excellent | Moderate | Moderate |

| Typical Applications | Industrial, automotive, chemical | Commercial doors, machinery | Outdoor, medical, food-grade |

Selection of the appropriate elastomer must align with operational temperature, exposure media, mechanical stress, and lifecycle requirements. Suzhou Baoshida Trading Co., Ltd. supports custom formulation and testing to ensure each sliding door seal meets exact OEM specifications.

Manufacturing Capabilities

Engineering Excellence in Sliding Door Rubber Seal Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver precision-engineered sliding door rubber seals that meet stringent global performance demands. Our core strength lies in the integrated synergy between dedicated Mold Engineering and Rubber Formulation disciplines. With five specialized mold engineers and two advanced formula engineers operating under one roof, we eliminate cross-functional silos to optimize material behavior, tooling precision, and production efficiency from concept to mass production. This dual-engineering approach ensures every seal achieves exact dimensional tolerances, environmental resilience, and functional longevity critical for high-cycle sliding door systems.

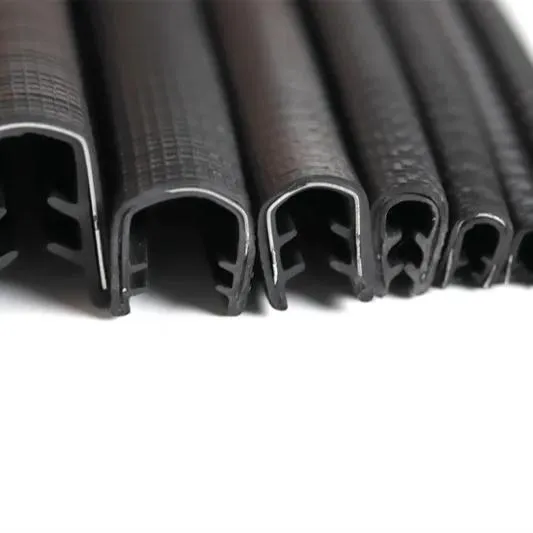

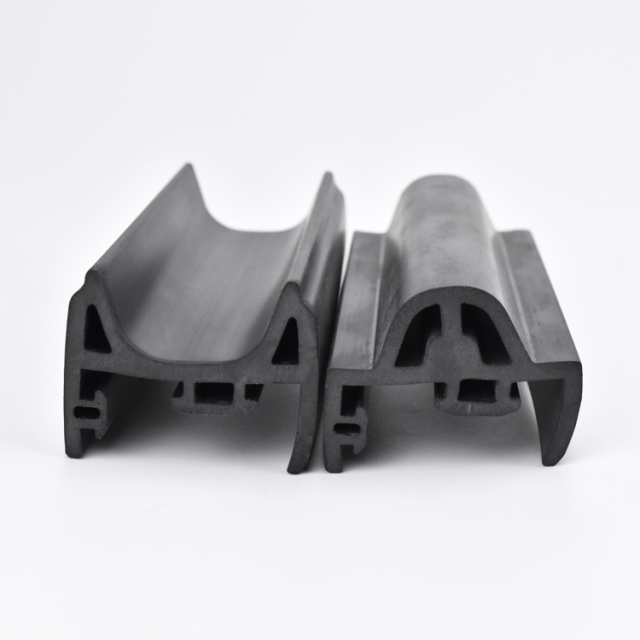

Our formula engineers focus exclusively on elastomer science, developing proprietary EPDM and TPE compounds tailored to sliding door dynamics. We prioritize low compression set (<25% per ASTM D395), exceptional UV/ozone resistance (5,000+ hours per ASTM D1148), and consistent Shore A hardness (60–75) across temperature extremes. By manipulating polymer chain mobility and crosslink density, we engineer seals that maintain sealing force after 100,000+ door cycles while resisting hardening below -40°C or softening above +120°C. Each formulation undergoes rigorous lab validation for extrusion stability, surface finish, and adhesion to metal/aluminum carriers—ensuring seamless integration into automated assembly lines.

Complementing material science, our mold engineering team utilizes 3D flow simulation (Moldflow) to perfect cavity geometry, runner systems, and thermal management. We resolve challenges like weld lines at corner joints, variable wall thickness distortion, and flash control through iterative prototyping. Precision-ground tooling with micron-level tolerances guarantees uniform durometer distribution and critical lip geometry for optimal wind/water ingress prevention. This proactive engineering reduces trial runs by 40% and extends tool life beyond 500,000 cycles.

As an OEM partner, we manage end-to-end development: from interpreting CAD models and material specifications to DFM analysis, mold validation, and PPAP documentation. Our engineers collaborate directly with clients to refine sealing profiles for noise reduction, ease of operation, or thermal expansion compensation—transforming functional requirements into manufacturable solutions. All processes adhere to IATF 16949 standards, with real-time SPC monitoring during production.

Key Sliding Door Seal Performance Specifications

| Property | Test Standard | Typical Value | Significance for Sliding Doors |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 | Balances sealing force and door glide ease |

| Compression Set (70°C/22h) | ASTM D395 | ≤ 22% | Ensures long-term sealing integrity |

| Tensile Strength | ASTM D412 | ≥ 8.0 MPa | Resists tearing during installation/use |

| Temperature Range | ISO 188 | -40°C to +120°C | Prevents brittleness in cold climates |

| Ozone Resistance | ASTM D1148 | No cracks (5,000h) | Critical for outdoor exposure durability |

This engineering rigor enables us to deliver sliding door seals that exceed OEM durability benchmarks while accelerating time-to-market. By embedding material and mold expertise into every project, Suzhou Baoshida transforms complex sealing challenges into reliable, cost-optimized manufacturing outcomes.

Customization Process

Customization Process for Sliding Door Rubber Seals at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered for performance, durability, and seamless integration into sliding door systems. Our customization process is structured to ensure technical accuracy, material suitability, and manufacturing efficiency. We follow a rigorous four-stage workflow: Drawing Analysis, Formulation Development, Prototyping, and Mass Production.

The process begins with Drawing Analysis, where our engineering team evaluates the client’s technical drawings and performance requirements. We assess dimensional tolerances, cross-sectional geometry, installation method, and environmental exposure conditions such as UV, temperature extremes, and moisture. This stage ensures that design intent aligns with manufacturability and functional reliability. Any discrepancies or optimization opportunities are communicated directly to the client for alignment.

Following drawing validation, we proceed to Formulation Development. Our rubber chemists select the optimal elastomer based on application demands. Common base materials include EPDM for weather resistance, silicone for high-temperature stability, and TPE for flexibility and recyclability. The formulation is tailored to achieve specific Shore A hardness, compression set resistance, tensile strength, and aging characteristics. All compounds are developed in-house and tested per ASTM and ISO standards to ensure repeatability and compliance.

Once the material is finalized, we move to Prototyping. Using precision extrusion and vulcanization techniques, we produce small-batch samples according to the approved design. These prototypes undergo dimensional inspection, fitment testing in simulated door assemblies, and environmental exposure trials. We provide clients with physical samples and test reports for validation. Feedback is integrated into final adjustments before release for production.

The final stage is Mass Production, executed in our ISO-certified facility equipped with automated extrusion lines, continuous vulcanization ovens, and real-time quality monitoring systems. We maintain strict process control to ensure batch-to-batch consistency, with 100% inline visual inspection and random sampling for mechanical testing. Production scalability supports both high-volume OEM contracts and mid-volume industrial applications.

Our end-to-end control over materials, engineering, and manufacturing enables Suzhou Baoshida to deliver customized sliding door rubber seals that meet exact functional and regulatory demands.

| Property | Typical Value | Test Standard |

|---|---|---|

| Shore A Hardness | 55–75 | ASTM D2240 |

| Tensile Strength | ≥8 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Operating Temperature Range | -40°C to +120°C | ISO 1817 |

| Weathering Resistance | 1500h QUV-A, no cracking | ASTM G154 |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Sliding Door Rubber Seal Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber sealing technology, specializing in high-performance sliding door seals for global architectural and industrial applications. Our technical team, led by experienced rubber formulation engineers, develops proprietary EPDM and TPV compounds specifically engineered to withstand cyclic stress, extreme UV exposure, and thermal fluctuations inherent in sliding door systems. Unlike generic seal suppliers, we prioritize material science rigor—ensuring every profile meets stringent compression set resistance, ozone stability, and low-temperature flexibility benchmarks critical for long-term weatherproofing integrity.

The consequences of substandard sliding door seals extend beyond mere drafts; they manifest as accelerated wear, premature hardening, and costly field failures impacting end-user satisfaction and brand reputation. Suzhou Baoshida mitigates these risks through ISO 9001-certified manufacturing processes, where raw material traceability, vulcanization control, and dimensional precision (±0.1mm tolerance) are non-negotiable. Our seals consistently achieve >50,000 open/close cycles without performance degradation, validated through in-house accelerated aging chambers simulating 15+ years of real-world exposure. Partnering with us translates to reduced warranty claims, simplified inventory management via bespoke compounding, and seamless integration with automated door assembly lines.

Below details the core performance metrics of our standard sliding door seal formulation, serving as a baseline for OEM collaboration. All parameters are customizable per project specifications and regional climatic demands.

| Property | Test Standard | Typical Value | Significance for Sliding Doors |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 | Optimal balance: firm sealing force without excessive friction during operation |

| Compression Set (70°C/22h) | ASTM D395 | ≤ 25% | Ensures permanent recovery after compression; prevents gap formation over time |

| Tensile Strength | ASTM D412 | ≥ 10 MPa | Resists tearing during installation and door movement |

| Elongation at Break | ASTM D412 | ≥ 350% | Accommodates thermal expansion/contraction without fracturing |

| Temperature Range | ISO 1817 | -40°C to +120°C | Maintains elasticity in arctic winters and desert summers |

Initiate a technical consultation with Mr. Boyce, our dedicated OEM Engagement Manager, to resolve your specific sealing challenges. Mr. Boyce possesses direct oversight of formulation adjustments, tooling coordination, and rapid prototyping—ensuring your sliding door system achieves Class A weather-tightness certifications (ASTM E283/E331). Forward your dimensional drawings, environmental requirements, and volume forecasts to [email protected]. Include reference to this technical guide to expedite material selection.

We commit to a 48-hour technical response window, providing not just samples but a comprehensive performance dossier including compound certificates, SGS test reports, and lifecycle cost analysis. Suzhou Baoshida operates under strict NDA protocols, treating your design specifications as proprietary intellectual property. For urgent projects requiring expedited tooling (≤15 days), mention “URGENT SLIDING SEAL” in your email subject line. Our Suzhou facility maintains ISO 14001 compliance and 200+ metric tons of monthly production capacity—guaranteeing scalability from pilot batches to multi-million-unit contracts. Do not settle for commodity rubber; demand engineered sealing precision. Contact Mr. Boyce today to fortify your sliding door performance legacy.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).