Technical Contents

Engineering Guide: Piston Check Valves

Engineering Insight: Material Selection in Piston Check Valves

In the design and deployment of piston check valves, material selection is not merely a secondary consideration—it is a foundational engineering decision that directly influences performance, longevity, and system reliability. These valves operate under dynamic pressure differentials, often in aggressive chemical environments, elevated temperatures, and cyclic mechanical stress. When off-the-shelf solutions are selected without rigorous evaluation of material compatibility, premature failure is not an exception; it is an inevitability.

Standard piston check valves frequently utilize generic elastomers such as Nitrile (NBR) or natural rubber, chosen for cost efficiency rather than operational suitability. While these materials may suffice in benign environments, they lack the resilience required in industrial applications involving oils, ozone, acids, or steam. For instance, NBR degrades rapidly when exposed to polar solvents or phosphate ester-based hydraulic fluids, leading to swelling, loss of tensile strength, and seal failure. Similarly, natural rubber exhibits poor resistance to UV radiation and oxidative aging, compromising long-term integrity.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific formulation of rubber compounds tailored to the service environment. Our engineered elastomers—such as fluorocarbon (FKM), ethylene propylene diene monomer (EPDM), and perfluoroelastomer (FFKM)—are selected based on chemical compatibility, thermal stability, and mechanical durability. FKM, for example, offers exceptional resistance to high temperatures (up to 200°C) and a broad range of chemicals, making it ideal for oil and gas or chemical processing applications. EPDM, with its outstanding resistance to steam and water-based fluids, is optimal in power generation and HVAC systems. FFKM, though higher in cost, delivers performance in extreme conditions where even FKM reaches its limits.

The failure of off-the-shelf valves often stems from a one-size-fits-all approach that ignores fluid compatibility, temperature cycling, and compression set resistance. A valve functioning adequately during initial installation may degrade within weeks when exposed to continuous thermal cycling or trace contaminants. This results in leakage, backflow, system downtime, and increased maintenance costs—issues that are preventable with precise material engineering.

Below is a comparison of common elastomers used in piston check valve seals, highlighting their performance characteristics:

| Material | Temperature Range (°C) | Key Chemical Resistances | Key Limitations | Typical Industrial Use |

|---|---|---|---|---|

| NBR | -30 to +100 | Aliphatic hydrocarbons, water, oils | Poor ozone and polar solvent resistance | General hydraulics, low-cost systems |

| EPDM | -50 to +150 | Steam, water, alkalis, oxygenated solvents | Poor oil and hydrocarbon resistance | Power plants, HVAC, water treatment |

| FKM | -20 to +200 | Aromatics, acids, fuels, silicone fluids | Limited low-temperature flexibility | Petrochemical, automotive, aerospace |

| FFKM | -15 to +300 | All FKM resistances plus strong acids, plasma | High cost, limited availability | Semiconductor, pharmaceutical, ultra-high purity |

Material selection must be guided by detailed fluid analysis, operating temperature profiles, and lifecycle expectations. At Baoshida, we support OEMs and system integrators with custom compound development and accelerated aging testing to ensure that every piston check valve performs reliably under real-world conditions. The cost of failure far exceeds the investment in engineered rubber solutions.

Material Specifications

Material Specifications for Piston Check Valve Sealing Elements

Selecting optimal elastomeric compounds for piston check valve sealing elements is critical for ensuring operational reliability, longevity, and compatibility with fluid media under dynamic pressure conditions. At Suzhou Baoshida Trading Co., Ltd., our rubber formulation expertise focuses on three primary materials—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—each engineered to meet stringent industrial demands. Precision in material selection directly impacts valve performance across temperature extremes, chemical exposure, and cyclic fatigue.

Viton (Fluoroelastomer, FKM) represents the pinnacle of chemical and thermal resistance for demanding applications. Our standard FKM compounds (ASTM D2000 classification FC 707) withstand continuous service temperatures from -20°C to +230°C and intermittent peaks up to +250°C. They exhibit exceptional resistance to aviation fuels, hydraulic fluids (including Skydrol), aromatic hydrocarbons, and acids. Viton seals maintain critical sealing integrity in aerospace, chemical processing, and high-performance automotive systems where exposure to aggressive media is unavoidable. Compression set values consistently remain below 25% after 70 hours at 150°C (ASTM D395 Method B), ensuring long-term resilience.

Nitrile (Acrylonitrile Butadiene Rubber, NBR) offers an optimal balance of cost efficiency and performance for petroleum-based fluid applications. Our high-acrylonitrile NBR formulations (ASTM D2000 classification BK 744) operate effectively between -30°C and +120°C, with short-term excursions to +150°C. These compounds demonstrate superior resistance to mineral oils, greases, aliphatic hydrocarbons, and water. NBR is the preferred choice for industrial hydraulic systems, fuel handling equipment, and general-purpose machinery due to its robust abrasion resistance and low compression set (≤ 20% after 70h at 100°C). Tensile strength typically exceeds 20 MPa (ASTM D412), supporting high-cycle durability.

Silicone (Polydimethylsiloxane, VMQ) provides unmatched flexibility across extreme temperature ranges but requires careful application engineering. Our reinforced VMQ compounds (ASTM D2000 classification GE 707) function reliably from -60°C to +200°C. While exhibiting excellent resistance to ozone, UV radiation, and water/steam, silicone shows limited compatibility with petroleum derivatives and certain solvents. It excels in food processing, medical devices, and cryogenic systems where wide thermal stability and biocompatibility are paramount. Tear strength is moderate (≥ 20 kN/m per ASTM D624), necessitating precise gland design to prevent extrusion under high pressure.

The following table summarizes critical comparative specifications for OEM validation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | ≥ 15 | ≥ 20 | ≥ 8 |

| Compression Set (70h) | ≤ 25% @ 150°C | ≤ 20% @ 100°C | ≤ 25% @ 150°C |

| Key Fluid Resistance | Fuels, Acids, Skydrol | Oils, Greases, Water | Water, Steam, Ozone |

| Critical Limitation | Cost, Low-temp flexibility | Poor ketone/aromatic resistance | Poor oil/fuel resistance |

Material selection must align with specific fluid chemistry, temperature profiles, and regulatory requirements. Suzhou Baoshida provides comprehensive OEM support through accelerated aging tests, fluid compatibility analysis, and custom compound development to mitigate field failure risks. Partnering early in the design phase ensures optimal seal performance and compliance with ISO 22309 valve standards.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. maintains a robust engineering foundation dedicated to the development and precision manufacturing of industrial rubber components, including critical flow control devices such as piston check valves. Our in-house engineering team comprises five specialized mould engineers and two dedicated rubber formulation scientists, enabling full vertical integration from concept to production. This technical depth ensures that every component we produce meets stringent performance, durability, and compatibility standards required in demanding industrial applications.

Our mould engineers bring extensive experience in precision tooling design, utilizing advanced CAD/CAM software and CNC machining techniques to develop high-tolerance moulds tailored to complex valve geometries. With a focus on dimensional accuracy, material flow optimization, and cycle efficiency, our team ensures consistent part quality and rapid prototyping capabilities. Each mould undergoes rigorous validation through iterative testing and dimensional analysis, guaranteeing long service life and minimal maintenance in operational environments.

Complementing our tooling expertise, our two rubber formula engineers specialize in polymer science and elastomer compounding. They develop custom rubber formulations engineered to meet specific performance criteria such as temperature resistance, chemical compatibility, compression set, and dynamic sealing capability. For piston check valves, this translates into seals and piston elements that maintain integrity under fluctuating pressures and exposure to aggressive media such as oils, acids, and industrial gases. Our formulation process includes laboratory-scale mixing, cure kinetics analysis, and accelerated aging tests to validate long-term performance before scale-up.

As an OEM manufacturing partner, Suzhou Baoshida offers comprehensive development support, including design for manufacturability (DFM) reviews, material selection guidance, and failure mode analysis. We work closely with client engineering teams to adapt designs for optimal production efficiency and functional reliability. Our facility supports low-volume prototyping through high-volume production runs, with full traceability and quality control per ISO standards.

The following table outlines typical performance specifications for our rubber-based piston check valve components, based on common customer requirements and material options:

| Property | Nitrile (NBR) | EPDM | Fluorocarbon (FKM) | Silicone (VMQ) |

|---|---|---|---|---|

| Temperature Range | -30°C to +120°C | -50°C to +150°C | -20°C to +200°C | -60°C to +180°C |

| Hardness (Shore A) | 60–90 | 50–80 | 70–90 | 40–80 |

| Tensile Strength | ≥15 MPa | ≥10 MPa | ≥12 MPa | ≥6 MPa |

| Elongation at Break | ≥250% | ≥200% | ≥150% | ≥300% |

| Fluid Resistance | Excellent (oils, fuels) | Good (water, steam) | Excellent (acids, oils) | Poor (hydrocarbons) |

| Compression Set (70h, 100°C) | ≤25% | ≤30% | ≤20% | ≤25% |

All materials are subject to customization based on OEM specifications. Our integrated engineering approach ensures that piston check valves manufactured by Suzhou Baoshida deliver reliable, long-term performance in hydraulic systems, pneumatic controls, and industrial processing equipment.

Customization Process

Customization Process for Precision Piston Check Valves

At Suzhou Baoshida Trading Co., Ltd., our piston check valve customization follows a rigorously controlled sequence to ensure absolute compliance with industrial fluid system requirements. This process eliminates operational risks associated with improper sealing, pressure surges, or media incompatibility. Each phase integrates material science expertise with precision manufacturing protocols.

Drawing Analysis

Initial technical review focuses on dimensional tolerances, surface finish specifications, and geometric deviations per ISO 2768-mK. We dissect GD&T callouts for seat sealing surfaces and piston guidance features, cross-referencing against fluid dynamics parameters like maximum differential pressure and flow velocity. Critical attention is given to groove geometry for elastomer retention under cyclic stress. Any ambiguity in OEM drawings triggers immediate clarification to prevent downstream nonconformities.

Formulation Development

Material selection is driven by media exposure temperature extremes and chemical resistance demands. Our rubber compounding laboratory synthesizes proprietary FKM, EPDM, or HNBR formulations with tailored polymer backbones and cure systems. For instance, aerospace-grade FKM variants incorporate peroxide curing for enhanced thermal stability above 250°C, while pharmaceutical applications demand ultra-low extractables via optimized filler dispersion. Shore A hardness is precisely modulated between 70–90 to balance compression set resistance and dynamic sealing force.

Prototyping & Validation

Three iterative prototype batches undergo accelerated life testing per ISO 3601. Each unit is subjected to 10,000+ cycles at 150% rated pressure while immersed in specified media. Leakage rates are quantified using helium mass spectrometry down to 1×10⁻⁹ atm·cm³/sec. Dimensional stability is verified via CMM scanning against nominal CAD data. Only when hysteresis curves and wear profiles meet OEM thresholds do we proceed to production release.

Mass Production Control

Serial production employs SPC-monitored injection molding with cavity pressure sensors ensuring ±0.5% weight consistency. Every batch includes traceable material certificates (ASTM D2000 line callouts) and undergoes 100% visual inspection for flash or voids. Final validation includes burst pressure testing at 3× working pressure and functional checks at minimum cracking pressure. Lot traceability is maintained from raw material drum to finished valve via laser-etched batch codes.

Key performance specifications for our standard piston check valve platform are summarized below. Custom formulations extend these parameters per project requirements.

| Parameter | Standard Range | Test Standard | Material Grade Example |

|---|---|---|---|

| Pressure Rating | 0.5–420 bar | ISO 2852 | FKM GLT 70 |

| Temperature Range | -40°C to +230°C | ASTM D2240 | HNBR 85 |

| Media Compatibility | Hydraulic oils, fuels | ISO 1817 | EPDM 70 |

| Cracking Pressure | 0.05–5 bar (adjustable) | ISO 10770 | FFKM 80 |

| Cycle Life | >1,000,000 cycles | ISO 6803 | FKM GLT 90 |

This disciplined workflow ensures Suzhou Baoshida delivers piston check valves that achieve zero leakage under extreme operational conditions while meeting global OEM quality frameworks. All stages are documented per IATF 16949 for full audit transparency.

Contact Engineering Team

For industrial manufacturers seeking high-performance piston check valves engineered for reliability and precision, Suzhou Baoshida Trading Co., Ltd. delivers advanced rubber solutions tailored to demanding operational environments. As a trusted partner in industrial sealing technology, we specialize in the design, formulation, and supply of elastomeric components that meet rigorous industry standards. Our expertise in rubber compounding ensures that each piston check valve performs optimally under fluctuating pressures, extreme temperatures, and exposure to aggressive media.

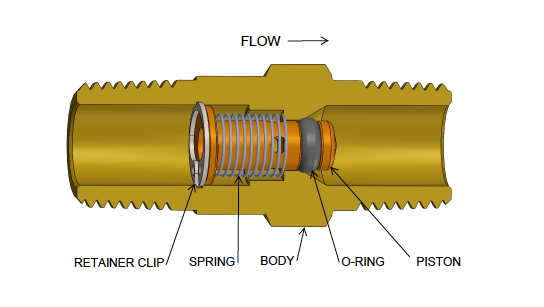

Piston check valves are critical in maintaining unidirectional flow in hydraulic and pneumatic systems, preventing backflow that can compromise system integrity and efficiency. At Suzhou Baoshida, we understand that material selection is paramount to valve longevity and performance. Our formulations are developed using high-grade nitrile (NBR), ethylene propylene diene monomer (EPDM), fluorocarbon (FKM), and other specialty elastomers, each selected based on chemical resistance, compression set, and dynamic sealing capability.

We support OEMs and industrial system integrators with custom compound development, precision molding, and full technical validation. Whether your application involves oil and gas, chemical processing, or heavy machinery, our engineering team collaborates closely to ensure material compatibility and dimensional accuracy. Our quality management systems adhere to ISO 9001 standards, and all products undergo stringent testing for burst pressure, cycle life, and environmental resistance.

Below is a representative specification table for a standard piston check valve configuration using NBR compound, commonly used in hydraulic systems:

| Parameter | Specification |

|---|---|

| Material | Nitrile Rubber (NBR), 70 Shore A |

| Operating Temperature Range | -30°C to +100°C (-22°F to +212°F) |

| Maximum Operating Pressure | 350 bar (5,076 psi) |

| Fluid Compatibility | Mineral oils, hydraulic fluids, water |

| Seal Hardness | 65–75 Shore A |

| Cycle Life | >1,000,000 cycles (tested) |

| Standards Compliance | ISO 3601, AS568, DIN 3869 |

| Customization Options | Material, size, durometer, color |

Our commitment extends beyond product supply—we provide technical consultation, failure analysis, and on-site support to ensure seamless integration into your systems. With a responsive supply chain and global logistics network, Suzhou Baoshida ensures on-time delivery without compromising quality.

For immediate assistance with piston check valve specifications, material recommendations, or custom development, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer, directly at [email protected]. Mr. Boyce leads our technical engagement with international clients and is available to discuss application-specific challenges, request samples, or initiate qualification protocols. Include your project details, performance requirements, and preferred communication method to expedite the evaluation process.

Partner with Suzhou Baoshida Trading Co., Ltd. for engineered rubber solutions that enhance system reliability and reduce total cost of ownership. Your next-generation sealing solution begins with a single contact.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).