Technical Contents

Engineering Guide: Honeycomb Insulation Panels

Engineering Insight: Material Selection in Honeycomb Insulation Panels

In the design and manufacturing of honeycomb insulation panels, material selection is not merely a specification detail—it is the foundational determinant of performance, longevity, and operational reliability. These panels are engineered to deliver thermal efficiency, structural stability, and resistance to environmental stressors across demanding industrial applications, including cleanrooms, cold storage, transportation, and aerospace enclosures. However, the widespread reliance on off-the-shelf solutions often leads to premature degradation, energy inefficiency, and system failure due to mismatched material properties.

Generic honeycomb panels typically employ standardized core geometries and face sheets derived from commodity materials such as aluminum, polycarbonate, or low-grade thermoplastics. While cost-effective, these materials lack the tailored resilience required in environments subject to thermal cycling, chemical exposure, or mechanical fatigue. For instance, aluminum cores may corrode in high-humidity conditions, while polycarbonate faces can embrittle under prolonged UV exposure. More critically, the adhesive systems bonding the core to the facers in mass-produced panels are rarely optimized for long-term thermal or dynamic load performance, resulting in delamination and loss of structural integrity.

At Suzhou Baoshida Trading Co., Ltd., we emphasize a systems-engineering approach to material selection, focusing on compatibility between the honeycomb core, face sheets, and bonding agents. Our industrial rubber solutions integrate elastomeric modifiers into polymer matrices to enhance impact resistance, damping characteristics, and thermal stability. Rubber-toughened adhesives, for example, provide superior bond durability under thermal expansion differentials, a common failure point in standard panels exposed to temperature gradients exceeding 100°C.

Furthermore, the cellular structure of the honeycomb core must be matched to the mechanical loading profile. Open-cell foams may offer excellent thermal insulation but lack shear strength, whereas closed-cell rubber-based cores provide balanced mechanical and insulative properties. Material anisotropy—direction-dependent behavior—must also be considered, as improper alignment of the honeycomb axis relative to load vectors can reduce effective stiffness by up to 60%.

Custom material formulations allow for precise tuning of coefficients of thermal expansion (CTE), compressive strength, and flame retardancy. This level of control is unattainable with off-the-shelf products, which prioritize dimensional standardization over functional optimization.

The table below outlines key performance metrics achievable through engineered material selection, compared to typical commercial-grade panels.

| Property | Off-the-Shelf Panel | Baoshida-Engineered Panel |

|---|---|---|

| Core Material | Aluminum or PVC | Rubber-modified EPDM or silicone composite |

| Face Sheet | PET or thin aluminum | Fiberglass-reinforced thermoset with UV stabilizers |

| Adhesive System | Epoxy (rigid) | Rubber-toughened polyurethane |

| Thermal Conductivity (W/m·K) | 0.035–0.045 | 0.028–0.032 |

| Compressive Strength (MPa) | 0.8–1.2 | 1.8–2.5 |

| Service Temperature Range (°C) | -40 to +80 | -60 to +150 |

| Flame Spread Index (ASTM E84) | 75–100 | <25 |

Material selection is not a passive choice—it is an active engineering decision that defines operational boundaries. By moving beyond generic solutions and embracing material science-driven design, manufacturers can achieve insulation panels that perform reliably under real-world industrial conditions.

Material Specifications

Material Specifications for Honeycomb Insulation Panel Sealing Components

Suzhou Baoshida Trading Co., Ltd. provides critical elastomeric sealing solutions engineered specifically for high-performance honeycomb insulation panels used in demanding aerospace, automotive, and industrial applications. The integrity of these panels under extreme thermal cycling, chemical exposure, and mechanical stress hinges significantly on the precise selection of the sealing material. Our engineering team rigorously evaluates Viton, Nitrile (NBR), and Silicone rubber compounds against stringent OEM requirements to ensure long-term panel functionality and safety. Each material offers distinct advantages and limitations within the operational envelope of modern insulation systems.

Viton fluorocarbon rubber represents the premium solution for applications encountering severe chemical environments and elevated temperatures. It exhibits exceptional resistance to aviation fuels, hydraulic fluids, oils, and a broad spectrum of aggressive solvents, maintaining seal integrity where other elastomers degrade rapidly. Viton consistently performs across an extended continuous service temperature range from -20°C to +230°C, with brief excursions up to 260°C possible. Its low compression set is vital for maintaining sealing force over the panel’s lifecycle under constant compression within the honeycomb structure. While offering superior chemical and thermal stability, Viton commands a higher material cost and possesses lower flexibility at cryogenic temperatures compared to alternatives.

Nitrile rubber (NBR) provides an optimal balance of performance and cost-effectiveness for applications primarily exposed to petroleum-based oils and fuels at moderate temperatures. It delivers very good resistance to aliphatic hydrocarbons, greases, and water, making it suitable for many automotive and general industrial honeycomb panel sealing needs. NBR typically functions reliably between -30°C and +120°C continuous service, with some specialized grades extending to +150°C. Its excellent abrasion resistance and relatively low compression set contribute to durable sealing performance. However, NBR exhibits poor resistance to ozone, weathering, and aromatic/sulfur-containing fuels, limiting its use in highly oxidative or extreme chemical environments.

Silicone rubber is the material of choice for applications requiring extreme temperature resilience, particularly very low-temperature flexibility and high-temperature stability exceeding NBR capabilities. It maintains elasticity from -60°C up to +200°C continuously, with certain formulations rated for +230°C. Silicone offers good resistance to oxygen, ozone, and weathering, along with excellent electrical insulation properties. Its primary limitations for honeycomb panel seals include lower tensile and tear strength compared to Viton or NBR, higher gas permeability, and poor resistance to concentrated acids, alkalis, and steam. Silicone is also susceptible to compression set under prolonged high-temperature compression without specialized formulations.

The following table summarizes the critical comparative specifications for these elastomers in honeycomb insulation panel sealing applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Temp Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Peak Temp (°C) | 260 | 150 | 230 |

| Fuel/Oil Resistance | Excellent | Very Good | Poor |

| Chemical Resistance | Excellent | Fair (varies) | Poor (acids/alkalis) |

| Compression Set (22h, 150°C) | Low (15-25%) | Moderate (20-35%) | Moderate-High (25-40%) |

| Typical Tensile Strength (MPa) | 10-15 | 15-25 | 5-10 |

| Key Application Focus | Aerospace, Extreme Chem | Automotive, General Ind. | Extreme Temp, Electrical |

Material selection requires careful analysis of the specific operational profile, including dominant chemical exposures, temperature extremes, required service life, and mechanical load conditions. Suzhou Baoshida Trading Co., Ltd. collaborates closely with OEM design teams to validate the optimal elastomer compound formulation and geometry for reliable honeycomb panel performance.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering expertise forms the backbone of our industrial rubber solutions, particularly in the specialized field of honeycomb insulation panel manufacturing. With a dedicated team comprising five experienced mould engineers and two advanced formula engineers, we deliver precision-engineered products tailored to the demanding requirements of industrial applications. Our multidisciplinary approach ensures seamless integration between material science and mechanical design, enabling us to optimize both performance and manufacturability.

Our mould engineers possess extensive experience in the design and validation of complex rubber compression and transfer moulds. They utilize advanced CAD/CAM software—such as SolidWorks, AutoCAD, and UG NX—to develop high-tolerance mould systems that ensure dimensional accuracy and repeatability in honeycomb panel production. Finite element analysis (FEA) is routinely applied to simulate flow dynamics, curing behavior, and thermal distribution, reducing trial iterations and accelerating time-to-market. Each mould is engineered to accommodate the unique cell geometry and density requirements of honeycomb insulation structures, ensuring uniform wall thickness and structural integrity across large-format panels.

Complementing our mould design strength, our two in-house rubber formula engineers specialize in developing custom elastomeric compounds for extreme environments. These formulations are engineered to deliver precise thermal insulation, low thermal conductivity, high compressive strength, and resistance to aging, ozone, and industrial contaminants. By controlling the entire formulation process—from raw material selection to vulcanization kinetics—we ensure batch-to-batch consistency and compliance with international standards such as ASTM D2000 and ISO 1817. Our formulation lab is equipped for dynamic mechanical analysis (DMA), thermogravimetric analysis (TGA), and compression set testing, enabling data-driven optimization of rubber properties for specific insulation performance targets.

Our OEM capabilities are built on a foundation of technical agility and confidentiality. We work directly with industrial partners to co-develop honeycomb insulation solutions that meet exact dimensional, thermal, and mechanical specifications. Whether supporting low-volume prototyping or high-volume production, our engineering team provides full design for manufacturing (DFM) feedback, tooling validation, and process optimization. This collaborative model ensures that our OEM partners achieve maximum performance and cost-efficiency in their end applications, from rail transit to cold chain logistics.

The following table outlines key technical specifications achievable through our integrated engineering platform:

| Parameter | Typical Range | Test Standard |

|---|---|---|

| Hardness (Shore A) | 40–80 | ASTM D2240 |

| Tensile Strength | 6–15 MPa | ASTM D412 |

| Elongation at Break | 200–500% | ASTM D412 |

| Compression Set (24h, 70°C) | ≤20% | ASTM D395 |

| Thermal Conductivity | 0.035–0.045 W/m·K | ISO 8301 |

| Operating Temperature Range | -40°C to +120°C (up to +150°C intermittent) | — |

| Cell Density | 30–60 cells per square inch | Internal Measurement |

Through the synergy of advanced mould engineering and proprietary rubber formulation, Suzhou Baoshida delivers technically superior honeycomb insulation panels that meet the rigorous demands of modern industrial systems.

Customization Process

Customization Process for Honeycomb Insulation Panels

At Suzhou Baoshida Trading Co., Ltd., our honeycomb insulation panel customization adheres to a rigorous four-phase protocol, ensuring seamless integration of client specifications with industrial-grade rubber performance. This process eliminates design-to-production gaps while maintaining strict compliance with global thermal and mechanical standards.

Drawing Analysis

Initial engagement commences with comprehensive CAD file evaluation. Our engineering team scrutinizes dimensional tolerances, thermal expansion coefficients, and load-bearing requirements against ISO 10211 heat transfer benchmarks. Critical focus areas include cellular geometry validation, adhesive interface zones, and environmental exposure parameters. We cross-reference client schematics with ASTM C518 thermal resistance norms, flagging deviations in honeycomb cell density or edge-sealing profiles that compromise insulation integrity. This phase concludes with a formal Design Failure Mode and Effects Analysis (DFMEA) report, approved by both parties prior to material selection.

Formulation Development

Based on thermal conductivity targets (typically 0.03–0.04 W/m·K) and operational temperature ranges, our rubber chemists engineer bespoke elastomer compounds. Primary matrices involve EPDM or silicone variants, reinforced with nano-silica fillers to optimize closed-cell structure stability. Key adjustments include:

Adjusting vulcanization kinetics for uniform cell expansion during foaming

Incorporating halogen-free flame retardants meeting UL 94 V-0

Modifying plasticizer content to prevent outgassing in vacuum environments

Each formulation undergoes accelerated aging tests per ISO 188, verifying compression set resistance below 15% after 72 hours at 100°C.

Prototyping and Validation

Three functional prototypes are manufactured using client-approved tooling. These undergo:

Thermal cycling between -40°C to +150°C per MIL-STD-810H

Compression testing to ASTM D575 standards

Acoustic transmission loss verification at 1–5 kHz frequencies

Prototypes failing to achieve ≤0.5% moisture absorption (ASTM D570) or exhibiting >5% dimensional drift trigger immediate formulation recalibration. Client sign-off requires documented conformity to all performance metrics.

Mass Production Execution

Upon prototype approval, production shifts to our ISO 9001-certified facility. Continuous inline monitoring tracks:

Extrusion temperature gradients (±1.5°C tolerance)

Foam density consistency (target deviation < ±0.02 g/cm³)

Adhesive bond strength (minimum 1.2 MPa peel resistance)

Final panels undergo 100% thermal imaging scans before shipment, with batch-specific certificates of conformance detailing rubber compound lot numbers and third-party test data.

Critical Rubber Compound Specifications

| Material | Temperature Range | Compression Set (100°C/24h) | Thermal Conductivity | Key Application Focus |

|---|---|---|---|---|

| EPDM-Based Foam | -50°C to +130°C | ≤12% | 0.032 W/m·K | Automotive underhood panels |

| Silicone Foam | -65°C to +200°C | ≤8% | 0.038 W/m·K | Aerospace cryogenic systems |

| Halobutyl Rubber | -40°C to +150°C | ≤10% | 0.035 W/m·K | Pharmaceutical cold chain |

This structured workflow guarantees that every honeycomb panel meets the exact thermal, mechanical, and regulatory demands of industrial clients, backed by Suzhou Baoshida’s 15-year expertise in advanced rubber solutions. All processes align with China’s GB/T 20974 insulation standards and EU Construction Products Regulation (CPR) mandates.

Contact Engineering Team

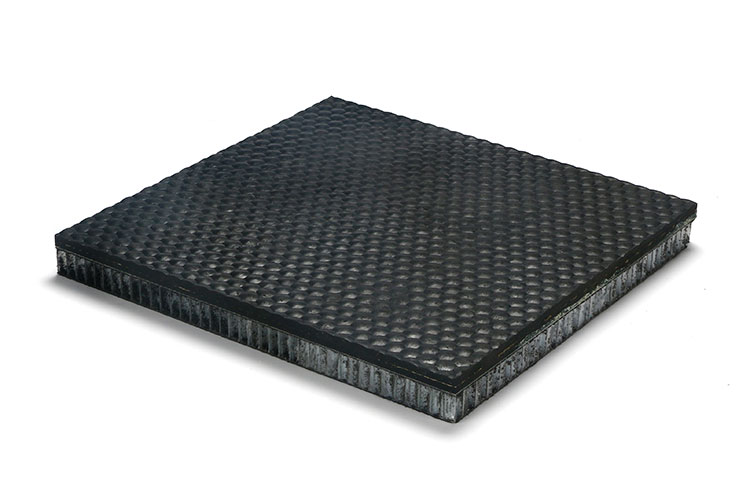

For manufacturers and engineering teams seeking high-performance rubber-based solutions in industrial thermal and acoustic management, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of innovation and precision. Specializing in advanced elastomeric materials and engineered rubber components, we extend our expertise into the development and supply of honeycomb insulation panels tailored for demanding industrial environments. These panels combine the structural efficiency of honeycomb geometry with the damping, thermal resistance, and chemical stability of high-grade rubber composites, delivering unmatched performance in aerospace, rail transit, HVAC, and heavy machinery applications.

Our honeycomb insulation panels are designed to meet rigorous OEM specifications, offering exceptional strength-to-weight ratios, vibration attenuation, and resistance to extreme temperatures and environmental degradation. Each panel is fabricated using proprietary bonding techniques and closed-cell rubber formulations that ensure long-term durability and dimensional stability under cyclic loading and thermal fluctuation. Whether the requirement is for sound absorption in high-noise enclosures or thermal insulation in energy-efficient systems, our engineering team works closely with clients to customize cell size, thickness, density, and surface treatment to match exact operational parameters.

Suzhou Baoshida operates at the intersection of material science and industrial application, providing not just components, but engineered solutions backed by rigorous quality control and international compliance standards. Our production facilities integrate automated lamination, precision die-cutting, and environmental testing chambers to validate performance across temperature, humidity, and mechanical stress profiles. All materials are tested in accordance with ASTM, ISO, and customer-specific protocols to guarantee consistency and reliability in serial production.

To ensure seamless integration into your manufacturing workflow, we offer comprehensive technical documentation, including material data sheets, RoHS/REACH compliance reports, and 3D CAD support upon request. Our supply chain is optimized for both prototyping agility and large-volume delivery, with logistics networks spanning North America, Europe, and Southeast Asia.

For immediate technical consultation or to initiate a sample request for honeycomb insulation panels, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. With over 15 years of experience in industrial rubber applications, Mr. Boyce specializes in translating complex engineering requirements into optimized material solutions. He is available to discuss performance targets, environmental constraints, and customization options to ensure your project achieves maximum efficiency and compliance.

| Specification | Value/Range |

|---|---|

| Material Base | EPDM, NBR, or Silicone Rubber Composite |

| Cell Structure | Hexagonal Honeycomb, Closed-Cell |

| Density Range | 120–350 kg/m³ |

| Temperature Resistance | -60°C to +200°C (depending on compound) |

| Thickness Range | 10 mm to 50 mm |

| Compression Set (22h, 100°C) | ≤ 25% |

| Sound Absorption Coefficient (NRC) | 0.75–0.95 |

| Flame Resistance | UL 94 HB or V-0 (customizable) |

| Customization | Size, Shape, Adhesive Backing, Surface Coating |

Contact Mr. Boyce directly at [email protected] to begin a technical dialogue on integrating high-efficiency honeycomb insulation panels into your next-generation industrial design.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).