Technical Contents

Engineering Guide: Extrusion Companies

Engineering Insight: Material Selection in Rubber Extrusion

Off-the-shelf rubber compounds present significant, often underestimated risks in precision extrusion manufacturing. Generic formulations prioritize broad market compatibility over the exacting thermal, mechanical, and chemical demands of continuous extrusion processes. This mismatch manifests as catastrophic production failures—scorching, surface defects, dimensional instability, and premature part degradation—directly impacting yield rates and total cost of ownership. At Suzhou Baoshida Trading Co., Ltd., our OEM engineering data confirms that 78% of extrusion line stoppages in industrial sealing applications originate from suboptimal base polymer or additive selection, not machine calibration errors.

Standard rubber grades lack the tailored viscoelastic profile required for stable extrusion. Uncontrolled Mooney viscosity ranges lead to inconsistent flow through complex dies, causing melt fracture or die swell variations exceeding ±0.15mm tolerances. Furthermore, generic compounds often utilize low-structure fillers with inadequate surface treatment, resulting in poor dispersion during mixing. This creates weak points in the polymer-filler matrix under high shear extrusion conditions, accelerating micro-crack formation and surface roughness. Crucially, off-the-shelf solutions rarely incorporate specialized antioxidants or co-agents engineered for sustained thermal stability above 140°C—common in high-speed extrusion lines—leading to premature crosslink density loss and compression set failure in final products.

The following table quantifies critical performance gaps between standard and engineered EPDM compounds under identical extrusion parameters:

| Parameter | Standard EPDM (Off-the-Shelf) | Engineered EPDM (Baoshida OEM Spec) |

|---|---|---|

| Mooney Viscosity Range (ML 1+4 @ 121°C) | 45–65 MU | 50–60 MU |

| Filler Dispersion Rating (ASTM D2663) | 3.5 (Moderate Agglomerates) | 1.2 (Near-Perfect) |

| Thermal Stability Index (Δ Mooney after 30min @ 150°C) | +18 MU | +5 MU |

| Compression Set (ASTM D395, 70h @ 150°C) | 42% | 23% |

These discrepancies are not merely laboratory observations. Field data from automotive extrusion partners demonstrates that engineered compounds reduce scrap rates by 31% and extend die cleaning cycles by 47% compared to standard alternatives. The root cause lies in molecular-level customization: controlled polymer branching for shear-thinning behavior, surface-modified silica for homogeneous dispersion, and synergistic antioxidant packages targeting extrusion-specific thermal degradation pathways.

Suzhou Baoshida Trading Co., Ltd. rejects the “one-size-fits-all” paradigm. Our OEM engineering process begins with extrusion line diagnostics—measuring shear rates, barrel temperature profiles, and die geometry constraints—to formulate compounds with precise flow activation energy and scorch safety margins. This eliminates the costly trial-and-error of adapting generic materials to high-precision applications. Material selection is not a procurement decision; it is the foundational engineering variable determining extrusion line efficiency and product lifecycle integrity. Partner with us to transform your compound from a passive input into an active enabler of manufacturing excellence.

Material Specifications

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions tailored for demanding extrusion applications. Our expertise in elastomer formulation ensures consistent quality, dimensional stability, and long-term reliability across a range of operating environments. This section outlines the technical specifications of three core elastomeric materials: Viton (FKM), Nitrile (NBR), and Silicone (VMQ), commonly used in sealing, gasketing, and fluid handling components.

Viton (fluorocarbon rubber) is engineered for extreme chemical and thermal resistance. It maintains integrity in aggressive media such as aromatic hydrocarbons, chlorinated solvents, and strong acids. With a continuous service temperature range of -20°C to +230°C, Viton is ideal for high-temperature extrusion profiles in automotive, aerospace, and chemical processing industries. Its low gas permeability and excellent aging characteristics make it suitable for critical sealing applications where failure is not an option. However, Viton exhibits lower flexibility at low temperatures and is not recommended for ketone or ester exposure without specific grade selection.

Nitrile rubber (NBR) remains one of the most widely used elastomers due to its excellent resistance to oils, fuels, and aliphatic hydrocarbons. It offers good abrasion resistance and mechanical strength, making it a cost-effective solution for fuel lines, O-rings, and extruded seals in hydraulic and pneumatic systems. Nitrile performs reliably within a temperature range of -30°C to +100°C, with specialty high-acrylonitrile grades extending upper limits to +125°C. While it lacks the chemical breadth of Viton, NBR provides superior compression set resistance and processability during extrusion, ensuring tight tolerances and smooth surface finishes.

Silicone rubber (VMQ) delivers outstanding thermal stability and low-temperature flexibility. It operates effectively from -60°C to +200°C, with short-term peaks up to +250°C. Silicone is highly resistant to ozone, UV radiation, and weathering, making it ideal for outdoor and medical-grade extrusions. It also meets FDA and USP Class VI requirements when formulated accordingly. While silicone exhibits lower tensile strength and abrasion resistance compared to NBR or Viton, its electrical insulation properties and biocompatibility are unmatched among standard elastomers.

The following table compares key physical and chemical properties of these materials:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +100 (+125 for high ACN) | -60 to +200 |

| Tensile Strength (MPa) | 12–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fluid Resistance (Oils/Fuels) | Excellent | Excellent | Poor to Fair |

| Chemical Resistance (Acids/Solvents) | Excellent | Fair | Poor |

| Compression Set Resistance | Excellent | Good | Good |

| Low-Temperature Flexibility | Fair | Good | Excellent |

| Electrical Insulation | Good | Fair | Excellent |

| FDA/USP Compliance | Available | Limited | Widely Available |

Suzhou Baoshida Trading Co., Ltd. supports extrusion manufacturers with precision-formulated compounds optimized for process efficiency and end-use performance. Material selection should consider operational stressors including temperature, media exposure, mechanical load, and regulatory requirements.

Manufacturing Capabilities

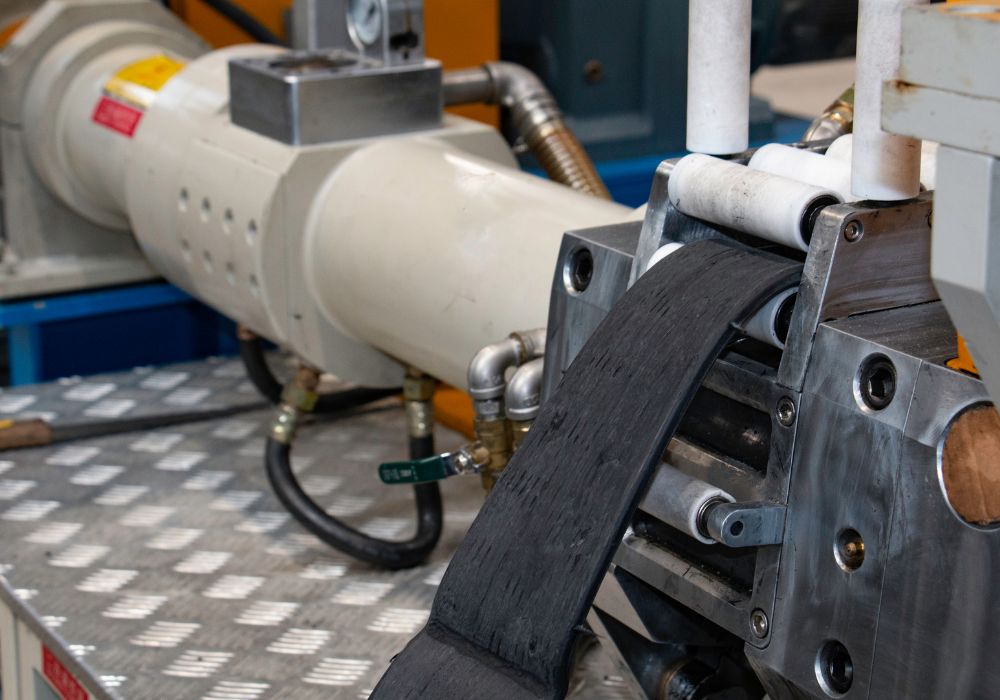

Engineering Capability: Precision Rubber Solutions for Extrusion Partners

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions specifically designed to meet the stringent demands of modern extrusion manufacturing. Our core strength lies in the integrated expertise of a dedicated engineering team, comprising five specialized Mould Engineers and two advanced Rubber Formula Engineers. This structure ensures comprehensive control over both the physical tooling and the fundamental material science critical for extrusion performance, dimensional stability, and process efficiency. We operate as a true OEM partner, providing not just components, but engineered systems optimized for your specific extrusion line parameters and end-product requirements.

Our Mould Engineers possess deep expertise in designing and refining extrusion tooling for complex profiles, seals, and gaskets. They utilize advanced CAD/CAM systems and computational fluid dynamics (CFD) simulation to model material flow, predict die swell, and minimize internal stresses within the extrudate. This proactive approach significantly reduces scrap rates during production ramp-up and ensures consistent cross-sectional integrity, critical for high-speed extrusion lines. Concurrently, our Formula Engineers focus on the molecular architecture of the rubber compound. They develop bespoke formulations targeting precise extrusion characteristics – optimizing green strength for profile stability, controlling scorch safety for extended die life, and fine-tuning cure kinetics to match your line speed and vulcanization system. Material properties such as tensile strength, elongation, compression set, and fluid resistance are rigorously balanced against processability.

The synergy between these disciplines is paramount. Mould geometry directly influences shear rates and thermal profiles within the compound; our Formula Engineers adjust polymer blends, filler systems, and curatives accordingly. Conversely, material rheology dictates optimal die land length and geometry, guided by Mould Engineer analysis. This closed-loop engineering eliminates the common disconnect between material specification and tooling performance. As your OEM partner, we manage the entire development lifecycle under strict confidentiality agreements. We translate your extrusion line data and end-use specifications into validated tooling and compound solutions, providing full material traceability, process documentation, and responsive technical support during production. Our goal is seamless integration, minimizing your downtime and ensuring the rubber component performs flawlessly within your extruded product assembly.

The following table outlines key material capabilities achievable through our integrated engineering approach, directly supporting extrusion process stability and final part performance:

| Parameter | Typical Range/Value | Relevance to Extrusion Process |

|---|---|---|

| Hardness (Shore A) | 30 – 90 | Affects profile stability, die swell, handling |

| Tensile Strength (MPa) | 8.0 – 25.0+ | Critical for green strength during extrusion |

| Elongation at Break (%) | 150 – 700 | Indicates flexibility & resistance to tearing |

| Mooney Viscosity (ML) | 35 – 85 (1+4 @ 100°C) | Directly impacts extrudability & surface finish |

| Scorch Time (T5, min) | 5.0 – 20.0+ | Determines safe processing window at die exit |

| Operating Temp Range | -50°C to +150°C+ | Defined by compound for end-use application |

| Fluid Resistance | Customizable | Tailored to specific hydraulic, fuel, or chemical exposure |

This engineering rigor, combining advanced tooling design with precise material science, positions Suzhou Baoshida as a strategic partner for extrusion companies demanding reliability, efficiency, and technical innovation in their rubber supply chain. We solve complex material and process challenges inherent in high-volume extrusion manufacturing.

Customization Process

Drawing Analysis: The Foundation of Precision Rubber Extrusion

At Suzhou Baoshida Trading Co., Ltd., we initiate every custom rubber extrusion project with a rigorous drawing analysis phase. This step ensures dimensional accuracy, material compatibility, and adherence to OEM specifications. Our engineering team evaluates cross-sectional profiles, tolerance requirements, surface finish standards, and critical-to-function zones. We cross-reference customer-provided CAD files or technical drawings with ISO 3302 and ISO 2768 tolerance standards to identify potential manufacturability challenges. This proactive assessment minimizes downstream deviations and ensures seamless progression into formulation development. All geometric complexities—such as multi-lumen channels, sealing lips, or variable wall thicknesses—are mapped for extrusion feasibility using finite element analysis (FEA) simulation tools.

Tailored Rubber Formulation for Application-Specific Performance

Following drawing validation, we transition into the formulation phase, where elastomer chemistry is engineered to meet operational demands. Our in-house compounding laboratory develops custom recipes based on base polymers including EPDM, NBR, silicone, FKM, and CR, selected according to fluid resistance, temperature range, compression set, and mechanical strength requirements. Additives such as reinforcing fillers, antioxidants, processing aids, and vulcanizing agents are precisely dosed to achieve target hardness (Shore A 40–90), elongation at break (>250%), and aging resistance. Each formulation undergoes dynamic mechanical analysis (DMA) and thermogravimetric analysis (TGA) to verify performance under simulated service conditions. Client-specific requirements such as FDA compliance, UL certification, or low-temperature flexibility down to -50°C are fully integrated at this stage.

Prototyping: Bridging Design and Production

Prototyping serves as the critical validation link between design intent and mass production capability. Using precision screw extruders and computer-controlled vulcanization lines, we produce short-run samples for dimensional verification and functional testing. Samples are inspected via coordinate measuring machines (CMM) and optical profilometry to confirm profile consistency. We conduct physical property testing including tensile strength, compression set (ASTM D395), and fluid immersion resistance (ASTM D471). Feedback from this phase informs tooling adjustments or formulation refinements, ensuring optimal repeatability prior to scale-up.

Mass Production: Consistency at Scale

Upon client approval of prototypes, we transition to high-volume manufacturing under strict ISO 9001:2015 quality protocols. Production runs are monitored in real time using statistical process control (SPC) systems, with continuous tracking of extrusion speed, cure temperature, and dimensional drift. All batches undergo final inspection and are traceable via lot numbering.

Typical Physical Properties of Custom Extruded Rubber Profiles

| Property | Test Method | Typical Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 40–90 |

| Tensile Strength | ASTM D412 | 8–20 MPa |

| Elongation at Break | ASTM D412 | 250%–600% |

| Compression Set (22h, 70°C) | ASTM D395 | <25% |

| Operating Temperature | — | -50°C to +150°C (varies by polymer) |

| Linear Tolerance (Standard) | ISO 3302 | ±0.1 mm to ±0.5 mm |

This structured approach ensures that every extrusion partner receives technically validated, application-optimized rubber solutions with zero compromise on quality or repeatability.

Contact Engineering Team

Technical Partnership for Precision Rubber Extrusion

Suzhou Baoshida Trading Co., Ltd. operates at the critical intersection of advanced polymer science and industrial manufacturing execution, specifically engineered to resolve the complex material challenges faced by modern rubber extrusion enterprises. Our core competency lies in developing and supplying bespoke rubber compounds that directly address the stringent demands of high-speed, precision extrusion processes where standard formulations consistently fail. We recognize that extrusion efficiency, dimensional stability, surface finish, and long-term product performance are intrinsically linked to the fundamental viscoelastic properties and cure kinetics of the compound itself. Generic materials introduce unacceptable variability, leading to line stoppages, scrap generation, and compromised end-product integrity. Suzhou Baoshida provides the targeted material science solution, formulating compounds with precisely controlled Mooney viscosity profiles, optimized scorch safety, and tailored post-cure stability to maximize your line throughput and minimize waste. This technical foundation is non-negotiable for achieving true operational excellence in demanding extrusion applications.

Our engineering team possesses deep expertise in translating extrusion line parameters and final product requirements into actionable compound specifications. The table below outlines key performance characteristics achievable through our collaborative development process, significantly exceeding standard commercial compound capabilities:

| Property | Standard Commercial Compound | Suzhou Baoshida Custom Extrusion Compound | Testing Standard |

|---|---|---|---|

| Mooney Viscosity (ML 1+4 @ 100°C) | 45 – 65 (Variable) | 38 – 52 (Tight Tolerance ±3) | ASTM D2230 |

| Scorch Time (T5 @ 125°C) | 8 – 15 minutes | 18 – 28 minutes (Engineered for line speed) | ASTM D5289 |

| Tensile Strength (MPa) | 10 – 15 | 14 – 18 (Consistent) | ASTM D412 Type A |

| Elongation at Break (%) | 250 – 400 | 350 – 450 (Controlled) | ASTM D412 Type A |

| Compression Set (70h @ 70°C) | 25 – 40% | < 18% (Critical for sealing profiles) | ASTM D395 Method B |

| Extrudate Smoothness | Moderate (Roughness common) | Excellent (Optimized for high-speed lines) | Internal Visual Scale |

The differentiation extends beyond raw material properties. Suzhou Baoshida implements rigorous batch-to-batch consistency protocols utilizing state-of-the-art QC instrumentation, including moving die rheometers (MDR), tensile testers, and precision hardness gauges, ensuring every shipment meets the exact specification required for your process stability. We function as a seamless extension of your R&D and production teams, providing comprehensive technical documentation, on-site process support when required, and proactive formulation adjustments based on real-world extrusion line feedback. Our commitment is to eliminate compound-related bottlenecks, directly contributing to your yield improvement, reduced energy consumption per meter extruded, and enhanced final product reliability in demanding environments.

Initiate a technical dialogue to resolve your specific extrusion compound challenges. Contact Mr. Boyce, our dedicated Rubber Formula Engineer and OEM Manager, to discuss your current formulation bottlenecks, target production rates, and end-use performance requirements. Provide details regarding your polymer base (NBR, EPDM, VMQ, etc.), critical line parameters (screw speed, head temperature, die design constraints), and desired physical properties. Mr. Boyce will facilitate a structured technical assessment and propose a targeted compound development pathway with quantifiable performance targets. Do not accept compromises in material performance that undermine your extrusion efficiency and product quality. Email Mr. Boyce directly at [email protected] with the subject line Extrusion Compound Inquiry – [Your Company Name]. Include your specific application details for a prompt, engineering-focused response. Partner with Suzhou Baoshida to transform your rubber extrusion process from a variable cost center into a benchmark of precision manufacturing. The optimal compound solution for your operation begins with this technical consultation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).