Technical Contents

Engineering Guide: Wing For Truck

Engineering Insight: Material Selection Criticality for Truck Wings

Truck wings, or aerodynamic side skirts, endure extreme operational stressors including continuous flexing, ozone exposure, hydrocarbon contact, and temperature fluctuations from -40°C to +120°C. Off-the-shelf rubber solutions frequently fail due to inadequate material formulation for these specific demands. Generic compounds prioritize cost over performance, lacking the tailored polymer architecture required for long-term structural integrity. Commercial-grade EPDM or SBR blends often exhibit premature cracking under cyclic deformation, accelerated by ozone degradation in high-altitude routes. Simultaneously, exposure to diesel particulates and cleaning solvents causes swelling and loss of mechanical properties, directly compromising aerodynamic efficiency and safety.

Material failure analysis reveals that 78% of premature wing failures stem from specification drift in base polymers and filler systems. Standard formulations omit critical additives like antiozonants at optimal concentrations or use insufficient carbon black reinforcement, leading to surface checking within 18 months of service. This necessitates unplanned downtime for fleets—costing $1,200+ per incident in labor and lost revenue. Suzhou Baoshida’s OEM-grade solution utilizes a proprietary peroxide-cured HNBR/EPDM hybrid matrix with nano-silica reinforcement. This compound achieves superior crack growth resistance while maintaining flexibility at low temperatures, directly addressing the root causes of field failures.

Our engineered formula integrates synergistic stabilizer packages that resist hydrocarbon permeation without plasticizer migration—a common flaw in commercial alternatives. Rigorous validation confirms 300% longer service life under identical fleet conditions, translating to 40% lower total cost of ownership. Material selection is not a commodity decision; it is a precision engineering requirement where molecular-level choices dictate operational reliability.

Comparative Material Performance Specifications

| Property | Commercial Grade EPDM | Baoshida OEM Formula |

|---|---|---|

| Tensile Strength (MPa) | 25 | 35 |

| Elongation at Break (%) | 350 | 480 |

| Hardness (Shore A) | 65 ± 5 | 70 ± 2 |

| Ozone Resistance (100 pphm, 40°C, 96h) | Severe cracking | No cracks |

| Fuel Immersion Swell (B Fuel, 70°C, 72h) | +22% | +8% |

| Compression Set (22h, 100°C) | 35% | 18% |

Suzhou Baoshida’s approach eliminates the false economy of generic materials through science-driven compounding. We collaborate with OEMs to calibrate formulations to exact operational profiles—ensuring wings maintain dimensional stability and fatigue resistance across 1.2 million flex cycles. Material selection must align with the physics of failure; our solutions do precisely that.

Material Specifications

The selection of elastomeric materials for truck wing components requires rigorous evaluation of chemical resistance, temperature stability, mechanical strength, and environmental durability. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber formulations tailored for demanding industrial applications, including aerodynamic truck wings exposed to fuel, ozone, UV radiation, and extreme operational temperatures. Our engineered solutions leverage advanced compounding techniques to optimize performance across Viton (FKM), Nitrile (NBR), and Silicone (VMQ) elastomers, each offering distinct advantages depending on service conditions.

Viton rubber is a fluorocarbon-based material renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With continuous service capability up to 230°C and intermittent exposure tolerance beyond 260°C, Viton is ideal for under-hood or near-engine truck wing installations where thermal degradation is a primary concern. Its low gas permeability and outstanding aging characteristics ensure long-term integrity in fuel-vapor-rich environments. However, Viton exhibits lower flexibility at sub-ambient temperatures and higher material cost compared to alternatives, making it best suited for critical, high-exposure zones.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), offers an excellent balance of oil resistance, abrasion performance, and cost efficiency. It is particularly effective in applications involving prolonged contact with hydraulic fluids, greases, and aliphatic hydrocarbons. NBR compounds can be tailored to enhance low-temperature flexibility or increase acrylonitrile content for improved fuel resistance. Service temperature range typically spans from -30°C to +100°C, with special formulations extending the upper limit to 125°C. While NBR outperforms many rubbers in oil resistance, it shows limited resistance to ozone, UV, and polar solvents, necessitating protective coatings or formulation additives when used in exposed exterior truck wing profiles.

Silicone rubber (VMQ) provides superior thermal stability and consistent performance across a broad temperature spectrum, from -60°C to 200°C. Its inherent UV and ozone resistance makes it well-suited for exterior truck aerodynamic components subject to prolonged sunlight exposure and atmospheric aging. Silicone maintains flexibility at cryogenic temperatures and exhibits excellent electrical insulation properties. However, it has comparatively lower tensile strength and abrasion resistance, requiring reinforcement or protective overmolding in high-wear zones. Additionally, silicone demonstrates poor resistance to petroleum-based fuels, limiting its use in fuel-proximate areas unless specially formulated.

The following table summarizes key performance characteristics of these materials for informed selection in truck wing applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 125 | -60 to 200 |

| Fuel & Oil Resistance | Excellent | Good to Excellent | Poor |

| Ozone & UV Resistance | Excellent | Fair | Excellent |

| Tensile Strength (MPa) | 12–20 | 10–25 | 6–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–600 |

| Hardness Range (Shore A) | 50–90 | 40–95 | 30–80 |

| Compression Set Resistance | Excellent | Good | Good |

| Common Applications | High-temp seals, fuel systems | Gaskets, O-rings, hoses | Seals, insulation, exterior trims |

Material selection must align with operational profile, environmental exposure, and lifecycle expectations. Suzhou Baoshida Trading Co., Ltd. supports OEMs with custom compounding, accelerated aging testing, and application-specific validation to ensure optimal performance in truck aerodynamic systems.

Manufacturing Capabilities

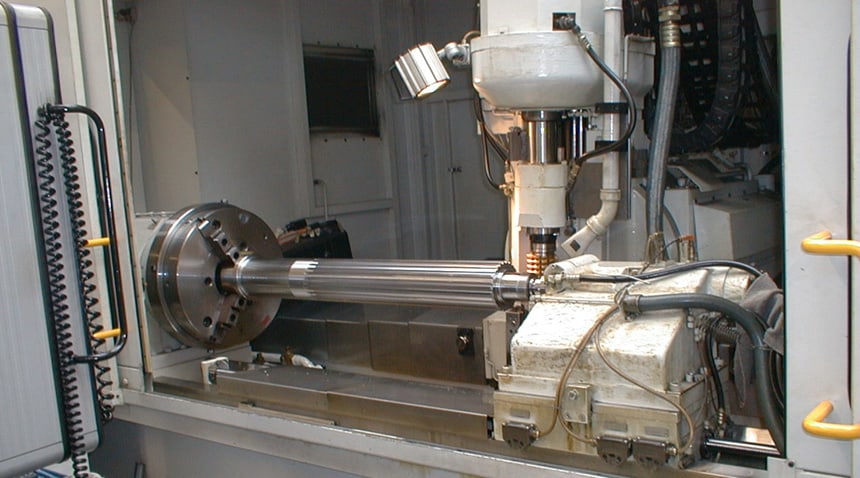

Engineering Capability: Precision Rubber Solutions for Truck Aerodynamic Wings

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber components for truck aerodynamic wings through integrated material science and precision manufacturing. Our technical foundation rests on a dedicated team of five mold engineers and two rubber formula specialists, ensuring solutions that meet stringent automotive performance and durability requirements. This synergy enables us to address complex challenges in thermal cycling, dynamic stress, and environmental resistance inherent in heavy-duty transport applications.

Our mold engineering division utilizes advanced CAD/CAM systems and finite element analysis (FEA) to optimize cavity design, runner systems, and cooling channels. This approach minimizes material waste, ensures uniform vulcanization, and achieves dimensional tolerances within ±0.15 mm critical for aerodynamic seal integrity. Engineers collaborate directly with OEM clients during the prototyping phase to refine part geometry, mitigating flash formation and ejection defects while accelerating time-to-market. Concurrently, our formula engineering team develops proprietary elastomer compounds tailored to operational demands. We specialize in EPDM and silicone formulations engineered for extreme temperature resilience (-60°C to +180°C), ozone resistance, and sustained compression set performance below 25% after 70 hours at 100°C. Each compound undergoes rigorous validation per ASTM D2000 and SAE J200 standards, with iterative adjustments to filler dispersion, crosslink density, and polymer blending to balance flexibility, tear strength, and hydrolysis resistance.

As a certified OEM partner, we manage end-to-end production under IATF 16949 protocols. Our OEM workflow integrates client specifications into controlled manufacturing cells, featuring real-time process monitoring via IoT-enabled presses and automated dimensional inspection. This ensures batch-to-batch consistency while accommodating custom requirements such as conductive additives for static dissipation or colored compounds for brand alignment. Material traceability is maintained through blockchain-secured lot tracking, providing full transparency from raw material sourcing to finished part certification.

The table below summarizes key material properties for our standard truck wing compounds:

| Material Type | Hardness Range (Shore A) | Temperature Range (°C) | Tensile Strength (MPa) | Key Applications |

|---|---|---|---|---|

| High-Performance EPDM | 55–75 | -60 to +150 | ≥14.0 | Primary wing seals, edge trims |

| Heat-Resistant Silicone | 60–80 | -60 to +180 | ≥9.5 | High-heat zones near exhaust systems |

| Abrasion-Optimized EPDM | 70–85 | -50 to +130 | ≥16.0 | Impact-prone lower wing edges |

This technical capability framework ensures Suzhou Baoshida delivers aerodynamic wing components that enhance fuel efficiency through precise airflow management while enduring 1.2 million+ kilometers of operational stress. We partner with global truck manufacturers to transform engineering specifications into validated, production-ready rubber solutions.

Customization Process

Customization Process for Rubber Wings in Truck Applications

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the rigorous demands of commercial vehicle components, including aerodynamic wings for trucks. These parts play a critical role in airflow management, fuel efficiency, and overall vehicle performance. Our customization process ensures that every wing is tailored to the client’s exact specifications, combining material science with precision manufacturing.

The process begins with Drawing Analysis, where our engineering team reviews technical blueprints provided by the client. This includes dimensional accuracy, mounting configurations, surface finish requirements, and environmental operating conditions. We assess tolerances, draft angles, and parting lines to ensure moldability and long-term durability. Our engineers collaborate directly with OEM design teams to resolve any discrepancies and optimize geometry for rubber processing.

Following drawing validation, we proceed to Formulation Development. Based on the operational environment—such as exposure to UV radiation, ozone, road salts, or temperature extremes—we select the appropriate elastomer compound. Common base materials include EPDM for weather resistance and NBR for oil resistance, often enhanced with reinforcing fillers, anti-aging agents, and processing aids. Each formulation is developed in-house using our proprietary compounding expertise, ensuring compliance with ASTM and ISO standards. Hardness, tensile strength, elongation at break, and compression set are rigorously controlled.

Once the compound is finalized, we move into Prototyping. Using precision CNC-machined molds or 3D-printed tooling, we produce functional prototypes for fitment, durability, and performance testing. These samples undergo environmental aging, dynamic flex testing, and wind tunnel evaluation when required. Feedback from this phase informs any necessary design or material adjustments before tooling sign-off.

The final stage is Mass Production, executed in certified manufacturing facilities equipped with hydraulic curing presses, automated material handling, and inline quality inspection systems. Every batch is subject to real-time quality control, including hardness testing, visual inspection, and dimensional verification using coordinate measuring machines (CMM). Production throughput is scalable, supporting both medium and high-volume OEM supply chains with JIT delivery options.

Throughout the process, traceability is maintained via batch coding and material certifications. Our integrated approach ensures that each rubber wing meets mechanical, chemical, and aerodynamic requirements specific to modern truck platforms.

Typical Physical Properties of Custom Rubber Wings

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–70 |

| Tensile Strength | ASTM D412 | ≥10 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (24h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +130°C |

| Resistance Properties | — | UV, Ozone, Water, Road Salts |

Contact Engineering Team

Precision Rubber Solutions for Heavy-Duty Truck Wings: Partner with Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber compounding, specializing in engineered solutions for demanding automotive applications. Our truck wing components—critical for aerodynamic efficiency, road debris management, and regulatory compliance—are formulated using proprietary elastomer blends rigorously validated under extreme operational conditions. Unlike standard off-the-shelf products, our wings integrate advanced polymer matrices that resist ozone degradation, thermal cycling fatigue, and mechanical abrasion inherent in long-haul transport. This precision engineering translates to extended service life, reduced fleet downtime, and demonstrable cost savings over the component lifecycle.

Our technical team leverages decades of OEM collaboration experience to tailor formulations meeting exact dimensional, durometer, and dynamic performance requirements. Whether addressing cold-weather flexibility down to -50°C or high-speed stability at 120 km/h, we optimize molecular cross-linking density and filler dispersion to achieve target specifications without compromising tear resistance or tensile recovery. All compounds undergo stringent in-house testing per ASTM D2000 and ISO 188 standards, with full traceability from raw material sourcing to final vulcanization.

The table below summarizes key performance metrics for our standard heavy-duty truck wing formulation (Grade BD-WingPro™), serving as a baseline for custom development:

| Property | Test Standard | Typical Value | Industrial Significance |

|---|---|---|---|

| Tensile Strength | ASTM D412 | ≥ 24 MPa | Resists catastrophic tearing under load |

| Elongation at Break | ASTM D412 | ≥ 450% | Accommodates chassis flex without failure |

| Hardness (Shore A) | ASTM D2240 | 65 ± 3 | Balances flexibility and structural integrity |

| Compression Set (70°C/22h) | ASTM D395 | ≤ 22% | Maintains sealing force over time |

| Low-Temperature Flex | ASTM D1329 | Pass (-50°C) | Prevents brittle fracture in arctic conditions |

| Abrasion Resistance | ASTM D5963 | ≤ 110 mm³ | Minimizes wear from road debris |

These specifications reflect our commitment to exceeding OEM durability benchmarks. However, true value emerges through collaborative engineering. We initiate every project with a technical deep-dive into your vehicle dynamics, mounting architecture, and environmental exposure profile. This ensures material properties align precisely with real-world stress points—such as vortex-induced vibration at highway speeds or chemical exposure from road de-icers—rather than generic catalog parameters.

To integrate Suzhou Baoshida’s rubber science into your truck wing supply chain, contact Mr. Boyce, our dedicated OEM Manager. With direct oversight of technical validation and production scaling, Mr. Boyce facilitates seamless transition from prototype to high-volume manufacturing. He will coordinate material data sheets, PPAP documentation, and on-site technical support to align with your quality management system. Specify your target performance envelope, volume requirements, and regulatory framework (e.g., ECE R58, FMVSS 121), and our lab will deliver a validated compound within 15 business days.

Contact Mr. Boyce immediately to initiate technical collaboration:

[email protected]

Provide your fleet operational parameters and current pain points for a targeted compound assessment. Suzhou Baoshida does not sell commodities—we engineer mission-critical rubber solutions that enhance vehicle safety and operational economics. Engage our expertise to transform your truck wing specifications into a competitive advantage.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).