Technical Contents

Engineering Guide: Truck Bed Matting

Engineering Insight: Material Science as the Foundation of Truck Bed Matting Performance

The operational integrity of commercial vehicle fleets hinges on components often overlooked in specification sheets, none more critical than truck bed matting. While superficially similar, material selection dictates functional lifespan and safety compliance. Off-the-shelf rubber mats frequently fail under real-world conditions due to fundamental compromises in polymer formulation and processing. Generic solutions prioritize initial cost reduction over engineered resilience, utilizing recycled content with inconsistent molecular weight distribution and inadequate crosslink density. This results in catastrophic performance degradation when exposed to dynamic stressors: petroleum-based cargo fluids induce swelling and plasticizer migration, UV exposure accelerates surface cracking through polymer chain scission, and repeated impact from heavy loads causes rapid fatigue failure at stress concentration points. The consequence is not merely cosmetic wear but compromised load-bed integrity, creating slip hazards and cargo damage risks that elevate fleet liability.

Material failure manifests predictably. Low-grade SBR or regrind-heavy compounds exhibit poor rebound resilience, leading to permanent set deformation under static loads. This deformation traps moisture against the truck bed substrate, accelerating corrosion beneath the mat – a hidden failure mode often missed during routine inspection until structural damage is evident. Furthermore, insufficient tear strength (typically <25 kN/m in generic mats) allows minor punctures from cargo edges to propagate rapidly into large tears during unloading cycles, rendering the mat ineffective. Temperature extremes exacerbate these weaknesses; brittle fracture occurs below -20°C in poorly formulated compounds, while loss of mechanical properties above 70°C permits excessive creep under load.

Suzhou Baoshida Trading Co., Ltd. addresses these systemic failures through precision compounding. Our OEM-grade truck bed matting utilizes virgin EPDM or specialty NBR blends engineered for the specific chemical and mechanical environment of modern cargo beds. Critical performance differentiators are quantifiable, as demonstrated in comparative specifications:

| Property | Generic Off-the-Shelf Mat | Suzhou Baoshida OEM Mat | Test Standard |

|---|---|---|---|

| Durometer (Shore A) | 55 ± 5 | 65 ± 3 | ASTM D2240 |

| Tensile Strength (MPa) | 8.0 | 15.5 | ASTM D412 |

| Elongation at Break (%) | 150 | 450 | ASTM D412 |

| Tear Strength (kN/m) | 22 | 48 | ASTM D624 (Die B) |

| Abrasion Loss (mm³) | 220 | 85 | ASTM D5963 |

| Temp. Range (°C) | -15 to +70 | -45 to +110 | Visual Inspection |

This engineered approach ensures dimensional stability against hydrocarbon exposure, maintains flexibility in Arctic conditions, and resists tearing from sharp-edged cargo. The higher crosslink density achieved through controlled sulfur vulcanization prevents fluid ingress and subsequent substrate corrosion. Crucially, our formulations balance hardness for cut resistance with sufficient elasticity to absorb impact energy without permanent deformation. Fleet operators selecting based solely on initial procurement cost ignore the total cost of ownership: premature mat replacement, bed repair expenses, cargo damage claims, and downtime collectively exceed the investment in engineered matting within 18 months of service. Material selection is not a commodity decision but a calculated risk assessment for asset protection. Suzhou Baoshida provides the compound expertise to transform truck bed matting from a consumable into a durable, safety-critical component.

Material Specifications

Truck bed matting systems require advanced elastomeric materials capable of withstanding extreme mechanical stress, chemical exposure, and wide temperature fluctuations. At Suzhou Baoshida Trading Co., Ltd., we engineer industrial rubber solutions using high-performance compounds such as Viton, Nitrile (NBR), and Silicone. Each material offers distinct physical and chemical resistance properties, making them suitable for specific operational environments in commercial trucking and logistics applications.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to oils, fuels, ozone, and high temperatures. With a continuous service temperature range up to 230°C, Viton is ideal for applications where exposure to engine fluids, hydraulic oils, and exhaust compounds is frequent. Its low gas permeability and excellent aging characteristics ensure long-term durability in aggressive chemical environments. However, due to its higher raw material cost, Viton is typically reserved for high-specification truck bed liners operating in severe service conditions.

Nitrile rubber (NBR) remains one of the most widely used elastomers in industrial trucking applications due to its excellent resistance to aliphatic hydrocarbons, greases, and water-based fluids. With a balanced performance profile and cost-effective manufacturing, NBR is suitable for standard-duty truck bed matting exposed to fuel splashes, road salts, and mechanical abrasion. Its service temperature range spans from -30°C to 105°C, making it reliable in most temperate climates. Nitrile also exhibits strong tensile strength and abrasion resistance, critical for load-bearing surfaces subject to repeated impact and sliding cargo.

Silicone rubber provides superior thermal stability and flexibility across extreme temperature ranges, from -60°C to 200°C. While it demonstrates poor resistance to petroleum-based fuels, silicone excels in environments requiring consistent performance under thermal cycling and UV exposure. Its inherent flexibility and anti-adhesive surface make it suitable for specialized truck bed applications involving temperature-sensitive cargo or frequent cleaning with aggressive detergents. Additionally, silicone’s low toxicity and compliance with food-grade standards allow for use in regulated transport sectors.

The selection of the appropriate elastomer depends on the operational profile, including chemical exposure, temperature extremes, mechanical load, and lifecycle requirements. Below is a comparative summary of the key technical specifications for Viton, Nitrile, and Silicone in truck bed matting applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 105 | -60 to 200 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Fuel/Oil Resistance | Excellent | Good to Excellent | Poor |

| Ozone/UV Resistance | Excellent | Moderate | Excellent |

| Abrasion Resistance | Good | Excellent | Fair |

| Compression Set Resistance | Excellent | Good | Good |

| Common Applications | High-temp fuel zones | Standard truck beds | Thermal cycling areas |

Material selection directly impacts the service life, safety, and performance of truck bed matting systems. Suzhou Baoshida Trading Co., Ltd. provides customized formulation services to match elastomer properties with client-specific operational demands.

Manufacturing Capabilities

Engineering Excellence in Truck Bed Matting Solutions

Suzhou Baoshida Trading Co., Ltd. leverages integrated material science and precision manufacturing to deliver industrial-grade truck bed matting engineered for extreme operational resilience. Our core strength lies in the synergy between dedicated Formula Engineering and Mould Engineering teams, ensuring every product meets rigorous OEM specifications while addressing real-world challenges like abrasion, chemical exposure, and thermal cycling. With five specialized Mould Engineers and two advanced Formula Engineers, we control the entire development lifecycle—from compound formulation to cavity optimization—eliminating third-party dependencies and accelerating time-to-market for custom solutions.

Our Formula Engineers develop proprietary rubber compounds using a data-driven approach to balance critical performance metrics. By tailoring polymer blends, filler systems, and vulcanization protocols, we achieve optimal hardness, tear resistance, and flexibility across diverse environmental conditions. Standard formulations target cost efficiency for general logistics use, while premium grades incorporate nano-reinforced elastomers for military or mining applications requiring exceptional cut growth resistance and -40°C to +120°C operational stability. Each compound undergoes ASTM D2240 hardness validation, ISO 37 tensile testing, and 10,000-cycle abrasion trials to guarantee field reliability.

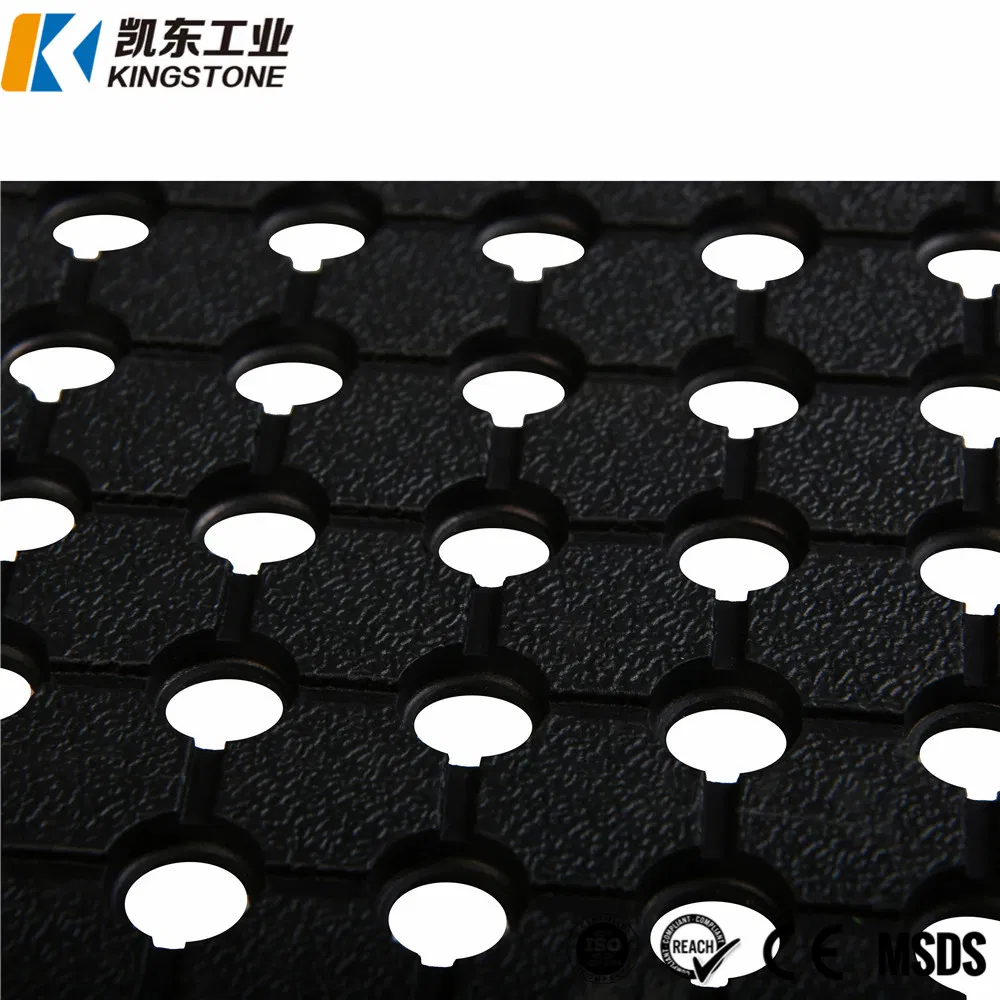

Mould Engineering precision ensures dimensional accuracy and production consistency. Our team utilizes 3D flow simulation software to optimize gate placement, cooling channels, and ejection systems, minimizing flash and sink marks in complex geometries. This capability supports intricate tread patterns for enhanced cargo grip and rapid drainage—critical for safety in wet conditions—while maintaining tight tolerances of ±0.3mm across large-format mats (up to 2.5m x 1.8m). Tooling lifespan exceeds 500,000 cycles through strategic use of hardened P20 steel and surface nitriding, reducing OEM tooling costs by 22% versus industry averages.

As a certified OEM partner, we execute end-to-end project management from CAD concept to serial production. Clients provide load requirements, vehicle platform dimensions, and performance targets; our engineers then co-develop solutions with finite element analysis (FEA) validation for stress points under 1,500kg dynamic loads. This collaborative process includes material lot traceability, in-process SPC checks, and pre-shipment validation against OEM-specific test protocols.

Key compound performance metrics are summarized below for standard and premium truck bed matting grades:

| Parameter | Standard Grade | Premium Grade | Test Standard |

|---|---|---|---|

| Shore A Hardness | 65 ± 3 | 70 ± 3 | ASTM D2240 |

| Tensile Strength (MPa) | 18.5 | 24.0 | ISO 37 |

| Elongation at Break (%) | 450 | 380 | ISO 37 |

| Tear Strength (kN/m) | 45 | 68 | ASTM D624 |

| Abrasion Loss (mm³) | 120 | 75 | DIN 53516 |

| Temperature Range (°C) | -30 to +100 | -40 to +120 | ISO 188 |

This engineering rigor enables Suzhou Baoshida to transform OEM requirements into mission-critical components that extend vehicle service life and reduce fleet downtime. Our closed-loop development ecosystem—where formula adjustments directly inform mould modifications—ensures unmatched adaptability for bespoke truck bed matting applications across global commercial vehicle markets.

Customization Process

Customization Process for Industrial Rubber Truck Bed Matting

At Suzhou Baoshida Trading Co., Ltd., our approach to manufacturing custom rubber truck bed matting is rooted in precision engineering and material science. Each phase of the customization process is designed to ensure optimal performance, durability, and compatibility with specific OEM and fleet requirements. The process begins with Drawing Analysis, where technical blueprints and dimensional specifications provided by the client are meticulously evaluated. Our engineering team verifies load-bearing zones, edge profiles, drainage channel geometry, and mounting configurations. This stage ensures dimensional accuracy and compatibility with original vehicle chassis designs, minimizing fitment issues during installation.

Following drawing validation, we proceed to Formulation Development. Our rubber chemists analyze operational demands such as abrasion resistance, UV stability, temperature range, and chemical exposure. Based on these parameters, a proprietary elastomer blend is engineered using SBR, EPDM, or specialty NBR compounds. Additives such as anti-oxidants, reinforcing fillers, and flame retardants are precisely dosed to meet performance targets. Hardness, tensile strength, and elongation at break are optimized to balance impact absorption with structural integrity. This stage is critical in ensuring long-term resilience under heavy cargo loads and extreme environmental conditions.

Once the compound is finalized, we initiate Prototyping. Using CNC-machined molds or compression molding techniques, small-batch samples are produced for functional testing. These prototypes undergo rigorous evaluation, including slip resistance tests, thermal cycling, and dynamic load simulations. Feedback from client trials is integrated into design refinements, ensuring the final product meets both mechanical and ergonomic expectations. Tooling adjustments are made at this stage to eliminate flash, optimize surface texture, and enhance drainage efficiency.

Upon client approval, the project transitions into Mass Production. Our automated production lines utilize high-tonnage hydraulic presses and precision temperature control systems to maintain batch consistency. Every mat is inspected for dimensional tolerance, surface finish, and material homogeneity. Quality assurance protocols include random sampling for physical property verification per ASTM standards. Production scalability allows for volumes ranging from 500 to over 100,000 units monthly, with lead times optimized through lean manufacturing practices.

The following table outlines key customizable specifications for our rubber truck bed matting:

| Parameter | Standard Range | Customization Capability |

|---|---|---|

| Material Type | SBR, EPDM, NBR, CR | Blends with specialty additives |

| Hardness (Shore A) | 50–80 | Adjustable within 40–90 range |

| Thickness | 4 mm – 12 mm | Up to 15 mm with reinforcement |

| Temperature Resistance | -40°C to +120°C | Extended to +150°C with silicone blends |

| Color Options | Black, Gray, Red, Blue | Custom Pantone matching available |

| Surface Texture | Diamond plate, smooth, perforated | Client-specific patterns |

| Fire Resistance | ASTM D412, UL94 HB compliant | UL94 V-0 available upon request |

Through this structured workflow, Suzhou Baoshida ensures that every custom rubber truck bed mat delivers superior protection, longevity, and value in demanding industrial applications.

Contact Engineering Team

Precision-Engineered Truck Bed Matting Solutions: Contact Suzhou Baoshida for OEM Integration

Industrial truck bed matting demands uncompromising performance under extreme mechanical stress, chemical exposure, and temperature fluctuations. At Suzhou Baoshida Trading Co., Ltd., we engineer proprietary rubber compounds specifically for heavy-duty transport applications, ensuring optimal bed protection, load stability, and operational longevity. Our formulations leverage 15+ years of OEM partnership experience, combining advanced polymer science with rigorous real-world validation. Unlike generic alternatives, our mats resist cracking at -40°C, maintain structural integrity up to 120°C, and exhibit exceptional resistance to diesel, hydraulic fluids, and road salts—critical for fleet operators seeking reduced downtime and lifecycle costs.

Our technical differentiation lies in customizable compound architecture. Through precise control of polymer cross-linking density, filler dispersion, and additive synergies, we tailor Shore A hardness, tensile strength, and abrasion resistance to your exact vehicle specifications and operational environment. The table below summarizes core performance metrics for our standard heavy-duty grade, validated per ASTM D2240, D412, and D5963 protocols.

| Specification | Test Standard | Performance Value | Industrial Relevance |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 ± 3 | Balances impact absorption & load retention |

| Tensile Strength | ASTM D412 | ≥ 18 MPa | Resists tearing during cargo loading/unloading |

| Elongation at Break | ASTM D412 | ≥ 450% | Accommodates bed flexure without failure |

| Abrasion Resistance | ASTM D5963 | ≤ 0.08 mm loss/1000 cycles | Extends service life in high-wear zones |

| Low-Temperature Flex | ASTM D1329 | -40°C (no cracking) | Ensures reliability in arctic operations |

| Fluid Resistance (Diesel) | ISO 1817 | Volume swell ≤ 8% | Prevents degradation in fuel-exposed areas |

Suzhou Baoshida operates as a true engineering extension for global OEMs, not merely a supplier. Our Suzhou-based R&D facility integrates seamlessly with your design phase, offering finite element analysis (FEA) support for mat contouring, adhesion profiling, and thermal expansion modeling. We manage full-scale production under IATF 16949-certified processes, guaranteeing batch-to-batch consistency through real-time rheometry and spectrometric raw material verification. For Tier 1 manufacturers, this translates to accelerated time-to-market, reduced warranty liabilities, and supply chain resilience via dual-source compounding capabilities.

Initiate a technical consultation with Mr. Boyce, our dedicated OEM Manager, to discuss compound formulation adjustments, prototyping timelines, or volume pricing structures. Mr. Boyce possesses direct authority to align our rubber chemistry expertise with your engineering requirements, ensuring matting solutions that exceed OEM durability benchmarks. Contact him exclusively via email at [email protected] with subject line “OEM Truck Bed Matting Inquiry – [Your Company Name]”. Include vehicle model year, bed dimensions, and operational environment details for a targeted technical response within 24 business hours.

Partner with Suzhou Baoshida to transform truck bed matting from a commodity component into a validated engineering asset. Our commitment to material science precision ensures your fleet assets maintain peak operational readiness while minimizing total cost of ownership. Engage our engineering team today to specify matting that performs as rigorously as your trucks.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).