Technical Contents

Engineering Guide: Aero Precision Jobs

Engineering Insight: Material Selection for Aero Precision Jobs

In aerospace manufacturing, precision rubber components operate under extreme conditions where failure is not an option. Standard off-the-shelf elastomers consistently underperform in these applications due to inherent limitations in molecular architecture and performance boundaries. Aerospace environments subject materials to rapid thermal cycling from -55°C to +200°C, prolonged exposure to aggressive aviation fuels and hydraulic fluids, and sustained dynamic stress without tolerance for dimensional drift. Commercial-grade compounds lack the tailored polymer networks required to maintain sealing integrity, resilience, and chemical resistance under such duress.

The core failure mechanism in non-specialized rubbers is accelerated degradation of crosslink density. During thermal aging or fluid immersion, standard formulations experience significant compression set increase, tensile strength loss, and volume swell. For instance, a generic EPDM seal in a fuel system may initially meet basic specifications but will rapidly harden and crack after 500 hours at 150°C, leading to catastrophic leakage. Similarly, silicone variants without aerospace-specific additives exhibit unacceptable compression set in static sealing applications after repeated thermal cycles, compromising joint integrity in critical airframe assemblies.

Material selection must address three non-negotiable criteria:

1. Long-term compression set resistance at operational extremes

2. Immunity to swelling/degradation from Skydrol, Jet A, and MIL-H-5606

3. Dimensional stability under continuous stress relaxation

Suzhou Baoshida Trading Co., Ltd. addresses these demands through custom-formulated compounds engineered to AMS, AS, and NAS standards. Our aerospace-grade elastomers integrate high-purity polymers with precision-cured crosslink systems and proprietary stabilizer packages. Below is a comparative performance analysis of standard versus aerospace-optimized EPDM:

| Performance Parameter | Standard EPDM (Commercial Grade) | Aerospace-Grade EPDM (Baoshida BD-Aero 700 Series) | Test Standard |

|---|---|---|---|

| Compression Set (22h @ 150°C) | 22% | 8% | ASTM D395 |

| Volume Swell in Skydrol 500B | 18% | 4% | ASTM D471 |

| Tensile Retention after Aging | 55% | 85% | ASTM D573 |

| Low-Temperature Flex (Brittleness) | -40°C | -65°C | ASTM D2137 |

This data underscores why generic solutions fail: they prioritize cost over molecular stability. Our formulations undergo rigorous validation per AMS7256, including 2,000-hour thermal aging and multi-fluid immersion testing. Crucially, we optimize cure kinetics to eliminate post-molding shrinkage—ensuring dimensional precision within ±0.05mm tolerances critical for fuel system O-rings or actuator boots.

Off-the-shelf elastomers represent a false economy in aerospace. The marginal cost savings are obliterated by field failures, recall expenses, and reputational damage. Precision demands precision: from polymer selection to vulcanization control, every parameter must align with the operational envelope. At Suzhou Baoshida, we collaborate with OEMs during the design phase to develop compounds where chemistry meets certification—delivering rubber solutions that perform flawlessly from takeoff to landing.

Material Specifications

Material selection is a critical factor in the performance and reliability of rubber components used in aero precision applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered to meet the rigorous demands of aerospace environments, where precision, temperature resistance, chemical compatibility, and mechanical integrity are non-negotiable. Our expertise includes the formulation and supply of high-performance elastomers such as Viton, Nitrile (NBR), and Silicone, each offering distinct advantages depending on the operational parameters of the application.

Viton, a fluorocarbon-based rubber (FKM), is widely regarded for its exceptional resistance to high temperatures, aviation fuels, lubricants, and a broad range of aggressive chemicals. With a continuous service temperature range up to 200°C and intermittent exposure capability up to 250°C, Viton is ideal for sealing applications in jet engines, fuel systems, and hydraulic units. Its low gas permeability and outstanding aging characteristics ensure long-term reliability in dynamic and static sealing roles under extreme conditions.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), offers excellent resistance to oils, greases, and aliphatic hydrocarbons, making it a cost-effective solution for fuel and oil handling systems. While not as thermally stable as Viton, Nitrile performs reliably within a temperature range of -30°C to 120°C, with certain formulations extending low-temperature flexibility down to -50°C. It exhibits good abrasion resistance and mechanical strength, suitable for O-rings, gaskets, and seals in auxiliary power units and hydraulic actuators.

Silicone rubber (VMQ or PVMQ) delivers superior performance in extreme temperature environments, functioning effectively from -60°C to 200°C, with short-term exposure up to 250°C. It is particularly valued for its stability under thermal cycling and resistance to ozone and UV radiation. While silicone has lower tensile strength and abrasion resistance compared to Viton or Nitrile, it excels in electrical insulation and biocompatibility, making it ideal for non-critical seals, sensor housings, and environmental sealing in avionics and cabin systems.

The following table provides a comparative overview of key physical and chemical properties for these materials:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 intermittently) | -30 to 120 (down to -50 in special grades) | -60 to 200 (up to 250 intermittently) |

| Fuel & Oil Resistance | Excellent | Excellent | Poor to Fair |

| Chemical Resistance | Excellent | Good | Fair |

| Compression Set Resistance | Excellent | Good | Good |

| Tensile Strength (MPa) | 10–20 | 15–25 | 5–10 |

| Hardness Range (Shore A) | 50–90 | 40–90 | 30–80 |

| Electrical Insulation | Good | Fair | Excellent |

| Outgassing Performance | Low | Moderate | Very Low |

Selection among Viton, Nitrile, and Silicone must be guided by a comprehensive evaluation of operational stressors, including media exposure, thermal profile, mechanical load, and regulatory compliance. At Suzhou Baoshida Trading Co., Ltd., we support OEMs and Tier suppliers with material data sheets, application engineering, and customized compounding to ensure optimal performance in aero precision environments.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Aerospace Applications

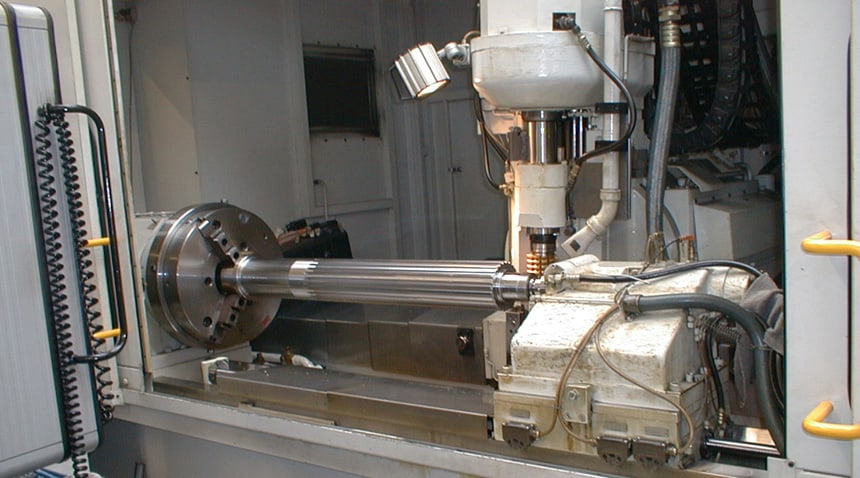

Suzhou Baoshida Trading Co., Ltd. delivers mission-critical rubber components for aerospace precision jobs through integrated engineering expertise and rigorous OEM processes. Our core strength lies in the seamless collaboration between dedicated Formula Engineering and Mould Engineering teams. Five specialized Mould Engineers optimize cavity design, gating systems, and thermal management for micron-level dimensional stability in complex geometries. Concurrently, two advanced Formula Engineers develop bespoke elastomer compounds meeting stringent aerospace material specifications, including AMS, AS, and ASTM standards. This dual-engineering approach ensures material performance and part geometry are co-optimized from inception, eliminating trade-offs between mechanical properties and manufacturability.

Our OEM workflow begins with joint design reviews to validate DFM (Design for Manufacturability) compliance, followed by iterative prototyping using in-house 3D printing and CNC-machined soft tooling. All compounds undergo accelerated aging, fluid resistance, and dynamic fatigue testing per AMS-STD-7404 requirements. Critical to aerospace reliability, we implement real-time process monitoring with cavity pressure sensors and automated SPC (Statistical Process Control) during production. This enables zero-defect manufacturing for seals, gaskets, vibration isolators, and fluid handling components operating under extreme thermal cycling (-55°C to +230°C) and pressure differentials.

Material performance is non-negotiable in aerospace systems. Below are key compound specifications validated for flight-critical applications:

| Material Grade | Hardness (Shore A) | Temp Range (°C) | Compression Set (ASTM D395) | Tensile Strength (MPa) |

|---|---|---|---|---|

| FKM 70 (Low Temp) | 68–72 | -40 to +230 | ≤25% @ 200°C/70h | ≥12 |

| EPDM 75 (Fluid Resistant) | 73–77 | -55 to +150 | ≤20% @ 150°C/70h | ≥10 |

| Silicone 60 (High Purity) | 58–62 | -60 to +200 | ≤15% @ 200°C/22h | ≥7 |

| HNBR 80 (Abrasion Resistant) | 78–82 | -40 to +170 | ≤18% @ 150°C/70h | ≥14 |

OEM project execution follows AS9100-aligned protocols, including full PPAP documentation with material traceability to batch level and 100% first-article inspection via CMM and optical comparators. We maintain dedicated cleanroom molding cells for contamination-sensitive programs and support rapid design iterations through digital twin simulation of cure kinetics and flow behavior. Suzhou Baoshida’s engineering framework guarantees that every component meets the weight, durability, and sealing integrity demands of modern aerospace platforms—proven through 12+ years of zero-failure field performance with Tier 1 aviation suppliers. Partner with us for rubber solutions where precision isn’t incremental—it’s absolute.

Customization Process

Drawing Analysis: The Foundation of Precision Rubber Components

At Suzhou Baoshida Trading Co., Ltd., the customization process for industrial rubber solutions begins with rigorous drawing analysis. This initial phase ensures that every dimension, tolerance, and functional requirement is fully understood before any material is selected. Our engineering team evaluates customer-provided technical drawings with a focus on critical features such as part geometry, sealing surfaces, wall thickness, and assembly constraints. We assess dimensional tolerances per ISO 3302 and ISO 2768 standards to determine feasibility and identify potential challenges in molding or post-processing. This stage also includes a review of environmental exposure conditions—such as temperature range, fluid compatibility, and dynamic stress—enabling us to align material performance with operational demands. Close collaboration with OEM design teams allows us to suggest design optimizations for manufacturability, reducing cycle time and enhancing part consistency.

Formulation: Engineering Material Performance to Specification

Once design parameters are confirmed, our rubber formula engineers develop a proprietary compound tailored to the application’s mechanical and chemical requirements. Utilizing advanced elastomer bases—including NBR, EPDM, FKM, silicone, and specialty blends—we customize formulations for optimal hardness, compression set resistance, tensile strength, and fluid resilience. Each formulation is documented and batch-traceable, ensuring repeatability across production runs. We conduct accelerated aging tests, swell analysis in target media, and dynamic mechanical analysis (DMA) to validate performance under real-world conditions. Regulatory compliance—such as FDA, ROHS, or UL certification—is integrated as required. This scientific approach to compounding ensures that the final material not only meets but exceeds OEM performance benchmarks.

Prototyping: Validating Design and Material Synergy

Following formulation approval, we proceed to prototype development using precision compression, transfer, or injection molding techniques. Prototypes are produced in mold tooling that mirrors final production conditions, enabling accurate assessment of fill behavior, flash control, and dimensional stability. Every prototype undergoes first-article inspection (FAI) with full metrology reports, including CMM verification where applicable. Functional testing—such as leak testing, compression deflection, and cycle endurance—is performed to verify performance. Feedback from this phase informs final adjustments to both design and process parameters, minimizing risk during scale-up.

Mass Production: Consistency at Scale

Upon prototype approval, we transition to mass production with strict adherence to APQP and PPAP protocols. Our automated production lines, in-line inspection systems, and statistical process control (SPC) ensure batch-to-batch consistency. All finished components are subjected to final quality checks per AQL 1.0 standards.

| Specification | Standard / Capability |

|---|---|

| Dimensional Tolerances | ISO 3302, ISO 2768 |

| Hardness Range | 30 to 90 ±5 Shore A |

| Material Types | NBR, EPDM, FKM, Silicone, CR, ACM |

| Production Capacity | Up to 500,000 pcs/month |

| Quality Standards | ISO 9001, IATF 16949 |

| Testing Capabilities | Fluid swell, compression set, tensile, aging |

Contact Engineering Team

Initiate Precision Rubber Component Collaboration for Aerospace Applications

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions meeting the uncompromising demands of aerospace precision manufacturing. Our expertise spans custom elastomer formulation, tight-tolerance molding, and rigorous validation for critical flight components. When dimensional stability, thermal resilience, and chemical resistance are non-negotiable, our ISO 9001:2015-certified processes ensure compliance with AS9100 aerospace standards. We specialize in converting complex technical drawings into high-integrity seals, gaskets, dampeners, and fluid-handling components where failure is not an option.

Our engineering team collaborates directly with OEMs to address material selection challenges across extreme operational envelopes. Whether mitigating fuel exposure at -55°C to +200°C or achieving Shore A hardness tolerances of ±2 points, we leverage proprietary compound databases and finite element analysis to preempt in-service performance risks. Every batch undergoes traceable testing per ASTM D2000 and AMS standards, with full material certification packages provided. The table below summarizes core capabilities relevant to aerospace precision jobs:

| Material Property | Aerospace Requirement | Suzhou Baoshida Standard |

|---|---|---|

| Temperature Range | -55°C to +200°C continuous | -60°C to +220°C (per spec) |

| Compression Set (70h/150°C) | ≤ 25% (AMS7256) | ≤ 18% (custom fluorosilicone) |

| Fuel Resistance (Jet A-1) | Volume swell ≤ 15% | ≤ 8% (FKM compounds) |

| Dimensional Tolerance | ±0.05mm (critical features) | ±0.025mm (molded to print) |

| Outgassing (TML) | ≤ 1.0% (NASA ASTM E595) | 0.35% (space-grade silicone) |

Partnering with Suzhou Baoshida eliminates supply chain vulnerabilities in mission-critical rubber component production. We maintain dedicated cleanroom molding cells for Class 10,000 environments and implement real-time SPC monitoring on all cavity pressures and cure times. Our technical team provides full DFM support during prototyping, reducing time-to-qualification by up to 40% compared to industry averages. For components requiring zero-defect validation, we offer witnessed testing at our Suzhou facility equipped with MTS fatigue rigs and FTIR spectrometry.

To initiate a technical consultation for your aerospace rubber component requirements, contact Mr. Boyce directly. As our OEM Manager with 12 years of aerospace rubber engineering experience, he will coordinate a cross-functional review of your specifications, material callouts, and production volumes. Mr. Boyce ensures seamless alignment between your engineering intent and our manufacturing execution, providing transparent lead time forecasting and PPAP documentation. Do not compromise on elastomer performance when safety and regulatory compliance are paramount.

Reach Mr. Boyce at [email protected] to submit technical drawings or discuss compound optimization for next-generation aircraft systems. Include your project timeline, annual volume estimates, and relevant specification references (e.g., AMS, MIL-R, or proprietary OEM standards) to accelerate our response. Suzhou Baoshida commits to a 24-hour technical feasibility assessment upon receipt of complete requirements. Your precision rubber solution begins with an engineered conversation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).