Technical Contents

Engineering Guide: Uhmw Polyethylene Material Properties

Engineering Insight: UHMW Polyethylene Material Properties

In industrial applications involving wear, impact, and chemical exposure, material selection is not merely a design consideration—it is a determinant of system longevity, efficiency, and total cost of ownership. Ultra-High Molecular Weight Polyethylene (UHMWPE) stands out among engineering thermoplastics due to its exceptional combination of low friction, high abrasion resistance, and impact strength. However, despite its widespread availability, off-the-shelf UHMWPE solutions frequently underperform in demanding environments. This discrepancy arises not from inherent material limitations, but from inadequate specification, improper processing, or mismatched application parameters.

Standard UHMWPE sheets, rods, or tapes sourced from generic suppliers often lack the consistency in molecular weight distribution, density, and processing controls required for mission-critical operations. For instance, improperly sintered or extruded UHMWPE may exhibit internal voids, inconsistent crystallinity, or residual stress, all of which compromise structural integrity under cyclic loading. Furthermore, many commercial-grade UHMWPE products are formulated for general-purpose use and do not account for specific operational variables such as temperature cycling, UV exposure, or sliding contact with abrasive media.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions tailored to the mechanical and environmental demands of each application. Our UHMWPE formulations are optimized for performance in sectors including mining, material handling, and automotive assembly lines—environments where failure due to wear or impact leads to costly downtime.

One of the defining characteristics of high-grade UHMWPE is its molecular weight, typically exceeding 3 million g/mol. This high chain length enables superior energy absorption and resistance to crack propagation. When processed correctly via compression molding or ram extrusion, the result is a homogeneous structure with minimal defects. Additionally, advanced grades may include additives such as silicone, molybdenum disulfide, or carbon fiber to enhance lubricity, dimensional stability, or ESD properties.

The following table outlines key mechanical and thermal properties of premium-grade UHMWPE, representative of the materials we supply and engineer for industrial clients:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength at Yield | 35–50 MPa | ASTM D638 |

| Impact Strength (Notched Izod) | >100 J/m | ASTM D256 |

| Density | 0.93–0.94 g/cm³ | ASTM D792 |

| Coefficient of Friction (vs. steel) | 0.10–0.22 | ASTM D1894 |

| Maximum Continuous Use Temperature | 80–90°C | ISO 2578 |

| Abrasion Resistance (Taber Wheel) | 10–15 mg/1000 cycles | ASTM D1044 |

| Water Absorption (24 hrs) | <0.01% | ASTM D570 |

Selecting the correct UHMWPE variant requires more than dimensional compatibility—it demands a deep understanding of stress regimes, mating surfaces, and environmental exposure. Off-the-shelf alternatives often fail because they are not engineered for these variables. At Baoshida, we collaborate with OEMs to ensure material performance aligns precisely with operational demands, reducing wear rates, minimizing maintenance cycles, and extending service life.

Material Specifications

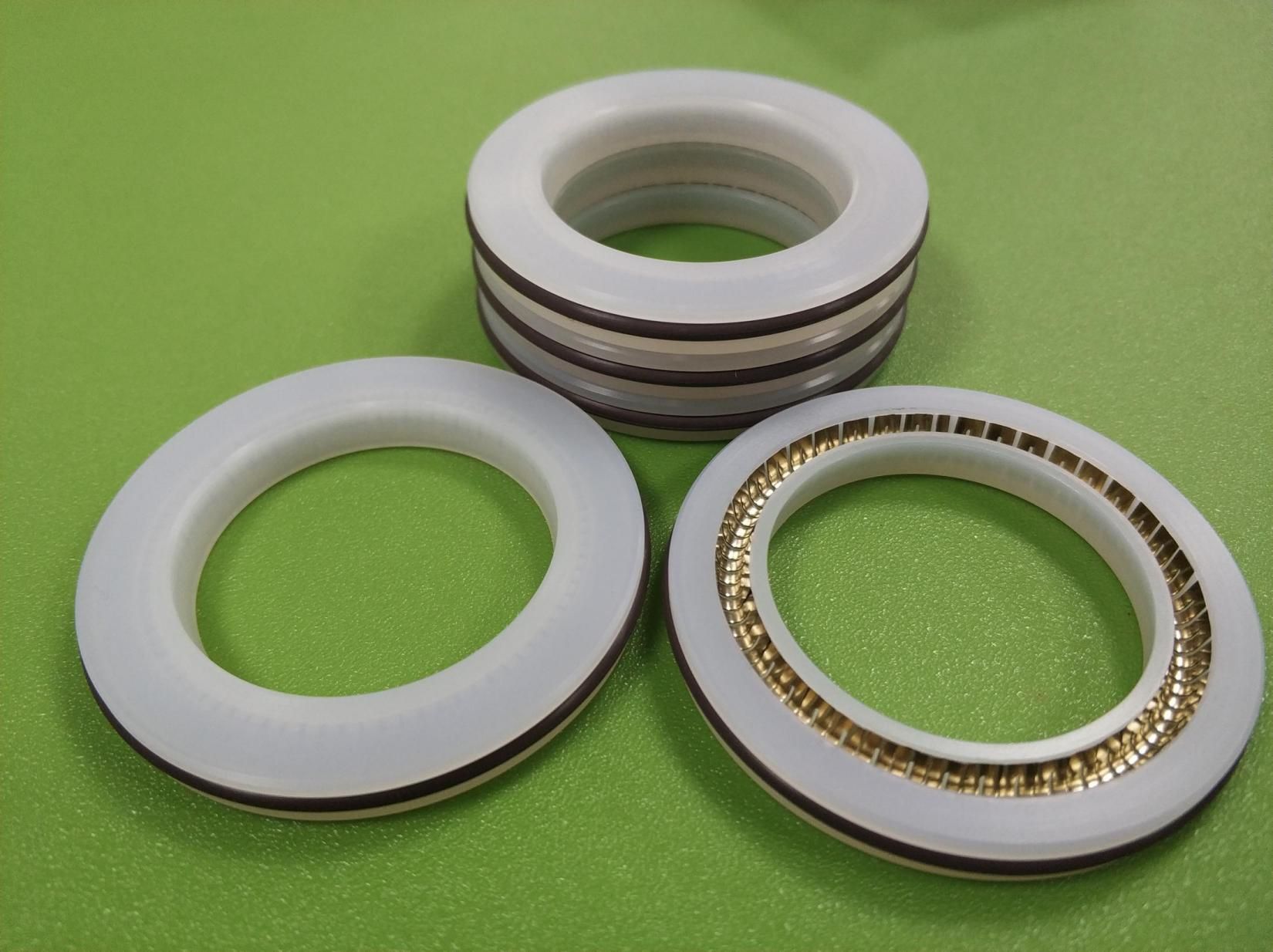

Material Specifications: Critical Elastomer Properties for Industrial Applications

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber solutions for demanding industrial environments. While UHMW polyethylene is a high-performance thermoplastic, this section focuses on core elastomeric materials essential to our sealing and component manufacturing: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each compound exhibits distinct chemical, thermal, and mechanical behaviors critical for OEM design validation. Understanding these properties ensures optimal material selection for fluid compatibility, longevity, and regulatory compliance in automotive, aerospace, and chemical processing systems.

Viton fluorocarbon rubber delivers exceptional resistance to high temperatures, aggressive fuels, and synthetic lubricants. Its molecular stability maintains integrity between -20°C and +230°C continuous service, with short-term excursions to 300°C. Viton formulations achieve tensile strengths of 10–15 MPa and hardness ratings of 60–90 Shore A, making it indispensable for aerospace fuel systems and semiconductor manufacturing where halogenated solvents are present. However, its cost and poor compatibility with ketones necessitate careful application screening.

Nitrile butadiene rubber remains the industry standard for petroleum-based fluid exposure due to its balanced cost-performance ratio. Operating effectively from -40°C to +120°C (special grades to 150°C), NBR offers tensile strengths of 15–20 MPa and hardness ranges of 40–90 Shore A. Its acrylonitrile content directly correlates with oil resistance; high-ACN variants withstand hydraulic fluids and mineral oils but exhibit reduced low-temperature flexibility. NBR’s abrasion resistance and compression set performance make it ideal for hydraulic seals, O-rings, and gaskets in automotive transmissions.

Silicone rubber excels in extreme temperature stability and biocompatibility. With service ranges spanning -60°C to +200°C (peroxide-cured grades to 230°C), VMQ provides tensile strengths of 6–10 MPa and hardness from 30–80 Shore A. Its inorganic backbone resists ozone, UV, and steam but shows poor resistance to concentrated acids and hydrocarbons. Silicone’s low toxicity and FDA compliance drive adoption in medical devices, food processing seals, and high-voltage insulation where electrical properties must remain stable across thermal cycles.

The following comparative analysis details critical specifications for engineering validation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 10–15 | 15–20 | 6–10 |

| Hardness Range (Shore A) | 60–90 | 40–90 | 30–80 |

| Fuel Resistance | Excellent | Good | Poor |

| Acid Resistance | Excellent | Poor | Moderate |

| Compression Set (22h/150°C) | <25% | 15–30% | 20–35% |

| Primary Applications | Aerospace seals, Chemical pumps | Automotive hoses, Hydraulic systems | Medical tubing, Food-grade gaskets |

Material selection must align with dynamic operational parameters beyond baseline specs. Factors including fluid concentration, pressure cycling, surface friction, and regulatory certifications (e.g., ISO 2230 for food contact) require rigorous prototyping. Suzhou Baoshida Trading Co., Ltd. leverages ASTM D2000 standards and in-house aging tests to validate compound performance against OEM failure thresholds. Our engineering team collaborates to refine formulations—adjusting filler systems, cure chemistry, or polymer grades—to resolve edge-case incompatibilities while maintaining cost efficiency. Contact our technical division for application-specific material dossiers and accelerated life testing protocols.

Manufacturing Capabilities

Engineering Excellence in UHMW Polyethylene Material Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capabilities are anchored in deep materials science expertise and precision-driven manufacturing. Within our Industrial Rubber Solutions division, we specialize in the formulation and processing of ultra-high molecular weight polyethylene (UHMWPE), a high-performance thermoplastic renowned for its exceptional wear resistance, low coefficient of friction, and outstanding impact strength. Our success in delivering tailored UHMWPE solutions to global OEMs stems from a dedicated team of 5 Mould Engineers and 2 Formula Engineers who work in close synergy to optimize both material performance and component geometry.

Our Formula Engineers focus on customizing UHMWPE compounds to meet exact application demands. By adjusting molecular weight distribution, filler content (such as molybdenum disulfide or carbon fiber), and processing aids, we enhance specific properties including abrasion resistance, dimensional stability, and thermal conductivity. This molecular-level control allows us to produce formulations that outperform standard-grade UHMWPE in demanding industrial environments such as conveyor systems, automotive components, and material handling equipment.

Complementing this material expertise, our Mould Engineering team ensures that each component is manufactured with precision and repeatability. Utilizing advanced CAD/CAM software and mold flow simulation tools, they design and refine molds that accommodate the unique shrinkage and flow characteristics of UHMWPE. This integrated approach minimizes defects, reduces cycle times, and ensures consistent part quality across large production runs. Our engineers also specialize in multi-cavity and family mold configurations, enabling cost-effective production for complex OEM assemblies.

As an OEM partner, Suzhou Baoshida offers full turnkey solutions—from concept and material selection to prototyping, mold development, and high-volume manufacturing. Our facility supports ISO-compliant production processes, with rigorous in-house testing to validate mechanical performance, wear life, and environmental resistance. We maintain full traceability and documentation, meeting the stringent requirements of automotive, logistics, and heavy machinery industries.

Below is a comparison of standard versus engineered UHMWPE formulations developed in-house:

| Property | Standard UHMWPE | Baoshida Engineered UHMWPE |

|---|---|---|

| Tensile Strength (ASTM D638) | 35–45 MPa | 48–55 MPa |

| Abrasion Resistance (Taber Wear, mg/1000 cycles) | 120–150 | 60–80 |

| Impact Strength (Notched Izod, J/m) | >900 | >1100 |

| Coefficient of Friction (vs. steel) | 0.10–0.15 | 0.08–0.12 |

| Operating Temperature Range | -200°C to +80°C | -200°C to +100°C (with thermal stabilizers) |

| Fillers | None | Optional: MoS₂, PTFE, Carbon Fiber |

Through the combined strength of formula innovation and mold precision, Suzhou Baoshida delivers UHMWPE components that exceed functional expectations. Our engineering team remains committed to advancing material performance while supporting OEMs with scalable, reliable manufacturing solutions.

Customization Process

UHMW Polyethylene Customization Process for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our UHMW polyethylene customization process integrates rigorous material science with precision manufacturing to deliver components meeting exact OEM specifications. This structured workflow ensures optimal performance in demanding industrial environments, from conveyor systems to chemical processing equipment.

Drawing Analysis

Initial client drawings undergo comprehensive dimensional and functional scrutiny. Our engineering team evaluates critical factors including load distribution, wear zones, chemical exposure, and thermal constraints. This phase identifies potential stress concentrations and defines tolerances within ±0.05 mm for high-wear applications. We cross-reference ISO 11542-2 standards to validate feasibility, ensuring the design leverages UHMW-PE’s inherent low-friction and impact resistance without compromising structural integrity.

Formulation Development

Based on analysis outcomes, our rubber formula engineers tailor UHMW-PE compound specifications. While UHMW-PE is inherently unfilled, we adjust molecular weight (3.5–6 million g/mol) and incorporate FDA-compliant additives for UV stability or color coding where required. Key properties are optimized through controlled sintering protocols, avoiding melt processing to preserve crystallinity. The table below summarizes critical baseline properties for grade selection:

| Property | Test Method | Value Range |

|---|---|---|

| Density (g/cm³) | ASTM D792 | 0.930–0.945 |

| Tensile Strength (MPa) | ASTM D638 | 20–35 |

| Impact Strength (kJ/m²) | ASTM D256 | >100 (Notched) |

| Coefficient of Friction | ASTM D1894 | 0.09–0.12 |

| Max Continuous Temp (°C) | ISO 11357 | 80–90 |

| Abrasion Resistance | ASTM D1242 | 10x HDPE |

Prototyping and Validation

Precision-machined prototypes are produced via ram extrusion or compression molding. Each sample undergoes accelerated life testing: Taber abrasion cycles (500+ rotations), ASTM D1894 friction coefficient mapping, and chemical immersion per NBR/NBR-HSN exposure matrices. Dimensional stability is verified under thermal cycling (−40°C to +80°C). Client feedback drives iterative refinements, typically resolving 95% of functional discrepancies within two prototype iterations.

Mass Production and Quality Assurance

Approved formulations transition to ISO 9001-certified production lines with strict in-process controls. Raw material lots are spectrometer-verified for molecular consistency, while sintering ovens maintain ±2°C thermal uniformity. Every batch undergoes 100% visual inspection and statistical sampling for density, tensile strength, and dimensional conformance. Traceability is maintained via laser-etched batch codes, with full material test reports (MTRs) provided. Our lean manufacturing system ensures on-time delivery of 50,000+ units monthly while sustaining defect rates below 0.15%.

This end-to-end process transforms theoretical UHMW-PE advantages into reliable industrial solutions, reducing client downtime through scientifically validated material performance. Suzhou Baoshida Trading Co., Ltd. stands ready to engineer components where extreme wear resistance and purity are non-negotiable.

Contact Engineering Team

For industrial manufacturers seeking high-performance polymer materials, UHMW polyethylene stands as a cornerstone solution in demanding mechanical and wear-resistant applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in supplying premium-grade UHMW polyethylene materials engineered to meet rigorous industrial standards. As a trusted partner in Industrial Rubber Solutions, we provide technical guidance, material certification, and customized supply chain support to manufacturers across Asia, Europe, and North America.

UHMW polyethylene—short for Ultra-High Molecular Weight Polyethylene—delivers exceptional impact strength, low coefficient of friction, and outstanding resistance to abrasion and chemicals. These properties make it ideal for use in conveyor components, liners, gears, guide rails, and material handling systems. Unlike conventional plastics, UHMWPE maintains performance under extreme conditions, including sub-zero temperatures and high mechanical stress, without cracking or degrading. Its self-lubricating nature reduces the need for external greasing, lowering maintenance costs and downtime in continuous operation environments.

We understand that material selection directly impacts system longevity and operational efficiency. That is why Suzhou Baoshida offers technical consultation to ensure the correct grade and form factor—sheet, rod, tube, or custom-machined part—are matched precisely to your application requirements. Whether you are retrofitting existing equipment or designing new industrial systems, our engineering team provides data-driven recommendations based on real-world performance metrics.

Below are the key material properties of standard UHMW polyethylene we supply:

| Property | Value | Test Method |

|---|---|---|

| Density | 0.93–0.94 g/cm³ | ASTM D792 |

| Tensile Strength at Yield | 30–40 MPa | ASTM D638 |

| Elongation at Break | ≥350% | ASTM D638 |

| Flexural Modulus | 1.0–1.4 GPa | ASTM D790 |

| Notched Izod Impact Strength | >100 J/m | ASTM D256 |

| Coefficient of Friction (vs. steel) | 0.10–0.22 | ASTM D1894 |

| Operating Temperature Range | -200°C to +80°C | — |

| Abrasion Resistance (Taber Wheel) | 10–15 mg/1000 cycles | ASTM D1044 |

All materials are sourced from ISO-certified producers and undergo in-house quality verification to ensure consistency and performance reliability. We support small trial orders as well as large-volume contracts with flexible lead times and global logistics coordination.

For technical inquiries, material samples, or custom fabrication quotes, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads our technical sales division and is available to assist with material substitution analysis, design validation, and long-term supply planning. Reach out via email at [email protected] to initiate a consultation. We respond to all technical requests within 24 hours during business days. Partner with Suzhou Baoshida to integrate UHMW polyethylene solutions that enhance durability, reduce friction losses, and extend service life in your industrial systems.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).