Technical Contents

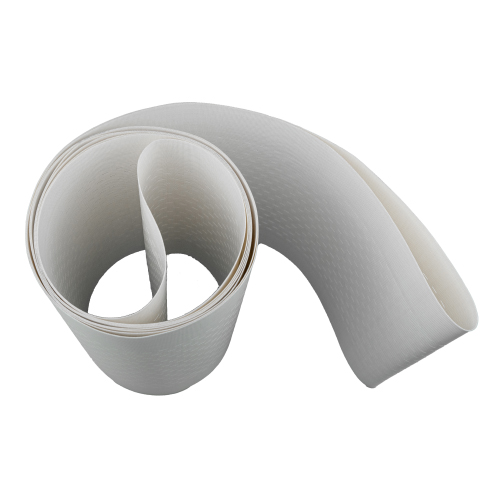

Engineering Guide: Ptfe Conveyor Belt

Engineering Insight Material Selection for PTFE Conveyor Belts Critical Failure Analysis

Generic PTFE conveyor belts frequently fail under demanding industrial conditions due to inadequate material formulation. Off-the-shelf solutions prioritize cost reduction over application-specific engineering, leading to premature degradation and costly production interruptions. The core issue lies in the misalignment between standardized PTFE composite structures and the unique thermal, mechanical, and chemical stresses encountered in specific manufacturing processes. PTFE itself offers exceptional non-stick properties and chemical inertness, but its performance ceiling is entirely dependent on the precise engineering of the reinforcement matrix and filler system. Standard belts often utilize insufficient glass fiber reinforcement or inappropriate filler types, resulting in catastrophic weaknesses. Premature delamination occurs when thermal cycling exceeds the interfacial bond strength between PTFE and substandard fiberglass scrim. Excessive elongation under tension compromises tracking accuracy in high-speed lines, while inadequate filler content fails to mitigate PTFE’s inherent cold flow under continuous load, causing permanent deformation and joint failure. Crucially, surface finish consistency—dictated by PTFE dispersion quality and filler particle size distribution—is frequently overlooked in generic products, directly impacting product release characteristics and contamination risk in food or pharmaceutical applications.

The performance delta between standard and engineered PTFE belts is quantifiable through critical material parameters. Suzhou Baoshida Trading Co., Ltd. emphasizes that OEM-specific formulation requires rigorous analysis of operational variables including peak temperature exposure, chemical contact profiles, line speed, and load dynamics. Our collaborative engineering process adjusts glass fiber architecture, filler composition, and PTFE resin molecular weight to match these parameters. The table below illustrates key differentiators:

| Parameter | Standard PTFE Belt | Engineered PTFE Belt (Baoshida OEM Specification) |

|---|---|---|

| Glass Fiber Content | 5-10% by weight | 25-35% by weight (optimized weave pattern) |

| Continuous Service Temp | 260°C | 315°C |

| Tensile Strength | 18-22 MPa | 32-38 MPa |

| Elongation at Break | 250-300% | 80-120% |

| Key Fillers | Unspecified calcium carbonate | PTFE-coated silica, molybdenum disulfide, ceramic |

| Surface Roughness (Ra) | 3.0-5.0 µm | 0.8-1.5 µm (controlled) |

Selecting a non-optimized belt incurs hidden costs far exceeding initial purchase price. Field data confirms engineered solutions reduce unplanned downtime by 60-75% in high-temperature curing ovens and eliminate product adhesion issues in adhesive coating lines. The critical failure mode—delamination at the PTFE-fiberglass interface—stems directly from incompatible thermal expansion coefficients in generic laminates. Our OEM-grade formulations utilize proprietary coupling agents and staged curing protocols to achieve molecular-level adhesion, validated through ASTM D903 peel testing exceeding 12 N/mm. Material selection is not a commodity decision; it is the foundational engineering variable determining system reliability. Suzhou Baoshida Trading Co., Ltd. partners with manufacturers to translate operational requirements into validated PTFE composite specifications, ensuring conveyor performance aligns with production throughput and quality targets. This precision engineering approach transforms the conveyor belt from a consumable component into a reliable, long-term production asset.

Material Specifications

Material Specifications for PTFE Conveyor Belts

In industrial conveying applications, the selection of backing material for PTFE-coated conveyor belts is critical to performance, longevity, and compatibility with operational environments. At Suzhou Baoshida Trading Co., Ltd., we engineer PTFE conveyor systems using high-performance elastomeric backing materials, including Viton, Nitrile (NBR), and Silicone. Each material offers distinct thermal, chemical, and mechanical properties, enabling tailored solutions for diverse manufacturing processes such as food processing, chemical drying, semiconductor handling, and textile curing.

Viton, a fluorocarbon-based synthetic rubber, delivers exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With a continuous service temperature range up to 230°C (446°F), Viton-backed PTFE belts are ideal for applications involving prolonged exposure to aromatic and chlorinated solvents, strong acids, and high-temperature oils. This material maintains structural integrity under extreme conditions, making it a preferred choice in aerospace, automotive, and chemical processing industries where reliability is paramount.

Nitrile rubber, or Buna-N, is widely used for its excellent resistance to petroleum-based oils, greases, and hydraulic fluids. It performs reliably within a temperature range of -30°C to +100°C (-22°F to 212°F), with short-term peaks up to 120°C (248°F). Nitrile-backed PTFE belts are cost-effective solutions for industrial printing, packaging, and oil-laden environments. While less resistant to ozone and UV exposure than other elastomers, Nitrile provides superior abrasion resistance and mechanical strength, ensuring durability in high-wear applications.

Silicone rubber is selected for its outstanding thermal stability and flexibility across extreme temperature ranges, typically from -60°C to +260°C (-76°F to 500°F). It exhibits excellent resistance to UV radiation, ozone, and weathering, making it suitable for outdoor and sterilization-intensive environments. Silicone-backed PTFE belts are commonly deployed in food processing, medical device manufacturing, and electronics curing, where compliance with FDA and USP Class VI standards is required. Although silicone has lower tensile strength compared to Viton or Nitrile, its non-reactive nature and ease of cleaning make it indispensable in hygienic and high-purity operations.

The following table summarizes key material properties to assist in the selection of the appropriate backing for PTFE conveyor belts based on application demands.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 (+120 short-term) | -60 to 260 |

| Temperature Range (°F) | -4 to 446 | -22 to 212 (248 short-term) | -76 to 500 |

| Chemical Resistance | Excellent (acids, oils, solvents) | Good (oils, greases, fuels) | Moderate (water, ozone, oxygen) |

| Oil/Fuel Resistance | Outstanding | Excellent | Poor |

| Abrasion Resistance | Good | Excellent | Moderate |

| UV/Ozone Resistance | Excellent | Fair | Excellent |

| FDA Compliance | Limited grades | Some grades available | Full compliance available |

| Typical Applications | Chemical processing, aerospace | Printing, automotive, packaging | Food, medical, electronics |

Selection of the appropriate backing material must align with process-specific requirements, including temperature exposure, chemical contact, mechanical stress, and regulatory standards. Suzhou Baoshida Trading Co., Ltd. provides expert consultation to ensure optimal material pairing for enhanced operational efficiency and product lifespan.

Manufacturing Capabilities

Engineering Excellence in PTFE Conveyor Belt Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver mission-critical PTFE conveyor belts for demanding industrial applications. Our core strength lies in the integrated synergy between specialized engineering disciplines: five dedicated mold engineers and two advanced formula engineers. This structure ensures end-to-end control from molecular material design to precision tooling, eliminating traditional supply chain gaps that compromise performance.

Our formula engineers focus exclusively on optimizing PTFE composite chemistry. They systematically adjust filler ratios (glass fiber, carbon, ceramic), resin dispersion, and sintering kinetics to achieve exact thermal stability, chemical resistance, and mechanical properties. This capability is critical for applications facing extreme temperatures (-200°C to +300°C) or aggressive solvents where off-the-shelf compounds fail. Concurrently, our mold engineering team translates these material specifications into flawless physical execution. They design and validate multi-cavity tooling with micron-level dimensional control, ensuring uniform belt thickness, edge integrity, and splice compatibility—factors directly impacting belt tracking, lifespan, and process efficiency in high-speed production lines.

This dual-engineering approach enables true OEM partnership. Clients specify operational parameters—line speed, load weight, chemical exposure, temperature cycles—and our team co-develops belts meeting exact functional requirements, not just dimensional drawings. We validate prototypes under simulated production conditions, measuring critical outputs like coefficient of friction, tensile strength retention after thermal cycling, and abrasion resistance per ASTM D3884. This eliminates costly trial-and-error during client implementation.

For standard and custom solutions, our manufacturing adheres to stringent tolerances unattainable through generic production. The table below outlines key specifications achievable through our engineered process:

| Specification | Standard Production | Custom OEM Capability |

|---|---|---|

| Thickness Tolerance | ±0.10 mm | ±0.05 mm |

| Tensile Strength | 25 MPa min | 32 MPa min |

| Operating Temperature | -190°C to +260°C | -200°C to +300°C |

| Surface Roughness (Ra) | 1.6 µm max | 0.8 µm max |

| Dimensional Stability | ±0.5% | ±0.2% |

| Chemical Resistance | Broad Spectrum | Tailored to Specific Media |

Material science and precision tooling converge in every belt we produce. Our formula engineers mitigate PTFE’s inherent creep through proprietary reinforcement matrices, while mold engineers compensate for thermal expansion variances during sintering. This prevents edge curling and thickness drift—common failure points in inferior belts. Clients in semiconductor manufacturing, aerospace composite curing, and high-temperature food processing rely on this engineering rigor to minimize unplanned downtime.

Suzhou Baoshida does not merely manufacture PTFE belts; we engineer reliability into every meter. Partner with us to transform material constraints into competitive advantages through science-driven customization and OEM collaboration.

Customization Process

Customization Process for PTFE Conveyor Belts at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our approach to manufacturing customized PTFE conveyor belts follows a rigorous, science-driven process designed to meet the exact operational demands of industrial clients. Each stage—from initial drawing analysis to mass production—is engineered for precision, durability, and performance consistency under extreme conditions.

The process begins with Drawing Analysis, where our engineering team evaluates technical specifications provided by the client. This includes dimensional tolerances, joint configuration, surface texture requirements, and environmental operating parameters such as temperature range, chemical exposure, and mechanical load. Our engineers verify compatibility with PTFE’s inherent properties—non-stick behavior, low coefficient of friction, and thermal stability up to 260°C. Any discrepancies or optimization opportunities are flagged for technical consultation before proceeding.

Following approval, we initiate the Formulation Phase. While pure PTFE is the base polymer, modifications may be required to enhance wear resistance, tensile strength, or dimensional stability. At Baoshida, we utilize reinforced variants incorporating glass fiber, carbon, or graphite fillers depending on application stress profiles. Our proprietary compounding process ensures uniform dispersion of additives, which is critical for consistent belt performance across large production runs. The formulation is validated against ISO 21303 and ASTM D4894 standards for mechanical and thermal integrity.

The next stage is Prototyping, where a pilot batch of 1–2 units is manufactured under controlled conditions. These prototypes undergo a battery of tests including elongation at break, peel strength (for joints), surface resistivity, and thermal cycling. Clients are provided with full test reports and physical samples for field evaluation. Feedback is incorporated into final design adjustments, ensuring functional alignment with real-world operating environments.

Upon client sign-off, we transition to Mass Production, executed in our ISO 9001-certified facility. Automated calendering, precision sintering ovens, and laser-guided cutting systems ensure micron-level accuracy across thousands of meters of belt material. Each production lot is traceable, with batch-specific certificates of conformance and QC data logs. Final inspection includes 100% visual screening and random sampling for mechanical retesting.

Our end-to-end customization framework ensures that every PTFE conveyor belt delivers optimal performance in applications ranging from food processing and semiconductor manufacturing to industrial drying and composite lamination.

Typical Customization Specifications for PTFE Conveyor Belts

| Parameter | Standard Range | Customizable Options |

|---|---|---|

| Thickness | 0.08 mm – 1.5 mm | Up to 2.0 mm with reinforcement |

| Width | Up to 3,200 mm | Non-standard widths on request |

| Length | Spliced or endless, up to 50 m | Custom joint patterns (butt, overlap) |

| Operating Temperature | -70°C to +260°C | Enhanced thermal grades available |

| Surface Finish | Matte, glossy, anti-slip, textured | Laser-etched patterns |

| Tensile Strength | ≥ 35 MPa (unfilled) | ≥ 50 MPa (glass fiber reinforced) |

| Elongation at Break | 150% – 300% | Optimized for low-stretch applications |

| Additive Reinforcement | None, glass fiber, carbon, graphite | Hybrid filler systems |

Contact Engineering Team

Engineering Precision in PTFE Conveyor Belt Solutions: Partner with Suzhou Baoshida

Selecting a PTFE conveyor belt transcends basic material procurement; it demands rigorous alignment with thermal stability, chemical resistance, and dimensional accuracy requirements inherent to high-stakes industrial processes. At Suzhou Baoshida Trading Co., Ltd., we engineer solutions where molecular cohesion meets operational integrity, ensuring your production line achieves zero-compromise performance under extreme conditions. Our proprietary fluoropolymer formulations undergo stringent ISO 9001-certified testing protocols, validated across semiconductor manufacturing, food processing, and aerospace composite curing applications. The technical specifications below reflect our baseline industrial-grade PTFE belt capabilities, though all parameters are fully customizable to your OEM integration needs.

| Property | Standard Specification | Test Method |

|---|---|---|

| Temperature Range | -70°C to +260°C | ASTM D1784 |

| Thickness Tolerance | ±0.05 mm | ISO 2768-mK |

| Tensile Strength | ≥25 MPa | ASTM D412 |

| Elongation at Break | ≥300% | ASTM D412 |

| Coefficient of Friction | 0.05–0.10 (vs. steel) | ASTM D1894 |

| Dielectric Strength | ≥60 kV/mm | IEC 60243-1 |

These metrics represent the foundation of reliability, yet true operational excellence emerges through application-specific engineering collaboration. Generic off-the-shelf belts inevitably compromise yield rates when exposed to aggressive solvents, cyclic thermal loads, or micron-level surface finish requirements. Our technical team dissects your process variables—conveyor speed, load distribution, media exposure—to recalibrate belt architecture at the polymer chain level. This includes optimizing PTFE dispersion ratios, substrate weave density, and edge reinforcement methodologies to eliminate delamination risks during continuous 24/7 operation.

For OEM partners, Suzhou Baoshida operates as a seamless extension of your R&D infrastructure. We provide full material traceability documentation, accelerated lifecycle testing data, and on-site failure mode analysis to preempt downtime. Our manufacturing facility in Suzhou integrates automated coating systems with real-time thickness monitoring, ensuring batch-to-batch consistency critical for automotive gasket production or photovoltaic cell handling. When dimensional drift exceeds 0.1mm per 10-meter run, production halts become inevitable; our process controls maintain tolerances within 0.03mm, directly protecting your OEE metrics.

Initiate your technical collaboration by contacting Mr. Boyce, our dedicated OEM Solutions Manager. With 14 years of specialized experience in fluoropolymer conveyor systems, Mr. Boyce will conduct a confidential process audit to identify hidden inefficiencies in your current belt performance. He will provide a formal engineering proposal within 72 hours, detailing material composition adjustments, lifecycle cost projections, and validation testing protocols specific to your machinery. Do not tolerate recurring maintenance cycles or suboptimal throughput when molecular-level precision is achievable.

Reach Mr. Boyce directly at [email protected] to schedule a technical consultation. Include your target application, operational parameters, and current pain points to receive a prioritized engineering action plan. Suzhou Baoshida Trading Co., Ltd. stands ready to transform your conveyor system from a maintenance liability into a competitive asset—engineered for zero-defect continuity. Your production line’s longevity begins with a single technical specification review. Act now to secure engineered reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).