Technical Contents

Engineering Guide: Non-Slip Strips For Exterior Stairs

Engineering Insight: Material Selection for Non-Slip Strips in Exterior Stair Applications

In industrial and commercial environments, exterior staircases are subjected to continuous mechanical stress, fluctuating temperatures, moisture exposure, and ultraviolet (UV) degradation. These conditions demand non-slip strips engineered for long-term durability and consistent performance. Off-the-shelf solutions, often constructed from generic rubber or plastic compounds, frequently fail under such conditions due to inadequate material formulation and insufficient environmental resistance. The root cause lies in the misalignment between material properties and real-world operational demands.

Standard retail-grade non-slip strips typically utilize soft PVC or low-grade thermoplastic rubber (TPR), which initially provide acceptable traction but degrade rapidly when exposed to outdoor elements. These materials are prone to hardening, cracking, and delamination within 6–12 months of installation. The loss of flexibility due to UV exposure and thermal cycling compromises both adhesion and surface texture, leading to reduced slip resistance and potential safety hazards. Additionally, poor resistance to water absorption and freeze-thaw cycles accelerates failure in temperate and cold climates.

In contrast, engineered solutions from industrial rubber specialists leverage high-performance elastomers such as EPDM (ethylene propylene diene monomer) and nitrile rubber (NBR), selected for their superior weathering resistance, thermal stability, and mechanical resilience. EPDM, in particular, offers exceptional resistance to ozone, UV radiation, and temperature extremes ranging from -40°C to +130°C, making it ideal for long-service-life exterior applications. When compounded with anti-slip mineral fillers and textured surface profiles, these materials maintain coefficient of friction (COF) values above 0.6 even under wet conditions, meeting or exceeding OSHA and ADA traction requirements.

Adhesion performance is equally critical. Industrial-grade strips utilize pressure-sensitive acrylic or polyurethane-based adhesives applied over primed backings, ensuring long-term bond integrity to substrates such as aluminum, steel, and concrete. This contrasts with consumer products that rely on weak adhesive tapes prone to edge lifting and moisture ingress.

At Suzhou Baoshida Trading Co., Ltd., our non-slip strips are formulated using precision-compounded rubber matrices tailored to environmental exposure levels, traffic load, and substrate compatibility. This engineering-first approach ensures sustained performance, reduced maintenance costs, and compliance with international safety standards.

Material Performance Comparison

| Property | EPDM Rubber | Nitrile Rubber (NBR) | Standard PVC/TPR |

|---|---|---|---|

| Temperature Range (°C) | -40 to +130 | -30 to +105 | -10 to +60 |

| UV Resistance | Excellent | Good | Poor |

| Water Absorption (24h, %) | < 1.5 | < 2.0 | > 5.0 |

| Coefficient of Friction (wet) | 0.65–0.80 | 0.60–0.75 | 0.40–0.55 (after aging) |

| Service Life (exterior) | 8–12 years | 5–7 years | 1–2 years |

Material selection is not a commodity decision—it is a critical engineering parameter. Choosing performance-grade rubber compounds ensures safety, longevity, and cost efficiency in exterior stair applications.

Material Specifications

Material Specifications for Exterior Stair Non-Slip Strips

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions optimized for demanding exterior applications. Non-slip stair strips require materials balancing abrasion resistance, environmental stability, and consistent traction under dynamic load conditions. Our formulations prioritize long-term performance in UV exposure, temperature extremes, moisture, and chemical contaminants common in outdoor infrastructure. Viton, Nitrile, and Silicone represent distinct polymer families selected based on project-specific environmental stressors and lifecycle cost analysis. Each material undergoes rigorous ASTM D2000 classification testing to ensure compliance with industrial safety and durability benchmarks.

Viton (FKM) fluorocarbon rubber excels in severe chemical and thermal environments. Its saturated polymer backbone provides exceptional resistance to ozone, UV degradation, and temperatures ranging from -20°C to +230°C. This material maintains structural integrity when exposed to automotive fluids, industrial solvents, and acid rain, making it ideal for stairways in chemical plants, marine terminals, or high-UV regions. Viton strips exhibit Shore A hardness of 70±5, ensuring optimal grip without compromising pedestrian comfort. While premium-priced, its 15+ year service life in aggressive settings delivers superior total cost of ownership.

Nitrile (NBR) butadiene-acrylonitrile rubber offers the optimal balance of oil/fuel resistance and cost efficiency for general industrial use. With acrylonitrile content tailored to 33-36%, our NBR compounds withstand hydraulic fluids, greases, and moderate UV exposure. Operating effectively between -30°C and +100°C, it provides reliable slip resistance in parking structures, factory access points, and urban infrastructure. Shore A hardness is maintained at 65±5 through proprietary carbon black reinforcement, enhancing abrasion resistance against foot traffic and wheeled equipment. NBR remains the most cost-effective solution for environments lacking extreme thermal or chemical exposure.

Silicone (VMQ) rubber delivers unmatched flexibility across extreme temperatures (-60°C to +200°C) and superior UV/ozone resistance. Its inorganic silica backbone prevents hardening or cracking in cyclic freeze-thaw conditions, critical for stairways in alpine or subarctic climates. While less resistant to petroleum derivatives than NBR or Viton, silicone maintains consistent Shore A 60±5 hardness and hydrophobic properties that repel water, reducing ice adhesion. Accelerated weathering tests per ASTM G154 confirm 500,000+ hours of UV stability, making it ideal for high-altitude or coastal installations where thermal cycling is severe.

The following table details critical performance parameters for OEM selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) | Test Standard |

|---|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +100 | -60 to +200 | ASTM D2000 |

| Shore A Hardness | 70 ± 5 | 65 ± 5 | 60 ± 5 | ASTM D2240 |

| Tensile Strength (MPa) | 15.0 min | 12.0 min | 6.5 min | ASTM D412 |

| Elongation at Break (%) | 150 min | 250 min | 300 min | ASTM D412 |

| Compression Set (%) | 20 max @ 200°C | 25 max @ 100°C | 20 max @ 200°C | ASTM D395 |

| UV Resistance | Excellent | Good | Excellent | ASTM G154 |

| Oil/Fuel Resistance | Exceptional | Excellent | Poor | ASTM D471 |

| Typical Service Life | 15+ years | 8-10 years | 12+ years | Field Data |

Suzhou Baoshida’s OEM engineering team collaborates with clients to select the optimal polymer matrix based on site-specific environmental data and lifecycle requirements. All compounds incorporate proprietary fillers and stabilizers to exceed ISO 13287 slip resistance standards under wet/dry conditions. Material certification dossiers and accelerated aging reports are available upon request for project validation.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. demonstrates advanced engineering capabilities in the design and production of industrial rubber solutions, particularly in the development of high-performance non-slip strips for exterior stairs. Our in-house technical team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling full vertical control from concept to final product. This integrated engineering approach ensures precision, durability, and compliance with rigorous environmental and safety standards required in exterior architectural applications.

Our mould engineers utilize CAD/CAM and 3D simulation software to design robust, high-tolerance steel and aluminum moulds optimized for long production runs and consistent part geometry. Each mould is engineered for efficient material flow, minimal flash, and rapid cycle times, ensuring cost-effective manufacturing without compromising quality. The integration of thermal analysis and stress modeling allows for preemptive correction of potential defects, enhancing product reliability and dimensional stability.

Complementing mould design, our rubber formula engineers focus on material science innovation tailored to outdoor performance. We develop custom EPDM, SBR, and NBR-based compounds that deliver superior traction, UV resistance, ozone stability, and low-temperature flexibility. These formulations are engineered to maintain grip under wet, icy, or oily conditions—critical for stair safety in commercial, industrial, and public infrastructure settings. Additives such as silica and nano-reinforced fillers are precisely calibrated to balance hardness, abrasion resistance, and elasticity, ensuring long service life even under heavy foot traffic.

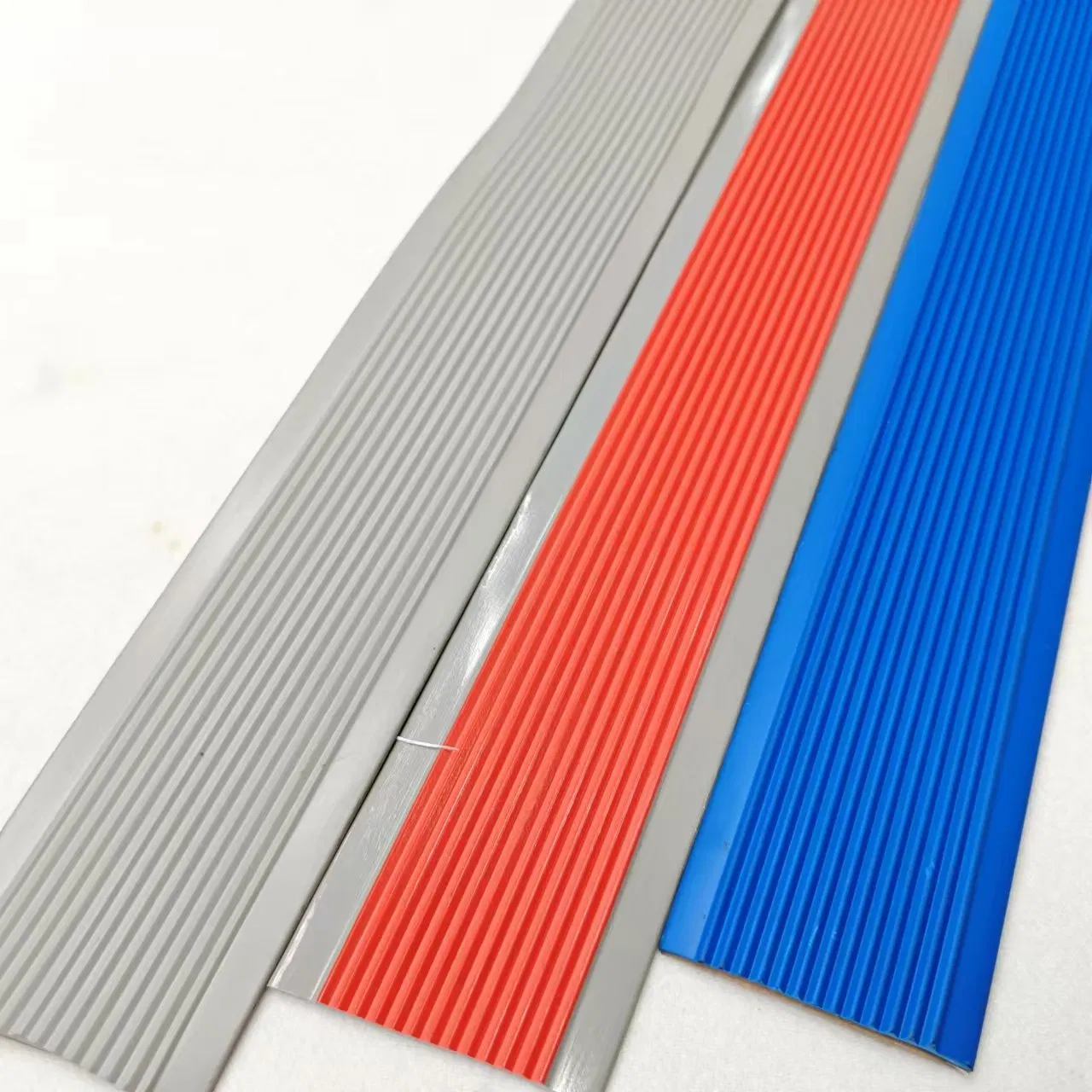

We offer comprehensive OEM services, supporting clients from prototype development to mass production. Our engineering team collaborates directly with partners to customize profile geometry, surface texture (e.g., diamond pattern, ribbed, or grit-coated), durometer (40–80 Shore A), and color integration (including pigment stability for long-term outdoor exposure). All formulations and designs undergo rigorous testing for slip resistance (ASTM F2913), tensile strength, compression set, and weathering (QUV and outdoor exposure).

The combination of advanced tooling expertise and material science proficiency enables Suzhou Baoshida to deliver non-slip stair solutions that meet international safety standards while offering design flexibility and production scalability.

| Property | Typical Value | Test Standard |

|---|---|---|

| Hardness (Shore A) | 50–75 | ASTM D2240 |

| Tensile Strength | ≥10 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (70°C, 22h) | ≤25% | ASTM D395 |

| Slip Resistance (wet surface) | COF ≥0.6 | ASTM F2913 |

| Operating Temperature | -40°C to +120°C | — |

| UV and Ozone Resistance | Excellent | ASTM G154, ASTM D1149 |

Through a disciplined engineering process and deep material knowledge, Suzhou Baoshida delivers technically superior non-slip rubber products that enhance safety and performance in demanding exterior environments.

Customization Process

Customization Process: Non-Slip Strips for Exterior Stairs

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven customization process for industrial non-slip stair treads, ensuring optimal performance under demanding exterior conditions. This structured methodology transforms client specifications into certified, high-reliability rubber components through four critical engineering phases.

Drawing Analysis & Environmental Assessment

Initial engagement focuses on meticulous technical drawing review against ASTM F1637 or EN 13376 standards. We evaluate substrate geometry, load profiles, and critical safety parameters including required coefficient of friction (minimum 0.5 dry, 0.4 wet per ANSI A1264.2). Crucially, we assess site-specific environmental stressors: UV exposure intensity, thermal cycling range, chemical contaminants (de-icing salts, oils), and pedestrian traffic volume. This phase determines material architecture requirements and validates dimensional tolerances within ±0.3mm for secure mechanical anchoring.

Advanced Rubber Formulation Development

Based on environmental analysis, our polymer chemists design bespoke compounds utilizing EPDM or specialty SBR bases. Key formulation targets include permanent anti-slip aggregate integration (typically 30-60 mesh aluminum oxide or silicon carbide at 18-25% loading), ozone-resistant crosslinking systems, and thermally stable plasticizers. Shore A hardness is precisely calibrated between 55-75 to balance pedestrian comfort with abrasion resistance. Accelerated aging protocols (ASTM D1148, ISO 4892-2) are embedded in the design phase to predict 10+ year service life under specified conditions.

Precision Prototyping & Validation

CNC-machined molds produce functional prototypes for comprehensive testing. Each sample undergoes quantitative validation: Taber abrasion loss (ASTM D1044, target <25 mg/1000 cycles), dynamic coefficient of friction measurement (Brungraber Mark II), and thermal shock cycling (-40°C to +70°C). Adhesion strength to common substrates (concrete, steel, aluminum) is verified per ASTM D429 Method B. Client approval requires documented conformance across all critical parameters before tooling release.

Controlled Mass Production

Serial production occurs in ISO 9001-certified facilities with real-time process monitoring. Key controls include:

Continuous durometer verification (±2 Shore A tolerance)

In-line spectrophotometric color consistency (ΔE <0.8)

Batch traceability via unique lot coding

100% visual inspection for surface defects

Final shipment includes full material test reports (MTRs) with hardness, tensile strength, elongation, and friction coefficients, ensuring compliance with the agreed performance matrix.

Material Performance Specifications by Application Tier

| Performance Parameter | Standard Commercial | Heavy Industrial | Extreme Climate |

|---|---|---|---|

| Shore A Hardness | 60 ± 3 | 68 ± 3 | 58 ± 3 |

| Operating Temperature Range | -30°C to +70°C | -40°C to +80°C | -50°C to +60°C |

| Taber Abrasion Loss (mg) | ≤ 35 | ≤ 25 | ≤ 30 |

| Min. Wet COF (ASTM E303) | 0.45 | 0.50 | 0.48 |

| UV Resistance (ASTM G154) | 1500 hrs | 2500 hrs | 3000 hrs |

| De-Icing Salt Resistance | Moderate | High | Extreme |

This systematic engineering approach guarantees non-slip stair solutions that exceed safety mandates while delivering predictable lifecycle performance in global exterior environments. Suzhou Baoshida maintains full technical accountability from specification validation through production continuity.

Contact Engineering Team

For industrial-grade non-slip solutions that meet the rigorous demands of exterior stair applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted leader in precision rubber engineering. Our non-slip strips are engineered to deliver maximum traction, long-term durability, and resistance to environmental stressors such as moisture, UV exposure, and temperature fluctuations. Designed for architects, construction firms, and OEM partners, our products ensure compliance with international safety standards while maintaining aesthetic integration into building designs.

We specialize in custom-formulated rubber compounds that balance hardness, flexibility, and wear resistance. Each non-slip strip is manufactured using advanced vulcanization techniques and tested under simulated real-world conditions to guarantee performance across diverse climates and foot traffic loads. Whether your project requires installation on concrete, metal, or composite stair treads, our adhesive-backed or mechanically fixed strip variants provide secure, long-lasting protection against slips and falls.

Partnering with Suzcho Baoshida means access to technical expertise backed by over a decade of experience in industrial rubber solutions. Our engineering team collaborates directly with clients to tailor product specifications—including durometer, profile geometry, color, and anti-skid surface texture—to meet exact project requirements. From initial concept to mass production, we ensure seamless integration into your supply chain with competitive lead times and rigorous quality control.

To support global clients, we offer comprehensive documentation, including material certifications (RoHS, REACH, ASTM), performance test reports, and installation guidelines. Our non-slip strips are widely used in commercial buildings, public infrastructure, marine environments, and industrial facilities where safety and reliability cannot be compromised.

For technical inquiries, custom development, or volume procurement, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads material innovation and client engineering support, ensuring every product delivers optimal functionality and cost-efficiency. Reach out via email at [email protected] to discuss your project specifications, request samples, or schedule a technical consultation.

Below are key technical specifications for our standard exterior non-slip strip offering:

| Property | Specification |

|---|---|

| Material | EPDM/NBR Rubber Blend |

| Hardness (Shore A) | 65 ± 5 |

| Tensile Strength | ≥ 12 MPa |

| Elongation at Break | ≥ 280% |

| Operating Temperature Range | -40°C to +120°C |

| Slip Resistance (DIN 51130 R10) | Yes |

| UV and Ozone Resistance | Excellent |

| Installation Method | Adhesive Backing or Mechanical Fasteners |

| Standard Colors | Black, Gray, Yellow |

| Custom Profiles | Available upon request |

Elevate safety and performance in your exterior stair systems with engineered rubber solutions from Suzhou Baoshida. Contact Mr. Boyce today at [email protected] to initiate a technical dialogue and receive application-specific recommendations tailored to your project’s environmental and mechanical demands.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).