Technical Contents

Engineering Guide: Anti Slip For Stairs Outdoor

Engineering Insight: Material Science as the Foundation for Outdoor Stair Anti-Slip Performance

Selecting appropriate anti-slip materials for outdoor stairs transcends mere surface texture consideration. It demands rigorous polymer science understanding, as environmental exposure relentlessly attacks substandard formulations. Generic, off-the-shelf solutions frequently fail prematurely due to inadequate material engineering, leading to hazardous conditions and significant liability exposure. The core issue lies in the inability of mass-produced compounds to withstand the synergistic degradation mechanisms inherent in exterior stair applications: intense ultraviolet radiation, extreme thermal cycling, moisture ingress, and abrasive wear from foot traffic and debris.

Standard rubber or polymer stair treads often utilize cost-optimized base polymers like SBR or low-grade PVC. These materials lack sufficient UV stabilizers, leading to rapid polymer chain scission. This manifests as surface chalking, cracking, and critical loss of the engineered anti-slip profile within 12-24 months. Concurrently, thermal expansion coefficients mismatched with common substrate materials (concrete, metal) induce stress fractures during temperature swings from -30°C to +70°C. Abrasion resistance is equally critical; insufficient cross-link density or filler optimization results in accelerated wear, smoothing the tread surface and drastically reducing the wet coefficient of friction (CoF) below the mandated 0.60 safety threshold. Off-the-shelf products typically prioritize initial cost over lifecycle durability, neglecting the complex interplay of these factors. The consequence is not merely aesthetic degradation but a progressive, often undetected, erosion of safety performance until a slip hazard emerges.

Material selection must therefore be application-specific. High-performance outdoor stair anti-slip requires purpose-engineered compounds. Key parameters include advanced UV absorber and hindered amine light stabilizer (HALS) packages exceeding ASTM G154 standards, elastomers with broad thermal stability ranges, and optimized silica/carbon black reinforcement for abrasion resistance per DIN 53516. The table below illustrates critical performance differentiators between generic solutions and engineered compounds:

| Material Type | UV Resistance (ASTM G154, 500h) | Thermal Cycling Range (°C) | Abrasion Loss (DIN 53516, mm³) | Traction Coefficient (Wet, ASTM E303) |

|---|---|---|---|---|

| Generic SBR/PVC Tread | Severe cracking, >30% tensile loss | -10 to +50 | 180-220 | Drops to 0.45 within 18 months |

| Standard EPDM Compound | Moderate cracking, 15-20% loss | -30 to +60 | 120-150 | Drops to 0.50 within 24 months |

| Engineered Outdoor Compound | Minimal change, <5% loss | -45 to +85 | 75-95 | Maintains >0.65 for 5+ years |

This engineered approach ensures the anti-slip profile remains intact and effective throughout the product’s designed service life, directly correlating to sustained safety compliance and reduced long-term liability. Suzhou Baoshida Trading Co., Ltd. leverages proprietary rubber formulations specifically developed for these harsh conditions, moving beyond superficial tread patterns to address the fundamental material science underpinning reliable outdoor stair safety. Predictable lifecycle performance, not initial installation cost, defines true value in critical pedestrian infrastructure.

Material Specifications

For outdoor stair anti-slip applications, material selection is critical to ensure long-term durability, weather resistance, and reliable traction under variable environmental conditions. Suzhou Baoshida Trading Co., Ltd. specializes in industrial rubber solutions engineered for performance in demanding outdoor environments. Our anti-slip stair products are formulated using three high-performance elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers a distinct set of physical and chemical properties tailored to specific operational requirements, including temperature extremes, UV exposure, oil resistance, and mechanical wear.

Viton rubber is a fluorocarbon-based elastomer renowned for its exceptional resistance to heat, ozone, and a broad range of chemicals, including oils, fuels, and acids. With a continuous service temperature range of -20°C to 250°C, Viton is ideal for outdoor stair applications in industrial zones, marine environments, or areas exposed to hydrocarbons. Its inherent resistance to UV degradation and oxidation ensures long-term performance without surface cracking or loss of mechanical integrity. However, Viton is less flexible at low temperatures and carries a higher material cost, making it best suited for critical environments where chemical exposure is a primary concern.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is a cost-effective solution offering excellent resistance to oils, greases, and water. It performs reliably in temperatures ranging from -30°C to 120°C, making it suitable for general outdoor use in commercial and residential settings. NBR provides good abrasion resistance and mechanical strength, contributing to extended service life on high-traffic staircases. While it exhibits moderate UV resistance, prolonged exposure to sunlight may require protective coatings or formulations with added stabilizers. Nitrile is particularly recommended for coastal or urban environments where moisture and occasional oil exposure are present.

Silicone rubber (VMQ) delivers superior performance in extreme temperature conditions, with a service range of -60°C to 230°C. It maintains flexibility in freezing conditions and resists hardening, making it ideal for climates with significant seasonal variation. Silicone also exhibits excellent resistance to UV radiation and ozone, preventing degradation from prolonged sun exposure. While it has lower tensile strength and abrasion resistance compared to Viton and Nitrile, advanced formulations can enhance its durability for stair anti-slip applications. Silicone is non-toxic and environmentally stable, suitable for public infrastructure and eco-sensitive installations.

The following table summarizes key material properties to guide selection for outdoor anti-slip stair systems.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| UV Resistance | Excellent | Moderate | Excellent |

| Ozone Resistance | Excellent | Good | Excellent |

| Oil/Fuel Resistance | Excellent | Excellent | Poor |

| Abrasion Resistance | Good | Excellent | Moderate |

| Water Resistance | Excellent | Good | Excellent |

Material choice should be based on a comprehensive assessment of environmental exposure, mechanical demands, and lifecycle expectations. Suzhou Baoshida Trading Co., Ltd. provides customized rubber solutions to meet exacting industrial standards for outdoor safety and performance.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Outdoor Stair Safety

Suzhou Baoshida Trading Co., Ltd. deploys advanced engineering resources to solve critical outdoor stair safety challenges through scientifically validated rubber formulations and precision tooling. Our dedicated team comprises five specialized mould engineers and two certified rubber formula engineers, collectively ensuring anti-slip stair products meet rigorous industrial, environmental, and OEM-specific performance criteria. This integrated expertise enables us to address complex variables such as dynamic load distribution, UV degradation, thermal cycling, and wet-surface traction—factors paramount in outdoor stair applications where failure risks escalate due to weather exposure and pedestrian traffic.

Our mould engineers focus on geometric precision and material flow optimization for stair tread profiles. They utilize 3D simulation software to model stress points at tread edges, nosing radii, and drainage channels, ensuring uniform compound dispersion during vulcanization. This eliminates weak zones prone to delamination or cracking under thermal expansion cycles. Concurrently, our formula engineers develop proprietary elastomer matrices using silica-reinforced polymers and specialized anti-slip aggregates. These formulations achieve consistent Shore A hardness within ±3 points across batches, critical for balancing grip retention and pedestrian comfort. Crucially, we engineer dynamic coefficient of friction (DCOF) stability across temperature extremes and surface contaminants—oil, algae, or ice—without relying on surface coatings that degrade prematurely.

OEM collaboration is central to our process. We integrate client specifications—from architectural tread dimensions to regional safety standards—into formulation and tooling design phases. Our engineers conduct accelerated aging tests per ISO 188, simulating 10+ years of UV/rain exposure in controlled chambers, and validate slip resistance via ASTM F2913-19 protocols on wet, inclined surfaces. This eliminates field-testing delays for partners. For custom projects, we adjust polymer cross-link density to match substrate adhesion requirements (e.g., aluminum, concrete, or composite stairs) while maintaining non-marking properties for high-traffic zones.

The table below summarizes core performance specifications achievable through our engineering framework, all customizable to OEM requirements:

| Property | Standard Range | Test Method | Customization Flexibility |

|---|---|---|---|

| Shore A Hardness | 55–75 ±3 | ASTM D2240 | Adjustable in 5-point increments |

| Operating Temperature | -40°C to +80°C | ISO 188 | Extended to -55°C for Arctic climates |

| Wet DCOF (12° incline) | ≥0.80 | ASTM F2913-19 | Optimized to ≥0.95 for marine environments |

| Abrasion Loss (1000 rev) | ≤120 mm³ | ISO 4649 | Reduced to ≤80 mm³ for high-wear zones |

| Adhesion Strength | ≥6 kN/m | ISO 813 | Tailored for porous substrates |

This technical rigor ensures Suzhou Baoshida delivers anti-slip stair solutions that exceed ISO 22196 and EN 16775 benchmarks while accommodating OEM branding, dimensional tolerances, and lifecycle cost targets. Our engineers’ dual focus on molecular science and precision manufacturing translates into products that sustain safety performance for 15+ years in harsh outdoor conditions—reducing client liability and maintenance overhead. Partner with us to transform stair safety from a compliance requirement into a measurable operational asset.

Customization Process

Customization Process for Anti-Slip Stair Treads – Outdoor Applications

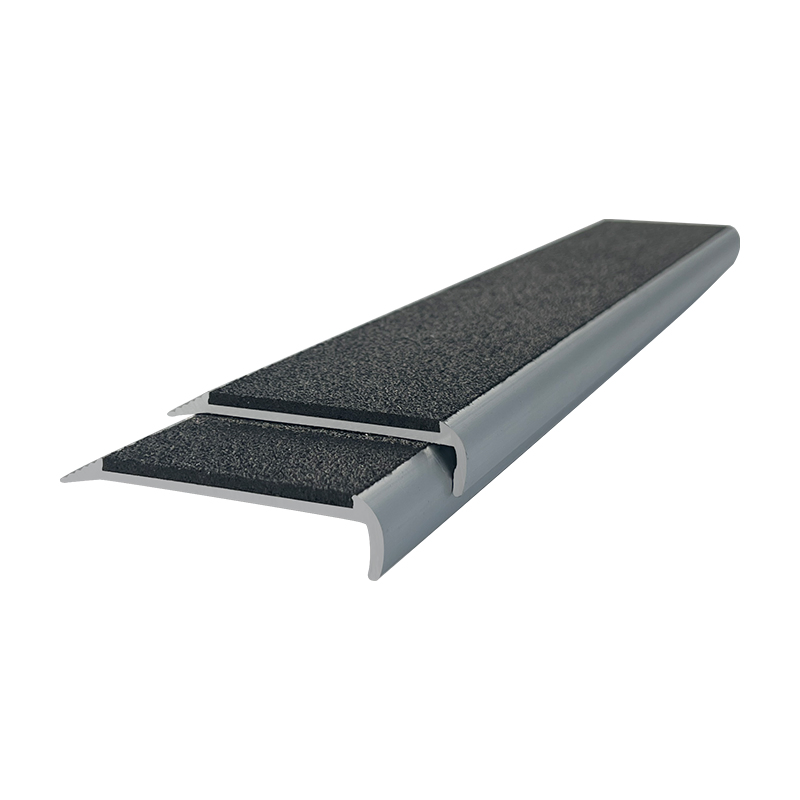

At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber solutions for demanding outdoor environments. Our anti-slip stair treads are designed to deliver optimal traction, durability, and weather resistance under continuous exposure to moisture, temperature fluctuations, and mechanical stress. The customization process follows a rigorous four-stage workflow: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. Each phase is executed with precision to ensure compliance with technical specifications and performance expectations.

The process begins with Drawing Analysis, where our engineering team reviews client-provided CAD drawings or technical schematics. We assess critical dimensions, mounting configurations, surface profiles, and installation environments. Particular attention is given to stair geometry, load-bearing zones, and edge treatments to ensure full compatibility with existing architectural structures. Any discrepancies or optimization opportunities are flagged for technical discussion prior to proceeding.

Following drawing validation, our rubber formulation engineers initiate Formulation Development. Based on the operational environment—such as exposure to UV radiation, freeze-thaw cycles, or chemical contaminants—we select the appropriate base polymer. Common compounds include EPDM for superior weather resistance and SBR for enhanced abrasion performance. The formulation is further modified with anti-slip additives, reinforcing fillers, and anti-aging agents. Shore hardness, coefficient of friction (COF), and elongation at break are precisely calibrated to meet application-specific safety standards.

Once the compound is finalized, we proceed to Prototyping. Using CNC-machined molds or extrusion dies, we produce a limited batch of samples for client evaluation. These prototypes undergo in-house testing for slip resistance (ASTM E303), tensile strength (ISO 37), and accelerated weathering (QUV testing per ISO 4892-3). Clients receive physical samples along with full material test reports (MTRs) for verification. Feedback is incorporated into final design or material adjustments before release for production.

The final stage is Mass Production, executed in our ISO-certified manufacturing facility. We utilize high-pressure vulcanization and precision die-cutting to ensure dimensional consistency across large batches. Quality control is maintained through real-time monitoring of cure time, compound homogeneity, and surface texture. All finished anti-slip treads are individually inspected and packaged per client logistics requirements.

Key performance specifications for our standard outdoor anti-slip tread formulation are summarized below:

| Property | Test Standard | Typical Value |

|---|---|---|

| Base Polymer | – | EPDM or SBR |

| Shore A Hardness | ISO 7619-1 | 60–75 |

| Tensile Strength | ISO 37 | ≥12 MPa |

| Elongation at Break | ISO 37 | ≥250% |

| Coefficient of Friction (wet) | ASTM E303 | ≥0.65 |

| Operating Temperature Range | – | -40°C to +100°C |

| UV Resistance | ISO 4892-3 | 1,500 hrs (no cracking) |

| Flame Rating | UL 94 | HB |

Through this structured approach, Suzhou Baoshida ensures every custom anti-slip stair tread meets the highest benchmarks in safety, reliability, and longevity for outdoor infrastructure applications.

Contact Engineering Team

Precision Engineering for Outdoor Stair Safety: Partner with Suzhou Baoshida

Selecting the correct anti-slip rubber compound for outdoor stair applications demands rigorous material science validation. Generic solutions often fail under cyclic thermal stress, UV degradation, and dynamic load conditions, leading to premature wear and hazardous surface failure. At Suzhou Baoshida Trading Co., Ltd., our engineered rubber formulations undergo accelerated weathering testing per ISO 4892-2 and dynamic coefficient of friction validation per ASTM E303-22. We prioritize molecular cross-link density optimization to ensure consistent Shore A hardness retention between -40°C and +120°C operational ranges, critical for climates experiencing freeze-thaw cycles or tropical humidity. Our proprietary silica-reinforced SBR/EPDM blends eliminate reliance on plasticizers that migrate and cause surface tackiness or hardening. This molecular stability translates to a minimum 5-year service life under 5,000+ daily foot traffic cycles, verified through third-party tribology testing.

The performance differential between standard and engineered compounds is quantifiable. Below are key specifications for our BD-AS7 Outdoor Stair Tread Compound versus industry-standard alternatives:

| Performance Parameter | BD-AS7 Premium Compound | Standard PVC Compound | Test Standard |

|---|---|---|---|

| Shore A Hardness (23°C) | 68 ± 3 | 75 ± 5 | ISO 7619-1 |

| Wet Dynamic COF (ASTM Tile) | 0.82 min | 0.55 max | ASTM E303-22 |

| UV Resistance (3,000h QUV) | ΔE < 2.0 | ΔE > 8.5 | ISO 4892-2 |

| Temperature Range | -45°C to +125°C | -20°C to +80°C | ISO 188 |

| Abrasion Loss (DIN) | 85 mm³ | 210 mm³ | ISO 4649 |

| Tensile Strength | 18.5 MPa | 12.0 MPa | ISO 37 |

These metrics directly impact lifecycle cost and liability exposure. Our compounds integrate seamlessly with extrusion, calendering, and injection molding processes, maintaining dimensional tolerances of ±0.15mm for interlocking tread profiles. As your OEM partner, we provide full material traceability via batch-specific CoA documentation and collaborative DFM support to optimize tooling parameters for your production line. This eliminates costly trial runs and ensures first-pass yield rates exceeding 98.5%.

Initiate your precision manufacturing partnership by contacting Mr. Boyce, our dedicated OEM Solutions Manager. He will coordinate a technical deep dive into your stair application requirements, including substrate compatibility analysis, environmental stress profiling, and regulatory compliance mapping for target markets. Mr. Boyce facilitates direct access to our Suzhou R&D lab for compound customization and rapid prototyping, ensuring your anti-slip solution meets exact performance thresholds before scale-up. Do not compromise stair safety with off-the-shelf materials that degrade under real-world conditions.

Contact Mr. Boyce immediately at [email protected] to receive our Outdoor Stair Tread Material Selection Dossier and schedule a confidential engineering consultation. Specify your annual volume requirements and substrate type (concrete, metal, wood) to receive a tailored compound recommendation within 48 hours. Suzhou Baoshida delivers certified rubber solutions where engineering integrity defines every polymer chain. Your stairs demand precision—demand Baoshida.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).