Technical Contents

Engineering Guide: 1/4 O Ring

Engineering Insight: 1/4 O Ring – The Critical Role of Material Selection in Precision Sealing

In precision rubber sealing applications, the 1/4 inch O ring—measuring 0.250 inches in cross-sectional diameter—is a standard size utilized across industries ranging from automotive hydraulics to semiconductor manufacturing. While its dimensions may appear generic, the performance of this component is anything but. A fundamental engineering oversight occurs when material selection is treated as secondary to dimensional conformity. Off-the-shelf 1/4 O rings often fail not due to incorrect size, but because of incompatible elastomer properties under specific operational conditions.

Material selection directly governs compression set resistance, thermal stability, chemical compatibility, and dynamic performance. For example, an NBR (nitrile butadiene rubber) 1/4 O ring may perform adequately in low-temperature hydraulic systems with mineral oil exposure. However, when deployed in an environment involving ozone, amines, or elevated temperatures above 100°C, rapid degradation occurs. Similarly, using silicone rubber in high-pressure dynamic sealing applications leads to extrusion and seal failure due to its low tensile strength and poor abrasion resistance.

The failure of generic O rings stems from a one-size-fits-all manufacturing approach that neglects application-specific variables. In chemical processing equipment, for instance, exposure to aggressive solvents such as ketones or chlorinated hydrocarbons demands fluorocarbon (FKM) or perfluoroelastomer (FFKM) materials. These elastomers maintain integrity where standard compounds degrade within hours. Likewise, in food and pharmaceutical systems, compliance with FDA 21 CFR 177.2600 requires platinum-cured silicone or specific EPDM formulations—requirements rarely met by mass-produced inventory items.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material matching as the foundation of reliable sealing. Each 1/4 O ring we supply is evaluated against fluid media, temperature profiles, pressure cycles, and regulatory standards. This precision-driven methodology prevents premature seal failure, reduces downtime, and extends service life.

The following table outlines common elastomer options for 1/4 O rings and their performance characteristics:

| Material | Temperature Range (°C) | Key Chemical Resistance | Typical Applications | Limitations |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +100 | Mineral oils, water, alcohols | Hydraulics, pneumatic systems | Poor ozone and heat resistance |

| FKM (Viton®) | -20 to +200 | Fuels, acids, chlorinated solvents | Aerospace, chemical processing | Higher cost, limited low-temp flexibility |

| EPDM | -50 to +150 | Steam, water, ketones, alkalis | HVAC, pharmaceutical, food processing | Swells in hydrocarbons |

| Silicone | -60 to +200 | Oxidation, UV, water | Medical devices, electronics | Low mechanical strength |

| FFKM (Perfluoro) | -15 to +300 | All chemicals, including strong acids | Semiconductor, ultra-high purity | Very high cost |

Understanding these material differences is essential for avoiding the pitfalls of off-the-shelf solutions. The 1/4 O ring is not merely a commodity—it is a precision component whose performance is defined by intelligent material engineering.

Material Specifications

Material Specifications for 1/4 Inch O-Rings: Precision Selection for Industrial Sealing

Selecting the optimal elastomer for 1/4 inch O-rings is critical for ensuring reliable sealing performance, longevity, and cost-effectiveness in demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., our engineering team emphasizes that material properties must align precisely with the operational environment, including fluid exposure, temperature extremes, pressure cycles, and mechanical stress. Standard 1/4 inch O-rings (AS568A-214 size) require materials offering consistent durometer, low compression set, and resistance to extrusion under load. The three primary elastomers specified for this size in precision sealing are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each with distinct performance profiles validated against ASTM D2000 and ISO 3601 standards.

Viton (Fluoroelastomer – FKM) represents the premium choice for severe chemical and thermal environments. Its molecular structure provides exceptional resistance to aggressive fluids including hydrocarbons, aromatic fuels, chlorinated solvents, and acids. Viton O-rings maintain integrity across a broad temperature range of -20°C to +230°C (-4°F to +446°F), with brief excursions up to 300°C possible. The standard 70-90 Shore A hardness ensures excellent extrusion resistance in high-pressure hydraulic and aerospace systems. While Viton commands a higher initial cost, its longevity in harsh conditions delivers superior lifecycle value for critical 1/4 inch sealing points in chemical processing, semiconductor manufacturing, and downhole oilfield equipment.

Nitrile (Acrylonitrile Butadiene Rubber – NBR) remains the industry workhorse for cost-sensitive applications involving petroleum-based oils and fuels. Offering good abrasion resistance and tensile strength at 60-90 Shore A, standard NBR formulations function reliably between -40°C and +120°C (-40°F to +248°F). Its key limitation is poor resistance to oxygenated solvents, phosphate esters, and extreme heat. NBR is the pragmatic selection for 1/4 inch O-rings in hydraulic systems, automotive transmissions, and general industrial machinery where exposure is limited to mineral oils and greases. Suzhou Baoshida provides custom NBR compounds with enhanced low-temperature flexibility or ozone resistance for specialized OEM requirements.

Silicone (Polysiloxane – VMQ) excels in extreme temperature applications but requires careful consideration of mechanical limitations. With an unmatched operational range of -60°C to +200°C (-76°F to +392°F), silicone maintains flexibility in cryogenic settings while resisting thermal degradation. Its inherent biocompatibility and low toxicity make it suitable for food, pharmaceutical, and medical device sealing. However, standard silicone exhibits lower tensile strength and abrasion resistance compared to NBR or Viton, with susceptibility to tearing under high pressure. For 1/4 inch O-rings in thermal cycling environments like aerospace ducting or laboratory equipment, reinforced silicone compounds mitigate these weaknesses while preserving thermal stability.

The comparative analysis below details essential properties for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Standard Hardness | 70-90 Shore A | 60-90 Shore A | 40-80 Shore A |

| Temp Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Fluid Resistance | Excellent: Fuels, oils, acids, solvents | Good: Petroleum oils, water | Poor: Oils, fuels; Excellent: Water, steam |

| Compression Set | Very Low (per ASTM D395) | Moderate | Low to Moderate |

| Key Limitation | Cost; Poor for ketones, amines | Limited heat/ozone resistance | Low tensile strength; Poor oil resistance |

| Typical 1/4″ Application | Chemical pumps, jet engines | Automotive hydraulics, gearboxes | Medical devices, oven gaskets |

Suzhou Baoshida Trading Co., Ltd. provides certified material test reports and OEM-specific formulation adjustments for all 1/4 inch O-ring compounds. Contact our engineering team to validate material suitability against your application’s exact pressure, media, and lifecycle requirements.

Manufacturing Capabilities

Engineering Capability: Precision Development for 1/4 O Rings

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our precision rubber seal manufacturing, particularly in the production of the widely used 1/4 inch O ring. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the entire development cycle—from material formulation to mould design and process optimization. This integrated technical structure ensures rapid prototyping, consistent quality, and superior performance under demanding application conditions.

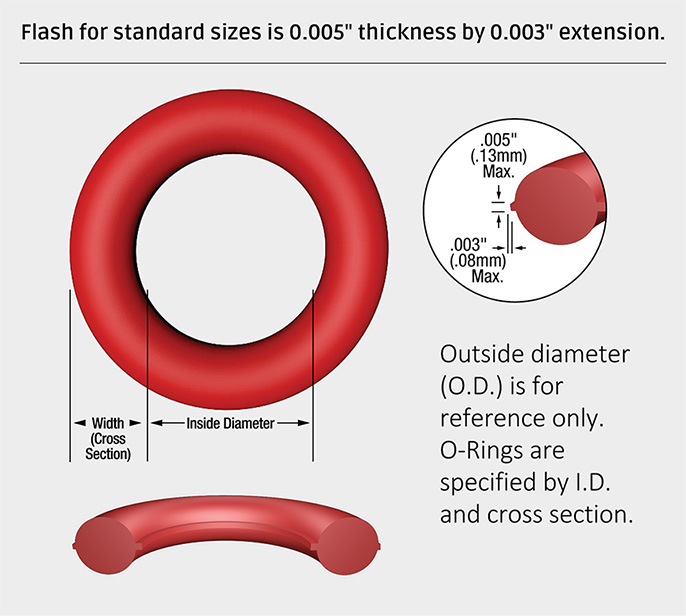

Our mould engineers possess extensive expertise in precision steel tooling, utilizing advanced CAD/CAM and CNC machining technologies to develop high-tolerance moulds tailored to the dimensional and functional requirements of the 1/4 O ring. Each mould is engineered to minimize flash, ensure uniform cross-sectional consistency, and support high-volume production with minimal cycle variation. Finite element analysis (FEA) is routinely applied to predict material flow and optimize gate design, contributing to long mould life and repeatable part geometry.

Complementing our tooling strength, our two rubber formula engineers focus exclusively on elastomer chemistry and compound development. They formulate custom rubber compounds based on application-specific requirements such as temperature resistance, chemical exposure, compression set, and dynamic performance. Whether the 1/4 O ring is destined for hydraulic systems, automotive engines, or industrial pumps, we engineer the rubber compound to match the operational environment. Our formulation library includes optimized grades of Nitrile (NBR), Fluorocarbon (FKM), Ethylene Propylene (EPDM), Silicone (VMQ), and other specialty elastomers, all developed and tested in-house using ASTM and ISO-compliant methodologies.

We operate as a full-service OEM partner, providing end-to-end development and production support. Our clients benefit from collaborative engineering input during the design phase, material selection guidance, and rigorous validation testing including hardness, tensile strength, volume swell, and accelerated aging. With full traceability and batch control, we ensure every 1/4 O ring meets the highest standards of dimensional accuracy and performance reliability.

The following table outlines the standard technical specifications for our 1/4 inch O ring offering, reflecting our commitment to precision and consistency.

| Parameter | Value / Range |

|---|---|

| Nominal Size (ID × CS) | 0.250 in × 0.070 in (6.35 mm × 1.78 mm) |

| Tolerance (ID / CS) | ±0.005 in / ±0.003 in (per AS568) |

| Material Options | NBR, FKM, EPDM, VMQ, CR, ACM |

| Hardness Range (Shore A) | 50 to 90 ±5 |

| Temperature Range (typical) | -40°C to +230°C (material-dependent) |

| Standard Compliance | ASTM D2000, ISO 3601, AS568 |

| Production Capacity | Up to 500,000 pcs/month per mould |

| OEM Customization | Full (size, material, packaging) |

Our engineering-driven approach enables Suzhou Baoshida to deliver technically robust, application-optimized 1/4 O rings with speed, precision, and scalability—making us a trusted partner in global industrial supply chains.

Customization Process

Customization Process for Precision 1/4″ O-Rings at Suzhou Baoshida Trading Co., Ltd.

The customization process for 1/4″ O-rings begins with rigorous Drawing Analysis. Our engineering team meticulously reviews client-provided technical drawings against the AS568A standard (Dash #012 size: ID 0.250″ ±0.004″, CS 0.070″ ±0.003″). We verify critical parameters including inner diameter, outer diameter, cross-section tolerance, groove dimensions, surface finish requirements, and any special features like chamfers or identification marks. Material specifications, fluid compatibility needs, temperature range, and pressure conditions are cross-referenced against application data sheets. This phase identifies potential design conflicts early, ensuring manufacturability and sealing performance before material selection proceeds. Non-conforming elements are flagged for immediate client consultation to prevent downstream delays.

Formulation development is our core technical differentiator. Based on the validated application requirements from the drawing analysis, our rubber chemists select the optimal polymer compound. For standard hydraulic applications requiring oil resistance, we formulate custom NBR blends targeting 70±5 Shore A durometer. High-temperature aerospace or chemical exposure scenarios trigger FKM formulations with 80±5 Shore A hardness and specific peroxide curing systems. Each compound is engineered with precise additive packages—reinforcing fillers for tensile strength, antioxidants for thermal stability, and processing aids for extrusion consistency. Material datasheets detailing compression set (<20% @ 150°C/70h), tensile strength (>15 MPa), and fluid resistance per ASTM D2000 are generated for client approval prior to prototyping.

Prototyping validates both design and material performance. We produce 5-10 sample O-rings using precision molding techniques under controlled vulcanization conditions (time, temperature, pressure). Samples undergo dimensional verification via optical comparators to confirm ±0.002″ cross-section accuracy. Critical performance testing includes compression set measurement per ASTM D395, leak rate validation in application-specific fixtures, and accelerated fluid immersion testing. Any deviation from target specifications triggers iterative compound adjustments or process recalibration. Client feedback on prototype functionality within their assembly is incorporated before final sign-off.

Mass production leverages our ISO 9001-certified manufacturing systems. Production runs commence only after formal client approval of prototypes and material certifications. We implement Statistical Process Control (SPC) with real-time monitoring of key parameters: rubber batch viscosity, mold cavity temperature (±2°C), cure time (±0.5s), and post-cure oven profiles. Every 1,000-piece lot undergoes 100% visual inspection and automated dimensional sampling. Full material traceability—from raw polymer batch to finished O-ring—is maintained via serialized barcoding. Final shipments include comprehensive quality documentation: dimensional reports, material certificates of conformance, and third-party test results where specified, ensuring seamless integration into the client’s assembly line.

Critical 1/4″ O-Ring Specifications (AS568A Dash #012)

| Critical Parameter | Standard Tolerance | Baoshida Precision Capability | Testing Standard |

|---|---|---|---|

| Inner Diameter (ID) | ±0.004″ (0.10mm) | ±0.002″ (0.05mm) | ASTM D3767 |

| Cross-Section (CS) | ±0.003″ (0.08mm) | ±0.0015″ (0.04mm) | ASTM D3767 |

| Durometer Hardness | ±5 Shore A | ±3 Shore A | ASTM D2240 |

| Compression Set (22hrs) | ≤30% | ≤18% @ 100°C | ASTM D395 Method B |

| Material Consistency | ASTM D2000 Grade | Customized per OEM spec | ISO 37, ISO 188 |

Contact Engineering Team

For precision-engineered rubber sealing solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the global industrial supply chain. Specializing in high-performance elastomeric components, we deliver consistent quality and technical excellence across demanding applications. Our expertise in manufacturing 1/4 inch O-rings ensures compliance with international standards, including AS568, ISO 3601, and JIS B 2401, making our products suitable for aerospace, automotive, hydraulics, pneumatics, and semiconductor processing industries.

Every 1/4 inch O-ring produced or supplied by Suzhou Baoshida is subject to rigorous material testing, dimensional verification, and batch traceability protocols. We offer formulations in Nitrile (NBR), Ethylene Propylene Diene Monomer (EPDM), Fluorocarbon (FKM/Viton®), Silicone (VMQ), and other specialty compounds designed to resist extreme temperatures, aggressive chemicals, and prolonged compression set. Whether your application requires low-temperature flexibility down to -55°C or resistance to jet fuel and hydraulic fluids at 200°C, our engineering team can recommend or customize a solution that meets your operational demands.

Our commitment extends beyond product delivery. We provide full technical documentation, including material certificates (e.g., RoHS, REACH, FDA), hardness reports, and aging test data upon request. With in-house molding capabilities and strategic partnerships with certified rubber compounders, we maintain tight control over lead times and quality assurance. Inventory management, just-in-time shipping, and OEM packaging options are available to support seamless integration into your production workflow.

To ensure your sealing challenges are met with precision and reliability, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads technical client engagement and brings over 12 years of experience in elastomer formulation and industrial sealing dynamics. He is available to support material selection, failure analysis, custom cross-section adjustments, and volume-based sourcing strategies tailored to your manufacturing scale.

Reach out directly via email at [email protected] to initiate a technical consultation, request samples, or obtain a formal quotation. Our team responds to all inquiries within 12 business hours and supports communication in English, Mandarin, and German.

Below are the standard specifications for our most commonly requested 1/4 inch O-ring configuration:

| Parameter | Specification |

|---|---|

| Nominal Size | 1/4 inch (AS568-214) |

| Inside Diameter (ID) | 0.244 inches ± 0.004 (6.198 mm ± 0.102) |

| Cross Section (CS) | 0.070 inches ± 0.003 (1.778 mm ± 0.076) |

| Volume | 0.0038 in³ (62.3 mm³) |

| Standard Materials | NBR, EPDM, FKM, VMQ, CR |

| Hardness Range | 50 to 90 Shore A |

| Temperature Range | -55°C to +200°C (material dependent) |

| Tolerance Grade | AS568 Class M (Standard) or Class H (Precision) |

Partner with Suzhou Baoshida for technically validated, consistently manufactured 1/4 inch O-rings. Contact Mr. Boyce today at [email protected] to elevate your sealing performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).