Introduction: Navigating the Global Market for kalrez o rings

Kalrez® O-rings have earned a reputation as the gold standard in industrial sealing technology, delivering the resilience and chemical compatibility demanded by today’s most critical operations. Across sectors such as oil and gas, chemical processing, pharmaceuticals, and advanced manufacturing, the stakes for performance, compliance, and reliability are higher than ever—especially for international B2B buyers navigating diverse regulatory landscapes and complex supply chains. For procurement professionals and technical teams in Africa, South America, the Middle East, and Europe, selecting the right Kalrez O-ring is not just a matter of product selection, but a strategic decision that can influence plant uptime, operational safety, and long-term costs.

In a global market defined by rapid industrialization, shifting standards, and persistent supply challenges, understanding the full spectrum of Kalrez O-ring options is essential. This guide offers a practical roadmap for buyers seeking to confidently source genuine, high-performance seals suited to their unique operating environments. Key areas covered include:

- Types and Specifications: Detailed analysis of Kalrez variants, sizing standards (inch/metric/custom), and application fit.

- Material Science and Performance: Insights into chemical resistance, temperature thresholds, and durability in extreme settings.

- Manufacturing & Quality Assurance: Best practices for verifying authenticity, compliance documentation, and minimizing the risks of counterfeit products.

- Supplier Evaluation: Strategies for identifying reputable global manufacturers, distributors, and local partners.

- Cost Dynamics & Market Trends: Regional pricing factors, lead time considerations, and emerging procurement trends.

- Common Pitfalls & Solutions: Practical FAQs and troubleshooting tips addressing real-world sourcing and installation challenges.

Armed with these insights, international buyers will be equipped to make informed, cost-effective sourcing decisions—ensuring operational continuity, regulatory compliance, and risk mitigation in demanding markets worldwide.

Understanding kalrez o rings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Kalrez O-Ring | Universal round cross-section, black, 75A durometer | Pumps, valves, flanges, instrumentation | Excellent thermal/chemical resistance; higher up-front cost vs. FKM |

| AS568 Inch Series | Made to SAE AS568 inch-standardized dimensions | US/Canada-origin equipment, global OEM components | Easy replacement, global compatibility; limited to inch sizes |

| Metric Series | Metric inside diameters and cross-sections | European, Asian machinery, international projects | Ideal for metric equipment; may be harder to source in US-centric markets |

| Custom Kalrez O-Ring | Bespoke shapes/sizes, made to specs | Unique grooves, specialized or legacy assets | Perfect fit; longer lead times, possible higher minimum order quantity |

| O-Ring with Compliance Certificates | Supplied with ASTM/ISO or regulatory documentation | Pharmaceuticals, food processing, energy sector | Eases audits, regulatory checks; includes certification price premium |

Standard Kalrez O-Ring

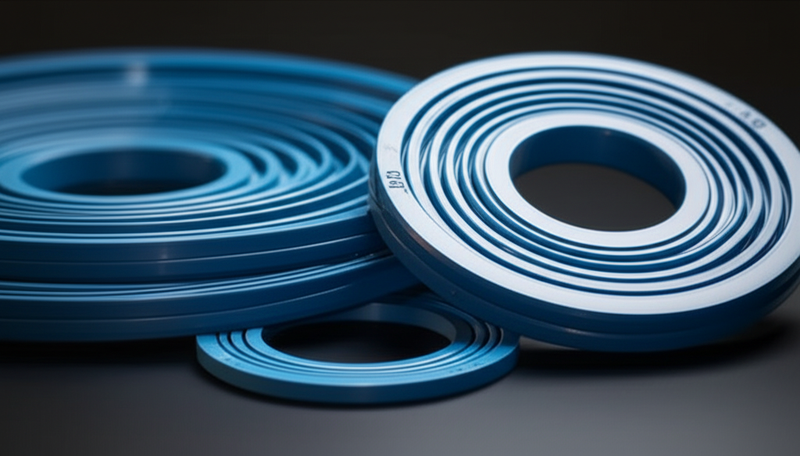

Standard Kalrez O-rings are engineered from high-performance perfluoroelastomer (FFKM) compounds, using a universal round cross-section with a 75A durometer. This type stands out for its exceptional resistance to aggressive chemicals and sustained high temperature exposure up to 275°C, making it suitable for pumps, valves, and general industrial sealing. For B2B buyers, these off-the-shelf variants minimize downtime and offer broad compatibility, but the initial investment is higher than conventional rubber O-rings. Long-term reliability and reduced replacement cycles can, however, deliver a favorable total cost of ownership.

AS568 Inch Series

AS568 Inch Series Kalrez O-rings comply with the SAE’s strict inch-dimension standards, ensuring consistency and interchangeability across equipment built to US specifications. This standardization streamlines procurement and inventory management for organizations operating or supporting North American–designed machinery worldwide. The primary benefit is simplified sourcing and stocking, as inch sizes are widely catalogued. B2B buyers must ensure that equipment is not metric-based to avoid sizing errors, particularly within mixed global fleets.

Metric Series

Metric Series Kalrez O-rings feature diameters and cross-sections measured in millimeters, aligning with European, Asian, and globally standardized equipment. These are essential for buyers serving international projects, where metric standards dominate. Adoption of metric sizes mitigates the risk of incorrect fitment, especially for facilities importing diverse machinery. While readily available in Europe and Asia, metric O-rings can sometimes be less accessible in US-centric supply chains, so dual stocking strategies are recommended for global operations.

Custom Kalrez O-Ring

Custom Kalrez O-rings address unique sealing requirements where standard sizes or profiles are insufficient—such as rare flange designs, legacy instruments, or specialized laboratory applications. These bespoke solutions guarantee compatibility and optimal performance in mission-critical environments. The custom order route requires advanced planning, as lead times, minimum order quantities, and unit pricing are often higher. For B2B buyers in sectors with non-standardized equipment, investing in custom options safeguards operational continuity and asset integrity.

O-Ring with Compliance Certificates

O-rings supplied with compliance certificates (such as ASTM or ISO documentation) meet the strict regulatory and traceability needs in industries like pharmaceuticals, food and beverage, and energy production. Certificates enhance trust during inspections, audits, or export processes, helping companies stay compliant with local and international regulations. For B2B buyers, this variant streamlines certification-heavy operations, but often carries a price premium. Buyers should validate the authenticity and scope of supplied documentation during procurement, especially when sourcing through regional distributors.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of kalrez o rings

| Industry/Sector | Specific Application of kalrez o rings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Sealing in pumps, valves, and downhole tools | Withstands corrosive fluids and high temperatures, enables safe operation and reduces unplanned downtime | Verify chemical compatibility, ensure compliance with relevant industry standards (API, NORSOK), and secure traceability certificates |

| Chemical Processing | Reactor vessel and pipe joint sealing | Resistant to aggressive solvents and process media, supporting continuous operation and safety | Prioritize chemical resistance data, source genuine parts, assess supplier reliability for aftermarket support |

| Pharmaceutical & Life Sciences | Sterile process equipment (e.g., bioreactors, transfer lines) | Maintains product purity, supports regulatory compliance, and minimizes contamination risk | Demand industry certification (FDA, USP), request compliance documentation, verify cleanroom packaging |

| Food & Beverage | Hygienic sealing in processing and filling equipment | Prevents contamination, withstands CIP/SIP cleaning, prolongs equipment lifecycle | Require food-grade approvals (EU 1935/2004, FDA), validate supplier’s hygiene standards |

| Energy & Power Generation | Valve and seal integrity in high-temperature turbines and generators | Ensures continuous energy production, reduces leakages, allows operation under severe thermal cycles | Confirm temperature ratings, check for compatibility with specific turbine lubricants, require long-term supply agreements |

Oil & Gas: Sealing in Pumps, Valves, and Downhole Tools

In upstream and downstream oil and gas operations, Kalrez o-rings deliver critical sealing in pumps, valves, and downhole equipment exposed to aggressive hydrocarbons, acids, amines, and sour gas. Their high thermal and chemical resilience ensures operational integrity, preventing leaks that can lead to environmental hazards or equipment shutdowns. B2B buyers—especially those in Africa’s oilfields, Middle East refineries, and offshore platforms in Europe—should prioritize material traceability and certifications, ensuring full compatibility with local standards and compliance requirements.

Chemical Processing: Reactor Vessel and Pipe Joint Sealing

Chemical facilities worldwide rely on Kalrez o-rings for their unparalleled resistance to acids, caustics, oxidizers, and solvents at varying temperatures and pressures. In Africa’s growing petrochemical hubs or South American agrochemical plants, these o-rings help maintain critical containment in reactors and pipelines. Securing genuine Kalrez parts from reputable global suppliers is vital, as counterfeit or inferior seals compromise plant safety and longevity. International buyers should demand in-depth chemical resistance data and ensure the supplier offers technical support for aftermarket requirements.

Pharmaceutical & Life Sciences: Sterile Process Equipment

Kalrez o-rings are essential in the pharmaceutical sector, where product purity and regulatory compliance are paramount. Used in sterile bioreactors, transfer lines, and filling machines, they prevent cross-contamination and withstand repeated clean-in-place (CIP) and sterilization-in-place (SIP) cycles. For buyers in Europe and emerging Middle Eastern pharmaceutical clusters, requesting seals with FDA, USP VI, or EU compliance—and verifying certification—is crucial for audit readiness and to avoid costly batch failures. Cleanroom packaging and documented lot traceability further support pharmaceutical production best practices.

Food & Beverage: Hygienic Sealing in Processing and Filling Equipment

In food and beverage production, Kalrez o-rings provide reliable seals where hygiene, taste neutrality, and resistance to cleaning chemicals are required. They are used in pumps, valves, and automated bottling lines frequently sanitized with caustic solutions or steam. Buyers in regions modernizing their food supply chain, like South America and parts of Africa, benefit from specifying food-grade Kalrez with full traceability and supplier hygiene compliance to safeguard consumer health and regulatory conformity.

Energy & Power Generation: Valve and Seal Integrity in High-Temperature Turbines

Power generation plants (gas, steam, nuclear) demand seals that endure severe thermal cycles, high pressures, and exposure to specialty lubricants. Kalrez o-rings, installed in turbine valves and generator housings, safeguard operational reliability and minimize maintenance intervals. For international buyers in European or Middle Eastern utilities, confirming the o-rings’ high-temperature and media compatibility is vital. Securing long-term supply agreements ensures availability during outages and major overhauls, supporting consistent power delivery and reducing procurement risks.

Related Video: Basics of O-Rings | Core Applications

Strategic Material Selection Guide for kalrez o rings

Selecting the Optimal Kalrez O-Ring Material: B2B Considerations

For international B2B buyers, the correct material choice for Kalrez O-rings is fundamental to equipment reliability, operational safety, and long-term cost management. Below is a detailed analysis of three widely used Kalrez materials, each tailored to demanding industrial environments. This overview emphasizes technical performance, cost-benefit evaluation, and region-specific procurement factors relevant to Africa, South America, the Middle East, and Europe.

Kalrez 6375: Broad Chemical Resistance Workhorse

Key Properties:

Kalrez 6375 is formulated for universal chemical resistance and superior thermal stability up to 275°C. It maintains elasticity in harsh environments, tolerates rapid temperature swings, and handles aggressive fluids—including acids, amines, and organic solvents.

Pros:

– Exceptional media compatibility, reducing the risk of chemical attack.

– Suitable for dynamic and static seals—pumps, valves, instrumentation.

– Certifiable to international standards (typically ASTM/ISO), simplifying audit compliance.

Cons:

– Higher acquisition cost than generic FKM or FPM elastomers.

– Complex manufacturing process may extend lead times, especially for custom sizes.

Application Impact:

Kalrez 6375 excels in chemical plants, refineries, and pharmaceutical manufacturing, where varied or changing process media are common. Its robust performance reduces unplanned downtime and replacement frequency.

International B2B Considerations:

Available in AS568 (inch), metric, and custom profiles, supporting both US and global equipment platforms. Buyers should verify documentation requirements—especially for regulated industries in the EU, UK, and Brazil where compliance audits are frequent.

Kalrez Spectrum 0040: Low-Temperature Resilience

Key Properties:

This grade is engineered for elasticity and sealing integrity at lower temperatures (down to -42°C), with a maximum service temperature close to 220°C. It covers applications where sub-ambient start-up or exposure is possible.

Pros:

– Superior flexibility and recovery at low temperatures.

– Good resistance to a broad chemical range, though not as universal as 6375.

– Widely supported with ISO and DIN compliance documentation.

Cons:

– Not optimal for sustained high-temperature operations beyond 220°C.

– Slightly less resistant to strong oxidizers or high-pH media.

Application Impact:

Spectrum 0040 is suited for cold storage, transportation, or outdoor processing—common in European climates and mineral extraction sectors across Africa and South America.

International B2B Considerations:

Widely available in both metric and inch formats, but buyers should confirm stock availability in target regions (especially for smaller or remote markets). EU and Middle East industry preference for DIN/ISO-compliant seals enhances ease of import and user acceptance.

Kalrez Spectrum 7275: For Aggressive Oxidizers and Reactive Chemicals

Key Properties:

Kalrez Spectrum 7275 delivers resistance to highly oxidizing or reactive chemical environments (e.g., chlorine, peroxide processes) with a continuous operating temperature up to 300°C.

Pros:

– Irreplaceable in applications with extreme oxidizers or plasma.

– Top-tier temperature performance for advanced processes.

– Supports certification to ASTM and specialized global standards.

Cons:

– Costs are significantly higher (premium grade).

– Not always stocked in all global hubs—may require import planning.

Application Impact:

Crucial for high-end specialty chemical production, semiconductor manufacturing, and energy installations—sectors where chemical attack risk is high and process temperature is at the limits.

International B2B Considerations:

Buyers in the Middle East (refining) and Europe (semiconductor/pharma) often specify this grade. Expect advanced compliance validation for documentation and, in regulated sectors, anticipate stricter audit scrutiny. Evaluate supplier logistics for timely delivery to remote or emerging markets.

Kalrez 4079: Balanced Chemical/Thermal Budget Material

Key Properties:

Kalrez 4079 is valued for general chemical resistance and moderate temperature endurance (up to 288°C). It offers good compression set and mechanical strength.

Pros:

– Reliable, workhorse material for many industrial applications.

– More cost-accessible than premium Kalrez grades.

– Widely supported in global supply chains.

Cons:

– Slightly lower chemical resistance than specialized grades.

– Not suitable for continuous exposure to highly aggressive or high-purity fluids.

Application Impact:

Frequently chosen for oil & gas, mining, and light chemical processing—especially where a balance of performance and economics is needed.

International B2B Considerations:

Well-represented in regional distributor inventories, and often enough for most maintenance or replacement schedules across Africa, South America, and Asia. Check for compliance with local standards (e.g., ASTM for Latin America, DIN for Europe).

Summary Table: Kalrez O-Ring Materials Selection

| Material | Typical Use Case for kalrez o rings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Kalrez 6375 | Universal chemical processing, pharma plants, refineries | Exceptional all-round chemical and thermal resistance | High unit price; lead time for custom orders | High |

| Kalrez Spectrum 0040 | Low-temp storage, mineral processing, equipment in cold climates | Reliable sealing at low temperatures | Not for ultra-high temps or harsh oxidizers | Medium-High |

| Kalrez Spectrum 7275 | Strong oxidizers, reactive chem processing, semiconductors | Resistance to aggressive/oxidizing chemicals, high heat | Premium pricing; limited availability | Very High |

| Kalrez 4079 | Oil & gas, mining, general industry maintenance | Good value, durable for moderate environments | Not for most aggressive media or high purity | Medium |

This analysis supports buyers in matching Kalrez material selections to their operational, regulatory, and geographical needs—assuring long-term performance and supply chain success.

In-depth Look: Manufacturing Processes and Quality Assurance for kalrez o rings

Kalrez O-rings stand at the pinnacle of elastomeric seal technology, trusted in high-stakes industries from petrochemicals to pharmaceuticals. The value they offer to B2B buyers is deeply rooted in advanced manufacturing processes and rigorous quality assurance protocols. Understanding these facets is critical for international procurement professionals seeking to minimize operational risks, ensure longevity, and support compliance in challenging environments across Africa, South America, the Middle East, and Europe.

Key Stages in Kalrez O-Ring Manufacturing

The manufacturing of Kalrez O-rings incorporates highly controlled processes to meet demanding performance and quality expectations. Here’s a breakdown of the standard stages and techniques:

1. Raw Material Preparation

- Polymer Synthesis: The primary ingredient for Kalrez O-rings is perfluoroelastomer (FFKM), engineered for exceptional chemical and thermal resistance. Specialist chemical processes are used to obtain the precise monomer structure, minimizing impurities that could affect final properties.

- Batch Compounding: FFKM is compounded with specific fillers, curatives, and additives using high-precision mixers. The batch recipe is tightly controlled—every ingredient, temperature, and mixing time is logged for traceability.

2. Forming and Shaping

- Molding: O-rings are commonly produced using compression, transfer, or injection molding. Compression molding is often preferred for intricate cross-sections and to reduce flow marks.

- Molds are precision-manufactured, often CNC-machined to global standards (e.g., AS568, metric series), ensuring exact dimensions and surface finish.

- Consistent molding pressure, temperature, and cycle times are verified by automated controls.

- Deflashing: Post-molding, O-rings undergo deflashing—a process that removes excess material and ensures smooth edges.

- Techniques include cryogenic tumbling or precision trimming, particularly important for regulatory-sensitive sectors.

3. Curing (Vulcanization)

- Thermal or Pressurized Curing: O-rings are cured under tightly regulated heat and pressure, cross-linking the polymer chains for optimal resilience and elasticity.

- Parameters are set according to the specific compound and application (e.g., high-purity or chemical-process settings).

- Advanced manufacturers employ in-line process controls to monitor and document curing conditions, supporting batch traceability.

4. Post-Curing and Finishing

- Secondary Curing: For applications such as semiconductor or pharmaceutical use, post-curing in specialized ovens reduces residual volatiles, enhancing purity and performance.

- Cleaning and Inspection: Finished O-rings are washed, often in cleanroom environments, to eliminate contaminants or particulates that can compromise critical equipment.

- Packaging: Products are vacuum-sealed or packaged to cleanroom standards as needed, with clear identification, lot coding, and documentation for buyer reference.

Comprehensive Quality Assurance Protocols

Kalrez O-rings undergo stringent quality assurance (QA) to meet both broad international and demanding local market standards. For B2B buyers, awareness of these checkpoints and how to verify them is essential to securing a supply chain free from costly failures or compliance issues.

1. Adherence to International and Industry Standards

- ISO 9001: Most leading Kalrez O-ring manufacturers operate under ISO 9001-certified quality management systems, covering all aspects of process control, document retention, traceability, and continuous improvement.

- Sector-Specific Standards:

- API (American Petroleum Institute): Relevant for oil & gas upstream/downstream applications.

- CE Marking: Required for conformity with European Union safety, health, and environmental standards, particularly in the UK and EU.

- FDA, USP, and 3-A Sanitary Standards: Critical for life sciences, food, and pharma buyers, supporting regulatory audits and end-user safety.

2. In-Process Quality Control (QC) Checkpoints

A robust QC program integrates several key phases:

- Incoming Quality Control (IQC): Raw materials and additives are tested for purity (e.g., FTIR spectroscopy), consistency (batch-to-batch checks), and compliance with supplier certifications.

- Ensures only approved polymers and compounds enter the manufacturing stream.

- In-Process Quality Control (IPQC): During molding and curing, operators and automated systems monitor:

- Dimensional accuracy (via in-mold sensors or post-mold inspection).

- Visual surface integrity and absence of defects (using high-contrast imaging or manual verification).

- Polymer cure state (using durometers and rebound tests).

- Final Quality Control (FQC):

- 100% inspection (manual or automated) for critical dimensions and surface defects.

- Batch statistical sampling for destructive testing or advanced analytics.

- Specialized physical and chemical testing—see next section for details.

3. Common Testing and Certification Methods

To ensure O-rings deliver on life cycle and safety, manufacturers apply a gamut of tests:

- Dimensional and Visual Inspection: Using calibrated gauges and digital comparators to ensure tolerance adherence (often ±0.08 mm for standard sizes).

- Material Verification: FTIR or NMR spectroscopy to confirm compound identity and purity.

- Thermal and Chemical Resistance: Representative samples are exposed to elevated temperatures and corrosive chemicals per ASTM or ISO protocols, with performance metrics maintained for records.

- Compression Set and Hardness: Assessed post-curing per ASTM D395 and D2240 to validate resilience and load retention.

- Outgassing and Extractables: Especially for semiconductor/pharma O-rings, low outgassing and minimal extractables are validated using specific gravimetric and chromatographic techniques.

- Traceability: Each batch is uniquely coded for trace-back in case of post-delivery issues, aligning with global traceability best practices.

How B2B Buyers Can Verify Supplier Quality

For international buyers, it is vital to actively manage and verify supplier quality claims:

- Request Documented Evidence:

- Ask for ISO 9001, CE, API, or other relevant certifications.

- Demand batch-specific Certificates of Analysis (COA), Material Safety Data Sheets (MSDS), and physical property test reports.

- Audit and Inspect:

- Conduct or commission supplier audits—either remote video or on-site (in-person or third-party)—with focus on process controls, traceability, and cleanliness.

- Inquire about previous audit outcomes or regulatory inspection reports.

- Utilize Third-Party Inspections:

- Engage reputable third-party inspection companies (such as SGS, TÜV, or Bureau Veritas) familiar with elastomeric components.

- Specify scope: from sample picking to complete batch inspection before shipment.

- Assess Supplier Transparency:

- Reliable vendors are open about process flows, testing methods, and are prompt in submitting technical datasheets and compliance records.

- Sophisticated suppliers offer digital traceability tools for shipment and batch tracking.

- Regional Considerations:

- For buyers in regulated industries in the UK or EU, ensure CE-marked O-rings and conformity with local directives (e.g., REACH, RoHS).

- In African, South American, or Middle Eastern markets, clarify if local standards apply or if international (ISO/API) certifications are required for your applications.

Practical Quality Control Guidance for Global B2B Buyers

- Insist on Full Documentation: Always secure technical datasheets, compliance certifications, and test reports with your shipments. For regulated sectors, consider only suppliers offering complete documentation packages.

- Monitor Post-Delivery Performance: Establish protocols for sample testing and batch verification upon receipt, especially for mission-critical applications. If periodic failures occur, utilize traceability data to collaborate on root-cause analysis.

- Factor in Supply Chain Challenges: Delays at international borders may compromise O-ring packaging integrity or introduce contamination. Specify sealed, batch-labeled, and cleanroom-packed O-rings where possible, especially for export to harsh or sensitive environments.

- Build Relationships with Preferred Suppliers: Long-term partnerships with reliable manufacturers enable better responsiveness in urgent situations and access to technical support for troubleshooting and joint product development.

Summary for International B2B Buyers

Navigating the procurement of Kalrez O-rings requires thorough vetting of manufacturing processes and QC disciplines. By understanding and verifying each stage—from raw material sourcing and forming to industry certifications and shipment inspection—B2B buyers across Africa, South America, the Middle East, and Europe can confidently secure genuine, high-performance Kalrez seals and protect mission-critical industrial operations worldwide.

Related Video: China’s Top 5 Manufacturing and Mass Production Videos | by @miracleprocess

Comprehensive Cost and Pricing Analysis for kalrez o rings Sourcing

Key Cost Components in Kalrez O-Ring Procurement

B2B buyers should recognize that Kalrez O-ring pricing is shaped by multiple upstream and downstream cost factors, many of which extend beyond basic material expense. The following components are central to the total unit cost:

- Premium Materials: Kalrez O-rings are made from advanced perfluoroelastomer (FFKM) compounds, significantly more expensive than standard elastomers (NBR, FKM). Raw polymer quality, proprietary DuPont formulations, and curing agents all add to the base cost.

- Specialized Labor and Manufacturing Overhead: FFKM processing requires specialized skills—cleanroom environments, strict process controls, and experienced operators. Equipment calibration, energy use, and downtime for retooling or maintenance accumulate in overheads.

- Tooling and Setup Fees: For custom sizes or profiles, new tooling/setups are often necessary. These one-off charges can be amortized over large volumes but may be significant for small orders or prototypes.

- Quality Control (QC) & Certification: Many Kalrez O-rings undergo extensive QC (including batch traceability and testing), especially when supplied with ASTM, ISO, FDA, or USP certificates. These regulatory and compliance measures increase direct costs.

- Logistics and Duties: International shipping, customs brokerage, insurance, and—where applicable—VAT/import duties, can comprise a notable portion of the landed cost, particularly for remote destinations in Africa and South America.

- Supplier Margins & Distribution Layers: Global supply chains typically involve manufacturer markups, distributor/agent fees, and local handling charges, especially if not buying direct from DuPont or an authorized distributor.

Primary Price Influencers: What Drives Pricing Variance?

Kalrez O-ring prices are rarely static due to a mix of global market dynamics and specific buyer requirements:

- Order Volume & Minimum Order Quantities (MOQ): High-volume purchases attract scale discounts, while single or small-batch orders often incur per-piece premiums and setup fees. Buyers should always clarify MOQ thresholds.

- Specifications and Customization: Non-standard sizes, custom cross-sections, or special compounding (e.g., for explosive decompression resistance or extreme purity) drive up both lead times and per-unit cost.

- Material Grade & Performance Requirements: Different Kalrez grades (e.g., Spectrum 6375 for broad chemical resistance, 0090 for high hardness) are priced according to proprietary formulations and intended operating environments.

- Quality and Certification Needs: O-rings supplied with full traceability, compliance documentation, or for regulated industries command higher prices owing to tighter tolerances and documentation labor.

- Supplier Reputation, Location, and Support: Authorized regional distributors and local partners may charge more for technical support, localized stock, and compliance assurance, potentially offsetting higher indirect and logistics costs.

- Incoterms and Delivery Conditions: Pricing can vary widely depending on the agreed Incoterms—FOB, CIF, DDP, and others—all impacting the buyer’s share of transportation, insurance, and duty costs.

Cost-Efficiency and Strategic Sourcing Tips for International Buyers

- Negotiate for Volume and Blanket Orders: Aggregate requirements within your organization or among subsidiaries to surpass volume discounts. For critical operations, long-term supply agreements can secure stable pricing and priority allocation.

- Balance Customization with Stock Availability: Where possible, standardize on widely-available inch or metric series to leverage faster delivery and lower cost per unit, reserving custom O-rings for truly non-standard applications.

- Request Comprehensive Quotations: Solicit itemized quotes that break down material, labor, certs, compliance, and delivery costs. Clarify all fees upfront, particularly customs, documentation, and expedited shipping fees.

- Evaluate Total Cost of Ownership (TCO): While Kalrez O-rings often carry a higher upfront expense, their long service life, reduced downtime, and compliance benefits typically result in a lower TCO versus lower-grade alternatives.

- Understand Regional Pricing Nuances: In Africa, South America, Middle East, and parts of Europe, local distributor networks might command higher unit costs, but often provide better after-sale support and regulatory guidance. Weigh these value-added services against direct import savings.

- Optimize Shipping and Consolidation: For long-distance sourcing (e.g., Indonesia, Brazil), work with logistics partners or distributors able to consolidate shipments, which cuts per-unit transport and handling costs.

Disclaimer: Prices for Kalrez O-rings are strongly influenced by global raw material trends, supply chain status, and specific buyer configurations. All cost and pricing information provided here is indicative, intended for general guidance only—exact terms and unit pricing must be validated with suppliers or authorized distributors.

By understanding these cost drivers and leveraging strategic sourcing practices, B2B buyers can position themselves for optimal quality, compliance, and value when sourcing Kalrez O-rings globally.

Spotlight on Potential kalrez o rings Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘kalrez o rings’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Kalrez® (www.dupont.com)

DuPont, the manufacturer behind Kalrez®, has built a reputation over four decades for advanced sealing solutions engineered for hostile environments. Kalrez® specializes in premium perfluoroelastomer (FFKM) O-rings, gaskets, and custom seals that deliver exceptional resistance to extreme chemicals and temperatures. Serving sectors such as oil and gas, chemical processing, pharmaceutical, and electronics, Kalrez® demonstrates a strong focus on both product reliability and process safety.

Key strengths include:

– Material Science Leadership: Proprietary FFKM compounds ensure optimal performance in demanding applications, reducing downtime and maintenance costs.

– Comprehensive Industry Certifications: Products are designed to meet or exceed stringent industry standards, supporting international regulatory compliance.

– Global Reach: Kalrez® is experienced in fulfilling B2B requirements across Africa, South America, the Middle East, and Europe, with established channels for technical support and logistics.

– Customization Capability: Offers tailored sealing solutions for unique process requirements, backed by expert engineering consultation.

For B2B buyers seeking proven, high-performance sealing products with global support and application expertise, Kalrez® represents a trusted industry partner.

Kalrez O-Rings (www.aceseal.com)

Ace Seal is a global supplier with over 35 years of experience specializing in high-performance sealing solutions, including genuine Dupont™ Kalrez® O-rings, seals, and gaskets. The company offers a broad portfolio of FFKM (perfluoroelastomer) Kalrez® products tailored for demanding chemical, pharmaceutical, energy, and industrial applications. Ace Seal demonstrates expertise in supplying both standard and custom-engineered O-rings, accommodating diverse sizing systems such as AS568 (inch) and metric standards—critical for serving international B2B clients with region-specific requirements across Africa, South America, the Middle East, and Europe.

Noted for their ability to support custom specifications and quick turnaround on requests, Ace Seal positions itself as a reliable partner for complex procurement needs. While detailed certifications or compliance standards (such as ISO 9001) are not explicitly referenced, their long-standing market presence and focus on globally recognized materials like Kalrez® reinforce their credibility among multinational buyers seeking consistent quality and supply continuity.

Kalrez O-Rings (www.globaloring.com)

Global O-Ring and Seal is a specialist supplier of high-performance Kalrez® O-rings, targeting the demanding needs of the chemical processing, oil & gas, and pharmaceutical industries. The company offers a broad portfolio of Kalrez® compounds—including the versatile Kalrez® 6375—recognized for outstanding chemical resistance, thermal stability, and durability in extreme environments. With multilingual support and accessible online resources in English, Spanish, French, and Portuguese, Global O-Ring and Seal demonstrates clear international market orientation, making procurement smoother for buyers across Africa, South America, the Middle East, and Europe.

Strengths:

– Comprehensive Range: Standard and custom Kalrez® O-rings available for rapid response to diverse industrial requirements.

– Technical Expertise: In-depth application knowledge for guiding material selection and specification matching.

– Quality Assurance: Focuses on genuine, certified products suitable for regulated industry applications.

– International Buyer Support: Multilingual staff and streamlined export services for global supply chains.

For B2B buyers, Global O-Ring and Seal stands out for its specialized focus on genuine Kalrez® solutions, responsive international service, and ability to cater to both standard and complex sealing needs.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| Kalrez® | Advanced FFKM seals, global compliance, customization. | www.dupont.com |

| Kalrez O-Rings | Global Kalrez O-ring supplier; custom solutions available. | www.aceseal.com |

| Kalrez O-Rings | Genuine Kalrez®, international B2B expertise, custom solutions. | www.globaloring.com |

Essential Technical Properties and Trade Terminology for kalrez o rings

Key Technical Properties Relevant to B2B Purchasing of Kalrez O-Rings

Understanding key technical specifications is fundamental for international B2B buyers. Selecting Kalrez O-rings that align with your facility’s operational, regulatory, and environmental needs ensures reliable sealing performance, safety, and long-term value. These are the most critical properties and why they matter in the procurement process:

-

Material Grade (Compound Formulation):

Kalrez O-rings are perfluoroelastomer (FFKM) seals, with unique grades (e.g., Kalrez 6375, Spectrum 7275) tailored for specific chemical and thermal environments. Each material grade offers distinct resistance profiles against aggressive chemicals, amines, acids, and high temperatures. For B2B buyers, matching the material grade with your process media is crucial to prevent unexpected seal failures and downtime—especially in sectors such as oil & gas, chemical processing, and pharmaceuticals. -

Temperature Resistance:

High-performance Kalrez O-rings endure continuous temperatures up to approximately 275°C, with some grades engineered for even more extreme ranges. This property decides the seal’s suitability for applications involving reactors, pumps, or valves exposed to varying heat loads. For global buyers, verifying the thermal resistance safeguards against process interruptions caused by thermal degradation—a major risk in both tropical and variable climates common in Africa, South America, and the Middle East. -

Chemical Compatibility:

Kalrez O-rings provide outstanding resistance to an extensive range of corrosive chemicals, including acids, amines, solvents, and hydrocarbons. Thoroughly checking compatibility charts and supplier datasheets is necessary to match the O-ring to your site’s chemical mix. Failing to confirm compatibility can lead to swelling, leaks, or premature degradation, impacting safety and compliance mandates in regulated industries. -

Durometer (Hardness):

The durometer rating (commonly measured in Shore A) reflects the O-ring’s hardness, influencing its ability to seal under different pressures and in static versus dynamic environments. Standard Kalrez O-rings often feature a 75A hardness, yielding a balance between resilience and flexibility. For multinational buyers standardizing across facilities, maintaining consistent durometer ratings helps ensure seamless equipment maintenance and minimizes inventory complexity. -

Dimensional Tolerance and Sizing Standard:

Kalrez O-rings are manufactured to tight dimensional tolerances, following either AS568 (inch) or metric sizing systems. Understanding and referencing the correct standard is essential when replacing seals in equipment sourced from various regions (e.g., US-made vs. EU/Asian machinery). Inaccurate sizing may cause leaks or assembly issues, leading to elevated maintenance costs and asset downtime. -

Certification and Traceability:

Documentation such as material compliance certificates (ASTM, ISO), batch traceability, and safety data sheets are routinely required in regulated sectors (e.g., pharmaceuticals, food, energy). Requesting such documentation upfront supports audit preparedness, regulatory compliance, and product authenticity—especially vital for facilities adhering to international standards.

Common Trade Terms and Jargon in Kalrez O-Ring Procurement

International sourcing often involves specific business language that B2B buyers must understand for efficient and transparent transactions:

-

OEM (Original Equipment Manufacturer):

Refers to the producer of the original machinery or equipment for which Kalrez O-rings are specified. Procuring OEM-approved or equivalent seals ensures fit, safety, and preserves equipment warranties—critical for buyers managing mixed fleets or requiring documented compliance. -

MOQ (Minimum Order Quantity):

The smallest quantity a supplier is willing to sell in a single transaction. Minimums are often higher for custom sizes or non-standard grades. Understanding MOQ helps buyers manage inventory costs and prevents procurement delays, particularly when serving multiple facilities across international borders. -

RFQ (Request for Quotation):

A formal process where buyers solicit price and delivery information from one or more suppliers, often specifying detailed technical requirements such as dimensional tolerances, material grade, or certification needs. Well-prepared RFQs minimize miscommunication and support apples-to-apples supplier comparisons. -

Incoterms (International Commercial Terms):

Standardized trade terms, such as FOB (Free On Board), CIF (Cost, Insurance, and Freight), or DDP (Delivered Duty Paid), defining buyer and seller responsibilities for shipping, insurance, customs clearance, and delivery. Choosing the right Incoterm clarifies financial and logistical obligations, safeguarding budgets from hidden costs—particularly important for buyers shipping across continents. -

Lead Time:

The expected duration between placing an order and receiving the product. Lead times for Kalrez O-rings may fluctuate based on size, grade, customization, and global supply chain conditions. Accurate lead time planning enables buyers to prevent equipment stoppages caused by inventory shortages, a key concern for process industries with limited downtime windows. -

Traceability:

The ability to track each O-ring batch from production to installation. Traceability is non-negotiable in regulated industries, and helps in managing recalls, quality audits, and root-cause analysis should a seal failure occur.

Familiarity with these technical properties and procurement terms empowers international buyers to make informed decisions—mitigating risk, supporting global operations, and ensuring dependable sealing solutions for critical applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the kalrez o rings Sector

Global Market Landscape and B2B Sourcing Trends

With rapid industrialization, stricter regulatory standards, and the need for highly reliable fluid and chemical handling systems, the market for high-performance sealing solutions such as Kalrez O-rings continues to grow. Recent years have seen particularly strong demand from sectors requiring maximum chemical resistance and thermal stability, such as oil & gas extraction, chemical processing, pharmaceuticals, and advanced manufacturing. For B2B buyers across Africa, South America, the Middle East, and Europe, Kalrez O-rings often represent a critical investment for reducing unplanned downtime and ensuring equipment compliance.

Market drivers vary by region but share several common themes. African and South American buyers are often motivated by harsh operational environments—such as aggressive mining chemicals or high-temperature oilfield applications—making durability and compatibility crucial. Middle Eastern buyers focus on securing supply for petrochemical and energy mega-projects, often demanding proven performance and predictable logistics. Europe, with its mature industrial base, emphasizes both technical certification (ASTM, ISO) and traceable compliance.

Emerging B2B trends include:

- Digital Sourcing Platforms: Increased use of e-commerce and digital catalogs streamlines cross-border procurement, reducing lead times and supporting real-time stock visibility.

- Regional Warehousing: Localized inventories near industrial hubs in West Africa, Brazil, the Gulf Cooperation Council (GCC), and Western Europe help buyers reduce shipping delays and customs hurdles.

- Supplier Auditing and Vetting: As counterfeit or mis-specified seals can lead to costly downtime, buyers are actively conducting due diligence and demanding official certificates of origin, compliance documentation, and technical datasheets.

- Custom Engineering Solutions: Growing demand for custom profile O-rings and seals to address non-standard equipment or unique chemical environments, supported by direct collaboration with manufacturers.

- Cost Management: Buyers navigate shifting price dynamics influenced by raw material fluctuations (e.g., fluoroelastomer costs), global supply chain disruptions, and currency impacts. Strategic sourcing—including dual-sourcing and maintaining safety stock—is increasingly common.

For international buyers, successfully navigating these trends means building relationships with authorized manufacturers, leveraging local distributors with technical support, and closely monitoring the overall cost of ownership rather than simply unit price.

Sustainability and Ethical Sourcing Practices in Sealing Solutions

Environmental and ethical considerations are becoming non-negotiable in global B2B procurement, and the Kalrez O-ring sector is no exception. Industrial clients and their supply chain partners are under pressure to minimize the ecological footprint of both their products and operations. This is particularly relevant for buyers engaged in export-driven manufacturing or those operating in jurisdictions with robust environmental regulations.

Key sustainability themes include:

- Material Innovation: The industry is investing in advanced perfluoroelastomers designed for longer lifecycle, which translates to fewer replacements, less resource consumption, and lower waste. Some Kalrez O-rings can survive extended exposure to aggressive chemicals and high temperatures, reducing overall sealing material waste.

- Green Certifications: B2B buyers increasingly look for suppliers with ISO 14001 (Environmental Management Systems), REACH, and RoHS certifications. These standards signal commitment to responsible chemistry, traceability, and restricted use of hazardous substances.

- Ethical Supply Chains: Transparency concerning raw material sourcing and labor practices throughout the value chain is growing in priority. Ethical auditing, conflict minerals certifications, and supplier ESG disclosures help buyers mitigate reputational and regulatory risk.

- Reduced Process Emissions: Modern manufacturing facilities for advanced elastomers, particularly those invested in by leading brands, are focusing on emission control, solvent recovery, and closed-loop systems.

For international buyers, proactively integrating sustainability criteria—with defined environmental requirements and ethical supplier mandates—into RFPs and contractual agreements not only ensures regulatory compliance but also aligns with rising customer and stakeholder expectations. Embracing a green procurement strategy can position organizations as leaders in environmental stewardship, particularly important for access to premium markets in Europe and parts of the Middle East.

Brief Historical Perspective: Evolution of Kalrez O-Rings

The development of Kalrez O-rings marked a significant milestone in industrial sealing technology. Introduced in the late 20th century as one of the first commercial perfluoroelastomer (FFKM) compounds, Kalrez enabled reliable operation in environments where traditional elastomers quickly failed. Over time, Kalrez became synonymous with high performance, especially in mission-critical sectors such as semiconductors, petrochemicals, and pharma, where chemical inertness and temperature stability are essential.

Advancements in material science have continually expanded the Kalrez portfolio, offering specialized grades tailored for low temperatures, strong amines, or highly oxidizing environments. The result is a global benchmark for sealing performance—one that has shaped procurement and maintenance practices for countless B2B companies worldwide. For buyers, understanding this evolutionary context highlights why investing in genuine Kalrez O-rings can deliver long-term reliability and consistent compliance in even the harshest operating conditions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of kalrez o rings

-

How can I verify the authenticity and reputation of Kalrez O-ring suppliers when sourcing internationally?

Thorough supplier vetting is critical. Request documentation verifying the supplier’s status as an authorized distributor or official partner of DuPont or reputable OEMs. Inspect business licenses, cross-check their physical address, and ask for references from international clients, preferably in your region. Review supplier audits, ISO certifications, and customer reviews. For large orders, conducting a third-party inspection or arranging a virtual factory tour can minimize the risk of counterfeit or subpar products entering your supply chain. -

Are customization options available for Kalrez O-rings, and what is the typical process for ordering custom sizes or profiles?

Yes, custom Kalrez O-rings can be manufactured to your specifications. Submit detailed technical drawings or sample measurements, specifying diameter, cross-section, durometer, and any regulatory compliance requirements. Engage early with the supplier’s engineering team to confirm material compatibility and production feasibility. Be prepared for higher minimum order quantities (MOQs) and longer lead times for non-standard items. Advance planning is essential, especially when dealing with unique equipment configurations or strict regulatory environments. -

What are the standard minimum order quantities (MOQs), typical lead times, and accepted payment terms for B2B orders of Kalrez O-rings?

MOQs vary—standard stock items may have low or no MOQs, while custom or less common sizes require higher volumes. Lead times for stock items are generally 1-2 weeks, but custom or large-quantity orders may range from 4-12 weeks depending on demand and location. Common payment terms include T/T (telegraphic transfer), L/C (letter of credit), and occasionally net terms for repeat buyers. Always clarify terms, including deposit and balance structure, before placing an international order. -

How do I ensure the quality and compliance of Kalrez O-rings for regulated industries such as oil & gas, pharma, or food processing?

Specify your compliance requirements (e.g., FDA, USP, ASTM, ISO) upfront and request supporting documentation. Quality assurance should include certificates of analysis (COA), material safety data sheets (MSDS), and traceability records. Prefer suppliers with robust quality management systems (such as ISO 9001), and consider random third-party lab testing—especially for high-value or mission-critical applications. For industries with strict audit trails, ensure your purchase includes all necessary documentation for local regulatory bodies. -

What are the key considerations for international logistics, shipping, and customs when importing Kalrez O-rings?

Accurate documentation (commercial invoice, packing list, certificates of origin) is essential to streamline customs clearance. Discuss incoterms (EXW, FOB, CIF, DDP) with your supplier to clarify who manages transport risks and costs. For high-value items, invest in reliable freight partners—preferably with experience handling industrial seals—and confirm insurance coverage. Buyers in Africa, South America, and the Middle East should also anticipate variable port processing times and potential tariff or VAT implications. -

What should I do if I receive defective or non-conforming Kalrez O-rings from an international supplier?

Notify the supplier immediately, providing evidence such as photos, batch numbers, and test results. Reference your contract terms regarding quality claims and returns. For added protection, insist on a written quality agreement before ordering, outlining steps for dispute resolution, including credit issuance, replacement, or refunds. In contentious cases, leverage international arbitration bodies or localized commercial dispute mechanisms, especially if payment was made via irrevocable L/C or similar means. -

How can I optimize cost-effectiveness without compromising quality when sourcing Kalrez O-rings?

Balance price considerations against total cost of ownership—including product longevity, failure risk, and maintenance overheads. Obtain quotes from multiple suppliers but scrutinize very low prices, as these may indicate counterfeit or inferior products. Consolidate orders to reduce unit costs and shipping expenses. Where possible, partner with suppliers offering technical support and after-sales service to further reduce downtime and long-term costs. Prioritize reliability and documented product origin over short-term savings. -

What trends or challenges should international B2B buyers watch for when procuring Kalrez O-rings in 2024 and beyond?

Expect ongoing supply chain fluctuations, particularly for specialty perfluoroelastomer materials. Regional regulatory updates and environmental standards may affect allowable materials, especially in the EU and Middle East. Demand for certified, traceable, and sustainable sourcing continues to rise. Buyers should also remain alert to changing global trade policies, possible raw material shortages, and opportunities to diversify suppliers to reduce risk. Building robust supplier relationships is increasingly vital for ensuring reliable, compliant component supply.

Strategic Sourcing Conclusion and Outlook for kalrez o rings

International B2B buyers are increasingly recognizing the mission-critical role of Kalrez O-rings in the reliability and longevity of industrial assets, especially in sectors exposed to high temperatures, aggressive chemicals, and demanding regulatory standards. Successful sourcing goes beyond simple procurement—it requires a granular understanding of specifications, certifications, and supplier credibility to mitigate operational risks and maximize lifecycle value.

Key takeaways for B2B procurement:

- Assess compatibility: Ensure alignment with local and global standards (AS568, metric, custom) to support both domestic and cross-border operations.

- Verify authenticity: Work exclusively with authorized distributors and demand documentation—such as compliance certificates—to guarantee genuine, high-performance products.

- Consider total cost of ownership: Factor in not just unit price, but also long-term performance, lead times, and supplier reliability—especially important for operations in remote or logistically complex regions.

- Anticipate market trends: Monitor global pricing and supply fluctuations, and be proactive in leveraging local inventory partners to avoid costly downtime.

Looking ahead, the international demand for advanced sealing solutions like Kalrez O-rings is set to intensify, propelled by stricter industry standards and the push for greater operational efficiency. Strategic sourcing is a differentiator—buyers who invest in robust supplier relationships, continuous market intelligence, and diligent quality assurance will secure more resilient, future-proof supply chains. Now is the time to elevate your sourcing practices, ensuring your operations across Africa, South America, the Middle East, and Europe remain both competitive and compliant as global industries evolve.