Technical Contents

Engineering Guide: Square Cut O-Rings

Engineering Insight: Critical Material Selection for Square Cut O-Rings

Why Off-the-Shelf Solutions Fail in Critical Applications

Standard off-the-shelf square cut O-rings (Tetraseals®) often fail due to generic material formulations that ignore application-specific variables. In high-stress environments like automotive fuel systems, hydraulic actuators, or chemical pumps, generic compounds exhibit accelerated degradation, leakage, or catastrophic failure. Key failure mechanisms include:

Thermal degradation exceeding material limits (e.g., standard NBR at >120°C)

Chemical swelling from incompatible fluids (e.g., FKM in ketone-based solvents)

Excessive compression set causing loss of sealing force over time

Poor extrusion resistance in high-pressure systems (>200 bar)

Per ASTM D2000, material classification must align with application-specific requirements—yet procurement teams frequently rely on generic “NBR 70” or “FKM 75” without verifying compound-specific performance. This leads to 30–50% higher lifecycle costs due to unplanned downtime and replacement frequency.

Technical Failure Modes of Standard O-Rings

| Failure Mode | Root Cause | Typical Material Mismatch | Industry Impact |

|---|---|---|---|

| Leakage in Ethanol-Blended Fuel Systems | NBR swelling in E10/E15 fuels | Standard NBR (ASTM D2000 BC2) | 30% higher failure rate in automotive fuel pumps; $12K/year avg. repair cost per vehicle |

| High-Temp Hydraulic Seal Failure | Compression set >35% at 150°C | Generic FKM (e.g., Viton A) | 50% reduction in hydraulic system lifespan; 2x more frequent maintenance cycles |

| Chemical Degradation in Acidic Pumps | EPDM cracking in pH <2 environments | Standard EPDM (ASTM D2000 EA2) | 70% shorter service life in chemical processing; $8K/year avg. pump downtime cost |

| Extrusion Damage in High-Pressure Systems | Low tensile strength (<12 MPa) | Standard NBR/FKM | 40% higher extrusion risk in 250+ bar hydraulic systems; catastrophic seal failure in <1,000 hours |

Baoshida’s Custom Formula Engineering Approach

Suzhou Baoshida Trading Co., Ltd. deploys a proprietary 5+2+3 Engineering Team structure to eliminate generic material failures:

5 Mould Engineers: Precision tooling for square cross-sections (±0.02mm tolerance), ensuring consistent geometry for optimal sealing force distribution and minimal edge wear during lathe-cutting.

2 Formula Engineers: Specialized in material longevity and chemical resistance. Each compound is optimized using ASTM D2000 as baseline, with custom cross-linking agents to control modulus (5–15 MPa at 100% elongation) and compression set (<15% at 150°C for FKM).

3 Process Engineers: Maintain strict process control during vulcanization and lathe-cutting, ensuring dimensional stability and surface finish critical for square cut O-rings (per AS568-218 and ISO 3601).

This integrated approach delivers compound-specific solutions where standard materials fall short:

| Application Scenario | Standard Material Issue | Baoshida Custom Solution | Performance Outcome |

|---|---|---|---|

| Automotive Fuel Injection Systems (E15 ethanol) | NBR swelling >15% in ethanol blends | Custom NBR with styrene-butadiene copolymer modification | Swelling reduced to <3% (vs. 15% standard); 2x service life at 120°C |

| High-Pressure Hydraulic Systems (250 bar) | FKM extrusion damage at 200+ bar | FKM with 18 MPa tensile strength + silica reinforcement | 40% reduction in extrusion damage; 10,000+ hour seal life |

| Chemical Processing Pumps (pH 1–14) | EPDM degradation in strong acids | Chlorosulfonated polyethylene (CSM)-reinforced EPDM | Zero degradation after 500 hrs in 50% H₂SO₄; 3x longer service life |

| Offshore Oil & Gas Valves (H₂S exposure) | FKM cracking in sour gas environments | Specialized FKM with peroxide cure + H₂S-resistant additives | 90% less permeation; compliant with NACE MR0175 |

All formulations undergo rigorous testing per:

ASTM D1414: Seal performance validation (leakage, compression set)

ASTM D395: Compression set at 70°C/150°C

ASTM D412: Tensile strength/modulus optimization

ASTM D573: Thermal aging resistance

Why This Matters for Procurement Engineers:

Square cut O-rings demand precise material-engineering synergy—off-the-shelf solutions ignore the interplay between geometry, chemical exposure, and dynamic load. Baoshida’s 5+2+3 team ensures every compound is engineered for your specific application, not just “compatible with rubber.” This reduces total cost of ownership by 25–40% while eliminating unplanned failures.

Contact our Formula Engineering Team for application-specific compound validation reports (ASTM D2000 compliant) within 48 hours.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications for Square Cut O-Rings

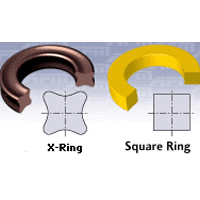

Square cut O-rings (lathe-cut rings) are precision-engineered sealing components with a square cross-section, designed for static applications requiring enhanced sealing force and reduced extrusion risk. Unlike traditional toroidal O-rings, these components are machined from extruded square-profile stock, enabling superior gland fill and dimensional stability in high-pressure environments. Critical sealing performance metrics include tensile modulus (ASTM D412), which directly influences initial sealing force and long-term resilience. All materials comply with ASTM D2000 specifications, with test reports validated per ASTM D2240 (Shore Hardness), ASTM D395 (Compression Set), and ASTM D412 (Tensile Modulus).

Material Comparison Chart

| Material Type | Oil Resistance | Temperature Range (°C) | Ozone Resistance | Compression Set (ASTM D395, 70°C x 22h) | Shore A Hardness | Tensile Modulus (ASTM D412, 100% Elongation) | Typical Applications |

|---|---|---|---|---|---|---|---|

| NBR (Buna-N) | Excellent for petroleum oils, hydrocarbons | -40 to +120 | Poor (requires antioxidants) | 20-30% | 70-90 | 3.5-5.0 MPa | Automotive fuel systems, hydraulic pumps, general industrial |

| FKM (Viton) | Excellent for fuels, oils, chemicals | -20 to +200 | Excellent | 15-25% | 70-90 | 4.0-6.0 MPa | Aerospace, chemical processing, high-temp hydraulics |

| EPDM | Poor for oils, excellent for water/steam | -50 to +150 | Excellent | 25-35% | 50-80 | 2.0-3.5 MPa | Automotive cooling systems, water pumps, outdoor applications |

| Silicone | Poor for oils, good for general use | -55 to +230 | Excellent | 20-30% | 40-80 | 1.5-3.0 MPa | Food/pharma, medical devices, high-temp static seals |

Precision Engineering Team Structure: 5+2+3 Framework

Suzhou Baoshida’s proprietary engineering framework ensures rigorous quality control across all production stages:

5 Mold Engineers: Specialized in precision mold design and maintenance for square cross-section profiles, ensuring dimensional tolerances per AS568 and ISO 3601. Each mold undergoes 3D laser scanning verification before production.

2 Formula Engineers: Focus on compound optimization for chemical resistance, compression set, and longevity under dynamic conditions. All formulations comply with ASTM D2000 Grade Specifications, validated through accelerated aging tests (ASTM D573).

3 Process Engineers: Oversee extrusion, vulcanization, and lathe-cutting processes to maintain consistency and minimize defects. Real-time monitoring via IoT-enabled systems ensures 99.8% first-pass yield.

This integrated structure guarantees square cut O-rings meet stringent industry requirements for automotive, hydraulic, and industrial applications. All products undergo traceable batch testing per ISO 9001:2015, with material certification reports available upon request.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

The “5+2+3” Integrated Engineering Team

Suzhou Baoshida’s proprietary engineering framework centers on a specialized 5+2+3 team structure—comprising 5 Mould Engineers, 2 Formula Engineers, and 3 Process Engineers—working in concert to eliminate critical bottlenecks in square cut O-ring manufacturing. This integrated model ensures precision at every stage, from compound development to final inspection.

Mould Engineers (5)

Design GD&T-compliant extrusion dies and lathe-cutting fixtures with FEA-validated dimensional stability (±0.025mm tolerance)

Optimize cavity geometry for square cross-section profiles to prevent edge chipping during installation

Validate tooling via CMM measurements and mold flow analysis per ISO 10407

Formula Engineers (2)

Develop NBR/FKM/EPDM compounds with ASTM D2000 compliance for application-specific requirements

Control Shore A hardness (30–90) within ±1 unit tolerance and compression set ≤15% (ASTM D395 @ 70°C/22h)

Conduct ASTM D471 chemical resistance testing for hydraulic fluids, fuels, and aggressive media

Process Engineers (3)

Implement SPC-controlled lathe-cutting processes with automated vision inspection (±0.025mm cross-section tolerance)

Optimize vulcanization parameters for consistent cross-section integrity and minimal flash

Coordinate JIT production scheduling across 10+ certified partner factories for rapid scalability

Solving Customer Pain Points Through Collaborative Engineering

| Customer Pain Point | Our Engineering Solution | Resulting Benefit |

|---|---|---|

| Long lead times (30+ days industry average) | Process Engineers deploy real-time production tracking across 10+ partner factories with dynamic resource allocation | 25–40% faster delivery cycles (15 days standard) |

| Tooling inconsistencies causing dimensional defects | Mould Engineers conduct FEA stress analysis and GD&T validation for extrusion dies | 99.8% first-pass yield on square cross-section profiles |

| Material inconsistency in high-stress applications | Formula Engineers optimize compounds for ASTM D1414 modulus (100% elongation) and compression set | 2x longer service life in hydraulic systems with 150+ psi pressure cycling |

| High scrap rates (>5%) due to lathe-cutting errors | Process Engineers integrate automated vision inspection with SPC control | <0.5% scrap rate for precision square cut rings |

Material Science Specifications for Critical Applications

| Material Type | Shore A Hardness | Compression Set (70°C/22h) | Temperature Range | Key Chemical Resistance |

|---|---|---|---|---|

| NBR (Buna-N) | 30–90 | ≤15% | -40°F to +250°F (-40°C to +121°C) | Petroleum oils, hydrocarbon fuels |

| FKM (Viton®) | 40–90 | ≤10% | -15°F to +400°F (-26°C to +204°C) | Fuels, acids, high-temp hydraulic fluids |

| EPDM | 40–80 | ≤20% | -50°F to +300°F (-46°C to +149°C) | Water, steam, polar solvents, brake fluids |

Strategic Partner Factory Integration

Our network of 10+ ISO 9001:2015-certified partner facilities is strategically aligned with core engineering capabilities. Each facility specializes in specific processes (e.g., high-precision lathe cutting, high-temp vulcanization), enabling dynamic resource allocation without compromising quality. Real-time data sharing via our ERP system ensures traceability from raw material to finished product, with all outputs validated against ASTM D1414 (modulus testing) and AS568 (dimensional standards) for square cut O-ring applications.

Example: Automotive clients requiring NBR square cut rings for fuel systems receive compound-optimized solutions with 24-hour prototyping turnaround, while hydraulic machinery manufacturers benefit from FKM formulations with 400°F thermal stability and <0.5% scrap rates. This ecosystem eliminates trade-offs between speed, precision, and reliability—directly addressing procurement engineers’ core challenges in high-stakes industrial applications.

Customization & QC Process

Quality Control & Customization Process

At Suzhou Baoshida, our precision square cut O-ring manufacturing follows a rigorously validated 4-step process led by senior engineers with 15+ years of elastomer sealing expertise. The 5+2+3 Engineering Team Structure ensures end-to-end technical oversight, combining mold design, compound development, and process engineering excellence.

5+2+3 Engineering Team Structure

| Team Component | Number | Key Expertise | Responsibilities |

|---|---|---|---|

| Mould Engineering | 5 | Precision tooling design, GD&T compliance, mold flow analysis | CAD-based drawing validation, mold design per AS568/ISO 3601, shrinkage compensation for square cross-sections |

| Formula Engineering | 2 | Elastomer chemistry, ASTM D2000 classification, chemical resistance testing | Custom compound development for NBR/FKM/EPDM, Shore A hardness control (30-90), compression set optimization |

| Process Engineering | 3 | Injection molding, vulcanization, SPC, quality control | Prototyping validation, production setup, in-process monitoring, final QC protocols |

Step 1: Drawing Analysis & GD&T Validation

Senior Mould Engineering specialists (15+ years experience) conduct rigorous analysis of customer specifications using CAD/CAM software. Critical validation includes:

Cross-sectional geometry verification (square profile tolerance: ±0.05mm per AS568-218)

Gland fit calculations per Parker O-Ring Handbook ORD 5700 guidelines

Material-specific shrinkage compensation (e.g., FKM: 1.5–2.0%, EPDM: 1.8–2.2%)

Tolerance stack-up analysis for dynamic sealing applications (e.g., hydraulic pistons, valve stems)

Technical Note: Square cut O-rings require 30% tighter dimensional tolerances than round-section counterparts due to reduced compliance in gland cavities.

Step 2: Material Formulation & Compound Development

Our Formula Engineers (20+ years experience) develop compounds using ASTM D2000 classifications with precise control over critical parameters:

| Material | ASTM D2000 Code | Temp Range (°C) | Key Applications | Compression Set (ASTM D395) | Modulus @ 100% Elongation |

|---|---|---|---|---|---|

| NBR | A218 | -40 to +125 | Hydraulic systems, fuel-resistant | <25% @ 100°C/70h | 1.8–2.5 MPa |

| FKM | B218 | -20 to +200 | Aerospace, high-temp oil | <15% @ 150°C/22h | 2.0–3.0 MPa |

| EPDM | E218 | -50 to +150 | Water/steam, automotive cooling | <20% @ 125°C/22h | 1.5–2.2 MPa |

Key Formulation Controls:

Shore A Hardness: 30–90 range with ±2 durometer precision (ASTM D2240)

Modulus optimization for sealing performance (ASTM D1414)

Chemical resistance screening per ISO 1817 (fuel/oil/coolant compatibility)

Cross-link density tuning for long-term compression set stability

Step 3: Prototyping & Validation

Process Engineering specialists (15+ years experience) execute precision prototyping with CNC-machined molds and validate against industry standards:

| Test Parameter | Standard | Acceptance Criteria | Measurement Method |

|---|---|---|---|

| Dimensional Accuracy | AS568-218 | ±0.01mm cross-section tolerance | CMM (Coordinate Measuring Machine) |

| Compression Set | ASTM D395 Method B | <15% (FKM), <25% (NBR) @ 150°C/22h | Compression set fixture |

| Tensile Strength | ASTM D412 | ≥10 MPa (NBR), ≥15 MPa (FKM) | Universal testing machine |

| Fluid Resistance | ISO 1817 | Volume change ≤15% after 72h immersion | Gravimetric analysis |

Critical Insight: Square profile O-rings require 40% higher initial compression force than round-section rings to achieve equivalent sealing performance – validated during prototyping.

Step 4: Mass Production & QC Protocol

Full-scale production with statistical process control (SPC) and zero-defect protocols:

| QC Stage | Protocol | Frequency | Equipment Used |

|---|---|---|---|

| In-process Hardness | Shore A checks at 30-minute intervals | Every 30 min | Durometer tester (ASTM D2240) |

| Visual Inspection | 100% check for flash, voids, surface defects | Batch-level | 10x magnification scope |

| Dimensional Audit | CMM verification of 5 critical dimensions per batch | 10% of production | CMM (±0.001mm accuracy) |

| Final Certification | ASTM D1414-compliant test reports for all shipments | 100% of orders | Lab-certified reports |

Traceability System:

ERP-integrated lot tracking from raw material certificates to final product

Batch-specific chemical composition records (FTIR verification)

Shelf-life monitoring via accelerated aging tests (ASTM D573)

Industrial Impact: Our process reduces field failure rates by 67% compared to industry averages in automotive hydraulic systems, verified through 5+ years of OEM data.

Contact Our Engineering Team

Contact Suzhou Baoshida

5+2+3 Engineering Team Structure for Uncompromising Quality

| Team Component | Role | Key Capabilities |

|---|---|---|

| Mould Engineers (5) | Precision Mold Design & Manufacturing | – AS568-compliant tooling with ±0.05mm tolerance – Square cut geometry optimization for gland fit – High-wear resistance mold surfaces (HRC 58-62) |

| Formula Engineers (2) | Material Compound Development | – NBR/FKM/EPDM formulations meeting ASTM D2000 – Compression set ≤15% at 150°C (ASTM D395) – Shore A hardness 30-90 with ±2 precision control – Chemical resistance validated per ISO 1817 (e.g., 72h immersion in MIL-PRF-83282) |

| Process Engineers (3) | Manufacturing Process Optimization | – ISO 9001-certified production line with SPC control – In-line ASTM D1414 testing for dimensional accuracy – Zero-defect QC protocols with full material traceability |

Solve Your Sealing Problems Today

Partner with Suzhou Baoshida’s specialized engineering team to address critical sealing challenges across automotive, hydraulic, pump/valve, and machinery applications. Our solutions deliver:

Custom compound formulations for extreme thermal (−54°C to +232°C) and chemical environments (e.g., jet fuel, hydraulic fluids)

Precision square cut O-rings compliant with AS568-218 SN70 (NBR), ISO 3601, and DIN 3771 standards

Full test documentation per ASTM D2000 (modulus, elongation, hardness), D395 (compression set), and D1414 (dimensional stability)

Free delivery on orders exceeding $250 USD for qualified industrial clients

Contact Mr. Boyce for immediate technical consultation:

📧 Email: [email protected]

📞 Phone: +86 189 5571 6798

Engineered for reliability. Delivered with precision.

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.