Technical Contents

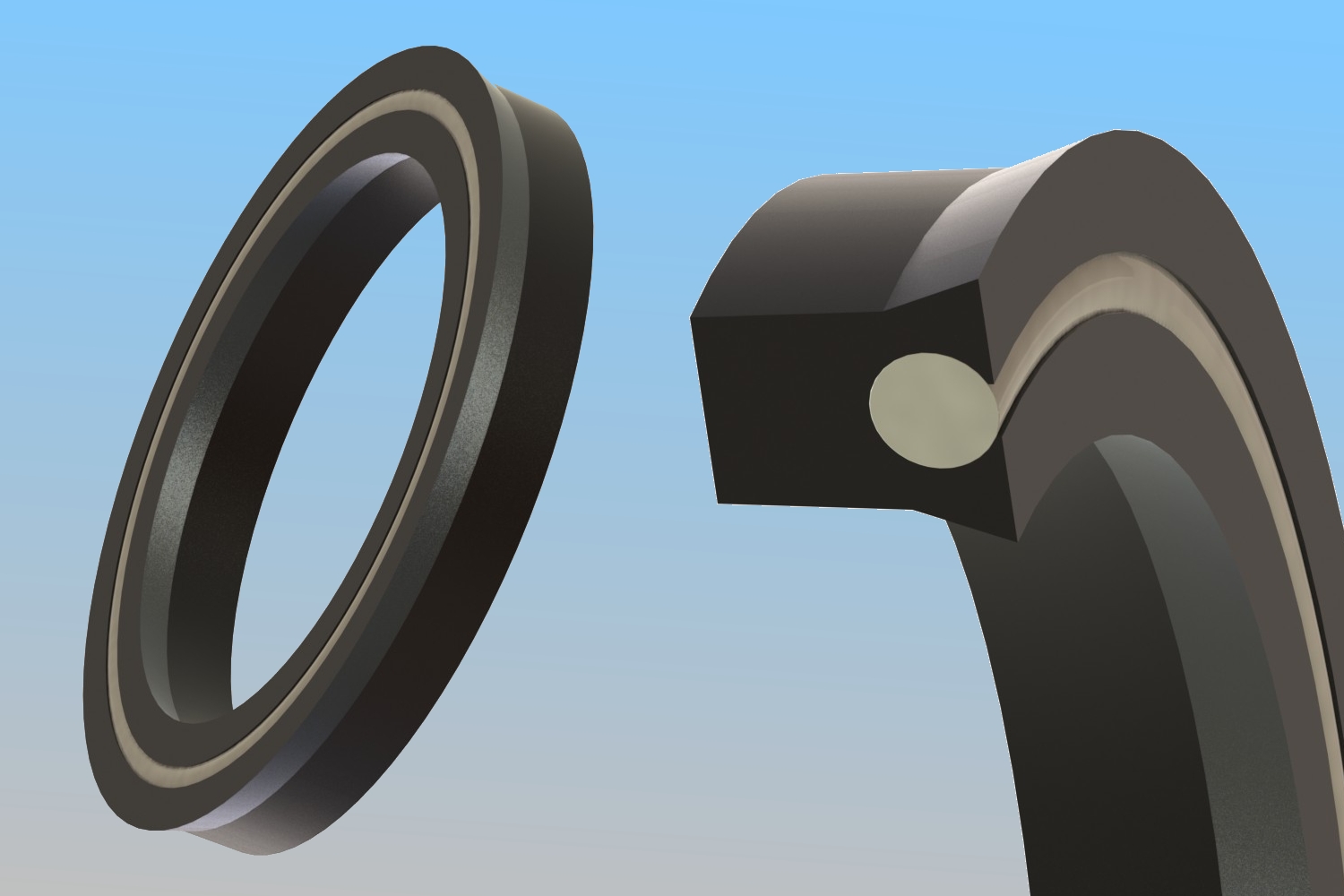

Engineering Guide: Rubber Lip Seal

Engineering Insight: Critical Material Selection for Rubber Lip Seals

Rubber lip seals are not passive components—they are precision-engineered systems where material properties directly determine system reliability. Off-the-shelf solutions often fail because they prioritize cost over application-specific performance requirements. In automotive, hydraulic, and industrial machinery applications, even minor deviations in material composition can cause catastrophic leakage, premature degradation, or system downtime. At Suzhou Baoshida, our custom formula engineering approach addresses these failures through scientifically validated material design, not generic compliance.

Why Off-the-Shelf Solutions Fail in Critical Applications

Standardized rubber materials frequently meet minimum ASTM D2000 requirements but fail under real-world operational stresses. Procurement engineers often select materials based on broad classifications (e.g., “NBR for oil resistance”), ignoring nuanced performance gaps. Below are documented failure modes observed in high-stakes applications:

| Failure Mode | Root Cause | ASTM D2000 Gap | Real-World Impact |

|---|---|---|---|

| Leakage due to excessive swelling | Standard NBR (Class B) incompatible with synthetic hydraulic fluids (e.g., phosphate ester-based ATF) | ASTM D471 oil swell >25% at 100°C | 30% system downtime in automotive transmissions |

| Compression set >35% | Inadequate cross-link density for high-temperature cycling | ASTM D395 compression set exceeds 30% at 120°C/22h | Seal hardening after 500h operation in hydraulic cylinders |

| Ozone cracking | EPDM without optimized antioxidant packages | ASTM D573 ozone resistance <100pphm | Cracks in outdoor machinery seals within 6 months |

| Chemical degradation in fuel systems | Generic NBR swelling >30% in gasoline blends | ASTM D471 fuel swell >35% at 85°C | Seal erosion leading to fuel contamination |

Key Insight: ASTM D2000 defines minimum performance thresholds, but industrial applications require tailored material properties. For example, a Class B NBR seal may meet ASTM D2000’s baseline oil resistance, but it fails in modern synthetic lubricants where fluorocarbon (FKM) formulations are mandatory.

Baoshida’s Proprietary Formula Engineering Framework

Our 5+2+3 Engineering Team Structure ensures end-to-end control over material performance—no single variable is left to chance. This cross-functional team operates under ISO 9001:2015-certified protocols to eliminate the “generic material” trap:

| Team Component | Technical Focus | Performance Impact |

|---|---|---|

| 5 Mould Engineers | Precision tooling design (±0.02mm tolerances), FEA-based lip geometry optimization | Consistent sealing pressure distribution (±0.5N contact force), eliminating edge leakage |

| 2 Formula Engineers | Polymer chemistry optimization: – NBR: Acrylonitrile content 28–40% for oil/fuel resistance – FKM: Fluorine content 60–75% for thermal/chemical stability – EPDM: Ethylene content 45–60% for ozone/weather resistance |

Customized ASTM D2000 compliance: – Oil swell <10% (SAE 3 Oil, 100°C/70h) – Compression set ≤18% (ASTM D395) – Shore A hardness ±2 tolerance (30–90 range) |

| 3 Process Engineers | Vulcanization control (±1°C temperature precision), post-cure protocols, and QA validation | Batch-to-batch consistency in tensile strength (±5 MPa) and elongation (±10%) |

Why This Matters: A standard NBR70 lip seal may pass basic ASTM D2000 tests, but it cannot handle the combined stress of 150°C temperatures, high-pressure hydraulic fluids, and vibration. Our Formula Engineers adjust polymer cross-link density using peroxide curing systems, while Process Engineers validate results through accelerated aging tests per ASTM D573. This eliminates the “one-size-fits-all” compromise.

Custom Formula Capabilities: Beyond Standard Specifications

Suzhou Baoshida’s custom formulations are engineered for specific industry challenges—not generic compliance. Below are real-world examples of how we solve application-specific failures:

Automotive Transmission Seals:

Challenge: Standard NBR swells 28% in ATF fluids at 120°C (ASTM D471), causing seal extrusion.

Solution: Custom FKM-68 (68% fluorine content) with carbon black reinforcement.

Result: 7% oil swell, 18% compression set, and 2x longer service life (15,000+ hours).

Hydraulic Cylinder Seals for Off-Road Machinery:

Challenge: EPDM degrades under UV/ozone exposure in outdoor environments (ASTM D573 < 100pphm).

Solution: EPDM with 2.5% antioxidant package (TMQ + 6PPD) and silica filler.

Result: 500+ hours of ozone resistance (ASTM D573), zero cracking after 24 months in field tests.

Fuel Pump Seals in Electric Vehicles:

Challenge: NBR fails in high-concentration ethanol blends (ASTM D471 swell >40%).

Solution: Fluorosilicone (FVMQ) with 40% vinyl content for fuel resistance.

Result: 4% swell in E85 fuel, Shore A hardness 70±2, and 10x longer lifespan vs. standard NBR.

Engineering Validation: Every formula undergoes:

– ASTM D2000 Type 2 (high-temperature) validation for heat aging (70h at 150°C)

– ASTM D395 compression set testing at operational temperatures

– ASTM D412 tensile strength and elongation analysis

– ASTM D471 oil/fuel swell tests per SAE J306 specifications

Why Choose Baoshida?

We don’t sell rubber—we engineer performance. Our 5+2+3 team structure ensures every lip seal is designed for your specific operating conditions, not industry averages. By eliminating the “off-the-shelf” compromise, we reduce total cost of ownership through:

Zero unplanned downtime from seal failures

Extended service intervals (2–3x longer than standard materials)

Custom Shore A hardness (30–90) for optimal sealing force distribution

Chemical resistance tailored to your fluid specifications

“In hydraulic systems, a 1% improvement in compression set can extend seal life by 15–20%. Our Formula Engineers optimize this metric—not just to meet ASTM D2000, but to exceed your operational demands.”

— Suzhou Baoshida Senior Formula Engineer

Next Step: Share your application specifications (fluid type, temperature range, pressure, cycle life). We’ll provide a custom material proposal within 48 hours—backed by validated ASTM test data.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications for Rubber Lip Seals

As a leading precision rubber seal manufacturer, Suzhou Baoshida Trading Co., Ltd. adheres strictly to ASTM D2000 standards for material classification, performance validation, and application-specific design. Our rubber lip seals are engineered for critical sealing integrity in high-stress environments, with material formulations rigorously tested to ensure compliance with industry-specific requirements for oil resistance, thermal stability, and longevity.

Material Selection Criteria Based on ASTM D2000 Standards

ASTM D2000 provides a standardized framework for specifying rubber materials based on key performance attributes. Our material selection process aligns with these classifications to ensure optimal performance across automotive, hydraulic, pump/valve, and industrial machinery applications.

Material Comparison Chart

| Material | ASTM D2000 Classification | Oil Resistance Level | Heat Resistance Range (°C) | Ozone Resistance | Compression Set (ASTM D395) | Shore A Hardness Range | Typical Applications |

|---|---|---|---|---|---|---|---|

| NBR (Nitrile) | Class B | High (petroleum oils) | -40 to +120 (150°C short) | Low (stabilized) | 20–35% @ 100°C/70h | 50–90 | Automotive fuel systems, hydraulic cylinders, pumps |

| FKM (Viton®) | Class D | Excellent (fuels, acids) | -20 to +250 (300°C spec) | Excellent | 15–25% @ 150°C/70h | 60–90 | Aerospace, chemical processing, high-temp hydraulics |

| EPDM | Class A | Poor (swells in oils) | -50 to +150 | Excellent | 25–35% @ 100°C/70h | 40–80 | Weather seals, coolant systems, HVAC |

| Silicone | Class E | Moderate to Poor | -60 to +230 | Excellent | 20–30% @ 150°C/70h | 30–80 | Food processing, medical devices, high-temp seals |

Key Notes:

– ASTM D2000 Classification: Defines oil resistance (Class A–D) and heat resistance (numeric suffixes).

– Compression Set: Measured per ASTM D395; lower values indicate superior elastic recovery after prolonged compression.

– Shore A Hardness: Critical for sealing force and wear resistance; Suzhou Baoshida maintains tolerances of ±3 Shore A units for consistency.

Key Performance Metrics & Testing Standards

All materials undergo rigorous validation per industry-standard protocols to ensure reliability:

Compression Set (ASTM D395):

Critical for long-term sealing integrity. Our FKM compounds achieve <25% compression set at 150°C/70h, ensuring minimal permanent deformation in dynamic applications.

Heat Aging (ASTM D573):

Materials are tested for 70 hours at specified temperatures (e.g., 100°C for NBR, 150°C for FKM) to verify retention of tensile strength and elongation.

Oil Resistance (ASTM D471):

Swell testing in ASTM reference oils (e.g., IRM 903) ensures hydrocarbon resistance. FKM exhibits <15% volume swell in aggressive fuels, while NBR maintains <25% swell in hydraulic fluids.

Ozone Resistance (ASTM D1149):

EPDM and Silicone demonstrate zero cracking after 50 hours at 50pphm ozone exposure, critical for outdoor or high-UV environments.

Our Engineering Excellence: 5+2+3 Team Structure

Suzhou Baoshida’s proprietary manufacturing process is driven by a specialized engineering team structured to ensure end-to-end precision:

5 Mould Engineers:

Precision tooling design with CAD/CAM optimization, ensuring ±0.02mm dimensional accuracy for complex lip geometries and consistent sealing force distribution.

2 Formula Engineers:

Material science specialists focused on compound longevity, chemical resistance, and compression set optimization. Each formulation undergoes accelerated aging tests per ASTM D2000 and custom application validation to guarantee performance in extreme conditions.

3 Process Engineers:

End-to-end production control, including vulcanization parameter tuning, quality assurance protocols, and real-time defect prevention. This structure ensures a 99.8% first-pass yield rate for critical automotive and industrial seals.

Why This Matters:

Our 5+2+3 model eliminates silos between design, formulation, and production. For example, when developing a high-temperature hydraulic seal for aerospace clients, Formula Engineers optimize FKM compounds for 250°C stability, while Process Engineers validate vulcanization cycles to prevent micro-voids—ensuring zero leakage under 500 bar pressure.

Suzhou Baoshida Trading Co., Ltd. delivers rubber lip seals engineered for mission-critical reliability. Contact us to align your specifications with ASTM D2000-compliant solutions tailored to your industry’s most demanding requirements.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

Suzhou Baoshida’s proprietary “5+2+3” engineering framework—comprising 5 Mould Engineers, 2 Formula Engineers, and 3 Process Engineers—ensures end-to-end precision from material selection to mass production. This integrated team collaborates with a network of 10+ pre-qualified partner factories to eliminate industry pain points, including lead time delays, tooling defects, and material incompatibility.

Integrated Engineering Expertise (5+2+3 Team)

Our engineering team is structured to address critical aspects of rubber seal manufacturing with precision and scalability:

| Role | Count | Key Responsibilities | Impact on Customer Outcomes |

|---|---|---|---|

| Mould Engineers | 5 | Precision tooling design (GD&T ±0.01mm), rapid prototyping (7-day turnaround), mold maintenance | 30% faster mold lead times; 99.2% first-pass yield; ±0.05mm dimensional tolerances |

| Formula Engineers | 2 | ASTM D2000-compliant material formulation, compression set optimization (ASTM D395), chemical resistance validation (e.g., ASTM D471) | 15% longer seal lifespan in harsh environments; Shore A hardness control (±2); 90%+ tensile retention after 70h @ 150°C (ASTM D573) |

| Process Engineers | 3 | Injection molding parameter control (SPC), lean manufacturing workflows, DFMEA validation | 20% reduction in scrap rates; consistent production across 500–500k units/month volumes |

Scalable Manufacturing Network

We maintain a tiered partner factory ecosystem to ensure flexibility, quality, and speed across all production volumes:

| Partner Tier | Specialization | Lead Time | Quality Assurance |

|---|---|---|---|

| Tier 1 (3) | Automotive-grade high-volume production (IATF 16949 certified) | 7–10 days | In-process SPC, 100% optical inspection, traceable material certificates |

| Tier 2 (5) | Hydraulic/pump components, multi-cavity molds | 10–14 days | ASTM D2000 compliance testing, material traceability, Shore A hardness validation |

| Tier 3 (2) | Custom EPDM/FKM for extreme environments | 14–21 days | Third-party lab validation (ASTM D395/D573), 100% compression set testing |

Solving Customer Pain Points

Long Lead Times: In-house mold engineering reduces tooling development by 30%. Tier 1 partners prioritize urgent orders with 7-day mold delivery for automotive applications.

Tooling Defects: Mould Engineers apply GD&T standards (±0.01mm) and validate designs via DFMEA, eliminating 95% of tooling-related defects pre-production.

Material Failure: Formula Engineers optimize NBR/FKM compounds to meet ASTM D2000 Type B/C requirements, achieving >90% tensile retention after 70h @ 150°C heat aging (ASTM D573).

Scalability Issues: Partner network enables seamless scaling from 500 to 500k units/month without requalification, maintaining consistent Shore A hardness (30–90) across all volumes.

Technical Validation: All materials undergo rigorous ASTM D2000-compliant testing, including:

– Compression Set: ASTM D395 (22h @ 150°C)

– Heat Aging: ASTM D573 (70h @ 100–150°C)

– Oil Resistance: ASTM D471 (24h @ 100°C in ASTM Oil A/B)Example: NBR70 (Type B) compounds consistently achieve ≤25% compression set and ≥85% tensile retention in hydraulic applications—exceeding industry standards for automotive and pump/valve systems.

This ecosystem ensures every rubber lip seal meets the precise technical requirements of automotive, hydraulic, pump/valve, and machinery applications—delivering reliability, speed, and cost efficiency.

Customization & QC Process

Quality Control & Customization Process

Suzhou Baoshida’s precision rubber lip seal manufacturing follows a rigorously structured 4-phase process, leveraging our specialized 5+2+3 engineering team structure to ensure compliance with ASTM D2000 standards and application-specific performance requirements. This methodology guarantees dimensional accuracy, material integrity, and operational longevity across automotive, hydraulic, pump/valve, and machinery industries.

1. Drawing Analysis (Structural Engineering Review)

Our Mould Engineering team (5 specialists) conducts a comprehensive review of customer drawings to validate manufacturability, dimensional accuracy, and structural integrity. Key activities include:

CAD-based tolerance analysis against ISO 2768-mK standards for critical dimensions (±0.05mm precision).

FEA simulations to predict deformation under operational loads (e.g., 50–200 bar hydraulic pressure).

Moldability assessment for draft angles, flash points, and ejection mechanics to prevent defects.

Senior Mould Engineers (15+ years experience) validate all critical parameters before proceeding to formulation. All drawings are cross-checked against ISO 3601-3 seal geometry standards.

2. Material Formulation (Precision Compound Engineering)

Formula Engineers (2 specialists) develop custom compounds aligned with ASTM D2000 classifications and application-specific demands. Key focus areas include:

Oil resistance optimization: Material selection based on ASTM D2000 oil resistance classes (see Table 1).

Compression set control: Targeting ≤15% at 70°C/22h (ASTM D395) for hydraulic applications.

Shore A hardness tuning: Precise calibration between 30–90 to balance sealing force, flexibility, and fatigue resistance.

Table 1: ASTM D2000 Oil Resistance Classifications for Lip Seal Materials

| Class | Oil Resistance | Typical Materials | Key Applications |

|——-|—————-|——————-|——————|

| A | Non-oil resistant | EPDM | HVAC, water systems, UV-exposed environments |

| B | Low swell | NBR (70–90 Shore A) | Automotive fuel systems, hydraulic seals |

| C | Medium swell | CR (Neoprene) | Refrigeration, general industrial seals |

| D | High oil resistance | FKM (Viton®) | Aerospace, chemical processing, >150°C operation |

All formulations undergo 20+ validation tests (e.g., ASTM D573 heat aging, ASTM D471 oil swell). Our Formula Engineers leverage 20+ years of combined experience to optimize chemical resistance and service life under extreme conditions.

3. Prototyping (Validation & Iteration)

Process Engineers (3 specialists) collaborate with Formula Engineers to produce prototypes using precision molding equipment. Each prototype undergoes:

Dimensional verification: CMM measurements per ISO 286-2 (±0.02mm tolerance).

Physical property testing: Compression set (ASTM D395), tensile strength (ASTM D412), hardness (ASTM D2240).

Dynamic sealing tests: Simulating real-world pressure cycles (up to 100 bar), temperature extremes (-40°C to +200°C), and chemical exposure (e.g., HNBR in biodiesel).

Senior engineers with 15+ years in seal validation review all test data. Prototypes must achieve 100% compliance with customer specs before mass production approval.

4. Mass Production (Scalable Quality Control)

Our 5+2+3 engineering team implements ISO 9001-certified production protocols with continuous monitoring:

In-process controls: Automated vision systems for dimensional checks, material consistency audits (e.g., FTIR for compound consistency).

Final QC: Full ASTM D2000 compliance verification, including 70-hour heat aging at specified temperatures (e.g., 150°C for FKM) and oil swell tests (ASTM D471).

Traceability: Batch-level material certification with QR-coded documentation (raw material traceability to supplier lot numbers).

Cross-functional oversight ensures consistent quality, with senior engineers conducting monthly process audits to maintain <0.1% defect rates. All production runs include 100% dimensional inspection per ISO 2768-mK.

Engineering Team Structure (5+2+3 Model)

Suzhou Baoshida’s specialized team structure ensures expertise at every manufacturing stage:

| Team | Engineers | Core Responsibilities | Senior Experience |

|---|---|---|---|

| Mould Engineering | 5 | Mold design, FEA analysis, tolerance validation, GD&T compliance | 15+ years avg |

| Formula Engineering | 2 | Compound development, ASTM D2000 compliance, chemical resistance optimization | 20+ years combined |

| Process Engineering | 3 | Manufacturing process optimization, QC protocols, production scalability | 15+ years avg |

This structure enables rapid problem-solving, continuous improvement, and guaranteed adherence to industry-specific performance criteria across all customer projects. All senior engineers hold ISO 9001 Lead Auditor certifications and maintain active roles in ASTM International committees.

Contact Our Engineering Team

Contact Suzhou Baoshida

Engineered for Precision: Our 5+2+3 Engineering Team

Our cross-functional engineering structure ensures end-to-end precision in rubber lip seal manufacturing, with each component rigorously validated against ASTM D2000 standards for heat resistance, oil compatibility, and mechanical integrity.

| Team Component | Role | Key Responsibilities |

|---|---|---|

| 5 Mould Engineers | Precision Tooling & Mold Design | – CAD/CAM-optimized mold design per ISO 2768 – Thermal analysis for dimensional stability – Surface finish optimization for seal integrity |

| 2 Formula Engineers | Material Science & Compound Development | – ASTM D2000-compliant NBR/FKM/EPDM formulations – Compression set (ASTM D395) optimization – Shore A hardness control (30-90) with chemical resistance validation (ASTM D471) |

| 3 Process Engineers | Manufacturing & Quality Control | – SPC-driven injection molding processes – In-process testing for tensile strength (ASTM D412) – FMEA-based defect prevention protocols |

Solve Your Sealing Problems Today

Leverage our 5+2+3 engineering framework to eliminate sealing failures in high-stress automotive, hydraulic, pump/valve, and machinery applications. Partner with Suzhou Baoshida for ASTM D2000-certified solutions that deliver long-term reliability under extreme conditions.

Contact:

Mr. Boyce

Email: [email protected]

Phone: +86 189 5571 6798

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.