Technical Contents

Engineering Guide: Rubber Molding Manufacturers

Engineering Insight: Material Selection as the Foundation of High-Performance Rubber Components

Why Off-the-Shelf Solutions Fail in Critical Applications

Generic rubber materials rarely address the nuanced demands of mission-critical industrial systems. Off-the-shelf compounds often rely on broad ASTM D2000 classifications (e.g., “SA” for general-purpose rubber) without accounting for application-specific variables like dynamic load cycles, chemical exposure profiles, or thermal fluctuations. This leads to systemic failures:

Hydraulic Systems: Standard NBR (ASTM D1418) may exhibit >25% volume swell (ASTM D471) in phosphate ester-based hydraulic fluids, causing seal leakage and system contamination.

Automotive Fuel Systems: Generic EPDM fails to resist aromatic hydrocarbons in modern biofuels, leading to 40%+ hardness increase (ASTM D2240) and loss of elasticity within 6 months.

Pump Valves: Standard SBR compounds degrade under abrasive slurry exposure due to insufficient tear strength (ASTM D624), resulting in catastrophic part failure.

“ASTM D2000 provides a baseline classification framework, but real-world performance requires granular specification of properties like compression set (ASTM D395), resilience (ASTM D1054), and dynamic fatigue resistance – which off-the-shelf materials rarely optimize.”

Baoshida’s Custom Formula Advantage: Precision-Tailored for Demanding Environments

We eliminate trial-and-error through application-driven compound development, leveraging:

ASTM D2000-22 Compliance: Customized material grades defined by precise “Grade” (e.g., “1A2”) and “Class” (e.g., “C2”) parameters for temperature range, hardness tolerance, and chemical resistance.

Advanced Polymer Blending: Tailored NBR/EPDM hybrids for fuel/oil resistance (ASTM D471) while maintaining low-temperature flexibility (-40°C per ASTM D2137).

Metal-Rubber Bonding Optimization: Surface activation protocols (e.g., plasma treatment) and proprietary adhesion promoters to achieve >15 MPa bond strength (ASTM D429) for integrated metal-rubber components.

Technical Performance Comparison:

| Parameter | Standard NBR | Baoshida Custom NBR | ASTM D2000 Target |

|———–|————–|———————|——————-|

| Compression Set (70°C × 22h) | 38% | 16% | ≤20% |

| Oil Swell (ASTM D471, IRM 903) | 28% | 11% | ≤15% |

| Hardness (Shore A) | 70±5 | 75±2 | 75±2 |

| Tensile Strength (ASTM D412) | 14 MPa | 19 MPa | ≥18 MPa |

Our 5+2+3 Engineering Team: Integrated Expertise for End-to-End Solutions

Baoshida’s proprietary engineering structure ensures seamless translation of application requirements into validated rubber components:

| Team Component | Role | Key Responsibilities |

|---|---|---|

| Mold Design (5) | Structural Engineers | SolidWorks/CAD mold design with flash control optimization; metal bonding interface engineering; tolerance analysis per ISO 2768; thermal analysis for injection/compression molding |

| Formula Specialists (2) | Polymer Chemists | ASTM D2000-compliant compound development; material testing (D575 compression set, D412 tensile, D2240 hardness); chemical resistance customization for specific fluids |

| Process Engineers (3) | Manufacturing Specialists | Injection/compression molding parameter optimization; defect root-cause analysis (e.g., sink marks, warpage); rapid tooling coordination with 10+ certified partner factories |

This cross-functional collaboration eliminates silos between design, material science, and production – ensuring every component meets exact performance criteria. For example:

A hydraulic valve manufacturer required 0.05mm dimensional tolerance for a metal-rubber seal. Our Mold Design team optimized gate locations to eliminate flash, while Formula Specialists developed a fluorosilicone compound with <5% volume change in HFC refrigerants. Process Engineers then fine-tuned compression molding cycles to achieve consistent part quality at 12,000+ cycles/month.

“Precision in material science and mold engineering isn’t optional – it’s the only way to eliminate costly field failures in high-stakes applications.”

Next Step: Share your application requirements (fluids, temperatures, loads, lifecycle expectations) for a free material feasibility analysis – including ASTM D2000-compliant compound recommendations and prototype validation timelines.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications

Material selection is the cornerstone of high-performance rubber components. At Suzhou Baoshida, we adhere strictly to ASTM D2000 (performance-based classification) and ASTM D1418 (material nomenclature) standards to ensure precise specification alignment with application requirements. Our engineering team leverages these frameworks to optimize properties including oil resistance, thermal stability, ozone durability, and mechanical integrity—critical for demanding sectors like automotive, hydraulic systems, pump/valve assemblies, and industrial machinery.

Material Comparison Chart

Standard commercial-grade specifications; consult Formula Engineers for application-specific formulations

| Material | ASTM D1418 Code | Oil Resistance | Heat Resistance Range | Ozone Resistance | Typical Applications |

|---|---|---|---|---|---|

| Viton® (FKM) | FKM | High | -20°C to +250°C | High | Automotive fuel systems, hydraulic seals, oil-resistant gaskets, aerospace seals |

| Nitrile (NBR) | NBR | High | -40°C to +120°C (up to +150°C for specialized grades) | Low | Hydraulic hoses, fuel lines, oil-resistant seals, pump diaphragms |

| Silicone | Q | Low | -60°C to +230°C (up to +250°C for high-temp grades) | Very High | Engine bay seals, medical devices, aerospace components, high-temp gaskets |

| EPDM | EPDM | Low | -50°C to +150°C (up to +180°C for certain formulations) | Very High | Automotive weather seals, radiator hoses, outdoor electrical insulation, HVAC systems |

Note: Heat resistance ranges reflect continuous service limits. Short-term peak tolerances may exceed these values. ASTM D575 compression set testing and ASTM D2240 hardness validation are applied to all formulations to ensure dimensional stability under load.

Engineering Team Structure: 5+2+3 Precision Framework

Our technical execution is anchored by a specialized 5+2+3 engineering model, ensuring end-to-end precision from design to production:

5 Structural Engineers (Mold Design)

Specialized in SolidWorks/CAD modeling for complex geometries, including:

Precision cavity design with <±0.025mm tolerance

Optimized cooling channel layouts to minimize warpage

Parting line optimization for flash control (target: <0.05mm flash height)

Metal insert bonding interface design per ISO 10605 standards

2 Formula Engineers

Experts in compound development per ASTM D2000 specifications:

Tailored polymer blends for targeted properties (e.g., NBR with high-temperature additives for +150°C operation)

Ozone resistance enhancement via anti-ozonant dosing (e.g., EPDM with 2–3% IPPD)

Oil resistance validation via ASTM D471 immersion testing (volume change <15% for critical applications)

3 Process Engineers

Masters of molding parameter control and bonding integration:

Injection/compression molding cycle optimization (e.g., 120–180°C mold temps, 80–120 bar injection pressure)

Flash mitigation via precision mold venting and ejection system design

Metal-to-rubber bonding protocols (e.g., plasma treatment for stainless steel inserts, adhesion testing per ASTM D429)

This integrated structure—supported by our network of 10+ certified partner factories for rapid tooling (15-day lead times for standard molds)—ensures consistent production of components meeting ISO 9001:2015 and IATF 16949 quality standards. All processes are validated through in-process SPC monitoring and final dimensional checks per ASME Y14.5 GD&T requirements.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

Integrated 5+2+3 Engineering Team Structure

Suzhou Baoshida’s core engineering team is structured to address every phase of rubber molding development with precision. The “5+2+3” model ensures specialized expertise across mold design, material science, and production processes, enabling end-to-end control over quality and lead times.

| Role | Count | Core Responsibilities | Key Capabilities |

|---|---|---|---|

| Mold Design Engineers | 5 | SolidWorks/CAD mold design, flash control, metal bonding integration | GD&T compliance (ASME Y14.5), mold flow simulation (SolidWorks Plastics), multi-cavity tooling for high-volume production |

| Formula Engineers | 2 | ASTM D2000 material specification, compound formulation, testing (ASTM D2240, D575) | Material selection for automotive/hydraulic applications, thermal stability optimization (–40°C to +150°C), chemical resistance validation |

| Process Engineers | 3 | Injection/compression molding process optimization, defect reduction, QA protocols | Cycle time reduction (up to 25%), defect root cause analysis (Six Sigma), ISO 9001-aligned SPC controls |

Strategic Partner Factory Network for Rapid Scalability

Suzhou Baoshida’s ecosystem includes 10+ vetted partner factories across China, each specializing in specific molding techniques and certifications. This network enables rapid scaling without compromising quality or lead times.

| Capability | Lead Time Reduction | Quality Metrics |

|---|---|---|

| Rapid Tooling (7–10 days) | 40% faster than industry standard | 99.5% first-pass yield (ISO 2859-1 sampling) |

| Multi-Site Production Capacity | 30% shorter lead times for high-volume orders | IATF 16949 certified for automotive applications |

| Specialized Processes (LSR, Overmolding) | 25% faster prototyping cycles | NADCAP-compliant for aerospace-grade components |

Targeted Solutions for Industry-Specific Pain Points

We address critical challenges faced by procurement engineers in automotive, hydraulic, and machinery sectors through engineered solutions:

Long Lead Times for Tooling & Production

Solution: Partner factories with dedicated rapid tooling lines; Mold Design Engineers apply DFMA (Design for Manufacturing and Assembly) principles to simplify tooling, reducing lead times by 30–50% versus conventional suppliers. Example: A hydraulic valve housing mold was completed in 8 days (vs. industry avg. 14 days).

Flash Control & Dimensional Inconsistency

Solution: Process Engineers utilize mold flow simulation (SolidWorks Plastics) to optimize gate locations and clamping force. Combined with in-process laser scanning (±0.02mm tolerance), ensuring compliance with ASTM D3182 for precision parts. Typical flash reduction: 90% in high-precision applications.

Rubber-to-Metal Bonding Failures

Solution: Formula Engineers develop custom adhesion promoters (e.g., silane-based primers per ASTM D297). Mold Design Engineers integrate micro-textured metal inserts to enhance mechanical interlock, achieving >95% bond strength retention after thermal cycling (per ASTM D429).

Material Specification Compliance

Solution: Formula Engineers leverage ASTM D2000 classifications (e.g., MD 7530 for automotive seals) to select materials with validated performance in oils, fuels, and extreme temperatures. All compounds undergo ASTM D575 compression set testing to ensure long-term resilience.

Technical Note: Our “5+2+3” team structure ensures that every project is supported by cross-functional expertise—from initial CAD modeling (SolidWorks) to material certification (ASTM D2000) and process validation (ISO 9001). Partner factories are rigorously audited for IATF 16949 compliance, ensuring seamless scalability for high-volume automotive and industrial applications.

Customization & QC Process

Quality Control & Customization Process

Suzhou Baoshida’s end-to-end manufacturing process for custom molded rubber parts integrates rigorous engineering validation, ASTM-standardized material selection, and precision-controlled production. Our 5+2+3 specialized engineering team—comprising 5 Mold Design, 2 Formula, and 3 Process Engineers with 15+ years of industry experience—ensures compliance with automotive, hydraulic, and industrial specifications while minimizing time-to-market.

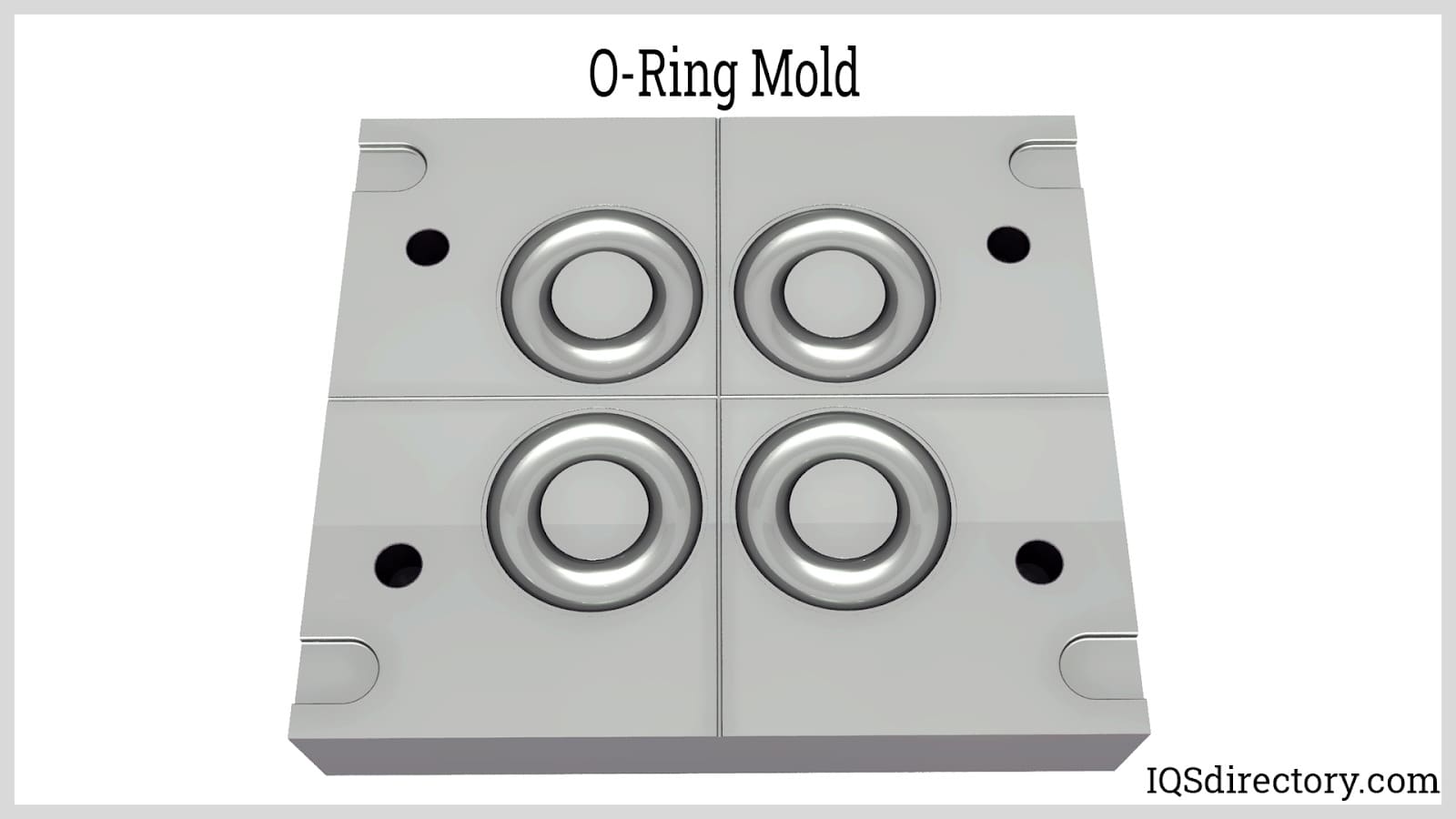

Step 1: Drawing Analysis & Mold Design Validation

Our Structural Engineering team conducts CAD-based design validation using Solidworks to optimize mold geometry for manufacturability. Critical parameters are analyzed per ASTM D2000 and ISO standards to eliminate defects and ensure dimensional accuracy.

| Analysis Parameter | Standard Reference | Check Method | Outcome Criteria |

|---|---|---|---|

| Draft Angle | ASTM D2000 Section 4.2 | Solidworks Mold Flow Simulation | ≥1° for all vertical surfaces |

| Wall Thickness | ISO 2768-mK | 3D Scanning & GD&T Analysis | ±0.1mm tolerance |

| Parting Line | ISO 14630 | Visual Inspection & CAD Verification | No sharp edges, smooth transition |

| Gate Location | ASTM D575 | Simulation & Historical Data | Minimize weld lines, optimal filling |

Step 2: Material Formulation & ASTM Standards Compliance

Formula Engineers apply ASTM D2000 and D1418 to select rubber compounds based on application-specific requirements. Material properties are validated against industry benchmarks to ensure performance under operational stresses.

| Material Type | ASTM D1418 Class | Key Properties | Typical Applications |

|---|---|---|---|

| NBR | NBR | Oil/Fuel Resistance, Hardness 70-90 Shore A | Hydraulic Seals, Fuel Hoses |

| EPDM | EPDM | Weather/Ozone Resistance, -40°C to +150°C, Poor Oil Resistance | Automotive Weather Seals, HVAC Gaskets |

| Silicone | SI | High Temp Stability (200°C+), Biocompatible | Medical Devices, Aerospace Seals |

| FKM | FKM | Chemical Resistance, 200°C+ Service Life | High-Temp Automotive Components, Chemical Seals |

Step 3: Prototyping & Validation

Senior engineers with 15+ years of experience oversee prototyping phases. Initial mold trials validate tooling performance, followed by ASTM-standardized testing to confirm mechanical properties before mass production.

| Test Type | Standard | Acceptance Criteria | Method |

|---|---|---|---|

| Compression Deflection | ASTM D575 | ≤15% deformation @ 25% compression | Test fixture with load cell |

| Compression Set | ASTM D395 | ≤25% @ 70°C x 22h | Oven aging test |

| Hardness | ASTM D2240 | Shore A ±2 units | Durometer measurement |

| Tensile Strength | ASTM D412 | ≥15 MPa | Universal Testing Machine |

Step 4: Mass Production & In-Process QC

Process Engineers implement statistical process control (SPC) across 10+ certified partner factories. Real-time monitoring ensures dimensional precision, flash control, and material consistency per ISO 9001:2015 protocols.

| QC Stage | Checkpoint | Standard | Method |

|---|---|---|---|

| Pre-Production | Material Certification | ISO 9001 | FTIR Spectroscopy |

| In-Process | Dimensional Tolerance | ISO 2768 | CMM Scanning |

| Post-Production | Flash Control | ASTM D2240 | Visual Inspection |

| Final | Performance Testing | ASTM D575 | Compression Deflection & Hardness |

Engineered Team Structure: 5+2+3 Specialization

Suzhou Baoshida’s core engineering team combines deep expertise in mold design, material science, and production processes to deliver precision-engineered rubber components. All team members maintain 15+ years of industry experience.

| Role | Count | Key Responsibilities | Experience Level |

|---|---|---|---|

| Mold Design Engineers | 5 | Solidworks mold design, GD&T validation, mold flow simulation | 15+ years average |

| Formula Engineers | 2 | ASTM D2000 material selection, compound formulation | 15+ years |

| Process Engineers | 3 | Production optimization, SPC implementation, QC protocol | 15+ years |

Technical Note: All processes adhere to ISO 9001:2015 and IATF 16949 standards. Flash control is achieved via precision-machined mold cavities (±0.02mm tolerance) and automated ejection systems. Bonding to metal substrates follows ASTM D429 protocols for adhesion strength validation.

Contact Our Engineering Team

Contact Suzhou Baoshida for Precision Rubber Molding Solutions

Engineering Team Structure: 5+2+3 Expertise Framework

Our integrated engineering model ensures end-to-end technical excellence:

| Team Component | Core Expertise | Key Capabilities |

|---|---|---|

| Mold Design (5 Structural Engineers) | SolidWorks/CAD, Precision Tooling Design | – Flash control optimization via GD&T-compliant mold geometry – Metal bonding integration (adhesion testing per ASTM D429) – Rapid tooling coordination with 10+ certified partners |

| Formula Engineering (2 Material Scientists) | ASTM D2000/D1418 Compliance, Compound Formulation | – Material selection for industry-specific requirements (e.g., NBR for oil resistance, EPDM for UV/weathering) – Hardness testing (ASTM D575), compression set analysis, and thermal stability validation |

| Process Engineering (3 Production Specialists) | Injection/Compression Molding, Quality Control Systems | – Process parameter optimization (curing time, pressure, temperature) – Defect root-cause analysis (sink marks, voids, inconsistent flash) – Scalable production for 1K–100K+ units with PPAP documentation |

Why Partner with Suzhou Baoshida?

10+ Certified Partner Factories: Rapid tooling turnaround (7–14 days) and scalable production for urgent project timelines.

End-to-End Engineering Support: Full compliance with ASTM D2000, ISO 3601, and AS9100 standards from material selection to final inspection.

Industry-Specific Expertise: Proven solutions for:

Automotive: Seals for transmission systems (heat-resistant HNBR compounds)

Hydraulic Systems: High-pressure piston seals (DIN 3771-compliant)

Pump/Valve Components: Wear-resistant polyurethane (PU) and EPDM parts

Industrial Machinery: Vibration-dampening mounts (50–90 Shore A hardness range)

Solve Your Sealing Problems Today

Contact Mr. Boyce for a technical consultation:

Email: [email protected]

Phone: +86 189 5571 6798

“Our 5+2+3 engineering framework delivers precision-engineered rubber components that meet your most demanding performance, durability, and cost targets. Let’s optimize your design for manufacturability.”

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.