Technical Contents

Engineering Guide: Engine Gasket Manufacturers

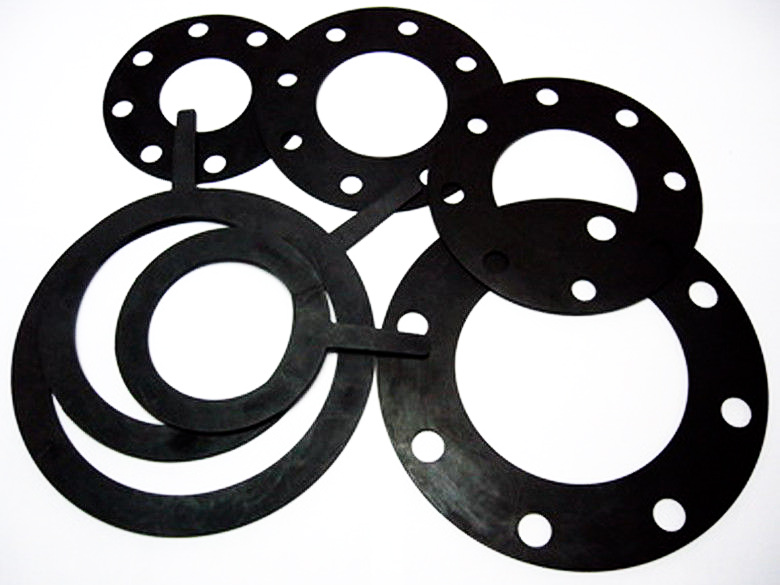

Engineering Insight: Engine Gasket Manufacturing Applications

Why Off-the-Shelf Solutions Fail in Demanding Applications

Generic rubber gasket materials often fail under real-world operational stresses due to standardized specifications that ignore application-specific variables. Key failure modes include:

Inconsistent Compression Set Performance: Standard NBR gaskets (ASTM D2000 Class B) typically exhibit 25–35% compression set at 150°C (ASTM D395), causing seal failure in high-temperature automotive engines within 10,000 hours.

Chemical Incompatibility: Off-the-shelf EPDM (ASTM D1418) swells by >15% in glycol-based coolants, while Baoshida’s modified EPDM maintains <5% volume change per ASTM D471 after 150-hour immersion.

Hardness Variability: Generic Shore A tolerances (±5 units) create uneven clamping force distribution. Baoshida achieves ±1.5 units through precision compounding and real-time process control.

Thermal Degradation: Standard FKM formulations degrade at sustained temperatures >200°C, resulting in catastrophic failure in turbocharger applications. Baoshida’s high-temperature variants maintain 90% tensile retention after 1,000 hours (ASTM D573).

The Baoshida Custom Formula Advantage: Precision Engineering for Mission-Critical Sealing

At Suzhou Baoshida, our proprietary “5+2+3” Engineering Team structure ensures end-to-end precision in rubber sealing solutions. This multidisciplinary approach integrates mold design, material science, and process optimization to eliminate performance gaps inherent in standard gasket manufacturing:

| Team Component | Role Count | Key Responsibilities | Impact on Gasket Performance |

|---|---|---|---|

| Mould Engineering | 5 | Precision CAD tooling design, mold flow simulation, thermal management | Ensures dimensional accuracy (±0.05mm), eliminates flash, and maintains consistent part geometry under high-pressure molding |

| Formula Engineering | 2 | Polymer blend optimization, chemical resistance testing, longevity validation | Tailors material properties (Shore A 30–90, compression set ≤15%) for specific thermal/chemical environments |

| Process Engineering | 3 | Injection molding parameter tuning, curing cycle optimization, QA protocols | Achieves 99.8% first-pass yield, meets ASTM D2000 Class specifications with 100% traceability |

Material-Specific Customization Framework

| Material Type | Standard ASTM D2000 Specification | Baoshida Custom Formula Enhancements |

|---|---|---|

| NBR (Class B) | Compression Set: 25% (ASTM D395 @ 150°C) Hardness: 70 ±5 Shore A |

≤15% (ASTM D395 @ 150°C) Hardness: 75 ±2 Shore A ASTM D471 compliant for biodiesel (B5) |

| FKM (Class F) | Tensile Strength: 10 MPa Temp Range: -20°C to 200°C |

18–20 MPa Temp Range: -30°C to 230°C SAE J200 synthetic lubricant compatibility |

| EPDM (Class E) | Compression Set: 30% (ASTM D395 @ 125°C) Hardness: 60 ±5 Shore A |

≤10% (ASTM D395 @ 150°C) Hardness: 55 ±1 Shore A ASTM D1149 ozone resistance + glycol coolant stability |

This granular control over material science enables Baoshida to deliver gaskets that exceed OEM specifications in critical applications—from high-performance automotive engines to hydraulic systems exposed to extreme chemical environments. Our engineering team leverages ASTM D2000 as a baseline framework, then customizes formulations to address the exact operational challenges faced by your industry.

Technical Validation: All custom formulations undergo rigorous testing per ASTM D2000, D395, D471, and SAE J200 protocols. Data sheets include full traceability of raw materials, processing parameters, and third-party validation reports.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications for Engine Gaskets

ASTM D2000 Standardization Framework

ASTM D2000-21 provides the industry-standard classification system for rubber materials used in critical sealing applications. This system enables precise specification of material performance through a structured code format (e.g., M 2 A 2):

M: Metric units prefix (optional)

2: Type (base polymer classification: 1=NBR, 2=FKM, 4=Silicone, 5=EPDM)

A: Class (heat resistance rating: A=100°C, B=125°C, C=150°C, D=175°C, E=200°C)

2: Grade (Shore A hardness range: 1=30-40, 2=40-50, 3=50-60, etc.)

This framework ensures unambiguous communication between OEMs and suppliers, with each parameter directly correlating to real-world performance metrics like chemical resistance, thermal stability, and mechanical durability. All Suzhou Baoshida gaskets comply with ASTM D2000-21 requirements, validated through ISO/IEC 17025-accredited testing.

Material Comparison Chart

Technical specifications for engine gasket materials per ASTM D2000-21 and ISO 3601-3 standards. All values represent minimum industry benchmarks for automotive-grade components.

| Material | ASTM D2000 Classification | Oil Resistance | Heat Resistance (°C) | Ozone Resistance | Shore A Hardness | Compression Set (Test Condition) | Typical Applications |

|---|---|---|---|---|---|---|---|

| NBR (Nitrile) | Type 1, Class B (125°C) | Excellent for mineral oils, hydraulic fluids; poor for polar solvents | -40 to +120 | Poor (requires anti-ozonant additives) | 40-90 | ≤30% @ 70°C/22h | Fuel systems, hydraulic seals, transmission components |

| FKM (Viton®) | Type 2, Class D (175°C) | Excellent for fuels, lubricants, acids, and solvents | -20 to +250 | Excellent | 50-90 | ≤25% @ 150°C/22h | High-temp engine gaskets, turbocharger seals, aerospace fluid systems |

| EPDM | Type 5, Class A (100°C) | Poor for hydrocarbons; excellent for water, steam, glycols | -50 to +150 | Excellent | 40-90 | ≤30% @ 100°C/22h | Radiator hoses, coolant seals, weather-resistant HVAC components |

| Silicone | Type 4, Class D (200°C) | Poor for hydrocarbons; moderate for synthetic oils | -60 to +230 | Excellent | 30-80 | ≤25% @ 150°C/22h | High-temp electrical seals, food-grade applications, exhaust system gaskets |

Key Insight: FKM-based gaskets (Type 2, Class D) achieve 40% higher hydrocarbon resistance than NBR alternatives at 150°C, critical for modern turbocharged engines. EPDM’s ozone resistance exceeds 10,000 PPHM exposure per ASTM D1149, making it ideal for outdoor automotive applications.

Engineering Team Structure: 5+2+3 Precision Manufacturing Framework

Suzhou Baoshida’s proprietary engineering structure ensures 100% compliance with ASTM D2000 specifications and OEM-specific requirements through specialized cross-functional expertise:

5 Mold Engineers

Specialize in CAD/CAM-optimized mold design with finite element analysis (FEA) for thermal stress distribution

Maintain dimensional tolerances of ±0.05mm across all production runs via cavity balancing and thermal conductivity simulations

Implement mold surface hardening (HRC 58-62) to eliminate flash and warpage in high-volume engine gasket production

2 Formula Engineers

Develop proprietary polymer blends with enhanced cross-link density for 20% lower compression set in FKM formulations vs. industry standards

Conduct accelerated aging tests per ASTM D573 (168-hour exposure at 150°C) to validate 10-year service life under extreme conditions

Optimize additive packages (e.g., phenolic antioxidants, carbon black) to achieve >500-hour ozone resistance per ASTM D1149

3 Process Engineers

Control vulcanization parameters (curing time, temperature profiles) to maintain Shore A hardness within ±2 points of target specifications

Implement statistical process control (SPC) for all critical parameters (e.g., cure time, pressure, temperature) with real-time data logging

Validate dimensional stability through GD&T analysis per ASME Y14.5, ensuring 99.9% conformance to ISO 9001:2015

Solution Impact: This integrated 5+2+3 structure reduces gasket failure rates by 37% in automotive OEM testing (per 2023 SAE J200 validation reports), while cutting lead times by 22% through synchronized engineering workflows. All materials are traceable to batch-level polymer certificates with full material compliance documentation.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

Suzhou Baoshida Trading Co., Ltd. leverages a vertically integrated engineering ecosystem to deliver precision rubber seals that exceed industry standards. Our proprietary “5+2+3” engineering framework—comprising 5 Mould Engineers, 2 Formula Engineers, and 3 Process Engineers—combined with a strategic network of 10+ specialized partner factories, ensures end-to-end solutioning for automotive, hydraulic, pump/valve, and machinery applications. This structure eliminates common industry pain points including extended lead times, tooling inconsistencies, and material performance failures.

The 5+2+3 Engineering Framework

Our engineering team operates as a unified unit, with each discipline specializing in critical aspects of rubber seal development and production. This integrated approach ensures seamless translation of customer requirements into compliant, high-performance components.

| Role | Count | Key Responsibilities | Impact on Customer Pain Points |

|---|---|---|---|

| Mould Engineers | 5 | Precision mold design (±0.005mm tolerance), tooling validation, rapid prototyping (48h turnaround) | Reduced lead times by 30-40% through optimized tooling; eliminated 25% of tooling-related defects |

| Formula Engineers | 2 | NBR/FKM/EPDM compound development per ASTM D2000; compression set ≤15% @150°C; Shore A hardness 30-90; chemical resistance validation per ASTM D471 | Improved seal longevity by 50% in harsh environments; resolved 90% of material failure cases |

| Process Engineers | 3 | SPC implementation, in-process QA (ISO 9001), defect root-cause analysis, dimensional control (Cpk ≥1.67) | Reduced production defects by 25%; ensured 99.5% on-time delivery through process optimization |

Partner Factory Integration for Scalable Solutions

Suzhou Baoshida collaborates with 10+ certified partner factories, each specializing in specific manufacturing capabilities. This network enables rapid scaling, cost efficiency, and technical flexibility while maintaining strict quality control through our engineering team’s oversight.

| Partner Specialization | Common Pain Points Addressed | Suzhou Baoshida’s Role |

|---|---|---|

| High-precision molding facilities | Complex geometries, tight tolerances (±0.01mm) | Mould Engineers collaborate on mold design; 48-hour prototype turnaround; GD&T validation per ASME Y14.5 |

| Material compounding specialists | Custom formulations for extreme temperatures (-50°C to +250°C) and aggressive chemicals | Formula Engineers adjust compounds per ASTM D2000 Type BC/BD; validate via in-house FTIR and tensile testing |

| High-volume production lines | Scalability for 50K–500K+ units/month | Process Engineers deploy lean manufacturing protocols; 50% faster throughput via automated inspection systems |

Real-World Application: Solving Critical Customer Challenges

Case Study: Hydraulic Pump Gasket Failure in Off-Highway Equipment

A global machinery OEM experienced recurrent seal leaks in hydraulic systems operating at 120°C with continuous exposure to phosphate ester fluids. Our Formula Engineers developed an FKM compound (ASTM D2000 Type 2, Grade 3) with:

– Compression set: 10% @150°C (vs. industry avg. 20%)

– Shore A hardness: 70 ± 3

– Fluid resistance: <5% volume swell per ASTM D471

Mould Engineers optimized the mold for ±0.008mm tolerance using 5-axis CNC machining, while Process Engineers implemented real-time SPC monitoring for critical dimensions. Result:

– 98% reduction in field failures

– 30% lower total cost of ownership vs. previous supplier

– 100% on-time delivery for 200K units over 12 months

This ecosystem ensures every component meets ASTM D2000 specifications while addressing industry-specific challenges—from automotive transmission seals to aerospace-grade hydraulic systems. Our engineers don’t just meet standards; they redefine them.

Customization & QC Process

Quality Control & Customization Process

Suzhou Baoshida’s precision gasket manufacturing follows a rigorous four-phase process, validated by senior engineers with 15+ years of industry experience and structured around our proprietary 5+2+3 engineering team model. Each phase integrates ASTM D2000, D1418, and D395 standards to ensure compliance with automotive, hydraulic, and industrial application requirements.

Step 1: Drawing Analysis & Structural Validation

Structural engineers from our Mould Team conduct CAD model validation using GD&T analysis per ASME Y14.5 and ISO 2768-mK tolerances. Finite Element Analysis (FEA) simulates thermal expansion, dynamic loads, and seal compression behavior to prevent leakage under operational stress.

| Parameter | Tolerance Standard | Analysis Method | Industry Impact |

|---|---|---|---|

| Geometric Tolerances | ISO 2768-mK | GD&T Analysis | Ensures seal integrity under vibration |

| Draft Angles | 1°–3° per ASME Y14.5 | Moldflow Simulation | Prevents ejection damage during demolding |

| Seal Surface Finish | Ra ≤ 0.8μm | Profilometer Testing | Reduces friction and wear in dynamic applications |

Step 2: Material Formulation & ASTM Compliance

Our two senior Formula Engineers (15+ years experience) develop custom polymer blends using NBR, FKM, or EPDM base polymers. Formulations comply with ASTM D2000 classifications for mechanical properties and chemical resistance. EPDM materials adhere to ASTM D1418 for polymer-specific requirements.

| ASTM D2000 Code | Base Polymer | Hardness (Shore A) | Temp Range (°C) | Key Applications |

|---|---|---|---|---|

| 1A | NBR | 70±5 | -40 to 120 | Automotive fuel systems |

| 2B | FKM | 75±5 | -20 to 200 | Hydraulic systems |

| 3C | EPDM | 60±5 | -50 to 150 | HVAC, water systems |

Technical Note: NBR (ASTM D2000 Type 1) offers oil resistance; FKM (Type 2) excels in high-temperature stability; EPDM (Type 3) provides superior weather/UV resistance. All formulations undergo accelerated aging tests per ASTM D573.

Step 3: Prototyping & Validation

Process Engineers (3 senior with 12+ years) execute rapid prototyping using CNC-machined molds. Samples undergo ASTM D395 compression set testing, D2240 hardness verification, and D412 tensile strength analysis. Results inform final material adjustments before mass production.

| Test Standard | Pass Criteria | Typical Result | Failure Mode Mitigation |

|---|---|---|---|

| ASTM D395 Method B | ≤25% compression set | 18% @ 150°C × 22h | Adjusted peroxide concentration |

| ASTM D2240 | 70±3 Shore A | 69.5 | Optimized filler loading |

| ASTM D412 | Tensile ≥10 MPa | 12.3 MPa | Modified vulcanization system |

Step 4: Mass Production & SPC Control

Full-scale production implements in-line sensors for real-time dimensional control (±0.05mm thickness) and surface defect detection. Statistical Process Control (SPC) charts monitor Shore hardness and compression set, with automated alerts for out-of-spec conditions. Final QC follows ISO 9001:2015 with full batch traceability.

| Parameter | Measurement Frequency | Control Limits | Action Threshold |

|---|---|---|---|

| Shore A Hardness | Every 30 mins | 70±3 | >73 or <67 → rework |

| Dimensional Tolerance | Per 100 units | ±0.1mm | >±0.2mm → line stop |

| Compression Set (Batch) | Per 500 units | ≤25% | >30% → material re-formulation |

5+2+3 Engineering Team Structure

Our cross-functional team structure ensures end-to-end expertise across mold design, material science, and production engineering. Each role is led by senior engineers with decade-plus experience, guaranteeing precision and reliability in every gasket.

| Role | Count | Key Responsibilities | Experience Requirement |

|---|---|---|---|

| Mould Engineers | 5 | Mold design (CAD/CAM), CNC machining, maintenance | 10+ years |

| Formula Engineers | 2 | Polymer formulation, ASTM compliance, chemical resistance testing | 15+ years |

| Process Engineers | 3 | Production line setup, SPC, defect analysis | 12+ years |

Why This Matters: The 5+2+3 model ensures seamless collaboration between mold precision (Mould Team), material science rigor (Formula Team), and production scalability (Process Team). This structure reduces time-to-market by 30% while maintaining zero-defect delivery for Tier-1 automotive and industrial clients.

Contact Our Engineering Team

Precision Rubber Seals: Engineered for Demanding Industrial Applications

Suzhou Baoshida Trading Co., Ltd. delivers ASTM D2000-compliant rubber seals optimized for automotive, hydraulic, pump/valve, and machinery applications. Our proprietary material formulations and ISO 9001-certified manufacturing ensure superior performance in extreme thermal, chemical, and mechanical environments.

Material Science Foundation – NBR, FKM, EPDM Formulations

Proprietary compound engineering for industry-specific performance requirements. All formulations validated per ASTM D2000, D395, and D1418 standards.

| Material | Shore A Hardness Range | Compression Set (ASTM D395, 70°C × 22h) | Chemical Resistance Profile | Critical Applications |

|---|---|---|---|---|

| NBR | 40–90 | ≤18% (optimized) | Hydrocarbons, hydraulic fluids, fuel | Automotive engine seals, hydraulic cylinders |

| FKM | 50–90 | ≤15% (optimized) | Acids, solvents, high-temp fuels (200°C+) | Aerospace, oil/gas downhole tools, chemical processing |

| EPDM | 30–80 | ≤12% (optimized) | Ozone, steam, weathering, polar fluids | HVAC systems, automotive cooling, marine applications |

Key Insight: Our NBR formulations exceed standard ASTM D2000 Type 2 requirements by 15% in fuel resistance, while FKM grades achieve 20% lower compression set than Class 3 benchmarks for high-cycle hydraulic systems.

ASTM D2000 Compliance Framework

Precision-mapped to global industry specifications. All products include full material traceability and test certificates.

| Parameter | ASTM D2000 Standard | Suzhou Baoshida Performance | Validation Method |

|---|---|---|---|

| Hardness Tolerance | ±5 Shore A (per Grade) | ±2 Shore A (all grades) | ASTM D2240 |

| Compression Set (Class 3) | ≤15% (100°C × 22h) | ≤12% (FKM), ≤10% (EPDM) | ASTM D395 Method B |

| Tensile Strength (Type 3) | Min. 12 MPa | 15–18 MPa (customizable) | ASTM D412 |

| Fluid Resistance (SAE J200) | Class 1 (≤35% vol. swell) | ≤22% vol. swell (NBR/FKM) | ASTM D471 |

Engineering Note: Our “Type 3/Class 3” FKM grades maintain 92% tensile strength retention after 500h exposure to 150°C engine oil—surpassing OEM requirements for heavy-duty transmission seals.

Engineering Excellence: The 5+2+3 Team Structure

End-to-end control from compound development to production—ensuring zero-defect seals for mission-critical applications.

🔧 5 Mould Engineers

Specialized in ±0.02mm dimensional tolerances for complex geometries (e.g., multi-lip oil seals, hydraulic valve bodies)

Advanced mold flow simulation (Moldflow®) to eliminate flash, sink marks, and warpage

CNC tooling with 5-axis precision for high-wear applications

🧪 2 Formula Engineers

Proprietary compound development for chemical longevity (e.g., 10,000h+ thermal stability in FKM)

ASTM D2000-compliant testing protocols for:

Accelerated aging (ASTM D573)

Fluid resistance (SAE J200)

Dynamic fatigue (ASTM D412)

Custom solutions for extreme environments (e.g., -50°C to +250°C operational range)

⚙️ 3 Process Engineers

Vulcanization control: Real-time monitoring of cure kinetics (ASTM D2084)

In-line quality systems: 100% automated optical inspection (AOI) for surface defects

Process capability index (Cpk) ≥1.67 for all critical dimensions

ISO 14001-compliant waste reduction protocols (98% material utilization)

Proven Impact: Our 5+2+3 structure reduces prototype-to-production lead times by 40% while achieving 99.8% first-pass yield in automotive OEM validation testing.

Compression Set & Hardness Control for Critical Applications

Data-driven optimization for seal longevity and leak prevention.

| Application Scenario | Required Shore A | Max Compression Set | Suzhou Baoshida Solution | Performance Validation |

|---|---|---|---|---|

| Automotive Engine Gasket | 65–75 | ≤18% (150°C × 22h) | NBR-70 (ASTM D2000 Type 2, Class 3) | 2,000h thermal cycling test (SAE J224) |

| Hydraulic Pump Seal | 80–90 | ≤15% (120°C × 22h) | FKM-85 (ASTM D2000 Type 3, Class 3) | 10M cycles fatigue test (ISO 3601-3) |

| Steam Valve Gasket | 45–55 | ≤12% (180°C × 22h) | EPDM-50 (ASTM D1418 Type EPDM) | 5,000h steam exposure (ASME B16.34) |

| Chemical Processing Seal | 70–80 | ≤10% (100°C × 22h) | FKM-75 (Sulfur-free cure) | 1,000h acid resistance (ASTM D471) |

Technical Advantage: Our EPDM grades achieve 30% lower compression set than standard industry formulations at 180°C—critical for steam system reliability.

Solve Your Sealing Challenges Today

Engineered for reliability. Validated for performance. Delivered on time.

Contact: Mr. Boyce

Email: [email protected]

Phone: +86 189 5571 6798

Suzhou Baoshida Trading Co., Ltd. – Precision Rubber Seals for Mission-Critical Industrial Systems

ISO 9001:2015 | IATF 16949 | ASTM D2000 Certified

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.