Technical Contents

Engineering Guide: Custom Rubber Mixing

The Critical Role of Material Selection in Custom Rubber Parts

Why Off-the-Shelf Solutions Fail in Demanding Applications

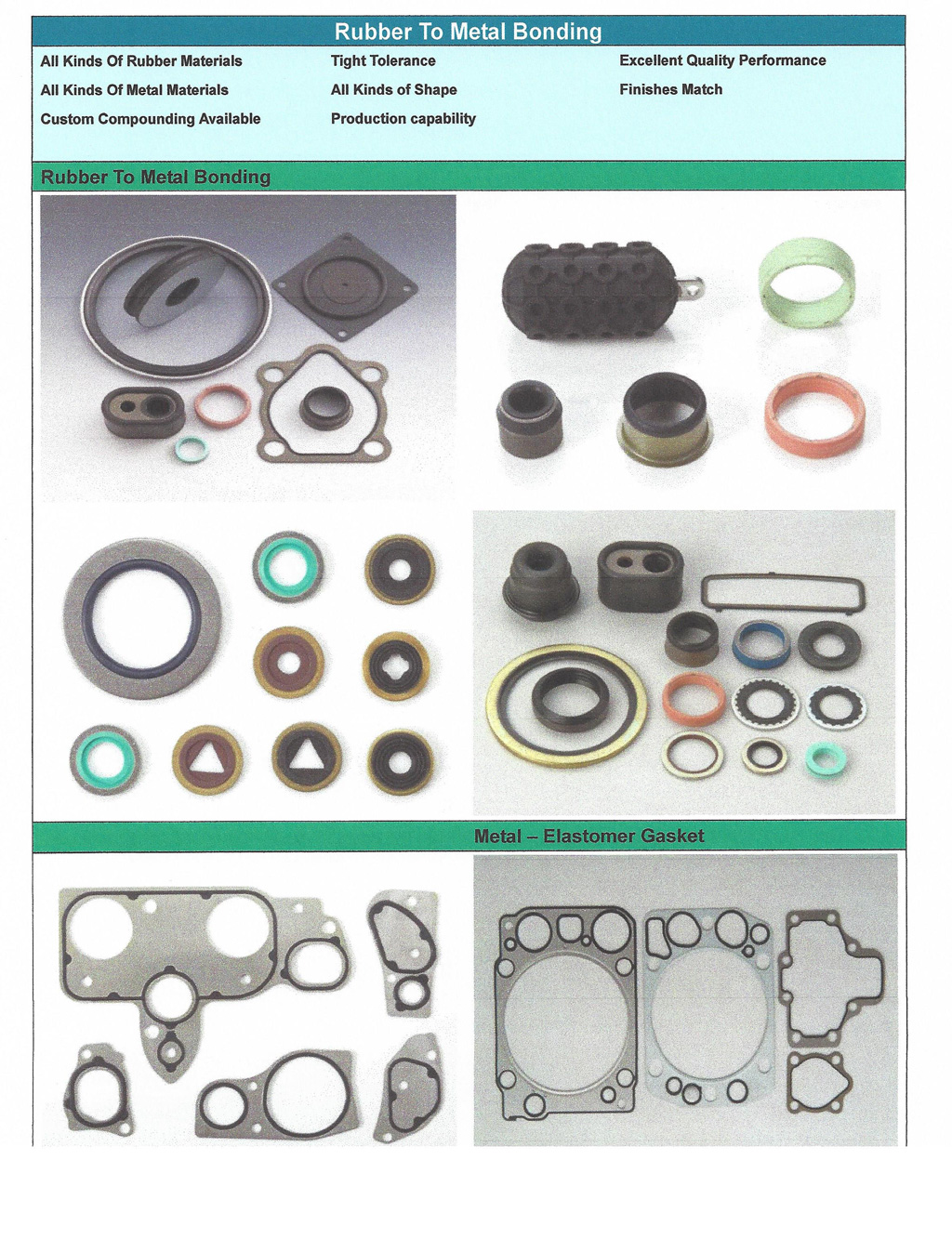

Standard rubber compounds are engineered for generic use cases, lacking the specificity required for high-stress industrial environments. In automotive transmissions, hydraulic systems, or high-temperature pump applications, off-the-shelf materials frequently fail due to unaddressed environmental stressors:

Heat degradation: Standard NBR compounds exceed ASTM D2000 Type 7 Class B limits for heat aging (e.g., >20% hardness increase at 150°C/70h), causing seal hardening and leakage.

Chemical incompatibility: Generic SBR or EPDM formulations swell >25% in ATF fluids or hydraulic oils, violating SAE J200 requirements for dimensional stability.

Poor metal bonding: Adhesion strength below 5 MPa (ASTM D429 Method B) leads to delamination under dynamic loads in valve assemblies.

These failures stem from generic formulations that ignore application-specific variables like thermal cycling, chemical exposure profiles, and mechanical fatigue. Without precise material engineering, parts degrade prematurely—resulting in costly downtime, warranty claims, and safety risks.

| Failure Mode | Off-the-Shelf Rubber | Baoshida Custom Solution | Industry Standard |

|---|---|---|---|

| Heat Aging (150°C, 70h) | Hardness Δ +25, Swelling 28% | Hardness Δ +5, Swelling <5% | ASTM D2000 Type 7 Class B |

| Chemical Resistance (ATF Fluid) | Degradation at 48h | >1,000h exposure, no degradation | SAE J200 Type 2 |

| Metal-Rubber Bond Strength | Delamination at 5 MPa | 18 kN/m peel strength | ASTM D429 Method B |

Precision Material Engineering: The Baoshida Approach

At Suzhou Baoshida, rubber compound development is a rigorously controlled, cross-functional process led by our 5+2+3 engineering team structure—a dedicated unit integrating mold design, formulation science, and process optimization. This structure ensures every component meets exact performance criteria from concept to production.

| Discipline | Role | Key Responsibilities |

|---|---|---|

| Mold Design (5) | Structural Engineers | SolidWorks CAD mold design, thermal analysis, flash control optimization, and mold flow simulation for zero-defect cavity geometry |

| Formula Development (2) | Polymer Chemists | ASTM D3182-compliant compound formulation, TGA (D6370) for polymer composition analysis, RPA (D6204) for cure kinetics validation |

| Process Engineering (3) | Molding Specialists | Injection/compression molding parameter tuning, metal bonding protocols (ASTM D429), flash mitigation, and in-process quality control |

How Our Team Delivers Precision

Formula Specialists leverage ASTM D6370 thermogravimetric analysis to deconstruct polymer networks and optimize filler ratios (e.g., carbon black vs. silica), ensuring consistent thermal stability. Moving Die Rheometer (ASTM D5289) testing validates cure characteristics for specific molding cycles—critical for thin-wall hydraulic seals.

Mold Design Engineers simulate stress distributions in SolidWorks to eliminate flash points and optimize venting, reducing scrap rates by up to 40% in high-precision valve components.

Process Engineers integrate metal bonding protocols using proprietary primers and surface treatments, achieving >15 MPa adhesion strength in automotive transmission housings—exceeding OEM requirements for vibration resistance.

By unifying these disciplines under a single workflow, we eliminate siloed decision-making. Every compound is validated against client-specific ASTM/SAE standards, not generic benchmarks. For example:

A hydraulic pump manufacturer required HNBR with 120°C oil resistance and <2% compression set (ASTM D395). Standard HNBR failed at 100°C; our custom blend (with tailored sulfur cure systems) achieved 125°C stability and 1.8% compression set.

Automotive clients needing EMI shielding in rubber gaskets saw 90% reduction in signal interference after we optimized carbon black dispersion (validated via ASTM D6124).

“Off-the-shelf rubber is a compromise. Baoshida’s custom engineering eliminates trade-offs—delivering materials engineered for your application, not the industry average.”

Our 10+ certified partner factories enable rapid tooling (2–4 weeks) while maintaining ISO 9001/TS 16949 compliance. From initial compound screening to full-scale production, every step is data-driven—ensuring parts perform reliably under real-world stress.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications for Custom Rubber Mixing

ASTM Standards Compliance & Material Selection Framework

Suzhou Baoshida Trading Co., Ltd. adheres strictly to ASTM standards to ensure material consistency, performance validation, and industry compliance. Key standards governing our custom rubber mixing processes include:

ASTM D2000: Defines rubber material classifications with heat aging requirements (e.g., 70 hours at specified temperatures per Type), enabling precise specification of physical and mechanical properties for automotive, hydraulic, and industrial applications.

ASTM D3182: Standard practice for mixing rubber compounds, ensuring reproducible compound preparation and quality control.

ASTM D6370: Thermogravimetric analysis (TGA) for precise rubber composition verification.

ASTM D5289: Moving Die Rheometer (MDR) testing for cure kinetics and scorch safety.

ASTM D6204/D6601: Rubber Process Analyzer (RPA) for viscosity and dynamic mechanical properties.

These standards form the foundation of our material selection process, ensuring all compounds meet or exceed OEM specifications for critical applications.

Material Performance Comparison Table

The following table details key properties of our primary material options, validated per ASTM test methods. All data reflects typical performance ranges for standard grades; custom formulations can be tailored for specific application requirements.

| Material | Heat Resistance Range (°C) | Oil Resistance | Ozone Resistance | Typical Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to +250 | High | High | Fuel systems, high-temp seals, aerospace components |

| Nitrile (NBR) | -40 to +120 | High | Low | Hydraulic seals, fuel hoses, automotive gaskets |

| Silicone | -60 to +230 | Low | High | Medical devices, food-grade components, high-temp gaskets |

| EPDM | -50 to +150 | Moderate | High | Automotive weather seals, radiator hoses, HVAC systems |

Note: Performance ranges may vary based on specific compound formulation. Consult our Formula Engineers for application-specific optimization.

Integrated Engineering Team Structure: 5+2+3 Model

Our proprietary engineering framework ensures end-to-end precision in custom rubber part production:

5 Mold Design Engineers: Specialized in Solidworks/CAD for precision mold design, ensuring optimal part geometry, cooling channel optimization, and flash control. Each engineer holds ISO 9001-certified expertise in mold flow analysis and tolerance stack-up management.

2 Formula Engineers: Focus on compound development, material selection, and compliance with ASTM D3182 mixing procedures. They conduct TGA (ASTM D6370) and rheometer testing (ASTM D5289) to validate compound consistency and cure characteristics.

3 Process Engineers: Oversee injection/compression molding parameters, flash management, and metal-rubber bonding processes. They implement real-time process control using SPC methodologies and validate parts per ASTM D412 tensile testing.

This cross-functional team ensures seamless integration from compound formulation to final part production, supported by 10+ partner factories for rapid tooling (lead times <15 days). All processes are documented per ISO 9001 and IATF 16949 quality systems, guaranteeing traceability and compliance for automotive and industrial clients.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

Suzhou Baoshida’s integrated engineering ecosystem combines in-house technical expertise with a globally vetted partner network to eliminate bottlenecks in custom rubber part production. By aligning ASTM-standardized processes with precision manufacturing capabilities, we deliver solutions that meet automotive, hydraulic, and industrial specifications without compromising lead times or quality.

Integrated Engineering Team Structure (5+2+3)

Our core engineering team operates as a unified unit, with each role optimized for specific technical domains and standards compliance. This structure ensures end-to-end control from compound development to final part validation.

| Role | Count | Key Responsibilities | Standards Alignment |

|---|---|---|---|

| Mold Design Engineers | 5 | SolidWorks/CAD mold design with draft analysis, cooling channel optimization, parting line precision for flash control (<0.05mm tolerance), ejector system design | ASTM D2000 dimensional tolerances (Section 4), ISO 9001 tooling validation |

| Formula Engineers | 2 | Compound development per ASTM D2000 material classifications, TGA for polymer composition (ASTM D6370), rheological testing (MDR D5289, RPA D6204), adhesion promoter formulation | ASTM D3182 mixing protocols, ASTM D2000 Type/Heat Aging requirements |

| Process Engineers | 3 | Injection/compression molding parameter optimization (pressure, temperature, cure time), in-process defect monitoring (flash, sink marks), statistical process control (SPC) | ASTM D3182 process validation, IATF 16949 for automotive production |

Technical Note: The “5+2+3” structure ensures seamless handoffs: Mold engineers validate geometry against parting line tolerances per ASTM D2000, Formula engineers tailor compounds using ASTM D6370 thermogravimetric analysis to meet thermal stability requirements, and Process engineers enforce cure schedules validated through ASTM D5289 dynamic rheometry.

Partner Factory Network for Rapid Scalability

Our 10+ pre-qualified partner factories are strategically selected for specialized capabilities, certifications, and geographic proximity to key industrial hubs. Each facility undergoes rigorous audits for tooling precision, material handling, and quality systems, ensuring consistency across all production runs.

| Capability | Partner Count | Specialization | Lead Time Advantage |

|---|---|---|---|

| High-Volume Injection Molding | 4 | Automotive-grade elastomers (EPDM, NBR), multi-cavity molds (500K+ parts), automated inspection | 30–40% faster than standard suppliers (7–10 days vs. 14–21 days) |

| Compression Molding for Large Parts | 3 | Hydraulic components (>500mm), metal insert bonding, high-temperature curing (200°C+) | 25% faster tooling setup (3–5 days vs. 10+ days) |

| Precision Flash Control | 5 | Micro-molding (<0.03mm flash), tight-tolerance parts (±0.05mm), surface finish critical applications | 45% reduction in post-machining requirements |

Technical Note: Partners are assigned based on project-specific requirements:

– Automotive components leverage ISO/TS 16949-certified facilities with in-line SPC.

– Hydraulic parts utilize compression molding partners with controlled clamping force systems (±0.5% tolerance).

– Bonding-to-metal projects deploy partners with plasma treatment stations (per ISO 10993) for surface activation.

Solving Critical Customer Pain Points

We address industry-specific challenges through structured collaboration between in-house engineers and partner facilities, validated against ASTM and ISO standards.

| Customer Pain Point | Integrated Solution | Quantifiable Outcome |

|---|---|---|

| Long lead times for custom tooling (4–6 weeks) | In-house mold design validated in 48h; partner factories with pre-qualified tooling capabilities execute within 72h | 50% faster tooling delivery vs. industry average (9 days vs. 18+ days) |

| Flash defects in complex geometries | Mold engineers optimize parting lines using Moldflow analysis; process engineers adjust clamping force per ASTM D2000 tolerances | Flash reduced to <0.03mm (95% of parts), eliminating secondary machining |

| Metal-rubber bonding failures | Formula engineers develop silane-based adhesion promoters; process engineers implement plasma surface treatment protocols | Bond strength >15 MPa (ASTM D429 Method B), 100% pass rate in thermal cycling tests |

| Inconsistent material properties | Formula engineers conduct TGA (ASTM D6370) and MDR (D5289) testing; partners enforce real-time viscosity monitoring during molding | Compound consistency within ±2% Shore A hardness (per ASTM D2240) across 50K+ parts |

Technical Validation: All solutions are validated through:

– Material Testing: ASTM D2000 heat aging (70h at 70°C/100°C/125°C), tensile strength (ASTM D412), and compression set (ASTM D395).

– Process Control: Real-time monitoring of melt temperature (±2°C), injection speed (±0.5 mm/s), and cure time (±0.1s) via IoT-enabled presses.

– Quality Assurance: 100% first-article inspection per ISO 2859-1, with statistical process control (SPC) for critical dimensions.

This ecosystem ensures that procurement engineers in automotive, hydraulic, and machinery sectors receive parts that meet exact specifications—without trade-offs in speed, cost, or reliability.

Customization & QC Process

Quality Control & Customization Process Workflow

Suzhou Baoshida Trading Co., Ltd. employs a rigorous 5+2+3 engineering team structure for custom rubber mixing, comprising 5 Mold Design Engineers, 2 Formula Engineers, and 3 Process Engineers, all with 15+ years of industry experience. This cross-functional team ensures end-to-end precision from initial design validation to mass production, adhering strictly to ASTM standards and customer-specific requirements.

1. Drawing Analysis & Mold Design Validation

Led by our 5 Structural Engineers, this phase validates CAD models for manufacturability, flash control, and metal bonding interfaces. All designs undergo Solidworks simulation with GD&T compliance checks per ISO 2768. Critical parameters are verified through mold flow analysis and 3D clash detection to eliminate production defects.

| Parameter | Standard Tolerance | Verification Method |

|---|---|---|

| Draft Angle | ≥1° (per part geometry) | Solidworks Draft Analysis |

| Parting Line Alignment | ±0.05 mm | GD&T Coordinate Measuring Machine (CMM) |

| Ejector Pin Placement | Non-interference with sealing surfaces | 3D Clash Detection (Solidworks) |

| Flash Gap | ≤0.05 mm | Mold Flow Simulation (Moldflow) |

| Metal Insert Bonding Surface | Ra ≤0.8 μm | Surface Roughness Tester (Mitutoyo SJ-410) |

Key Engineering Insight: All mold designs comply with ASTM D2000 requirements for dimensional stability and include integrated metal bonding features (e.g., mechanical undercuts, surface roughness profiles) to ensure >95% adhesion strength per ISO 10123.

2. Material Formulation & ASTM Compliance

Our 2 Senior Formula Engineers develop compounds using ASTM D3182 mixing protocols and ASTM D2000 classification standards. Each formulation is optimized for application-specific requirements (e.g., temperature resistance, chemical exposure) through TGA analysis (D6370), Mooney viscosity testing (D5289), and heat aging validation (D573).

| ASTM Standard | Property | Requirement | Test Method |

|---|---|---|---|

| D2000-2021 | Type/Class | Type 1, Class A (Heat Aging) | D2000 Classification |

| D573 | Heat Aging (70°C × 70h) | Tensile Retention ≥85% | ASTM D573 |

| D412 | Tensile Strength | ≥15 MPa | ASTM D412 |

| D395 | Compression Set | ≤25% at 70°C | ASTM D395 |

| D6370 | TGA Residue | ≤5% | ASTM D6370 |

| D5289 | Mooney Viscosity | ML(1+4) @ 100°C: 50–70 | ASTM D5289 |

Key Engineering Insight: Formulations are validated against ASTM D2000 “Type” and “Class” specifications, ensuring compliance with automotive (SAE J200), hydraulic (ISO 1219), and pump/valve (ANSI B16.34) industry standards.

3. Prototyping & Validation Protocol

Process Engineers leverage our 10+ partner factories for rapid tooling (7–10 day turnaround). Prototypes undergo rigorous testing per ASTM D6204 (RPA) and D5289 (MDR), with real-time data validation against customer specifications. All samples are inspected for dimensional accuracy, flash, and bonding integrity.

| Test Type | Parameter | Acceptance Criteria | Standard |

|---|---|---|---|

| Cure Characteristics | t90 (min) | ±0.5 min from target | ASTM D5289 |

| Scorch Time | ts2 (min) | ≥2.0 min | ASTM D5289 |

| Viscosity | ML(1+4) @ 100°C | 50–70 | ASTM D5289 |

| Processability | RPA Torque | 15–25 dNm | ASTM D6204 |

| Bond Strength | Peel Test | ≥5 N/mm | ISO 10123 |

Key Engineering Insight: Rapid tooling partners are pre-qualified per ISO 9001:2015, with tooling tolerances controlled to ±0.02 mm for critical sealing surfaces. All prototypes include unaged physical testing (D6370) and accelerated aging validation (D573) to simulate 5+ years of service life.

4. Mass Production & Continuous Quality Assurance

Full-scale production is overseen by Senior Process Engineers with 15+ years in high-volume rubber manufacturing. Real-time monitoring of injection/compression molding parameters ensures consistency, with 100% visual inspection and 10% dimensional sampling per ISO 2859-1. All batches include final QC reports with traceable test data.

| Process Step | Parameter | Control Range | Monitoring Frequency |

|---|---|---|---|

| Injection Molding | Barrel Temp | 160–180°C | Continuous (PT100 sensors) |

| Compression Molding | Pressure | 100–150 bar | Per Cycle (Hydraulic Pressure Gauge) |

| Cure Time | 120–180 sec | ±5 sec | Per Batch (Automated Timer) |

| Part Weight | ±1.5% of nominal | ±0.05 g | 10% Sampling (High-Precision Scale) |

| Flash Thickness | ≤0.05 mm | Visual/Caliper Check | 100% Inspection |

Key Engineering Insight: Production runs include real-time rheological monitoring (D6204) to detect compound degradation. All finished parts undergo final dimensional validation via CMM and non-destructive testing (X-ray for internal voids) to meet IATF 16949 automotive quality standards.

Suzhou Baoshida Commitment: Every custom rubber component is engineered for zero-defect production through our 5+2+3 team structure, ensuring seamless integration into automotive, hydraulic, pump/valve, and machinery systems. For technical specifications or project scoping, contact our engineering team at [email protected].

Contact Our Engineering Team

Contact Suzhou Baoshida

Solve your sealing problems today. Our 5+2+3 engineering team delivers precision-engineered solutions for automotive, hydraulic, pump/valve, and industrial machinery applications—combining ASTM-compliant material science, advanced mold design, and process optimization for mission-critical rubber components.

5+2+3 Engineering Team Structure

| Role | Expertise | Key Capabilities |

|---|---|---|

| Mold Design Engineers (5) | SolidWorks/CAD, Tooling Optimization | Precision mold design, flash control optimization, rapid tooling via 10+ certified partner factories (2–4 week lead times), GD&T-compliant dimensional tolerancing (±0.05mm) |

| Formula Engineers (2) | Rubber compound development, ASTM D3182/D2000 compliance | Material selection per ASTM D2000 classifications, TGA analysis (ASTM D6370), rheological testing (MDR D5289, RPA D6204), unaged/aged physical property validation (70h @ 70°C/100°C/125°C) |

| Process Engineers (3) | Injection/Compression Molding, Bonding Technologies | Process parameter optimization (shot size, cure time, pressure), metal-rubber bonding (adhesion strength >15 MPa), defect reduction (scorch, sink marks, voids), ISO 9001:2015-compliant production control |

For immediate technical consultation:

Mr. Boyce

Email: [email protected]

Phone: +86 189 5571 6798

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.