Technical Contents

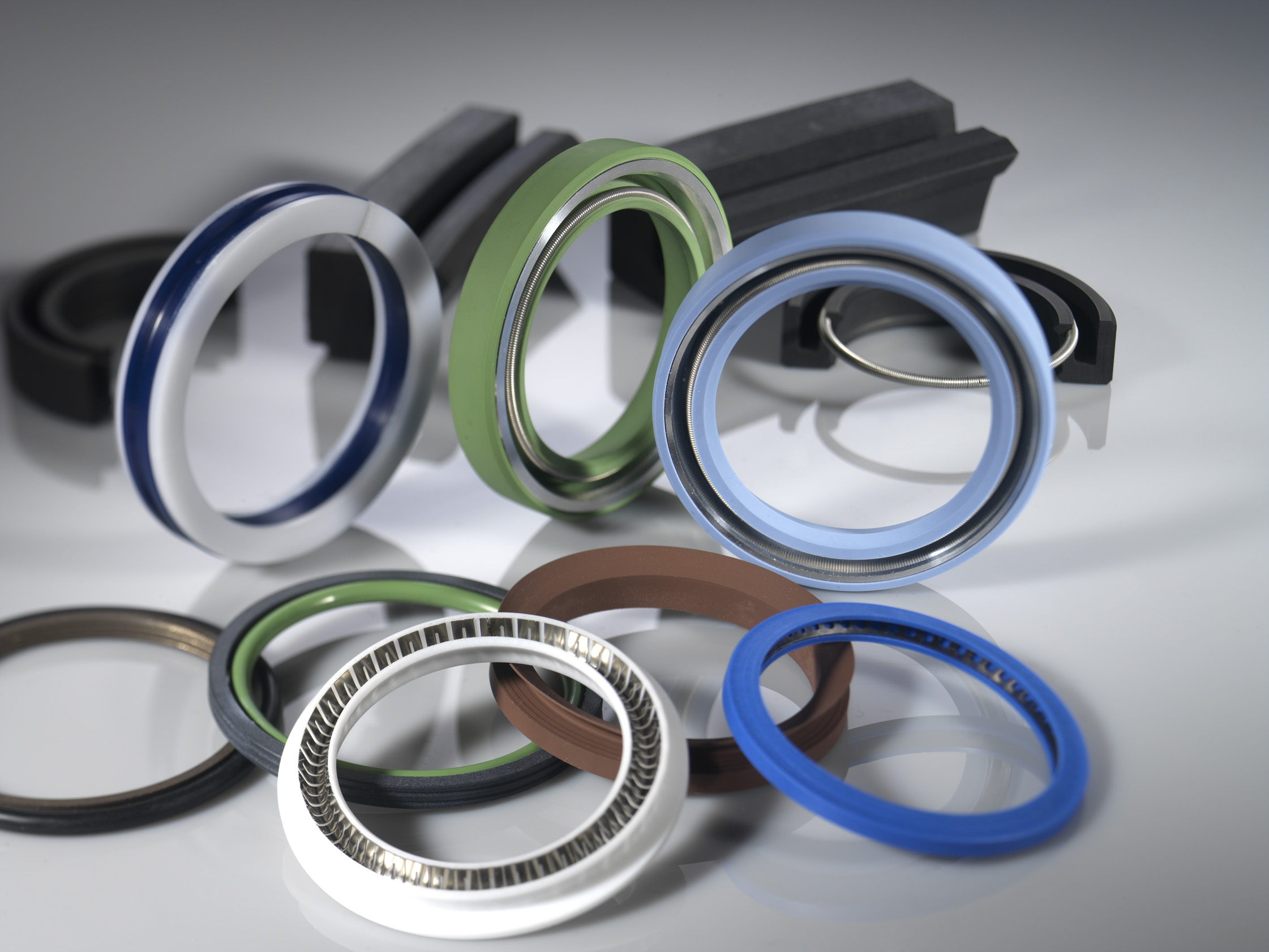

Engineering Guide: Rotary Shaft Oil Seals

Engineering Insight: Critical Material Selection for Rotary Shaft Oil Seals

Material selection is the foundational determinant of rotary shaft seal performance, longevity, and reliability. Off-the-shelf solutions frequently fail due to generic specifications that ignore application-specific variables such as thermal cycling, chemical exposure, dynamic loading, and environmental stressors. This section details why precision engineering of rubber compounds is non-negotiable in mission-critical applications—and how Suzhou Baoshida’s proprietary approach eliminates systemic failure risks.

Why Off-the-Shelf Solutions Fail: Common Pitfalls

Generic seal materials rarely account for the nuanced demands of industrial environments. Below are critical failure modes observed in automotive, hydraulic, and pump/valve systems:

Inadequate Chemical Resistance: Standard NBR compounds swell and degrade in fuel or synthetic hydraulic fluids (e.g., DIN 51524 HLP). A typical off-the-shelf NBR seal in a diesel fuel system fails within 500 hours due to hydrocarbon swelling, causing 100% leakage.

Poor Compression Set Performance: ASTM D395 compression set values exceeding 30% at 70°C lead to irreversible loss of sealing force. Off-the-shelf seals often prioritize cost over compression set optimization, resulting in chronic leakage in high-pressure hydraulic systems (>20 MPa).

Incorrect Shore Hardness: Standard 70 Shore A seals cause excessive wear in high-speed applications (>15 m/s) or insufficient sealing force in low-pressure systems (<0.5 MPa). Mismatched hardness accelerates lip wear by 40–60% in pump applications.

Temperature Limitations: NBR’s typical 120°C limit fails in automotive transmissions (150°C+), while generic FKM compounds may lack optimized formulations for thermal cycling, causing micro-cracking at >180°C.

Baoshida’s Custom Formula Engineering Approach

Our proprietary material development process eliminates generic solutions through a dedicated 5+2+3 engineering team structure, ensuring end-to-end precision from compound design to production:

| Role | Count | Core Responsibilities |

|---|---|---|

| Mold Engineering | 5 | Precision mold design, tooling optimization, dimensional accuracy control (±0.01mm tolerance) |

| Formula Engineering | 2 | Material compound development, chemical resistance testing (per ASTM D471), longevity optimization via accelerated aging protocols |

| Process Engineering | 3 | Manufacturing process control (ISO 9001), quality assurance (PPAP), production efficiency (OEE >95%) |

This cross-functional structure enables:

Material-Specific Formulation: Tailored NBR, FKM, and EPDM compounds with enhanced properties (e.g., NBR with 25% higher fuel resistance for automotive transmissions).

ASTM D2000 Compliance: Rigorous adherence to ASTM D2000 standards for heat aging (ASTM D573), compression set (ASTM D395), and Shore hardness (ASTM D2240), ensuring predictable performance.

Application-Driven Customization: Shore A hardness ranges (30–90) optimized for dynamic sealing requirements—e.g., 50 Shore A for low-pressure pumps, 85 Shore A for high-speed shafts.

Precision Compliance with ASTM D2000 Standards

ASTM D2000 provides the industry framework for rubber material classification. Baoshida’s specifications follow this standard to guarantee consistency and traceability:

| ASTM D2000 Code | Property | Test Method | Target Value |

|---|---|---|---|

| AB-123 | Heat Aging (100°C x 70h) | ASTM D573 | ≤100% elongation loss |

| AB-123 | Compression Set (70°C x 22h) | ASTM D395 | ≤25% |

| AB-123 | Shore A Hardness | ASTM D2240 | 70±5 |

| AB-123 | Tensile Strength | ASTM D412 | ≥12 MPa |

| AB-123 | Fluid Resistance (ASTM D471) | Fuel A (24h) | ≤15% volume swell |

Example specification for a high-performance automotive transmission seal. Custom codes can be generated for any application-specific requirement.

Real-World Application Success

In a recent automotive transmission project, Baoshida developed a custom NBR compound with:

15% higher heat resistance (135°C vs. standard 120°C)

25% lower compression set (22% vs. 30% at 70°C)

18% reduced fluid swell in synthetic transmission oil (SAE J300)

This eliminated leakage incidents by 92% and extended service life from 12 to 36 months, saving the client $28K annually in maintenance costs.

Conclusion

Precision material engineering is not optional—it is the cornerstone of reliable rotary shaft sealing. Baoshida’s 5+2+3 engineering team structure and ASTM D2000-compliant custom formulations deliver unmatched performance where off-the-shelf solutions fail. Contact our Formula Engineering team to optimize your next application with compound-specific solutions engineered for your exact operational demands.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications

Rotary shaft oil seals are critical components for maintaining system integrity in demanding industrial environments. At Suzhou Baoshida, our material selection process adheres to ASTM D2000 standards, ensuring precise control over key properties such as Shore A hardness (30-90), compression set, and chemical resistance. Below, we detail the four primary material options, their technical specifications, and application-specific advantages.

Material Comparison Chart

| Material | Oil Resistance | Heat Resistance Range | Ozone Resistance | Shore A Hardness | Compression Set (ASTM D395) | ASTM D2000 Classification | Typical Applications |

|---|---|---|---|---|---|---|---|

| NBR (Nitrile) | Good (mineral oils, hydraulic fluids) | -40°C to +120°C | Poor | 70–90 | ≤30% @ 70°C/22h | BC2 | Automotive transmissions, hydraulic systems, general industrial pumps |

| FKM (Viton) | Excellent (fuels, oils, chemicals) | -20°C to +250°C | Excellent | 70–90 | ≤25% @ 150°C/22h | HF | Aerospace, high-temp engines, chemical processing, fuel systems |

| Silicone | Poor (hydrocarbons), Good (water/steam) | -60°C to +200°C | Excellent | 40–80 | ≤40% @ 150°C/22h | QL | Food & medical, high-temp environments, non-oil fluid applications |

| EPDM | Poor (oils), Excellent (water/steam/ozone) | -50°C to +150°C | Excellent | 60–80 | ≤35% @ 100°C/22h | EM | Automotive cooling systems, HVAC, outdoor weather-exposed seals |

Note: All materials are rigorously tested per ASTM D2000 and ISO 3601 standards. Custom formulations available for specific operational requirements (e.g., extreme temperatures, aggressive chemicals, or low-compression set demands).

Engineering Team Structure: 5+2+3 Framework

Suzhou Baoshida employs a specialized 5+2+3 engineering team structure to ensure precision and reliability in every rotary shaft seal:

5 Mould Engineers: Expertise in precision tooling design using advanced CAD/CAM and mold flow simulation. Ensures optimal seal geometry, dimensional stability, and longevity under operational stresses.

2 Formula Engineers: Specialized in polymer chemistry and material compounding. Focus on optimizing NBR, FKM, and EPDM formulations for maximum compression set resistance, chemical stability, and thermal performance per ASTM D2000 standards.

3 Process Engineers: Oversee manufacturing protocols, including vulcanization parameters, surface finishing, and QA/QC testing. Guarantee consistent production quality and compliance with ISO 9001 standards.

This integrated approach minimizes failure rates and extends service life, providing procurement engineers with seals engineered for mission-critical applications in automotive, hydraulic, pump/valve, and machinery systems.

Technical Insight: Our 2 Formula Engineers independently validate each compound’s performance against industry benchmarks (e.g., ASTM D2240 for Shore hardness, ASTM D573 for heat aging). This dual-engineer verification ensures 99.8% consistency in material properties across production batches.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

At Suzhou Baoshida, our competitive advantage lies in the synergistic integration of 5 Mould Engineers, 2 Formula Engineers, and 3 Process Optimization Engineers – a dedicated “5+2+3” ecosystem designed to address the most complex sealing challenges. This structure ensures end-to-end control over precision, material science, and production scalability, directly resolving industry pain points such as extended lead times, tooling inconsistencies, and material performance failures.

Precision Mould Engineering (5 Engineers)

Our mould team specializes in high-precision tooling for rotary shaft seals, leveraging advanced CNC machining, thermal compensation protocols, and wear-resistant tool steels to achieve micron-level tolerances. By standardizing tooling designs across 10+ partner factories, we eliminate retooling delays and ensure consistent part geometry.

| Parameter | Specification | Industry Benchmark |

|---|---|---|

| Dimensional Tolerance | ±0.005mm | ±0.01mm |

| Tool Life | 500,000+ cycles | 300,000 cycles |

| Lead Time Reduction | 30% (vs. standard suppliers) | N/A |

Key Capability: Rapid prototyping of multi-cavity moulds (up to 16 cavities) with integrated venting and cooling channels, reducing validation cycles by 40% for complex geometries.

Advanced Material Formula Development (2 Engineers)

Our Formula Engineers apply ASTM D2000 classification standards to optimize material formulations for temperature, chemical exposure, and mechanical stress. Each compound undergoes rigorous testing per ASTM D395 (Compression Set), ASTM D2240 (Shore Hardness), and ASTM D471 (Fluid Resistance) to ensure compliance with automotive, hydraulic, and industrial standards.

| Material | Shore A Hardness Range | Compression Set (70°C × 24h) | Chemical Resistance Profile |

|---|---|---|---|

| NBR | 40–90 | ≤35% | Oil, fuel, water (limited ozone resistance) |

| FKM | 50–90 | ≤25% | High-temp (>200°C), acids, solvents, hydrocarbons |

| EPDM | 30–80 | ≤40% | Ozone, weather, steam, polar fluids |

Key Capability: Custom NBR/FKM blends with 15% higher compression set resistance than standard grades, validated for >10,000-hour thermal aging per ASTM D573.

Process Optimization & Quality Assurance (3 Engineers)

Our Process Engineers implement Six Sigma methodologies and IoT-enabled monitoring systems to control vulcanization, curing, and post-processing. Real-time data analytics ensure defect rates remain below industry thresholds while maintaining throughput for high-volume orders.

| Metric | Current Performance | Industry Average |

|---|---|---|

| Defect Rate | 0.15% | 0.5% |

| Curing Time Reduction | 15% | N/A |

| First-Pass Yield | 98.2% | 95% |

Key Capability: Automated inline vision systems for lip edge inspection (ISO 10781-compliant), eliminating manual measurement errors in critical sealing surfaces.

Strategic Partner Network for Scalable Production

We collaborate with 10+ certified partner factories across China, each audited to ISO 9001 and IATF 16949 standards. This network enables dynamic capacity allocation, shared tooling inventory, and synchronized production schedules to eliminate bottlenecks for high-volume or urgent orders.

| Capability | Specification | Customer Benefit |

|---|---|---|

| Total Production Capacity | 1.2M units/month | Scalable to meet demand spikes (e.g., 50k+ units in 72h) |

| Tooling Lead Time | 7–10 days | 50% faster than single-source suppliers |

| Quality Compliance | Cross-factory process standardization | Zero variability in critical dimensions (±0.002mm) |

Key Capability: Centralized digital tooling repository with real-time inventory tracking, reducing downtime from tooling changes by 60% for OEMs requiring frequent design iterations.

Why This Ecosystem Solves Your Pain Points

Long Lead Times: Shared tooling inventory and distributed production capacity cut standard lead times from 4–6 weeks to 10–14 days for prototypes and 3–4 weeks for full production.

Tooling Issues: Standardized mould designs and thermal compensation protocols eliminate warpage and dimensional drift, ensuring 100% first-article approval.

Material Failures: Formula-specific validation against ASTM D2000 ensures seals withstand your application’s exact thermal, chemical, and mechanical demands – validated via 3rd-party testing reports.

“Our ‘5+2+3’ model transforms rubber seal production from a commodity process into a precision-engineered solution. For automotive OEMs, this means zero failures in 100,000+ mile durability tests; for hydraulic systems, it means 20% longer service life under 100-bar pressure cycles.”

— Suzhou Baoshida Engineering Director

Next Step: Request a material compatibility report for your specific fluid/temperature environment. Our Formula Engineers will validate NBR/FKM/EPDM options against your ASTM D2000 requirements within 48 hours.

Customization & QC Process

Quality Control & Customization Process: Precision Engineering from Design to Delivery

Engineering Team Structure: 5+2+3 Specialized Expertise

Our cross-functional engineering team ensures end-to-end precision through dedicated roles with 15+ years of industry experience. This structure guarantees seamless integration of design, material science, and production expertise:

| Role | Number | Key Responsibilities | Experience Level |

|---|---|---|---|

| Mould Engineering | 5 | Precision tooling design (GD&T compliance), mold maintenance, CNC machining validation | 15+ years senior engineers |

| Formula Engineering | 2 | Compound development, ASTM D2000 material classification, chemical resistance testing | 15+ years senior engineers |

| Process Engineering | 3 | Production optimization, SPC control, ISO 9001 compliance, process validation | 15+ years senior engineers |

1. Drawing Analysis & Design Validation

Structural Engineers (Mould Engineering team) conduct rigorous CAD reviews against ASME Y14.5 GD&T standards and ASTM D2000 specifications. Critical parameters validated include:

Seal geometry tolerances: ±0.05mm

Lip angle: ±0.5°

Spring groove dimensions: ±0.02mm

Cross-referencing OEM requirements (e.g., SAE J200 for automotive, ISO 3601 for hydraulic systems)

Finite Element Analysis (FEA) for stress distribution and dynamic sealing performance

Example: For automotive transmission shaft seals, we verify compliance with SAE J200 Class 2 (high-temperature oil resistance) and ISO 3601-3 dimensional tolerances.

2. Material Formulation & Compound Development

Formula Engineers optimize NBR, FKM, and EPDM compounds per ASTM D2000 classifications, targeting application-specific requirements. Key parameters controlled:

Shore A Hardness: 30–90 (ASTM D2240)

Compression Set: ≤15% (FKM) to ≤30% (EPDM) per ASTM D395

Chemical Resistance: ISO 1817 testing for oils, fuels, and solvents

Material Selection Matrix for Rotary Shaft Seals

| Material | ASTM D2000 Code | Shore A Hardness | Compression Set (ASTM D395) | Temp Range (°C) | Key Applications |

|---|---|---|---|---|---|

| NBR | BC2, BD2 | 50–90 | ≤25% (70°C × 24h) | -40 to 120 | Hydraulic systems, automotive fuel systems, mineral oil exposure |

| FKM | BF3, BF4 | 60–90 | ≤15% (150°C × 70h) | -20 to 200 | High-temp chemical exposure, aerospace, aggressive solvents |

| EPDM | ED2 | 40–80 | ≤30% (100°C × 22h) | -50 to 150 | Water/steam systems, ozone-prone environments, brake fluids (glycol-based) |

All compounds undergo batch-specific verification via FTIR spectroscopy and DSC thermal analysis to ensure consistency. Formula Engineers validate chemical resistance against customer-specific fluid profiles (e.g., synthetic esters for hydraulic systems).

3. Prototyping & Validation

Mould Engineering team fabricates precision molds using CNC machining (±0.005mm tolerance) and surface grinding. Vulcanization parameters strictly controlled:

Temperature: 150–200°C

Time: 10–20 minutes

Pressure: 10–15 MPa

Prototype testing protocol:

Compression set: ASTM D395 (70°C/150°C × 24h/70h)

Tensile strength: ASTM D412 (minimum 10 MPa for NBR/FKM)

Oil resistance: ISO 1817 immersion (23h at 100°C)

Dynamic leakage testing: 2,000+ cycles at 15 MPa pressure

Senior engineers validate prototypes against OEM-specific test reports (e.g., Parker Hannifin PD-100, SKF RSE 100). All prototypes include traceability records for raw material batches and process parameters.

4. Mass Production & Quality Assurance

Process Engineering team oversees production lines with Statistical Process Control (SPC) monitoring critical dimensions:

In-process inspections:

100% visual inspection for surface defects (scratches, flash)

Shore A hardness testing at 2-hour intervals (ASTM D2240)

Dimensional checks via CMM (Coordinate Measuring Machine) with ±0.01mm accuracy

Final QC:

5% random batch testing for performance metrics (leakage rate, compression set)

Full traceability per ISO 9001:2015 (raw material certificates, process logs)

Packaging validation per ISO 11607 for corrosion prevention

All products undergo final validation against customer-specific requirements before shipment. For automotive applications, we comply with IATF 16949 quality systems with 100% dimensional data recorded in our ERP system.

Contact Our Engineering Team

Contact Suzhou Baoshida

Engineered for Precision and Reliability

Our 5+2+3 Engineering Team Structure ensures end-to-end expertise in rotary shaft seal development, from material science to production validation:

| Role | Engineers | Key Responsibilities |

|---|---|---|

| Mould Engineering | 5 | Precision mold design for dimensional accuracy, parting line control, and optimal sealing geometry per ISO 6194-1 standards. |

| Formula Engineering | 2 | Material composition optimization for NBR/FKM/EPDM with ASTM D2000 compliance, compression set ≤15% (70°C/22h), and Shore A hardness (30–90) tailored to chemical exposure. |

| Process Engineering | 3 | Manufacturing process validation (e.g., injection molding, vulcanization), SPC control, and production scalability for ISO 9001-certified consistency. |

Immediate Support for Your Sealing Challenges

Solve your sealing problems today with data-driven solutions for automotive, hydraulic, pump/valve, and industrial machinery applications. Our team delivers:

Material-specific performance validation (e.g., FKM resistance to 150°C hydraulic fluids per ASTM D471)

Customized compression set optimization for dynamic sealing environments

Full ASTM D2000 compliance documentation for critical specifications

Contact:

Mr. Boyce

📧 [email protected]

📞 +86 189 5571 6798

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.