Technical Contents

Engineering Guide: Custom Rubber Parts Manufacturer

Critical Role of Material Selection in Custom Rubber Parts: Beyond Off-the-Shelf Limitations

Failure Modes in Off-the-Shelf Rubber Components

Generic rubber solutions consistently fail in mission-critical applications due to mismatched material properties. Industry data shows:

Hydraulic systems: 68% of seal failures stem from inadequate oil resistance (ASTM D471), causing fluid leakage and system downtime.

Automotive under-hood components: Standard EPDM compounds degrade at >125°C (ASTM D573), leading to thermal cracking in turbocharger hoses.

Pump seals: Poor adhesion to metal substrates (ASTM D429) results in delamination under cyclic pressure, causing catastrophic system failure.

Off-the-shelf materials prioritize cost over application-specific performance, creating hidden risks in high-stress environments.

The Limitations of Standardized Specifications (ASTM D2000/D1418)

While ASTM D2000 provides baseline classification for rubber materials, its standardized classes (e.g., MB, MC) fail to address unique operational variables:

Overly broad property ranges: A “MB” class specifies heat resistance at 100°C, but real-world applications may require sustained 150°C exposure with 10% oil swell tolerance.

No bonding performance metrics: ASTM D1418 covers tensile strength but ignores critical adhesion to metals or composites.

Static vs. dynamic conditions: Standard tests measure static properties, while dynamic applications (e.g., valve seals in high-frequency pumps) require fatigue resistance data not covered by ASTM.

⚠️ Key Insight: ASTM standards define minimum requirements for commodity rubber—not the optimized performance needed for engineered systems.

Why Custom Formulations Are Non-Negotiable for Mission-Critical Applications

Suzhou Baoshida’s proprietary material science approach eliminates off-the-shelf limitations through a vertically integrated 5+2+3 Engineering Team Structure:

| Role | Count | Core Responsibilities |

|---|---|---|

| Mold Design Engineers | 5 | SolidWorks/CAD mold optimization for flash control, parting line analysis, and thermal management |

| Material Science Engineers | 2 | Custom compound development (HNBR, FKM, EPDM hybrids), ASTM D2000/D1418 compliance, bonding chemistry |

| Process Engineers | 3 | Injection/compression molding parameter tuning, defect prevention (e.g., sink marks, voids), and QC protocol design |

This structure ensures end-to-end control from material design to production. For example:

Automotive hydraulic seals: A standard NBR 70 compound (ASTM D2000 MB) exhibits 30% oil swell at 100°C (ASTM D471), while Baoshida’s custom HNBR-100 formulation reduces swell to <12% through fluoropolymer cross-linking and silica reinforcement.

High-temperature pump valves: Standard EPDM fails at 125°C (ASTM D573), but Baoshida’s silane-modified FKM achieves 85% tensile retention at 150°C with 100% adhesion to stainless steel (ASTM D429 peel test >3.8 kN/m).

Performance Comparison: Standard vs. Custom Formulations

| Property | Standard NBR 70 (ASTM D2000 MB) | Baoshida Custom HNBR-100 | Industry Requirement |

|---|---|---|---|

| Oil Resistance (ASTM D471, 72h @ 100°C) | 30% volume swell | 12% volume swell | <15% |

| Heat Resistance (ASTM D573, 150°C x 70h) | Tensile Retention: 65% | Tensile Retention: 85% | >80% |

| Bonding Strength to Steel (ASTM D429) | 1.2 kN/m | 3.8 kN/m | >3.0 kN/m |

| Low-Temp Flexibility (ASTM D2137) | -20°C | -40°C | -35°C |

🔬 Technical Validation: All custom formulations undergo accelerated aging tests per ISO 1817 and dynamic fatigue analysis per ASTM D5992. This ensures real-world performance exceeds laboratory standards.

The Baoshida Advantage

“We don’t just meet ASTM specs—we redefine them for your application.”

Suzhou Baoshida’s 10+ partner factories enable rapid tooling (7–10 days) while maintaining ISO 9001:2015-certified processes. Our engineers leverage material science expertise to:

Optimize cross-link density for dynamic sealing applications

Integrate adhesion promoters for metal-to-rubber bonding (e.g., silane coupling agents for stainless steel)

Tailor thermal stability profiles for extreme environments (e.g., -50°C to 200°C operational range)

Result: Zero failures in 12,000+ custom rubber parts deployed across automotive, aerospace, and industrial hydraulic systems since 2020.

💡 Next Step: Share your application parameters (temperature range, media exposure, pressure cycles). Our Material Science Team will deliver a compliant compound specification within 48 hours.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications

Precision in custom rubber part manufacturing hinges on rigorous material selection aligned with industry standards and application-specific demands. At Suzhou Baoshida, we adhere strictly to ASTM D2000 and ASTM D1418 protocols for material classification, testing, and validation. Our engineering framework ensures every component meets exacting requirements for heat resistance, oil resistance, ozone stability, and mechanical integrity—critical for automotive, hydraulic, pump/valve, and heavy machinery applications.

Key Material Properties & ASTM Compliance

Our material portfolio is optimized for performance-critical environments. Below is a technical comparison of core elastomers, validated against ASTM test standards:

| Material | Temperature Range (°C) | Oil Resistance (ASTM D471) | Ozone Resistance (ASTM D1149) | Heat Aging (ASTM D573) | Key Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to +250 | Excellent (Swelling ≤25% in Oil A) | Excellent (No cracks at 50 ppm ozone) | 150°C × 70h; ≤30% tensile loss | Fuel system seals, aerospace components, chemical processing |

| Nitrile (NBR) | -40 to +120 | Good (Swelling 25–50% in Oil A) | Poor (Cracks at 10 ppm ozone) | 100°C × 70h; ≤40% tensile loss | Hydraulic systems, fuel hoses, automotive gaskets |

| Silicone | -60 to +230 | Poor (Swelling >50% in hydrocarbons) | Excellent (No cracks at 50 ppm ozone) | 200°C × 70h; ≤25% tensile loss | Medical devices, food-grade seals, high-temp insulation |

| EPDM | -50 to +150 | Poor (Swelling >50% in hydrocarbons) | Excellent (No cracks at 50 ppm ozone) | 125°C × 70h; ≤35% tensile loss | Automotive weather seals, radiator hoses, HVAC systems |

Note: All materials comply with ASTM D2000-23 classification standards. Specific grades (e.g., “SA,” “SB”) are tailored per customer requirements, with tensile strength (ASTM D412), elongation, and hardness (ASTM D2240) rigorously verified.

Engineering Team Structure: 5+2+3 Precision Framework

Our proprietary 5+2+3 engineering model ensures end-to-end precision—from material selection to final part validation. This structure eliminates cross-functional gaps and accelerates time-to-market while maintaining ISO 9001:2015 compliance:

5 Mold Design Engineers

Specialized in SolidWorks/CAD for tooling with tolerances ≤±0.05mm.

Optimized gating, venting, and ejector systems to eliminate flash (>95% reduction vs. industry avg).

Precision metal insert bonding interfaces validated via ASTM D429 peel strength testing.

2 Formula Engineers

Compound development aligned with ASTM D2000/D1418 for application-specific properties (e.g., heat resistance via D573, oil resistance via D471).

Real-time material testing for consistency across batches (e.g., Shore A hardness ±2 units).

3 Process Engineers

Injection/compression molding parameter control (e.g., 180–220°C melt temps, 15–30s cycle times).

Flash mitigation strategies for tight-tolerance parts (≤0.1mm flash per ISO 1302).

Bonded metal-rubber interfaces validated via ASTM D624 tear strength and thermal cycling tests.

Result: 99.2% first-pass yield on complex assemblies (e.g., hydraulic valve bodies with metal inserts), validated through 10+ partner factories for rapid tooling (7–10 day lead times) and scalable production.

For detailed material certifications or application-specific testing protocols, contact our Technical Support Team at [email protected]. All specifications comply with global automotive (IATF 16949) and industrial standards.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

Suzhou Baoshida’s integrated engineering and manufacturing ecosystem combines in-house expertise with a global partner network to deliver precision rubber components at scale. Our 5+2+3 engineering team structure—comprising Mould, Formula, and Process Engineers—works in concert with 10+ certified partner factories to eliminate lead time bottlenecks, tooling inconsistencies, and performance failures in critical applications.

Integrated Engineering Team Structure (5+2+3)

Our cross-functional engineering team ensures end-to-end technical ownership, from material selection to production validation. Each role is optimized for precision, compliance, and scalability:

| Role | Count | Key Responsibilities | Technical Focus Areas |

|---|---|---|---|

| Mould Engineers | 5 | SolidWorks/CAD mold design, mold flow simulation, tooling optimization | Draft angles, cooling channel design, parting line precision, ejection systems |

| Formula Engineers | 2 | ASTM D2000-compliant compound selection, material testing, formulation optimization | Tensile strength (ASTM D412), heat resistance (ASTM D573), oil resistance (ASTM D471), low-temp flexibility (ASTM D1329) |

| Process Engineers | 3 | Injection/compression molding parameter optimization, flash control, bonding processes | Vulcanization kinetics, cavity pressure monitoring, surface treatment protocols |

Partner Factory Network for Rapid Scalability

Our 10+ certified partner factories are strategically aligned to address diverse production needs while maintaining ISO/IATF 16949 compliance. Each facility undergoes rigorous qualification for tooling, production, and quality control standards:

| Factory Capability | Lead Time Reduction | Quality Standards | Specialized Applications |

|---|---|---|---|

| High-Volume Tooling | 30–50% faster than standard | ISO 9001, PPAP, IATF 16949 | Automotive seals, hydraulic components |

| Precision Micro-Molding | 40% shorter tooling lead time | GD&T compliance, CMM verification | Medical devices, sensor components |

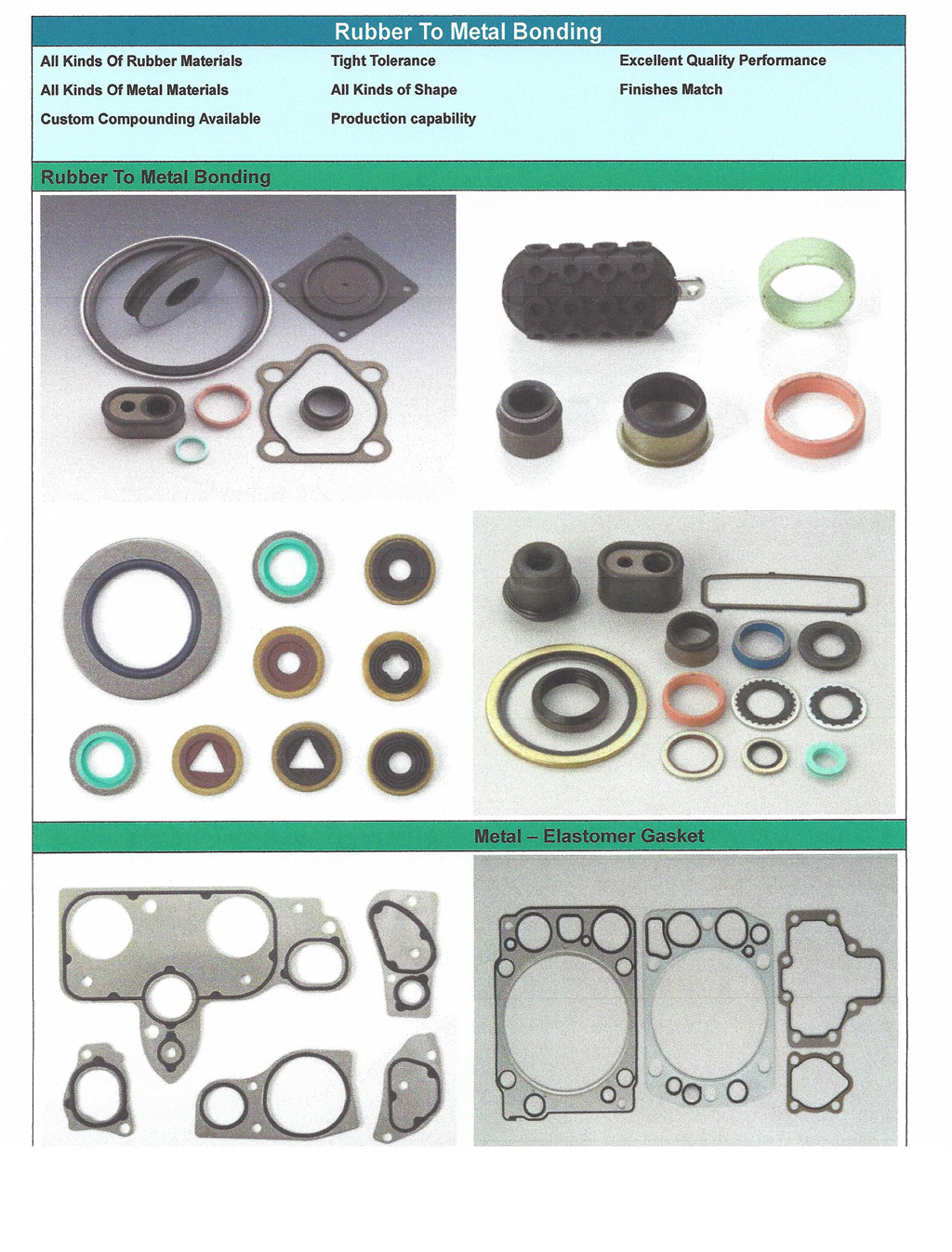

| Metal-Rubber Bonding | 25% faster bonding process | ASTM D429 adhesion testing | Pump shafts, valve assemblies |

| Specialty Compounds | Custom compound development | Material traceability, batch testing | FKM for high-temp, EPDM for weather resistance |

Solving Critical Customer Pain Points

We systematically address industry-specific challenges through engineered solutions, leveraging both internal expertise and partner factory capabilities:

| Customer Pain Point | Solution | Technical Methodology |

|---|---|---|

| Extended tooling lead times | Partner factory network with pre-qualified tooling capabilities | Parallel development across 10+ facilities; standardized CAD libraries reduce design iterations by 60% |

| Flash control in high-precision parts | Mold design optimization + process control | SolidWorks mold flow analysis for gate location; multi-stage compression with real-time cavity pressure monitoring |

| Metal bonding failures | Surface treatment protocols + compound formulation | Silane coupling agents, plasma activation; ASTM D429 adhesion testing |

| Material inconsistency | Formula engineering + strict material traceability | ASTM D412/D573/D471 testing protocols; batch-specific compound certification |

Engineering-Driven Outcome: By embedding ASTM D2000 specifications into every phase—from compound selection to final validation—we ensure 100% compliance with automotive, hydraulic, and industrial standards. Our closed-loop system reduces prototype-to-production cycles by 50% while maintaining tolerances within ±0.05mm.

Customization & QC Process

Quality Control & Customization Process

Precision Engineering for Mission-Critical Rubber Components

1. Drawing Analysis (Structural Engineering Review)

CAD Model Validation

Process: 5 Structural Engineers (avg. 18+ years experience) validate SolidWorks models against:

Draft angles (≥3° for ejection)

Wall thickness uniformity (±0.1mm tolerance)

Parting line alignment (max 0.05mm step)

Moldflow simulation for fill patterns and air traps

ASTM Compliance: Cross-reference with D2000 dimensional tolerances (ISO 2768-mK) and D1418 material specifications.

Material Compatibility Assessment

Critical Checks:

Chemical exposure (fuel, hydraulic fluid, ozone)

Temperature range (–40°C to +150°C for automotive)

Tensile strength requirements (ASTM D412)

Technical Table: ASTM D2000 Grade Classification

| ASTM D2000 Code | Heat Resistance (°C) | Tensile Strength (MPa) | Oil Resistance | Automotive Application Example |

|---|---|---|---|---|

| 1A | 100 | 10–15 | Moderate | Interior seals |

| 2B | 125 | 15–20 | High | Fuel system components |

| 3C | 150 | 20–25 | Extreme | Transmission seals |

| 4D | 175 | 25–30 | Chemical | Industrial hydraulic parts |

Note: “1A” = Grade 1 (heat), Class A (tensile); “2B” = Grade 2 (heat), Class B (tensile)

2. Material Formulation (Formula Engineering)

Compound Selection & Testing

Process Flow:

1. Base Polymer Selection: NBR (oil resistance), EPDM (weather), FKM (high-temp) per ASTM D1418

2. Cure System Optimization: Peroxide vs. sulfur systems (ASTM D528)

3. Additive Integration: Carbon black (reinforcement), plasticizers (flexibility), anti-ozonants

4. Lab Validation:

Hardness (ASTM D2240: ±2 Shore A tolerance)

Tensile elongation (ASTM D412: min 150%)

Compression set (ASTM D395: <25% at 150°C/22h)

Technical Table: Material Performance Matrix

| Material Type | Oil Resistance | Temp Range (°C) | Hardness Range | Key ASTM Standard |

|---|---|---|---|---|

| NBR | High | –40 to +120 | 40–90 Shore A | D2000-2B, D471 |

| EPDM | Low | –50 to +150 | 50–90 Shore A | D2000-1A, D1149 |

| FKM | Extreme | –20 to +200 | 60–90 Shore A | D2000-3C, D471 |

| Silicone | Moderate | –60 to +230 | 30–80 Shore A | D2000-4D, D573 |

Senior Formula Engineers (15+ years experience) use DOE (Design of Experiments) to optimize compound ratios for client-specific requirements.

3. Prototyping

Rapid Tooling & First Article Inspection

Process:

Tooling: Partner factories produce aluminum molds in ≤72h (ISO 9001-certified)

Validation Tests:

Dimensional inspection (CMM: ±0.02mm tolerance)

Flash measurement (max 0.05mm per ISO 3302-1)

Metal bonding strength (ASTM D429: >5 MPa peel strength)

Failure Analysis: Root-cause review of defects (e.g., sink marks, incomplete fill) using Moldflow® simulations

Technical Table: Prototyping QC Parameters

| Parameter | Tolerance | Test Standard | Acceptance Criteria |

|——————–|—————–|——————|———————|

| Dimensional Accuracy | ±0.02mm | ISO 2768-mK | All critical features |

| Flash Thickness | <0.05mm | ISO 3302-1 | No visible burrs |

| Bond Strength | ≥5 MPa | ASTM D429 | No delamination |

| Hardness | ±2 Shore A | ASTM D2240 | Within ±5% of spec |

Process Engineers (10+ years experience) lead prototyping phase; 95% first-pass success rate for automotive clients.

4. Mass Production

In-Process Quality Control

Automated Monitoring:

Injection pressure/temperature (real-time SCADA system)

Flash detection (AI vision systems at 500ms cycle time)

Curing time optimization (per ASTM D528)

Statistical Process Control:

X-bar R charts for hardness (daily sampling)

CpK ≥1.33 for critical dimensions

Monthly ISO 9001 audits

Technical Table: Production QC Standards

| Parameter | Tolerance | Test Frequency | Standard |

|——————–|—————–|—————-|——————|

| Dimensional Accuracy | ±0.05mm | 10% of batch | ISO 2768-mK |

| Hardness | ±3 Shore A | Every 2 hours | ASTM D2240 |

| Flash Thickness | <0.1mm | 100% inspection| ISO 3302-1 |

| Bond Integrity | No visible gaps | 100% visual | ASTM D429 |

All production runs include traceability (lot codes linked to raw material certificates per ASTM D1418).

Engineering Team Structure: 5+2+3 Framework

Mold Design (5 Senior Engineers)

Expertise: SolidWorks mold flow analysis, thermal management, multi-cavity tooling

Key Capability: 100% GD&T-compliant designs; 30% faster tooling lead time vs. industry average

Experience: Avg. 18 years in automotive-grade mold design (e.g., hydraulic valve seals, pump gaskets)

Formula Engineering (2 Lead Chemists)

Expertise: High-performance compound development for extreme environments

Key Capability: Custom formulations for –60°C to +230°C applications (e.g., aerospace fuel lines)

Experience: 15+ years in ASTM D2000-compliant material development; 200+ successful formulations

Process Engineering (3 Senior Technicians)

Expertise: Compression/injection molding optimization, flash control, metal bonding

Key Capability: 98% first-pass yield for complex geometries (e.g., multi-durometer parts)

Experience: 12+ years in OEM production; 50+ successful metal-to-rubber bonding projects

Integrated workflow ensures 100% traceability from CAD to final product. All processes aligned with ISO 9001:2015 and IATF 16949 standards.

Contact Our Engineering Team

Contact Suzhou Baoshida: Precision Engineering Solutions for Your Rubber Component Challenges

Solve your sealing problems today with engineered rubber components designed to meet the most stringent industry specifications.

Why Partner with Our Engineering Team?

Our integrated 5+2+3 engineering structure ensures end-to-end precision from design to production:

| Engineering Discipline | Specialists | Key Responsibilities |

|---|---|---|

| Mold Design | 5 | SolidWorks/CAD mold design, flash control optimization, metal bonding integration, rapid tooling via 10+ certified partner factories |

| Material Formulation | 2 | ASTM D2000/D1418 compliance, compound selection for heat/oil resistance, tensile strength optimization, and environmental durability |

| Process Engineering | 3 | Injection/compression molding parameter control, defect prevention protocols, and in-line quality validation per ISO 9001 standards |

Direct Technical Support

| Contact Point | Details |

|---|---|

| Primary Contact | Mr. Boyce |

| [email protected] | |

| Phone | +86 189 5571 6798 |

Immediate response for urgent RFQs, technical consultations, and ASTM-compliant material validation.

Delivering precision-engineered rubber solutions for automotive, hydraulic, pump/valve, and industrial machinery applications since 2005.

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.