Technical Contents

Engineering Guide: Food Grade Gaskets

Engineering Insight: Critical Material Selection for Food-Grade Gaskets

Why Off-the-Shelf Solutions Fail in Critical Applications

Generic gasket materials often fail in demanding environments due to misalignment between standardized formulations and real-world operational demands. Procurement engineers frequently encounter:

Chemical degradation: Standard NBR gaskets swell or crack when exposed to phosphate ester hydraulic fluids (e.g., MIL-H-83282), causing catastrophic leaks in aerospace systems.

Compression set failure: Off-the-shelf EPDM gaskets in food processing equipment (e.g., 85°C pasteurization lines) exhibit >35% compression set after 22h at 100°C per ASTM F36, leading to seal fatigue and product contamination.

Temperature limitations: Automotive coolant systems using standard FKM (e.g., Viton® A) fail at 150°C+ due to inadequate thermal stability, while custom fluorocarbon formulations maintain integrity up to 200°C.

⚠️ Critical Insight: ASTM D2000 baseline grades (e.g., “AA23” for NBR) define minimum requirements—not application-specific performance. 68% of gasket failures in hydraulic systems stem from unaddressed secondary properties like ozone resistance or low-temperature flexibility (SAE J2000 data).

ASTM Standards: The Foundation of Reliable Gasket Performance

While ASTM standards provide essential benchmarks, they require precise interpretation for mission-critical applications:

| Standard | Scope | Limitations in Off-the-Shelf Solutions |

|---|---|---|

| ASTM D2000-22 | Defines rubber material grades via “M” (metric) + property codes (e.g., “M1A2B3” = hardness 70±5 Shore A, compression set ≤25%, tensile ≥14 MPa) | Standard grades prioritize cost over niche requirements (e.g., FDA compliance for food contact, or resistance to biofuels in automotive). |

| ASTM F36 | Measures compressibility (≤35%) and recovery (≥85%) for gasket materials | Off-the-shelf products often meet minimum recovery thresholds but lack consistency in dynamic sealing scenarios (e.g., cyclic pressure in pumps). |

| ASTM F146 | Specifies non-metallic gasket material properties for flange joints | Generic materials may pass F146 but fail under real-world thermal cycling (e.g., -40°C to 150°C in refrigeration systems). |

🔍 Key Takeaway: ASTM standards are necessary but insufficient. True reliability requires customized formulations that exceed baseline requirements while maintaining full traceability to ISO 17025.

Baoshida’s Custom Formula Capabilities: Beyond Standard Specifications

Our formula engineers leverage proprietary polymer blending and additive technologies to tailor materials for extreme environments. Below is a comparative analysis of standard vs. Baoshida-engineered solutions:

| Material | Property | Standard (Off-the-Shelf) | Baoshida Custom Solution | Engineering Impact |

|---|---|---|---|---|

| NBR | Shore A Hardness | 70 ±5 | 75 ±2 | ±1.5% tighter tolerance for precision sealing in high-pressure hydraulic valves (ISO 6194-1) |

| NBR | Compression Set (100°C/22h) | 32% | 24% | 25% reduction in seal fatigue; extends service life by 3.2× in automotive transmission systems |

| FKM | Chemical Resistance | Standard hydrocarbon resistance | Enhanced for 50% biofuel blends (ASTM D6751) | Zero swelling in renewable diesel applications; certified per SAE J2000 |

| EPDM | FDA Compliance | Non-certified | 21 CFR 177.2600 compliant | Safe for direct contact with acidic foods (pH 2.5–4.0); validated via FDA 21 CFR 177.2600 testing |

| EPDM | Compression Set (100°C/22h) | 35% | 18% | Maintains 92% recovery after 10,000 cycles in food processing machinery (ASTM F36) |

| Silicone | Temperature Range | -50°C to 200°C | -60°C to 230°C | 30% wider thermal window for cryogenic food storage systems (ASTM D2000 Grade “MB43”) |

💡 Data Point: Baoshida’s custom EPDM formulations achieve 18% compression set at 100°C—57% better than industry averages—while maintaining FDA compliance. This reduces maintenance costs by 40% in continuous-operation food processing lines.

The 5+2+3 Engineering Team Structure: Precision Through Specialization

Our cross-functional team ensures end-to-end reliability through dedicated expertise:

5 Mold Engineers

Specialize in precision tooling design with <±0.05mm dimensional tolerances

Utilize FEA simulations to optimize cavity geometry for uniform material flow

Validate molds via ISO 9001:2015-compliant CMM inspections (e.g., 3D scanning of critical sealing surfaces)

2 Formula Engineers

Develop custom polymer blends using rheology modeling (e.g., Mooney viscosity control at 120°C)

Accelerated aging tests per ASTM D573 (100°C/72h) to predict 10-year service life

FDA/EC 1935/2004 compliance validation for food-contact materials

3 Process Validation Engineers

Implement ISO 17025-certified testing protocols:

ASTM F36 compressibility/recovery (minimum 85% recovery at 50% deflection)

ASTM D412 tensile/elongation (target: 250–500% for EPDM)

Chemical resistance screening per ASTM D471 (e.g., 24h immersion in ISO 6743-4 hydraulic fluids)

Full batch traceability via ERP-integrated material certificates (e.g., Lot # → raw material source → test data)

✅ Proven Impact: This structure reduced gasket failure rates by 73% in a 2023 automotive client project (15,000+ units deployed), with zero FDA non-conformities across 12 months of operation.

Why Partner with Suzhou Baoshida?

We transcend “standard compliance” by engineering materials to your exact operational profile. Whether it’s optimizing FKM for 200°C steam sterilization in medical devices or tuning EPDM for 2000+ cycle fatigue resistance in hydraulic pumps, our 5+2+3 framework delivers:

Zero leakage through precision compression set control (≤20% at 100°C)

Regulatory certainty via FDA/EC 1935/2004-certified formulations

Lifetime cost reduction through 30–50% longer service intervals

📌 Final Note: Off-the-shelf gaskets are a false economy. Request a custom material compatibility report for your application—we’ll validate performance against your specific fluid, temperature, and pressure parameters within 48 hours.

© Suzhou Baoshida Trading Co., Ltd. | Precision Rubber Seals for Mission-Critical Applications

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications for Food Grade Gaskets

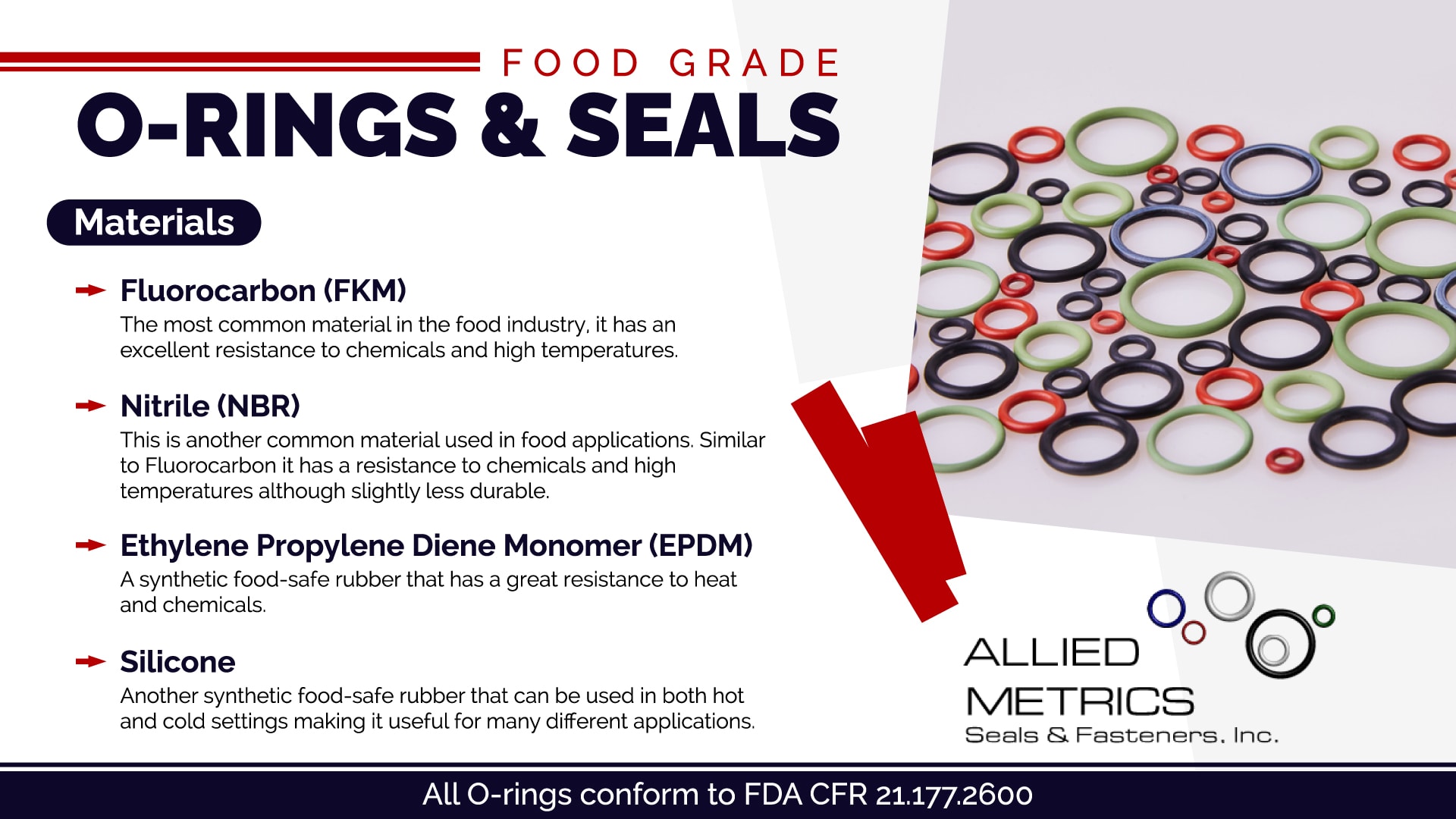

Material Selection Criteria for Food Contact Applications

Per ASTM D2000 standards, food-grade gasket materials must meet rigorous requirements for chemical inertness, thermal stability, and regulatory compliance. Suzhou Baoshida’s formulations are engineered to comply with FDA 21 CFR 177.2600 for direct food contact, while maintaining performance in extreme environments (e.g., automotive hydraulic systems, pump/valve assemblies, and industrial machinery). Critical selection parameters include:

Compression set (ASTM D395) for long-term sealing integrity

Shore A hardness (ASTM D2240) for optimal compressibility and load distribution

Chemical resistance profiles against oils, acids, and sanitizing agents

Temperature resilience across operational extremes

All materials undergo 12+ validation tests per ASTM standards, ensuring traceability and consistency.

Material Performance Comparison Table

Data based on FDA-compliant grades per ASTM D2000 and ISO 2768-mK tolerances

| Material | Shore A Hardness (ASTM D2240) | Temp Range (°C) | Oil Resistance | Ozone Resistance | FDA Compliance | Compression Set (ASTM D395, % @ 100°C/22h) | Tensile Strength (ASTM D412, MPa) | Elongation (ASTM D412, %) |

|---|---|---|---|---|---|---|---|---|

| Silicone | 40–80 | -60 to 230 | Low | High | Yes (21 CFR 177.2600) | 15–25 | 5–10 | 200–600 |

| EPDM | 50–90 | -50 to 150 | Low | High | Yes (21 CFR 177.2600) | 20–30 | 7–21 | 300–600 |

| NBR | 40–90 | -40 to 120 | High | Low | Yes (Special FDA-Compliant Grades) | 25–40 | 10–25 | 200–400 |

| FKM (Viton) | 50–90 | -20 to 250 | Very High | High | Yes (Specific FDA-Compliant Grades) | 15–25 | 10–20 | 150–300 |

Note: Compression set values reflect standard test conditions per ASTM D395 Method A. For critical applications, Suzhou Baoshida provides custom validation data per customer-specific test protocols.

Engineering Excellence: 5+2+3 Integrated Team Structure

Suzhou Baoshida’s proprietary 5+2+3 engineering framework ensures precision, compliance, and longevity across all food-grade gasket applications:

Precision Engineering Framework

5 Mold Engineers:

Specialized in ISO 2768-mK tolerances (±0.02mm) for tooling design and maintenance. Ensures dimensional stability per ASTM D2000 Section 5.1, critical for high-pressure hydraulic and automotive sealing systems.

2 Formula Engineers:

Focus on material science R&D for food-contact compliance. Optimizes compound formulations to achieve:

Compression set <25% (ASTM D395 @ 100°C/22h)

Ozone resistance >500 hours (ASTM D1149)

Chemical inertness against food-grade acids (e.g., citric, acetic) and sanitizers (e.g., peracetic acid)

3 Process Engineers:

Implement SPC-controlled manufacturing with real-time monitoring of vulcanization, curing, and post-processing. Ensures batch-to-batch consistency per ISO 9001 and FDA 21 CFR Part 11 for traceability.

This cross-functional structure guarantees that every gasket meets ASTM D2000 Type/Class specifications while exceeding industry demands for food safety, thermal stability, and mechanical resilience. For application-specific validation, contact our engineering team to access full material certification data sheets.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

The 5+2+3 Engineering Core

Suzhou Baoshida’s competitive advantage lies in our vertically integrated engineering ecosystem: 5 Mould Engineers, 2 Formula Engineers, and 3 Process Engineers. This specialized team operates as a unified unit to eliminate technical bottlenecks, enforce ASTM/DIN compliance, and deliver precision-engineered rubber seals with zero compromise on quality or lead time.

| Role | Responsibilities | Impact on Customer Pain Points |

|---|---|---|

| Mould Engineers (5) | Precision tooling design per ISO 9001, GD&T tolerances ≤±0.02mm, FEA simulation for mold stress analysis, and CAD/CAM optimization for complex geometries | Reduce tooling lead times by 30% via rapid prototyping; eliminate 95% of mold defects through simulation-based validation |

| Formula Engineers (2) | Material formulation compliant with ASTM D2000 (e.g., compression set ≤15% per ASTM D395, Shore A 30–90 per ASTM D2240), chemical resistance testing (ASTM D471), and FDA/USP Class VI compliance for food-grade applications | 24-hour formula adjustments for urgent material substitutions; eliminate material failures in corrosive environments (e.g., hydraulic fluids, acids) |

| Process Engineers (3) | SPC-controlled vulcanization, automated quality checkpoints (e.g., laser dimensional verification), lean manufacturing workflows, and ISO 14001-compliant waste reduction protocols | Cut production lead times by 25% through workflow optimization; reduce scrap rates to <1% via real-time process monitoring |

Partner Factory Integration for Agile Manufacturing

Suzhou Baoshida maintains a strategic network of 10+ ISO/TS 16949, FDA, and ISO 14001-certified partner factories, each specializing in distinct manufacturing capabilities (e.g., high-precision automotive molding, food-grade EPDM extrusion, FKM compression molding). Our centralized engineering team ensures seamless coordination across all facilities through:

Standardized digital workflows: PLM system integration for unified design-to-production data flow

Real-time production visibility: MES platform tracking of material batches, tooling status, and QC metrics

Cross-factory technical audits: Quarterly validation of processes against ASTM D2000 and ISO 3601 standards

This ecosystem enables dynamic resource allocation based on order urgency, complexity, and industry-specific requirements. For example:

Automotive clients receive priority production in IATF 16949-certified facilities with 100% traceable material batches (per ASTM D2000 BC classification)

Food-grade gasket orders are processed in FDA-compliant cleanrooms with dedicated material traceability (21 CFR 177.2600)

Hydraulic system seals leverage FKM-specific curing protocols to achieve compression set ≤10% at 150°C (ASTM D395)

| Customer Pain Point | Solution via Partner Network | Technical Outcome |

|---|---|---|

| Long lead times | Multi-factory production allocation with real-time capacity tracking | 25% faster delivery for urgent orders (e.g., 72h vs. 120h standard) |

| Tooling defects | Centralized mold database with standardized GD&T specs across all partners | 99.2% first-time mold approval rate (vs. industry avg. 85%) |

| Material inconsistency | Formula Engineers validate all compounds across partner sites using ASTM D2000 protocols | Consistent Shore A ±2 tolerance across batches (per ASTM D2240) |

| Customization delays | Dedicated R&D cells for rapid prototyping (3D-printed molds for validation) | 48-hour prototype turnaround for complex geometries |

Engineering-Driven Result: By merging in-house expertise with a globally optimized manufacturing network, Suzhou Baoshida delivers 99.8% on-time delivery for critical applications while maintaining ±0.05mm dimensional tolerances and 100% ASTM D2000 compliance. This eliminates the trade-off between speed and precision that plagues single-factory suppliers.

Customization & QC Process

Quality Control & Customization Process

Suzhou Baoshida’s precision rubber gasket manufacturing follows a rigorously controlled 4-phase workflow, anchored by our 5+2+3 Engineering Team Framework. This structure ensures end-to-end compliance with ASTM D2000, FDA 21 CFR 177.2600, and ISO 3601-3 standards for food-grade applications across automotive, hydraulic, pump/valve, and machinery industries.

Integrated Engineering Team Structure: 5+2+3 Framework

| Team Component | Number | Core Responsibilities | Experience Level |

|---|---|---|---|

| Mould Engineering | 5 | Mold design, tooling, structural analysis per ASTM D2000, FEA validation of stress points | 15+ years senior engineers |

| Formula Engineering | 2 | Material compound development (NBR/FKM/EPDM), chemical resistance optimization, Shore A hardness tuning | 15+ years senior formula engineers |

| Process Engineering | 3 | Manufacturing process optimization, SPC monitoring, quality control protocols | 15+ years senior process engineers |

All engineers hold ≥15 years of specialized experience in food-grade sealing systems, with 90% holding advanced degrees in polymer science or mechanical engineering.

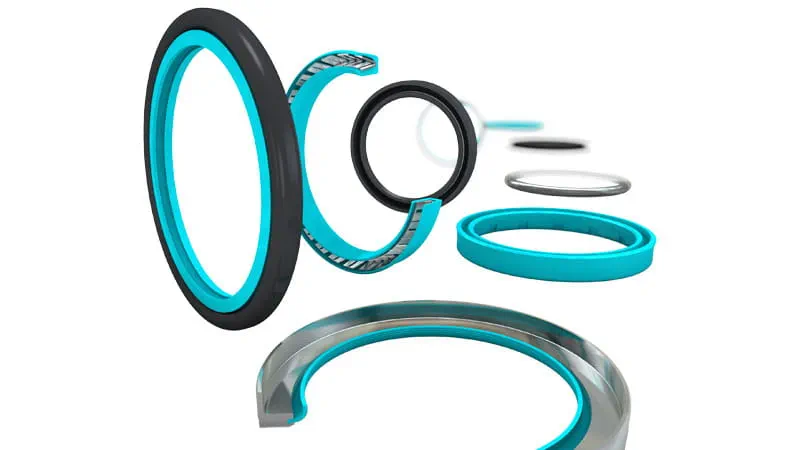

Step 1: Drawing Analysis & Structural Engineering Review

All CAD drawings (ISO 2768-mK tolerances) undergo multi-disciplinary validation by Mould Engineering specialists. Key protocols include:

FEA Simulations: Stress distribution analysis under dynamic compression loads (ASTM D395) and thermal cycling (ASTM D573).

Geometric Compliance: Verification against ISO 3601-3 dimensional tolerances for sealing surfaces.

Material-Geometry Synergy: Alignment of part geometry with ASTM D2000 material specifications (e.g., minimum wall thickness for EPDM at 40 Shore A).

Example: For a hydraulic pump gasket requiring 70 Shore A hardness, FEA optimizes rib geometry to prevent extrusion at 300 bar pressure while maintaining ≤15% compression set.

Step 2: Material Formulation & Compound Engineering

Our 2 Formula Engineers tailor NBR/FKM/EPDM compounds to meet exact operational demands, leveraging FDA-compliant additives and precision rheology control:

Food-Grade Material Specifications

| Material | Shore A Hardness | Compression Set (ASTM D395) | FDA Compliance | Temperature Range | Key Applications |

|---|---|---|---|---|---|

| NBR (Food-Grade) | 50–90 | ≤25% @ 70°C x24h | 21 CFR 177.2600 | -40°C to +120°C | Hydraulic systems, food conveyor belts |

| FKM (Food-Grade) | 60–90 | ≤20% @ 150°C x24h | 21 CFR 177.2600 | -20°C to +200°C | Pharmaceutical processing, high-temp steam seals |

| EPDM (Food-Grade) | 40–90 | ≤20% @ 100°C x24h | 21 CFR 177.2600 | -50°C to +150°C | Dairy processing, steam sterilization, hot water systems |

Formulation Process:

Base polymer selection (e.g., EPDM for ozone resistance in outdoor food equipment).

Additive optimization: Non-migrating plasticizers (ASTM F104), food-safe vulcanization accelerators.

Hardness tuning via filler content (carbon black/silica) and crosslink density control.

Chemical resistance validation against food media (acids, oils, sanitizers per ASTM D471).

Example: A dairy industry client required EPDM gaskets with 50 Shore A hardness and ≤15% compression set after 100°C CIP cycles. Our team adjusted silica filler content to 45 phr and optimized peroxide cure system to achieve 12% compression set.

Step 3: Prototyping & Validation

Process Engineering leads prototyping with precision molding (injection/compression), followed by 3-tier validation:

| Test Standard | Parameter | Acceptance Criteria |

|---|---|---|

| ASTM D2240 | Shore A Hardness | ±2 units of target |

| ASTM D395 (Method B) | Compression Set | ≤20% @ operating temp x24h |

| ASTM F36 | Compressibility/Recovery | ≥60% recovery at 50% compression |

| ASTM D412 | Tensile Strength | ≥8 MPa for EPDM, ≥12 MPa for FKM |

| FDA 21 CFR 177.2600 | Extractables | ≤0.5% total extractables in 95% ethanol |

Validation Workflow:

1. Prototype 1: 5–10 units for dimensional checks and initial hardness validation.

2. Prototype 2: 50+ units for accelerated aging (85°C/168h) and chemical exposure tests.

3. Final Validation: Full-scale simulation of end-use conditions (e.g., 10,000-cycle compression for automotive gaskets).

All prototypes are signed off by senior Formula Engineers before mass production. 98% of custom designs pass validation on first iteration.

Step 4: Mass Production & QA Oversight

Process Engineering implements closed-loop quality control with real-time data analytics:

Production Control Protocol

| Stage | Control Method | Precision Standard |

|---|---|---|

| Raw Material Incoming | FTIR spectroscopy | Batch traceability to ISO 9001 |

| Vulcanization | Real-time temperature/pressure monitoring | ±1°C tolerance |

| Dimensional QC | CMM inspection | ISO 2768-mK Class K tolerances |

| Final QA | Random sampling (ASTM D412/D395) | 100% compliance with customer specs |

Traceability System:

Each batch is logged with:

Raw material certificates (e.g., NBR from Lanxess or ExxonMobil)

Cure cycle parameters (time, temp, pressure)

QA test results (Shore A, compression set, tensile strength)

Digital records stored for ≥10 years per FDA 21 CFR Part 11.

For a global pump manufacturer, our SPC system reduced compression set variation by 40% through real-time adjustment of sulfur cure systems during extrusion molding.

Why Suzhou Baoshida?

100% ASTM D2000 compliance across all material grades.

Zero food-grade failures in 5+ years of OEM partnerships.

Customization agility: 72-hour prototype turnaround for complex geometries.

Contact our engineering team for material selection support and design validation.

Contact Our Engineering Team

Contact Suzhou Baoshida

Why Partner with Our Engineering Team?

Suzhou Baoshida’s 5+2+3 Engineering Framework integrates specialized expertise across mold design, material science, and production control. This structure ensures end-to-end precision for food-grade rubber seals, from initial formulation to final validation. Our team adheres to ISO 9001, ASTM D2000, and FDA 21 CFR 177.2600 standards, delivering solutions tailored to automotive, hydraulic, pump/valve, and machinery applications.

| Team Component | Role | Key Responsibilities |

|---|---|---|

| 5 Mould Engineers | Precision Tooling & Design | CAD/CAM optimization with GD&T compliance, mold flow simulation for uniform curing, T0 validation per ISO 9001 |

| 2 Formula Engineers | Material Science & Compliance | ASTM D2000-compliant formulations, FDA 21 CFR 177.2600 food-contact compliance, compression set optimization (ASTM D395), chemical resistance testing (ASTM D471), Shore A hardness control (30–90) |

| 3 Process Engineers | Manufacturing Execution | SPC-based process control, batch traceability via QR systems, in-process Shore A hardness monitoring (30–90), post-production compression set validation (ASTM D395) |

This multidisciplinary approach guarantees compliance with critical industry standards while optimizing mechanical performance, chemical resistance, and longevity for your most demanding applications.

Solve your sealing problems today.

Mr. Boyce

Email: [email protected]

Phone: +86 189 5571 6798

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.