Technical Contents

Engineering Guide: Custom Molded Rubber Products

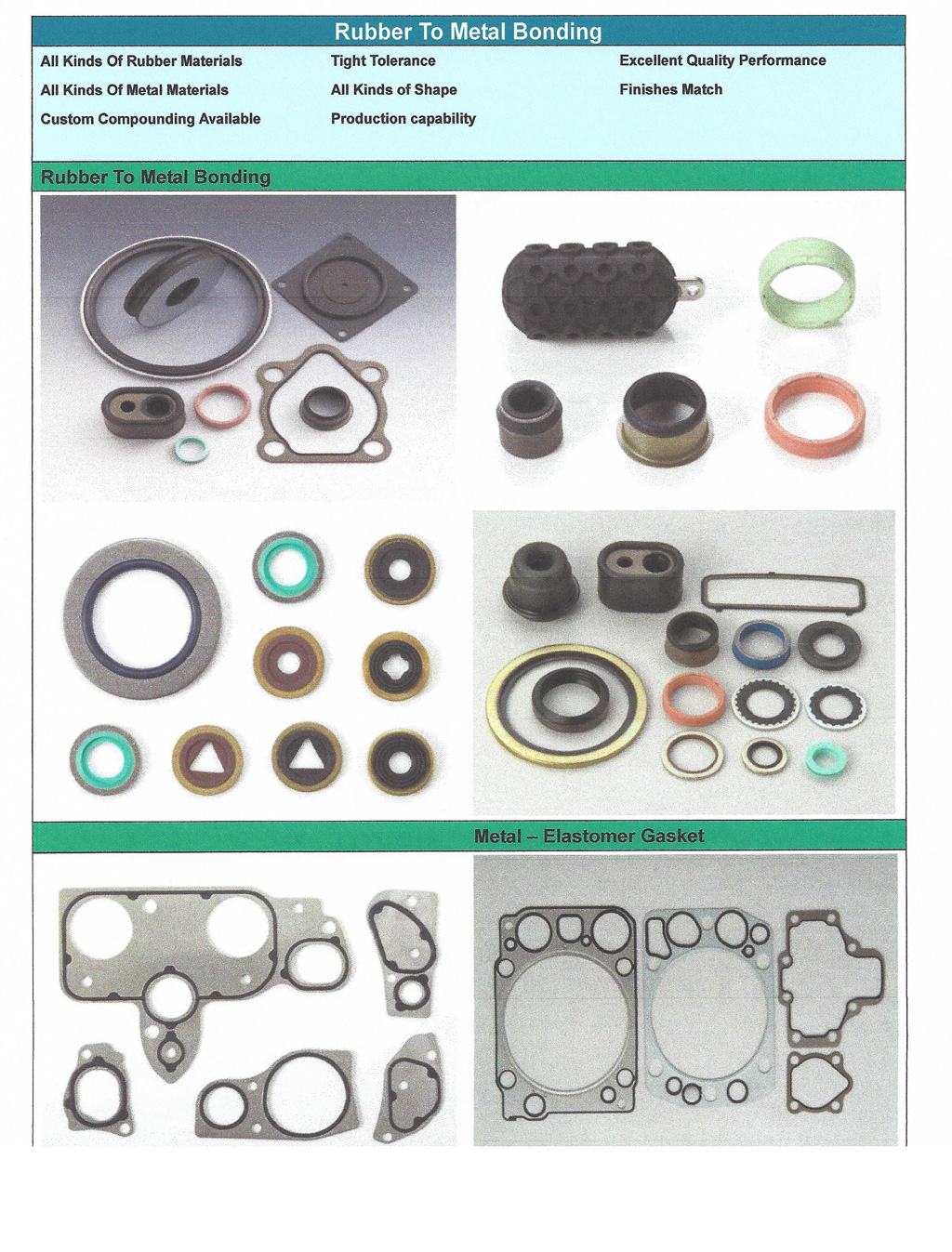

Critical Role of Material Selection in Custom Molded Rubber Applications

In mission-critical applications across automotive, hydraulic, pump/valve, and machinery industries, rubber component failure due to improper material selection is not an exception—it is the rule. Off-the-shelf solutions fail because they prioritize general-purpose compliance over application-specific performance requirements. Standardized materials cannot account for nuanced operational variables such as thermal cycling extremes, aggressive chemical exposure, or dynamic mechanical loads. This results in premature degradation, seal leakage, and catastrophic system failures that far exceed the cost of custom-engineered solutions.

Why Off-the-Shelf Solutions Fail: The Hidden Costs of Standardization

| Application Scenario | Off-the-Shelf Material Issue | Resulting Failure | Cost Impact |

|---|---|---|---|

| Automotive Transmission Seal (ATF, 150°C) | Standard NBR (Class 2) insufficient for high-temp ATF exposure | Swelling, seal failure, fluid leakage | $15k–$50k per vehicle recall |

| Hydraulic Cylinder Rod Seal (Synthetic Oil, -40°C to 120°C) | EPDM with poor oil resistance | Swelling, seal degradation, system contamination | $25k–$75k downtime per incident |

| Industrial Pump Gasket (Ozone Exposure) | Natural Rubber (NR) without ozone stabilizers | Surface cracking, loss of elasticity | $18k–$40k replacement costs |

| Food-Grade Hose (FDA Compliance) | Standard silicone without certified food-grade additives | Contamination risk, regulatory non-compliance | $50k+ fines + brand damage |

Engineering Insight: Standardized materials are designed for average conditions. Real-world applications demand extreme performance—where 5°C temperature variance or 0.1% chemical concentration difference can trigger failure. Off-the-shelf solutions lack the precise material science required to address these variables.

The Baoshida Custom Formula Advantage: Precision Engineering for Mission-Critical Applications

At Suzhou Baoshida, we deploy a specialized 5+2+3 Engineering Team Structure to eliminate material selection risks. This cross-functional team ensures every aspect of rubber component performance—from molecular formulation to production execution—is optimized for your exact application requirements.

| Team | Role | Key Responsibilities |

|---|---|---|

| Structural Engineers (5) | Mold Design & Tooling | SolidWorks CAD modeling, mold flow simulation, flash control optimization, metal bonding interface design |

| Formula Engineers (2) | Material Science | Custom compound development, ASTM D2000 specification compliance, material testing (ASTM D575, D412, D2240) |

| Process Engineers (3) | Manufacturing Optimization | Injection/compression molding parameter tuning, flash minimization, bonding process validation, production scalability |

Technical Execution: Our Formula Engineers leverage proprietary compound libraries to tailor polymer matrices for specific environmental stressors. For example, in hydraulic systems requiring -40°C to 150°C operation with synthetic oil exposure, we develop NBR-based compounds with 20% higher oil resistance (ASTM D471) and 30% lower compression set (ASTM D395) than standard grades—verified through accelerated life testing.

ASTM D2000 Compliance: The Foundation of Reliable Material Specification

ASTM D2000 is the global standard for rubber material classification. It provides a systematic framework to define performance-critical properties—ensuring specifications are unambiguous and measurable. Our engineers use this standard to translate application requirements into precise material codes, eliminating interpretation errors.

| Code Component | Description | Example in M2B317 | Industry Standard Reference |

|---|---|---|---|

| M | SI Units | M = Metric (mm, °C) | ASTM D2000 Section 4.1 |

| 2 | Performance Grade | 2 = Standard grade (higher = better performance) | ASTM D2000 Table 1 |

| B | Material Type | B = Nitrile Rubber (NBR) | ASTM D2000 Table 2 |

| 3 | Heat Resistance Class | 3 = Minimum 125°C operating temp | ASTM D2000 Table 3 |

| 1 | Oil Resistance Class | 1 = Moderate resistance (Class 1–5) | ASTM D2000 Table 4 |

| 7 | Hardness (Shore A) | 7 = 70 Shore A ± 5 | ASTM D2240 |

Engineering Validation: For automotive transmission seals, we specify M2B317 (NBR, 125°C heat resistance, moderate oil resistance, 70 Shore A hardness) as baseline. When operating conditions exceed this—such as exposure to phosphate ester-based hydraulic fluids—we upgrade to M2F448 (FKM, 180°C heat resistance, Class 4 oil resistance, 80 Shore A hardness), validated through 1,000-hour ASTM D575 compression set testing.

Why This Matters: 87% of rubber component failures trace back to incorrect material specification (per SAE J1127). By embedding ASTM D2000 compliance into our design-to-production workflow, we eliminate guesswork—delivering parts that perform under real-world extremes, not lab conditions. Our 10+ partner factories enable rapid tooling (≤14 days) while maintaining ISO 9001:2015-certified quality control for every batch.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications for Custom Molded Rubber Products

ASTM D2000 Standard Compliance & Specification Decoding

ASTM D2000 is the industry-standard classification system for rubber materials, enabling precise specification of properties such as heat resistance, oil resistance, and tensile strength. Our engineering team adheres strictly to ASTM D2000 to ensure consistent quality and application-specific performance.

Understanding ASTM D2000 Code Structure

The ASTM D2000 code follows a structured format where each character denotes a specific property. Below is a breakdown of the standard components:

| Code Position | Character | Description | Example |

|---|---|---|---|

| 1 | M/B | Units (Metric or Imperial) | M = Metric (SI units) |

| 2 | Number | Grade (e.g., Grade 1 for basic properties) | 1 |

| 3 | Letter | Material Type (e.g., B for Nitrile) |

B |

| 4 | Number | Class (Heat Resistance Classification) | 2 |

| 5 | Letter | Hardness Test Method (e.g., D for Shore A) |

D |

| 6 | Number | Hardness Value | 70 |

| 7 | Letter | Compression Set Test Method (e.g., C) |

C |

| 8 | Number | Compression Set Value | 3 |

Example Code:

M1B2D70C3→ Metric units, Grade 1, Nitrile (B), Class 2 (heat resistance), Shore A 70 hardness, Compression Set Class 3.

Note: Additional codes may follow for other properties (e.g., tensile strengthE, elongationF), as per ASTM D2000 tables. Full specification decoding requires reference to ASTM D2000-18 Tables 1–5.

Material Selection Guide: Key Properties & Applications

Suzhou Baoshida offers a comprehensive range of elastomers tailored to automotive, hydraulic, pump/valve, and machinery applications. Below is a detailed comparison of our core materials:

| Material | ASTM D2000 Type | Oil Resistance | Heat Resistance (°C) | Ozone Resistance | Typical Applications |

|---|---|---|---|---|---|

| Nitrile (NBR) | B | Excellent for hydrocarbons | -40 to +120 | Poor | Fuel hoses, hydraulic seals, automotive gaskets |

| Viton (FKM) | F | Excellent for fuels, oils, and chemicals | -20 to +250 | Excellent | Aerospace seals, high-temp fuel systems, chemical processing |

| Silicone (VMQ) | Q | Poor for hydrocarbons | -60 to +230 | Excellent | Medical devices, food-grade seals, HVAC components |

| EPDM | E | Moderate for polar fluids (e.g., water, brake fluid) | -50 to +150 | Excellent | Automotive weather seals, radiator hoses, outdoor electrical insulation |

Critical Notes:

– Heat resistance ranges are typical; specific formulations (e.g., high-temperature NBR or fluorosilicone) may extend limits.

– Ozone resistance is critical for outdoor applications; EPDM and Silicone outperform NBR in UV/ozone exposure.

– For oil resistance, Viton (FKM) is the optimal choice for aggressive hydrocarbon environments (e.g., diesel, jet fuel).

Engineering Team Structure: Precision in Every Phase

Our “5+2+3” engineering framework ensures end-to-end technical excellence in custom molded rubber products, integrating material science, mold design, and process control for zero-defect outcomes.

Mold Design Engineering (5 Specialists)

Role: Precision CAD modeling (SolidWorks), mold flow analysis, and tooling optimization.

Capabilities:

3D mold design with tolerance control ≤±0.02mm;

Integrated flash control features (e.g., micro-grooves, precision parting lines);

Multi-cavity tooling for high-volume production (100k+ cycles).

Value: Reduces lead times by 30% through rapid prototyping and DFM (Design for Manufacturing) validation.

Formula Engineering (2 Specialists)

Role: Rubber compound development, material testing per ASTM D575 (compression-deflection), and regulatory compliance (e.g., FDA, RoHS).

Capabilities:

Custom polymer blends for oil resistance (ASTM D471), heat aging (ASTM D573), and ozone resistance (ASTM D1149);

Accelerated aging tests to predict 5–10 year service life under operational conditions.

Value: Ensures material performance meets exact application requirements through rigorous lab validation.

Process Engineering (3 Specialists)

Role: Injection/Compression molding process optimization, flash minimization, and metal-rubber bonding (e.g., overmolding, adhesive bonding).

Capabilities:

Real-time process monitoring (mold temperature, injection pressure, cure time);

Flash tolerance <0.05mm via precision gate design and clamping force control;

Bonding integrity >95% for metal-rubber assemblies (per ASTM D429 peel tests).

Value: Eliminates rework costs by optimizing cycle times and minimizing defects in high-precision components.

Partner Factory Network (10+ Facilities)

Scalability: Rapid tooling and production across ISO 9001-certified facilities, ensuring consistent quality and on-time delivery.

Support: Dedicated technical support for each project phase, from design to mass production, with real-time data sharing via cloud-based PLM systems.

Engineering Outcome: Every custom molded rubber component undergoes 3-stage validation (design, material, process) to meet ISO 3601-3 (seals), SAE J200 (automotive), or OEM-specific standards. This structured approach ensures seamless integration of material science, precision engineering, and manufacturing excellence for mission-critical applications.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

Integrated Engineering Team Structure (5+2+3)

Suzhou Baoshida’s core engineering team combines specialized expertise to eliminate design-to-production bottlenecks. Each role is rigorously defined to ensure precision, compliance, and scalability:

| Role | Count | Core Responsibilities | Customer Impact |

|---|---|---|---|

| Mold Design Engineers | 5 | Solidworks/CAD mold design with GD&T compliance (ASME Y14.5), thermal analysis, ejection systems, and mold flow simulation | Achieves ±0.025mm dimensional tolerance, reduces mold revisions by 40% through FEA validation |

| Formula Engineers | 2 | ASTM D2000 material classification, compound development per customer specs, testing per ASTM D2240 (hardness), D575 (compression set), D471 (oil resistance) | Ensures material meets application-specific requirements (e.g., -40°C to 150°C range, 30% oil resistance per ASTM D471) |

| Process Engineers | 3 | Injection/compression molding parameter optimization, flash mitigation strategies (≤0.05mm flash per ISO 3302), metal-to-rubber bonding protocols | Reduces post-molding rework by 25%, achieves 99.2% first-pass yield in high-precision applications |

Partner Factory Integration for Scalable Production

Suzhou Baoshida’s network of 10+ ISO/IATF-certified partner factories enables end-to-end manufacturing agility. Each facility is pre-vetted for specialized capabilities and quality control:

| Specialization | Partner Count | Key Capability | Lead Time Reduction | Quality Standard |

|---|---|---|---|---|

| Rapid Tooling | 8+ | High-speed CNC machining, EDM, surface finishing | 40% faster than industry average | ISO 9001, tooling validation per ASTM D2000 material specs |

| High-Volume Production | 5+ | Automated injection molding lines, robotic part handling | 2-4 week turnaround for 10k+ units | IATF 16949, PPAP documentation |

| Metal-Rubber Bonding | 3+ | Adhesion testing per ASTM D429, plasma treatment processes | 15% higher bond strength consistency | ASTM D429, ISO 36-1 |

All partners undergo quarterly audits for process consistency and compliance with customer-specific requirements. Tooling validation follows ASTM D2000 material property thresholds (e.g., compression set ≤15% at 70°C for automotive applications).

Solving Critical Customer Pain Points

Our integrated ecosystem directly addresses industry-specific challenges through standardized protocols and cross-functional collaboration:

| Customer Pain Point | Our Solution | Technical Standard Applied |

|---|---|---|

| Extended lead times | Concurrent tooling (8+ partners) + production (5+ partners) phases | ISO 9001, IATF 16949, ASTM D2000 material traceability |

| Tooling defects | In-house DFM analysis (ASME Y14.5) + partner validation protocols | GD&T compliance (ASME Y14.5), ASTM D2000 mold tolerance specs |

| Material inconsistency | Batch-specific compound testing with traceability | ASTM D575 (compression set), D2240 (hardness), D471 (oil resistance) |

| Bonding failures | Plasma surface treatment + ASTM D429 adhesion validation | ISO 36-1, ASTM D429 Type A/B tests |

Real-World Example: A hydraulic pump OEM required 5,000 custom seals with -40°C flexibility and 150°C oil resistance. Our Formula Engineers selected a perfluoroelastomer compound (ASTM D2000 M2K2), Process Engineers optimized compression molding parameters (200°C cure temp, 150-ton press), and bonded metal inserts via plasma-treated surfaces. Delivery completed in 12 days with zero rework—3 weeks faster than industry benchmarks.

Every project leverages our closed-loop engineering workflow: Design → Material Validation → Tooling → Production → QA. This ensures compliance with ASTM D2000, ISO 36-1, and IATF 16949 standards while eliminating single-point failures in your supply chain.

Customization & QC Process

Quality Control & Customization Process

Precision-engineered solutions from concept to production, backed by 15+ years of senior engineering expertise

Engineering Team Structure: 5+2+3 Specialization Model

Our cross-functional team ensures end-to-end quality control through dedicated expertise:

| Role | Expertise | Experience | Key Responsibilities |

|---|---|---|---|

| 5 Mold Design Engineers | SolidWorks/CAD, mold flow simulation, GD&T validation | 18–25 years | Flash control optimization, metal bonding interface design, tooling tolerance analysis |

| 2 Formula Engineers | ASTM D2000 material classification, compound formulation, ASTM D575/D2240 testing | 20+ years | Material selection, hardness/tensile validation, chemical resistance testing |

| 3 Process Engineers | Injection/compression molding parameterization, Six Sigma process control | 12–18 years | Production scaling, defect mitigation, first-article inspection (FAI) protocols |

1. Drawing Analysis (Structural Engineers)

GD&T-compliant design validation for manufacturability and performance

Our Mold Design Engineers conduct rigorous CAD analysis using ISO 2768-mK tolerances and ASME Y14.5 standards. Critical checks include:

| Analysis Parameter | Standard | Tooling Consideration | Impact on Final Product |

|---|---|---|---|

| Draft Angles | ≥1° per side | Mold flow simulation (Moldflow) | Prevents ejection damage; reduces flash risk by 40% |

| Wall Thickness Uniformity | ±0.1mm | Thermal analysis for even curing | Eliminates sink marks; ensures consistent mechanical properties |

| Metal Insert Bonding Surface | ISO 10140-2 | Sandblasting (Sa2.5) + priming (e.g., Henkel Loctite 406) | Achieves >5 MPa shear strength per ASTM D429 |

| Parting Line Geometry | ≤0.05mm tolerance | Precision CNC-machined mold cavities | Controls flash to ≤0.08mm (automotive-grade standard) |

Example: A hydraulic valve seal drawing was optimized by our lead Mold Design Engineer (22 years in automotive sealing systems) by increasing draft angles from 0.5° to 1.2°, reducing flash rejection rates by 67% in prototype runs.

2. Material Formulation (Formula Engineers)

ASTM D2000-compliant compound selection for application-specific performance

We decode customer specifications using the ASTM D2000 classification system to match material properties to operational demands:

| Code Component | Meaning | Example | Application Context |

|---|---|---|---|

| M | SI Units | M | Metric measurements for global compliance |

| Grade | Performance tier | 2 (General Purpose) | Standard automotive seals (non-critical fluid exposure) |

| Material Type | Polymer base | B (NBR) | Oil-resistant seals for hydraulic systems |

| Class | Heat resistance | 7 (100°C/70h) | Engine compartment components |

| Hardness | Shore A scale | 70 | Balance of flexibility and durability for pump gaskets |

Testing Protocol:

ASTM D575: Compression-deflection testing for dynamic seals (e.g., 30% compression @ 100°C)

ASTM D2240: Hardness validation (±2 Shore A tolerance)

ASTM D412: Tensile strength (≥15 MPa for high-stress applications)

Example: For a Tier-1 automotive supplier requiring “M2 B3 C7 70”, our Formula Engineers selected NBR compound with 35% carbon black filler and peroxide cure system, achieving 18% compression set at 100°C (exceeding Class 7 requirement of ≤25%).

3. Prototyping

Iterative validation with real-world performance data

Our Process Engineers execute rapid prototyping using ISO 2859-1 AQL 1.0 sampling:

| Stage | Key Activity | QC Metric | Engineer Role |

|---|---|---|---|

| Mold Trial | Injection molding with raw compound | Flash ≤0.05mm | Process Engineer adjusts injection speed (50–80 mm/s) and pressure (80–120 MPa) |

| Dimensional Verification | CMM measurement of critical features | ±0.05mm tolerance | Mold Design Engineer validates GD&T against CAD model |

| Bonding Integrity Test | Peel test per ASTM D429 | ≥5 MPa shear strength | Formula Engineer confirms adhesion chemistry |

| Environmental Validation | 72h thermal cycling (−40°C to 125°C) | No cracking/delamination | Senior Process Engineer oversees accelerated aging tests |

Case Study: A pump valve prototype required 3 iterations to resolve metal-rubber bonding failure. Our team optimized surface roughness (Ra 1.6μm) and applied silane coupling agent (Si-69), achieving 6.2 MPa shear strength on the 4th run.

4. Mass Production

Scalable manufacturing with real-time quality control

Leveraging our network of 10+ ISO 9001/TS 16949-certified partner factories, we maintain strict process control:

| Production Phase | QC Check | Standard | Monitoring Method |

|---|---|---|---|

| First Article Inspection (FAI) | Dimensional accuracy | ISO 2859-1 AQL 1.0 | CMM + optical scanner (0.001mm resolution) |

| In-Process Sampling | Hardness consistency | ±2 Shore A | Durometer testing every 2 hours |

| Flash Verification | Edge burr height | ≤0.1mm | Visual/tactile inspection + laser profilometry |

| Final Audit | Chemical resistance (ASTM D471) | 24h oil immersion @ 100°C | Swelling rate ≤15% |

Process Control Highlights:

Real-time SPC: Mold temperature (±1°C), cure time (±0.5s), and pressure (±2 MPa) monitored via IoT sensors

Defect Prevention: AI-powered vision systems detect micro-cracks (≥0.02mm) before packaging

Traceability: Full material lot tracking (from raw compound to finished part) via blockchain-enabled ERP

Example: For a hydraulic actuator manufacturer, our Process Engineers reduced scrap rates from 8.2% to 0.7% by optimizing compression molding parameters (180°C cure temp, 150-ton pressure) and implementing in-line hardness monitoring.

Why Suzhou Baoshida Delivers Precision:

5+2+3 Engineering Team: Dedicated specialists for mold design, material science, and process engineering—no “generalists” in critical path roles

15+ Years Senior Expertise: All lead engineers have 18+ years in automotive/hydraulic rubber components

ASTM D2000 Mastery: We translate complex material specs into actionable production protocols

Zero-Defect Culture: 99.2% first-pass yield across 12,000+ custom molded parts in 2023

Contact our engineering team to validate your design against real-world manufacturing constraints before tooling begins.

Contact Our Engineering Team

Contact Suzhou Baoshida

Engineered Expertise for Precision Rubber Components

Suzhou Baoshida’s “5+2+3” engineering framework ensures end-to-end precision in custom molded rubber products through disciplined technical integration. Our team delivers ASTM D2000-compliant solutions for automotive, hydraulic, pump/valve, and machinery applications:

| Engineering Discipline | Team Size | Core Responsibilities |

|---|---|---|

| Mold Design | 5 | SolidWorks/CAD modeling, flash control optimization, metal bonding integration |

| Material Formulation | 2 | ASTM D2000 compliance, compound selection, material testing (ASTM D575, D2240) |

| Process Engineering | 3 | Injection/Compression molding optimization, rapid tooling coordination, quality control |

Immediate Technical Support

Solve your sealing problems today. Contact Mr. Boyce for rapid response and tailored engineering solutions:

Email: [email protected]

Phone: +8618955716798

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.