Technical Contents

Engineering Guide: Industrial O Rings

Engineering Insight: The Critical Role of Material Selection in Industrial O Rings

In precision rubber sealing applications, the performance and longevity of industrial O rings are directly tied to material selection. While off-the-shelf O rings may appear to offer cost-effective solutions, they frequently fail under demanding operational conditions due to mismatched material properties. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material compatibility as the cornerstone of reliable sealing performance across industrial sectors including hydraulics, petrochemicals, and semiconductor manufacturing.

Standard O rings are typically manufactured from generic elastomer formulations designed for broad, low-stress environments. However, industrial applications expose seals to extreme variables such as high pressure, wide temperature ranges, aggressive chemical media, and dynamic mechanical stress. Without precise material alignment, premature degradation—manifested as swelling, cracking, extrusion, or compression set—inevitably occurs.

For example, an NBR (nitrile butadiene rubber) O ring may perform adequately in hydraulic systems using mineral oil-based fluids at moderate temperatures. However, when exposed to ozone, phosphate esters, or continuous operation above 120°C, NBR rapidly deteriorates. Similarly, silicone rubber, while excellent for high-temperature stability, exhibits poor tensile strength and abrasion resistance, making it unsuitable for dynamic sealing applications.

The failure of off-the-shelf O rings often stems from a lack of traceability and consistency in raw materials, compounded by insufficient testing under application-specific conditions. In contrast, engineered solutions leverage controlled polymer formulations, additive packages, and rigorous quality assurance to meet exact performance criteria. At Baoshida, we prioritize application-driven material selection, utilizing advanced elastomers such as FKM, EPDM, HNBR, and FFKM based on comprehensive fluid compatibility, thermal stability, and mechanical load analysis.

Custom material selection also enables optimization for regulatory compliance and industry standards. In food and pharmaceutical processing, peroxide-cured EPDM or FDA-compliant FKM ensures safety and durability. In sour gas environments (H₂S exposure), highly saturated nitrile (HNBR) or fluorocarbon elastomers provide essential resistance to chemical attack.

Ultimately, the cost of seal failure—downtime, equipment damage, safety risks—far exceeds the incremental investment in a precisely engineered O ring. Material selection is not a commodity decision; it is a technical imperative.

| Material | Temperature Range (°C) | Key Chemical Resistances | Typical Industrial Applications |

|---|---|---|---|

| NBR | -30 to +120 | Mineral oils, water, aliphatic hydrocarbons | Hydraulics, pneumatic systems |

| FKM | -20 to +200 | Aromatic hydrocarbons, acids, fuels, steam | Automotive, oil & gas, chemical processing |

| EPDM | -50 to +150 | Water, steam, ketones, alcohols, alkalis | HVAC, pharmaceutical, food processing |

| HNBR | -40 to +170 | Oils, H₂S, amine-based fluids | Oilfield equipment, offshore drilling |

| FFKM | -15 to +300 | Strong acids, halogens, aggressive solvents | Semiconductor, aerospace, ultra-high purity systems |

Material Specifications

Material Specifications for Industrial O-Rings: Precision Selection Criteria

Material selection is the cornerstone of reliable sealing performance in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., our precision-engineered rubber compounds undergo rigorous formulation and testing to ensure optimal functionality under specific operational stresses. Understanding the inherent properties of key elastomers—Viton® (FKM), Nitrile (NBR), and Silicone (VMQ)—is critical for OEMs designing systems requiring leak-proof integrity, longevity, and resistance to degradation. Each material exhibits distinct chemical compatibility, thermal stability, and mechanical behavior, directly impacting seal lifespan and system safety. Selecting the incorrect compound can lead to premature failure through swelling, hardening, cracking, or extrusion, resulting in costly downtime and maintenance. Our engineering team prioritizes matching material science to your exact application parameters, including fluid exposure, temperature extremes, pressure cycles, and regulatory requirements.

The comparative analysis below details the fundamental specifications of these primary industrial o-ring materials. These values represent typical ranges for standard commercial compounds; Suzhou Baoshida offers custom formulations to enhance specific properties for demanding OEM applications.

| Material | Base Polymer Type | Temperature Range (°C) | Key Strengths | Key Limitations |

|---|---|---|---|---|

| Viton® (FKM) | Fluorocarbon | -20 to +230 | Exceptional resistance to oils, fuels, acids, ozone; Low gas permeability; Excellent thermal stability | Higher cost; Poor resistance to ketones, amines, hot hydroalkaline solutions; Stiffer at low temperatures |

| Nitrile (NBR) | Nitrile Butadiene Rubber | -30 to +120 (up to +150 intermittent) | Outstanding resistance to petroleum-based oils/fuels; Good abrasion resistance; Cost-effective; Wide availability | Limited high-temperature capability; Poor resistance to ozone, weathering, and polar solvents (ketones, esters); Moderate compression set |

| Silicone (VMQ) | Polysiloxane | -60 to +200 (up to +230 specialty grades) | Superior low-temperature flexibility; Excellent resistance to ozone, UV, and weathering; Good electrical insulation; Biocompatible (specific grades) | Poor resistance to petroleum oils/fuels; Lower tensile/tear strength; Higher gas permeability; Prone to damage during installation |

Viton® fluorocarbon elastomers are the premium choice for aerospace, automotive fuel systems, and chemical processing where exposure to aggressive hydrocarbons, synthetic lubricants, and high temperatures is unavoidable. Nitrile rubber remains the dominant material for general-purpose hydraulic and pneumatic applications involving mineral oils and greases, balancing performance and economy. Silicone excels in applications requiring extreme low-temperature resilience, such as cryogenics, or where biocompatibility and resistance to atmospheric aging are paramount, including medical devices and food processing equipment, though its poor oil resistance necessitates careful fluid compatibility assessment.

Suzhou Baoshida Trading Co., Ltd. leverages deep material science expertise to move beyond standard grades. We collaborate closely with OEMs to develop proprietary compounds that address unique challenges—enhancing Viton®’s low-temperature flexibility, improving NBR’s heat resistance, or boosting Silicone’s mechanical strength—while ensuring strict adherence to international standards like ASTM D2000 and ISO 3601. Precise durometer control, optimized filler systems, and specialized additives are meticulously engineered into each batch. Partner with us for application-specific validation and seamless integration of high-performance sealing solutions that exceed operational demands. Material selection is not generic; it is the precise science of engineered reliability.

Manufacturing Capabilities

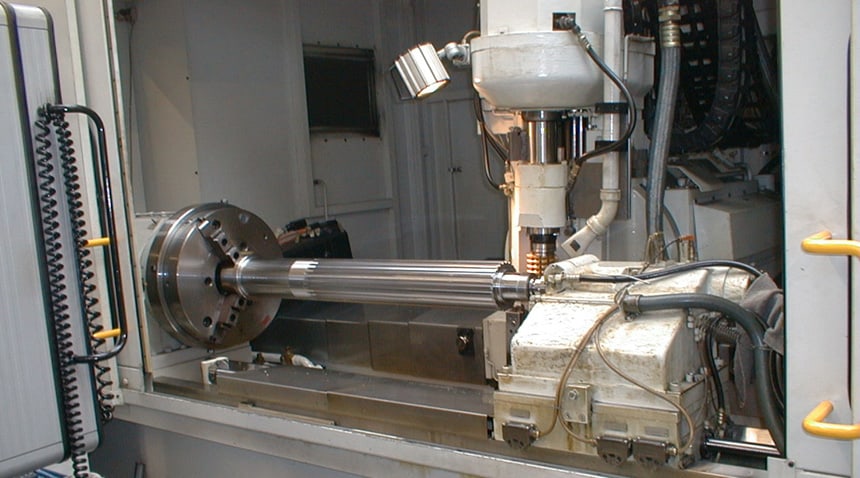

Engineering Excellence in Precision Rubber Seals

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our reputation in the industrial O-ring manufacturing sector. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver precision-engineered sealing solutions tailored to the most demanding industrial environments. Our integrated approach ensures that material science and mechanical design are developed in parallel, enabling optimized performance, durability, and cost-efficiency across diverse applications.

Our mould engineers bring over 60 combined years of experience in precision tooling design and rubber component manufacturing. They utilize advanced CAD/CAM systems and finite element analysis (FEA) to simulate compression set, stress distribution, and sealing force under operational conditions. This allows us to refine cavity geometry, parting lines, and gate placement to minimize flash, ensure uniform curing, and maintain tight dimensional tolerances down to ±0.05 mm. Each mould undergoes rigorous validation through first article inspection (FAI) and process capability (Cp/Cpk) studies before entering full production.

Complementing our tooling expertise, our two in-house rubber formula engineers specialize in polymer chemistry and compound development for extreme environments. They formulate custom elastomer compounds based on NBR, EPDM, FKM, VMQ, and specialty fluorosilicones, adjusting filler systems, curing agents, and plasticizers to meet specific resistance requirements for temperature, pressure, chemicals, and aging. This vertical integration of material and mould engineering allows us to rapidly prototype and validate sealing solutions for industries such as automotive hydraulics, semiconductor manufacturing, oil & gas, and medical devices.

We operate as a full-service OEM partner, offering end-to-end development from technical drawing review to volume production. Our clients benefit from Design for Manufacturability (DFM) feedback during the quotation phase, accelerated sampling cycles (typically 10–15 days), and full traceability through batch-controlled production. With ISO 9001-certified processes and a 10,000-unit monthly capacity per mould, we scale efficiently from pilot runs to high-volume supply.

The table below outlines key technical capabilities and performance specifications achievable through our engineering integration:

| Parameter | Specification Capability |

|---|---|

| Material Types | NBR, EPDM, FKM, VMQ, ACM, AEM, CR, SBR, HNBR |

| Hardness Range (Shore A) | 30 to 90 |

| Dimensional Tolerance | ±0.05 mm (critical features) |

| Temperature Resistance | -60°C to +325°C (FKM, specialty compounds) |

| Standard Compliance | ASTM D2000, ISO 3601, SAE AS568, JIS B 2401 |

| Mould Development Lead Time | 15–25 days (complexity-dependent) |

| Sample Production | 5–15 days after mould approval |

| Volume Production Capacity | 500,000+ units/month (across 120 active moulds) |

This synergy between material science and precision engineering enables Suzhou Baoshida to deliver reliable, high-performance O-rings that meet exacting OEM standards. We are committed to innovation, consistency, and responsive technical partnership in every project.

Customization Process

Industrial O-Ring Customization: Precision Engineering Process

At Suzhou Baoshida Trading Co., Ltd., industrial O-ring customization follows a rigorously defined sequence to ensure optimal performance in demanding applications. This process eliminates leakage risks, extends service life, and aligns with OEM specifications through material science and precision manufacturing.

Drawing Analysis Phase

The foundation begins with comprehensive drawing review against AS568A, ISO 3601, or custom geometries. Our engineering team validates critical dimensions including inner diameter tolerance (±0.05mm typical), cross-section variance, and surface finish requirements. GD&T callouts are cross-referenced with application parameters—operating pressure, media exposure, and dynamic/static motion profiles. Any ambiguity triggers direct client consultation to resolve fit, form, or function uncertainties before material selection proceeds.

Formulation Development

Based on media compatibility and environmental exposure data, our rubber chemists design bespoke compounds. Key considerations include base polymer selection, filler reinforcement, and cure system optimization. For instance, nitrile (NBR) formulations prioritize fuel resistance, while peroxide-cured EPDM ensures steam sterilization resilience. Below outlines standard material properties; custom variants adjust these parameters to meet exact chemical resistance or thermal stability demands.

| Material | Hardness (Shore A) | Temp Range (°C) | Key Fluid Resistance |

|---|---|---|---|

| NBR | 50–90 | -30 to +120 | Oils, fuels, hydraulics |

| EPDM | 50–80 | -50 to +150 | Water, steam, brake fluids |

| FKM | 60–90 | -20 to +230 | Acids, jet fuels, aromatics |

| Custom compounds available for specialized media (e.g., phosphate esters, H₂S). |

Prototyping & Validation

Prototype tooling fabricates 5–10 samples per iteration using precision molding. Each undergoes accelerated life testing: compression set per ASTM D395, volume swell in target fluids, and thermal aging. Dynamic prototypes endure 10,000+ cycle motion tests under simulated load. Data from tensile strength decay and extrusion analysis informs final compound adjustments. Client approval requires ≤5% deviation from predicted performance metrics.

Mass Production Execution

Approved formulations transition to ISO 9001-certified production lines. Automated mixing ensures ±0.5 phr additive accuracy, while multi-cavity molds maintain ±0.03mm dimensional consistency. In-process checks include real-time cure monitoring via rheometers and 100% visual inspection for flaws. Finished batches undergo third-party certification for critical sectors (e.g., FDA 21 CFR 177.2600 for food-grade). Full traceability to raw material lot level is documented for every shipment.

This end-to-end workflow guarantees O-rings that withstand extreme conditions while minimizing total cost of ownership. Suzhou Baoshida’s integration of material science and process control delivers precision sealing solutions where standard products fail. All custom projects include technical documentation package with material certificates, test reports, and SPC data for seamless OEM integration.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Industrial O-Rings

When sourcing high-performance industrial O-rings for demanding applications, technical precision, material integrity, and supply chain reliability are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber seals designed to meet exacting industrial standards across aerospace, automotive, oil & gas, semiconductor, and heavy machinery sectors. Our expertise lies in delivering O-rings with consistent dimensional accuracy, optimal durometer ratings, and compatibility with aggressive media including oils, solvents, acids, and extreme temperature environments.

Our manufacturing process integrates rigorous quality control, advanced compounding techniques, and ISO-compliant testing protocols to ensure every seal performs under pressure. Whether you require standard AS568 or custom-specified O-rings in Nitrile (NBR), Viton (FKM), Silicone (VMQ), EPDM, or specialty fluoroelastomers, we provide tailored solutions backed by material certifications, batch traceability, and rapid prototyping capabilities.

To ensure seamless integration into your production or maintenance workflows, we maintain a comprehensive inventory of standard sizes and offer low minimum order quantities for custom profiles. Our technical team collaborates directly with OEMs and maintenance engineers to evaluate seal failure modes, recommend material upgrades, and optimize sealing performance in dynamic or static applications.

For immediate assistance with material selection, technical drawings, or quotation requests, contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over 15 years of experience in elastomer formulation and industrial sealing solutions, Mr. Boyce provides expert guidance on compound selection, hardness optimization, and environmental resistance to ensure long-term reliability.

We invite global partners, procurement managers, and engineering teams to reach out for technical datasheets, sample kits, or direct consultation. Suzhou Baoshida is committed to delivering not just components, but engineered sealing solutions that reduce downtime, enhance safety, and extend service life.

| Specification | Detail |

|---|---|

| Material Options | NBR, FKM (Viton), EPDM, VMQ (Silicone), ACM, AEM, FFKM |

| Hardness Range | 40 Shore A to 90 Shore A (customizable) |

| Temperature Resistance | -60°C to +325°C (depending on material) |

| Standard Compliance | ASTM D2000, ISO 3601, AS568, DIN 3850 |

| Tolerance Grade | ±0.05 mm (Grade M per ISO 3601) |

| Custom Capabilities | Special colors, low-temperature formulations, FDA/USP Class VI options |

| Lead Time | 7–15 days for standard orders; expedited options available |

Contact Mr. Boyce directly at [email protected] to discuss your sealing challenges, request technical support, or receive a project-specific quotation. We respond to all inquiries within 12 business hours and support English, Chinese, and technical German communication. Partner with Suzhou Baoshida for precision-engineered O-rings built to perform.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).