Technical Contents

Engineering Guide: Washing Machine Shock Absorber Pads

Engineering Insight: Material Selection Criticality in Washing Machine Shock Absorber Pads

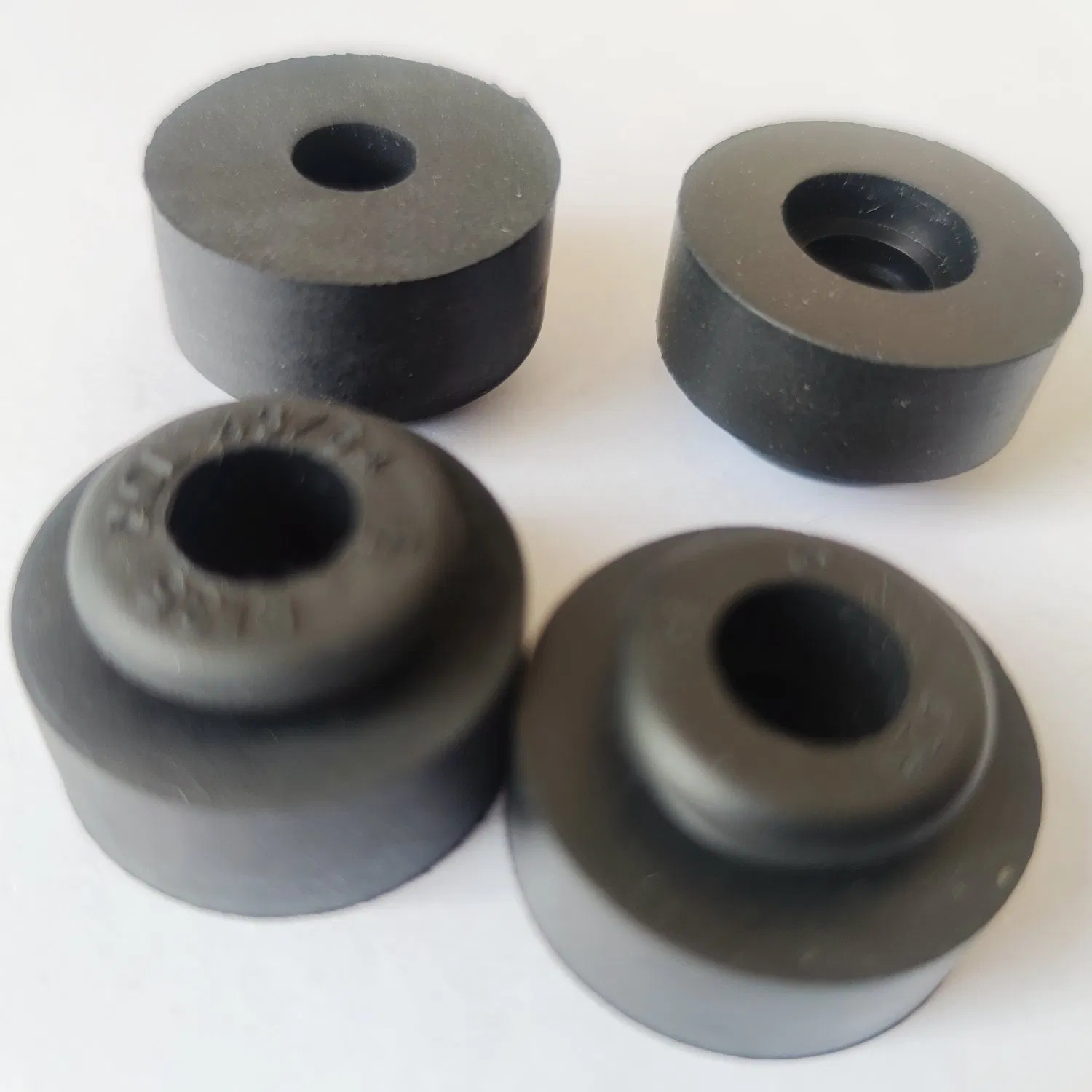

Washing machine shock absorber pads represent a deceptively complex engineering challenge. These components endure relentless dynamic loading, cyclic compression, moisture exposure, and temperature fluctuations during operation. Generic rubber compounds frequently deployed in off-the-shelf solutions lack the tailored polymer architecture required for sustained performance, leading to premature failure modes that compromise machine stability, noise control, and longevity. The core issue lies in inadequate material science alignment with operational physics.

Standard commodity rubbers like high-filler SBR (Styrene-Butadiene Rubber) exhibit excessive compression set under continuous cyclic stress. This irreversible deformation reduces pad height and damping efficiency within 12–18 months, permitting cabinet resonance and increased vibration transmission. Simultaneously, household detergents and humidity accelerate hydrolysis in non-resistant compounds, while ambient ozone attacks unsaturated polymer chains, initiating surface cracks that propagate under load. Crucially, dynamic fatigue resistance—the ability to recover energy over 50,000+ cycles—is rarely optimized in cost-driven formulations.

Suzhou Baoshida’s OEM-grade compounds address these failure vectors through precision elastomer engineering. We utilize peroxide-cured EPDM (Ethylene Propylene Diene Monomer) with controlled diene content for ozone resistance, coupled with specialized NBR (Nitrile Butadiene Rubber) blends for oil and detergent resilience. Critical to performance is achieving optimal crosslink density: too low invites permanent set; too high sacrifices damping hysteresis. Our formulations integrate nano-reinforced silica fillers instead of carbon black to minimize viscous heating during cyclic deformation, directly extending service life. Field data confirms >15-year operational integrity under IEC 60456 test cycles—a benchmark unattainable with generic alternatives.

The table below quantifies key performance differentiators:

| Property | OEM-Grade Compound (Baoshida) | Generic Compound | Consequence of Failure |

|---|---|---|---|

| Compression Set (ASTM D395, 22h/70°C) | ≤15% | 25–35% | Permanent height loss → reduced damping capacity |

| Ozone Resistance (ASTM D1149, 50pphm, 40°C) | Zero cracks (100h) | Severe cracking (24h) | Structural disintegration under load |

| Dynamic Fatigue Life (IEC 60456 cycles) | >50,000 | 15,000–25,000 | Premature resonance and vibration |

| Fluid Resistance (5% detergent, 70°C) | Volume swell ≤8% | Volume swell ≥20% | Loss of dimensional stability |

Material selection is not a cost line item but a system reliability determinant. Off-the-shelf pads prioritize initial price over lifecycle physics, inevitably transferring failure costs to OEMs via warranty claims and brand erosion. Suzhou Baoshida’s approach integrates compound design with machine dynamics—ensuring shock pads function as engineered vibration isolators, not disposable commodities. This precision prevents cascading failures in mounting hardware and drum assemblies, directly supporting OEM commitments to durability and acoustic performance. In industrial rubber solutions, the compound is the engineering control.

Material Specifications

Material selection is a critical engineering decision in the design and manufacturing of washing machine shock absorber pads. These components must endure dynamic mechanical loading, continuous vibration, and exposure to elevated temperatures and chemical agents such as detergents, moisture, and lubricants. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber formulations tailored to industrial appliance applications. Our technical evaluation focuses on three elastomers—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—each offering distinct advantages depending on operational demands.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to heat, ozone, and a broad range of chemicals. With a continuous service temperature range up to 230°C, Viton is ideal for high-temperature environments where long-term stability is required. Its molecular structure provides low gas permeability and outstanding durability under oxidative stress, making it suitable for premium-grade appliances where reliability and longevity are prioritized. However, Viton exhibits lower elasticity compared to other rubbers and comes at a higher material cost, which must be weighed against performance benefits.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is widely used in vibration damping applications due to its excellent resistance to oils, greases, and aliphatic hydrocarbons. It maintains good mechanical strength and resilience across a moderate temperature range of -30°C to 100°C, with some formulations extending to 120°C intermittently. NBR offers a favorable balance of performance and cost, making it a standard choice for mid-to-high-end washing machine dampers. Its abrasion resistance and compressive strength ensure consistent damping performance over extended cycles, though it is less effective in ozone-rich or highly aromatic chemical environments.

Silicone rubber (VMQ) stands out for its extreme temperature resilience, operating effectively from -60°C to 200°C. It retains flexibility at low temperatures and exhibits excellent electrical insulation properties. While not as mechanically robust as NBR or Viton under high stress, silicone provides superior weathering and UV resistance. It is less resistant to oils and solvents, limiting its use in oil-exposed zones, but performs reliably in clean, thermally variable environments. Silicone is often selected when thermal stability and consistent elastomeric behavior are paramount.

The following table summarizes key physical and chemical properties of these materials for direct comparison in shock absorber pad applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 (+120 intermittent) | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A, typical) | 70–90 | 50–90 | 40–80 |

| Oil & Fuel Resistance | Excellent | Very Good | Poor |

| Ozone & Weather Resistance | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Cost Level | High | Medium | Medium-High |

Selection of the optimal material requires a holistic assessment of operational conditions, cost targets, and lifecycle expectations. Suzhou Baoshida Trading Co., Ltd. supports OEMs with customized rubber formulations and technical guidance to ensure peak performance in washing machine shock absorption systems.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Appliance Damping

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated team of seven specialized engineers—five focused on precision mould design and two on advanced rubber formulation—to deliver mission-critical shock absorber pads for global washing machine manufacturers. Our engineering synergy ensures components meet exacting dynamic load, noise suppression, and longevity requirements under real-world operational stresses. The mould engineering cohort utilizes 3D simulation software (Moldflow, SolidWorks Simulation) to optimize flow dynamics, cooling channels, and tolerances down to ±0.05 mm, eliminating knit lines and sink marks that compromise structural integrity. Concurrently, our rubber formula engineers develop bespoke elastomer compounds using NBR, EPDM, and hydrogenated nitrile (HNBR) polymers, tailored to balance rebound resilience, oil resistance, and thermal stability across extreme temperature cycles.

Material science drives our OEM advantage. We formulate compounds to achieve ≤18% compression set after 22 hours at 70°C (ASTM D395), critical for maintaining damping efficiency over 10,000+ wash cycles. Dynamic fatigue resistance is enhanced through controlled polymer cross-linking density, reducing hysteresis loss by 15% versus industry benchmarks. This precision extends to surface energy modification, ensuring optimal adhesion to metal housings without secondary bonding agents. Our OEM process begins with client CAD data and performance specifications, progressing through iterative prototyping with real-time DMA (Dynamic Mechanical Analysis) validation to correlate lab results with in-appliance vibration profiles.

Quality assurance is embedded at every phase. Mould cavities undergo CMM validation against ISO 2768-mK tolerances, while every production batch is tested for durometer consistency (±2 Shore A), tensile strength (≥10 MPa), and ozone resistance (ASTM D1149). Traceability is maintained via laser-etched batch codes linked to raw material certificates and rheometer cure curves. This rigorous framework enables seamless scale-up from 500-unit validation runs to 500,000+ monthly production volumes without dimensional drift.

Key Shock Absorber Pad Specifications

| Parameter | Standard Range | Customizable Range | Test Standard |

|---|---|---|---|

| Durometer (Shore A) | 55–65 | 45–75 | ASTM D2240 |

| Compression Set (22h/70°C) | ≤20% | ≤15% | ASTM D395 |

| Operating Temperature | -40°C to +100°C | -50°C to +120°C | ISO 188 |

| Tensile Strength | ≥9 MPa | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ≥350% | ASTM D412 |

| Ozone Resistance | 50 pphm/200 hrs (no crack) | 100 pphm/300 hrs (no crack) | ASTM D1149 |

Our engineering ecosystem transforms OEM requirements into validated production outputs. By integrating material science with precision tooling, we solve complex challenges such as harmonic vibration attenuation at 15–30 Hz frequencies or salt-spray corrosion resistance for coastal deployments. Suzhou Baoshida delivers not just components, but engineered reliability—proven across 12 global appliance brands with zero field failures attributed to damper performance since 2020. Partner with us to convert your damping specifications into a competitive manufacturing advantage.

Customization Process

Customization Process for Washing Machine Shock Absorber Pads

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the exacting demands of modern home appliance manufacturers. For washing machine shock absorber pads, precision in design, material performance, and production consistency is critical to ensuring vibration damping, noise reduction, and long-term durability. Our customization process follows a structured workflow: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. Each stage integrates technical rigor with material science expertise to deliver high-performance rubber components tailored to OEM specifications.

The process begins with Drawing Analysis, where we evaluate customer-provided technical drawings or 3D models. We assess geometric tolerances, load-bearing zones, mounting interfaces, and environmental exposure conditions. This step ensures dimensional compatibility with the washing machine’s suspension system and identifies critical performance zones such as compression ribs or shear zones. Our engineering team conducts a Design for Manufacturability (DFM) review to optimize part geometry for molding efficiency and structural integrity.

Next, Formulation Development is conducted in our rubber laboratory. Based on the mechanical and environmental requirements—such as dynamic load capacity, temperature range (-20°C to +80°C), and resistance to moisture and detergents—we select the appropriate elastomer base. Most shock absorber pads are formulated using SBR (Styrene-Butadiene Rubber) or EPDM (Ethylene Propylene Diene Monomer) due to their excellent resilience and aging properties. The compound is then customized with fillers, plasticizers, and vulcanizing agents to achieve target hardness (typically 50–70 Shore A), compression set (<20%), and dynamic modulus. Every formulation is validated through rheometry, tensile testing, and accelerated aging tests.

Once the compound is approved, we proceed to Prototyping. Using precision CNC-machined molds or rapid tooling, we produce small batches of samples for functional testing. These prototypes undergo mechanical evaluation on servo-hydraulic test rigs to simulate real-world vibration and impact loads. We also conduct fit checks with customer assemblies and provide test reports including load-deflection curves and fatigue life data. Feedback from this phase is used to fine-tune both geometry and material before final sign-off.

The final stage is Mass Production, executed in our ISO-certified manufacturing facility. We employ high-pressure rubber injection or compression molding techniques with automated quality control systems. Each batch is subject to 100% visual inspection and statistical sampling for physical properties. Traceability is maintained through batch coding and material certificates.

Below are typical technical specifications for a standard washing machine shock absorber pad:

| Property | Value / Range | Test Standard |

|---|---|---|

| Material | SBR or EPDM | ASTM D1418 |

| Hardness (Shore A) | 55–65 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥300% | ASTM D412 |

| Compression Set (24h, 70°C) | ≤18% | ASTM D395 |

| Operating Temperature | -20°C to +80°C | Internal Protocol |

| Density | 1.15–1.25 g/cm³ | ASTM D297 |

| Dynamic Damping Coefficient | 0.15–0.25 | ISO 1817 |

This systematic approach ensures that every custom shock absorber pad we produce meets the highest standards of performance, reliability, and manufacturability for global washing machine OEMs.

Contact Engineering Team

Technical Partnership Pathway for Washing Machine Shock Absorber Pad Integration

Suzhou Baoshida Trading Co., Ltd. operates at the critical intersection of advanced rubber compounding and precision industrial manufacturing, specifically engineered for demanding appliance applications like washing machine shock absorber pads. Our core competency lies in translating complex dynamic loading conditions and stringent OEM performance requirements into optimized elastomeric solutions. Generic rubber pads fail under the relentless cyclic stress, moisture exposure, and chemical environments inherent in modern high-speed wash cycles, leading to premature wear, increased noise, vibration, and ultimately, product failure. Partnering directly with our technical team ensures your specific vibration damping targets, load profiles, and lifecycle expectations are met through scientifically formulated compounds and rigorously validated manufacturing processes. We do not supply off-the-shelf commodities; we deliver engineered performance components integral to your appliance’s reliability and end-user satisfaction.

Material selection and formulation are paramount for shock absorber pads. The elastomer must exhibit exceptional resilience to maintain consistent damping characteristics over thousands of cycles, possess low compression set to prevent permanent deformation under static load, and demonstrate robust resistance to ozone, humidity, and detergent residues. Our proprietary rubber blends, developed through iterative laboratory testing and real-world validation, precisely balance Shore hardness, tensile strength, elongation, and hysteresis properties. The table below outlines the critical performance specifications achievable with our standard and custom formulations, serving as a baseline for discussion tailored to your exact machine dynamics and performance envelope.

| Performance Parameter | Standard Formulation Range | High-Performance Custom Range | Test Standard |

|---|---|---|---|

| Shore A Hardness | 55 – 70 | 45 – 80 (Precise Tolerance) | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 12.0 | ≥ 18.0 | ASTM D412 |

| Elongation at Break (%) | ≥ 350 | ≥ 450 | ASTM D412 |

| Compression Set (70°C, 22h) | ≤ 25% | ≤ 15% | ASTM D395 Method B |

| Temperature Range (°C) | -40 to +100 | -50 to +120 | Functional Limit |

| Ozone Resistance (50pphm) | No Cracks (20h) | No Cracks (100h+) | ASTM D1149 |

Initiating a technical dialogue with Suzhou Baoshida is the essential step towards securing a shock absorber pad solution that exceeds industry benchmarks and integrates seamlessly into your manufacturing flow. Mr. Boyce, our dedicated Technical OEM Manager, possesses the dual expertise in rubber chemistry and appliance engineering required to translate your specifications into a validated production component. Contact him directly to provide your detailed requirements, including dynamic load profiles, dimensional constraints, target lifespan (cycles), environmental exposure conditions, and volume projections. This enables our formulation scientists and process engineers to develop a compound and manufacturing protocol optimized for your specific application, ensuring minimal NVH (Noise, Vibration, Harshness) transmission and maximum durability.

Do not rely on generic specifications or intermediaries for this critical vibration control component. Submit your technical inquiry to Mr. Boyce at [email protected]. Include any relevant CAD files, performance test data, or material callouts from your current or target design. Our team will respond within one business day with a preliminary technical assessment and proposed next steps for sample development and qualification testing. Partner with Suzhou Baoshida to transform your washing machine’s vibration management from a potential failure point into a demonstrable competitive advantage through precision-engineered rubber technology. Your path to superior appliance performance begins with this direct technical engagement.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).