Technical Contents

Engineering Guide: Tube Material Fabric

Engineering Insight: The Critical Role of Material Selection in Tube Material Fabric

In industrial rubber applications, tube material fabric serves as a foundational component in systems demanding resilience under pressure, temperature extremes, and chemical exposure. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary consideration—it is the cornerstone of performance, longevity, and safety. Off-the-shelf solutions, while appealing due to lower initial cost and faster delivery, frequently fail in demanding environments due to their generic composition and lack of application-specific engineering.

Standardized tube fabrics are typically formulated for broad compatibility rather than targeted performance. This one-size-fits-all approach neglects the nuanced requirements of specific industrial processes, such as resistance to ozone degradation, dynamic flexing, or exposure to aggressive media like oils, acids, or solvents. As a result, premature cracking, delamination, or structural failure often occurs, leading to unplanned downtime, safety hazards, and increased total cost of ownership.

The correct material matrix must be engineered at the molecular level to align with operational parameters. For instance, nitrile rubber (NBR) offers superior resistance to petroleum-based fluids, making it ideal for hydraulic systems. Conversely, ethylene propylene diene monomer (EPDM) excels in environments with steam, hot water, or polar solvents but performs poorly when exposed to hydrocarbons. Silicone rubber provides extreme temperature resilience but lacks the tensile strength required for high-pressure applications. Selecting the optimal base polymer is only the first step—reinforcement fabrics, adhesive interlayers, and curing protocols must also be precisely calibrated.

At Suzhou Baoshida, we deploy a systems-engineering approach to tube material fabrication. Each solution is validated against the client’s operational profile, including pressure cycles, media compatibility, ambient conditions, and mechanical stress factors. This ensures that the final product is not merely compliant but optimized for sustained performance.

The following table outlines key material properties and their industrial implications:

| Material Type | Temperature Range (°C) | Key Resistance Properties | Typical Industrial Use Cases |

|---|---|---|---|

| Nitrile (NBR) | -30 to +100 | Oils, fuels, hydraulic fluids | Automotive hydraulics, fuel lines |

| EPDM | -50 to +150 | Steam, water, alkalis, ozone | HVAC systems, chemical processing |

| Silicone | -60 to +200 | Extreme temperatures, UV, ozone | Medical devices, aerospace |

| Neoprene | -40 to +120 | Weather, flame, moderate oils | Marine applications, industrial hoses |

| Fluorocarbon (FKM) | -20 to +200 | Aggressive chemicals, high-temp oils | Semiconductor manufacturing, oil & gas |

Custom-engineered tube material fabric mitigates the risks inherent in off-the-shelf alternatives. By integrating material science with application-specific design, Suzhou Baoshida delivers solutions that enhance system reliability and reduce lifecycle costs. In the realm of industrial rubber, precision in material selection is not optional—it is imperative.

Material Specifications

Material Specifications for Industrial Rubber Tubing

Selecting the appropriate elastomer for tube material fabric is critical for performance longevity in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we engineer solutions where chemical exposure, thermal cycling, and mechanical stress define operational success. Viton, Nitrile, and Silicone represent three foundational polymers, each offering distinct advantages for specialized applications. Understanding their precise material properties ensures optimal compatibility with fluids, temperatures, and dynamic loads encountered in hydraulic systems, fuel lines, semiconductor manufacturing, and pharmaceutical processing.

Viton fluorocarbon rubber excels in extreme chemical resistance and high-temperature stability. With continuous service capabilities up to 250°C and intermittent peaks near 300°C, it withstands aggressive fuels, oils, acids, and solvents where other elastomers degrade. Its low permeation rates make it indispensable for aerospace fuel lines and chemical transfer hoses. However, Viton exhibits higher compression set values above 200°C and commands a premium cost, necessitating justified application-specific use. Nitrile butadiene rubber (NBR) delivers superior resistance to petroleum-based fluids, hydraulic oils, and greases at a cost-effective balance. Operating effectively between -40°C and 120°C, it maintains robust tensile strength and abrasion resistance for industrial hydraulic tubing and automotive fuel systems. Limitations include poor ozone resistance and reduced flexibility below -30°C, requiring protective formulations for outdoor exposure. Silicone rubber provides exceptional flexibility across extreme temperatures from -60°C to 230°C, coupled with outstanding electrical insulation and biocompatibility. Its inertness suits food-grade, medical, and semiconductor tubing, though lower tensile strength and susceptibility to撕裂 under high pressure demand careful design considerations.

The following table details critical performance specifications per ASTM D2000 and ISO 37 standards, reflecting typical compounded formulations for industrial tubing applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -40 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 12–18 | 15–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Compression Set (70h/150°C) (%) | 15–30 | 20–40 | 20–35 |

| Key Chemical Resistance | Fuels, Acids, Ozone | Petroleum Oils, Water | Steam, Alcohols, Water |

| Typical Shore A Hardness Range | 60–90 | 50–90 | 30–80 |

Material selection must align with fluid compatibility charts and dynamic stress analysis. For instance, NBR remains the standard for hydraulic systems with mineral oils, while Viton is non-negotiable for biofuel exposure. Silicone’s low compression set at elevated temperatures ensures reliable sealing in thermal cycling applications but requires reinforcement for high-pressure scenarios. Suzhou Baoshida Trading Co., Ltd. provides OEM-specific compounding adjustments—such as hydrogenated NBR for improved ozone resistance or fluorosilicone blends for ketone resistance—to meet exacting client specifications. Our technical team collaborates directly with manufacturers to validate material performance against application-specific test protocols, ensuring tubing integrity across the product lifecycle. Contact our engineering department for application-specific data sheets and custom formulation support.

Manufacturing Capabilities

Engineering Excellence in Industrial Rubber Fabric Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and manufacturing of high-performance tube material fabric. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we maintain precise control over every phase of product development—from concept and material formulation to tooling design and final production validation. This integrated engineering approach ensures that our tube material fabric meets the rigorous demands of industrial applications, including resistance to pressure, temperature extremes, and chemical exposure.

Our rubber formula engineers focus on developing custom elastomer compounds tailored to specific performance criteria. By selecting and modifying base polymers such as EPDM, NBR, silicone, and neoprene, they optimize key properties including tensile strength, elongation, compression set, and environmental resistance. These formulations are rigorously tested under simulated operational conditions to guarantee long-term durability and consistency. The ability to engineer materials in-house allows us to respond rapidly to OEM requirements, offering formulations that align precisely with customer specifications and industry standards.

Complementing material innovation, our five mould engineers specialize in the design and refinement of precision tooling for extrusion and curing processes. They utilize advanced CAD/CAM software and finite element analysis (FEA) to simulate flow dynamics and thermal behavior, ensuring uniform wall thickness, dimensional accuracy, and structural integrity in the final tube fabric. Their expertise extends to multi-layer co-extrusion tooling, enabling the production of complex composite tubes with integrated fabric reinforcement, barrier layers, and outer protective jackets.

We operate as a full-service OEM partner, providing end-to-end manufacturing support for custom tube material fabric solutions. Our OEM capabilities include prototype development, design for manufacturability (DFM) reviews, small-batch pilot runs, and scalable serial production. All processes are conducted under strict quality control protocols, with full traceability and compliance documentation available for each production lot. This makes our solutions ideal for industries such as automotive, aerospace, industrial machinery, and fluid handling systems, where reliability and repeatability are paramount.

Below is a summary of typical technical specifications achievable with our engineered tube material fabric:

| Property | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength | 12–20 MPa | ASTM D412 |

| Elongation at Break | 250–400% | ASTM D412 |

| Hardness (Shore A) | 50–80 | ASTM D2240 |

| Operating Temperature Range | -40°C to +150°C (up to +250°C for silicone) | ISO 1817 |

| Burst Pressure (6mm ID tube) | ≥ 12 MPa | ISO 1402 |

| Reinforcement Layer | Polyester or Nylon Fabric | Custom Weave Patterns |

| Fluid Resistance | Oil, water, air, mild chemicals | ASTM D471 |

Through the synergy of advanced material science and precision engineering, Suzhou Baoshida delivers technically robust, application-specific tube material fabric solutions that meet the evolving needs of global industrial OEMs.

Customization Process

Customization Process for Industrial Rubber Tube Material Fabric

At Suzhou Baoshida Trading Co., Ltd., our OEM-driven customization process for rubber tube material fabric integrates precision engineering with rigorous material science. Serving global industrial clients, we prioritize dimensional accuracy, chemical resilience, and lifecycle performance. Our four-phase workflow ensures seamless transition from concept to volume production while adhering to ISO 9001 and IATF 16949 standards.

Drawing Analysis

We initiate with comprehensive technical drawing review, focusing on geometric dimensioning and tolerancing (GD&T), wall thickness uniformity, and critical feature callouts. Our engineering team cross-references client specifications against material behavior models, identifying potential stress points or extrusion limitations. This phase includes validation of media compatibility requirements—such as hydraulic fluids, fuels, or steam—and verification of regulatory compliance (e.g., SAE J517, EN ISO 1307). Any ambiguities trigger immediate client consultation to prevent downstream deviations.

Formulation Development

Leveraging our proprietary compound database spanning 200+ validated rubber formulations, we engineer bespoke elastomer blends. Key parameters include polymer backbone selection (EPDM, NBR, FKM), filler reinforcement (silica/carbon black ratios), and additive packages for ozone/UV resistance. Each formulation undergoes predictive simulation for compression set, tensile strength, and low-temperature flexibility per ASTM D2000. Accelerated aging tests validate performance against client-specified service conditions before material release.

Prototyping & Validation

Precision extrusion prototypes are produced under controlled cleanroom conditions. We conduct destructive and non-destructive testing: burst pressure verification (ISO 1436), permeation rate analysis, and dynamic flex fatigue cycles. Dimensional conformity is confirmed via CMM scanning against original CAD data. Clients receive a full test report including Durometer variance maps and chemical immersion results. Two revision cycles are included to refine tolerances or material properties.

Mass Production Execution

Upon prototype approval, we deploy automated production lines with real-time SPC monitoring. Each batch undergoes traceability coding linking raw material lot numbers to operator logs and environmental conditions. In-line vision systems inspect surface defects at 0.1mm resolution, while statistical process control ensures dimensional drift remains within ±0.15mm. Final shipment includes material certificates, full QA documentation, and packaging certified for global logistics.

Key Material Performance Specifications

| Material Type | Pressure Rating (MPa) | Temp Range (°C) | Media Resistance | Shore A Hardness |

|---|---|---|---|---|

| Hydrogenated NBR | 35 | -40 to +150 | Fuels, Oils, HFDU | 60–90 |

| Peroxide-Cured EPDM | 25 | -55 to +150 | Steam, Brake Fluid | 50–80 |

| Fluorosilicone | 20 | -60 to +200 | Jet Fuels, Solvents | 55–75 |

| Specialty FKM | 40 | -25 to +230 | Aggressive Chemicals | 70–90 |

This systematic approach minimizes time-to-market while guaranteeing tubes meet exact operational demands. Suzhou Baoshida’s engineering oversight from formulation to final inspection delivers zero-defect reliability for critical industrial applications.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Tube Material Fabric Solutions

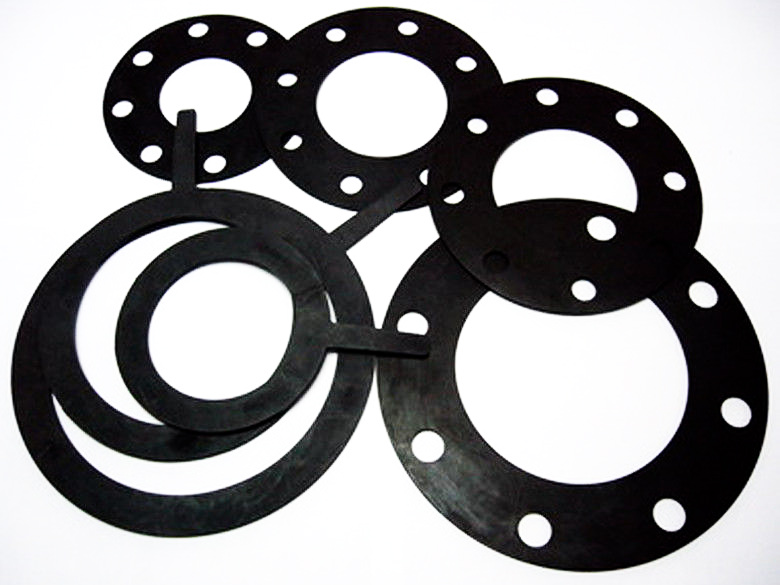

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to the exacting demands of modern manufacturing. Our expertise in tube material fabric production combines advanced polymer engineering with rigorous quality control, ensuring consistent performance across diverse operating environments. Whether you require custom formulations for extreme temperature resistance, enhanced tensile strength, or specialized chemical compatibility, our team is equipped to provide engineered solutions that meet your technical specifications.

Our tube material fabrics are designed for critical applications in automotive systems, industrial hydraulics, pneumatic equipment, and heavy-duty machinery. These materials serve as the backbone for reinforced rubber hoses, expansion joints, and fluid transfer systems where durability and reliability are non-negotiable. We utilize precision-calendared fabric substrates laminated with high-grade synthetic rubbers such as NBR, EPDM, and CR, ensuring optimal adhesion and long-term structural integrity under dynamic stress conditions.

To support OEMs and industrial partners globally, Suzhou Baoshida maintains strict adherence to international quality standards, including ISO 9001 certification and ASTM/GB compliance for physical and chemical properties. Our production lines are optimized for scalability, enabling low-volume prototyping and high-volume manufacturing with equal precision. Every batch undergoes comprehensive testing for tensile strength, elongation, adhesion peel resistance, heat aging, and fluid immersion performance.

The following table outlines key technical specifications for our standard tube material fabric offerings:

| Property | Test Method | Value (Typical) |

|---|---|---|

| Fabric Type | Visual/Microscopy | Polyester Cord, Rayon, Nylon, or Aramid |

| Rubber Coverage (g/m²) | ASTM D3767 | 180 – 320 |

| Adhesion Strength (N/cm) | ASTM D413 | ≥ 8.0 |

| Tensile Strength (MPa) | ASTM D412 | 18 – 26 |

| Elongation at Break (%) | ASTM D412 | 350 – 520 |

| Temperature Range (°C) | ISO 188 | -40 to +135 |

| Fluid Resistance (Oil, Water, Coolants) | ASTM D471 | Excellent to Good |

| Hardness (Shore A) | ASTM D2240 | 60 – 75 |

For application-specific requirements, we offer custom compounding services, including halogen-free formulations, flame-retardant variants, and ozone-resistant coatings. Our technical team collaborates directly with clients to optimize material selection, bonding protocols, and processing parameters for seamless integration into existing production workflows.

To discuss your project requirements or request samples and technical data sheets, contact Mr. Boyce, OEM Manager at Suzhou Baoshida Trading Co., Ltd. He is available to provide engineering support, quotation details, and logistical coordination for global shipments. Partner with us to ensure your rubber components meet the highest benchmarks in performance and reliability.

Reach out today via email at [email protected] to initiate a technical consultation and discover how our tube material fabrics can enhance the efficiency and lifespan of your industrial systems.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).