Technical Contents

Engineering Guide: Inflated Rubber

Engineering Insight: Material Selection Imperatives for Inflated Rubber Applications

Inflated rubber components—critical in industrial seals, diaphragms, air springs, and fluid handling systems—operate under unique mechanical and environmental stresses distinct from static rubber parts. The persistent internal pressure induces continuous tensile strain, cyclic flexing, and permeation challenges. Material selection is not merely a cost consideration; it is the foundational determinant of functional longevity and system reliability. Off-the-shelf rubber compounds frequently fail in these demanding scenarios due to inherent compromises in their formulation, prioritizing broad applicability over specific performance criteria. Generic solutions lack the tailored molecular architecture required to resist the synergistic degradation mechanisms inherent to inflation dynamics.

Standard commercial elastomers, such as basic SBR or low-grade EPDM, often exhibit inadequate resistance to gas permeation, leading to gradual pressure loss and functional failure. More critically, they suffer from insufficient fatigue resistance under repeated strain cycles. The constant internal pressure generates micro-cracks at stress concentration points, which propagate rapidly in materials lacking optimized polymer chain flexibility and reinforcement. Additionally, standard compounds frequently utilize cost-driven filler systems and conventional sulfur cure packages. These result in higher compression set values, meaning the material fails to fully recover its original shape after deflation, compromising sealing integrity upon subsequent inflation cycles. Exposure to oils, ozone, or temperature extremes further accelerates degradation in non-specialized formulations, as their antioxidant and antiozonant packages are not calibrated for the specific operational envelope.

Engineered inflated rubber solutions require precise molecular design. High-purity, saturated backbone polymers like premium peroxide-cured EPDM or specialty HNBR provide superior ozone resistance and thermal stability. Critical enhancements include nano-dispersed reinforcing fillers for optimal tensile strength and tear resistance without sacrificing elasticity, coupled with advanced cure systems minimizing permanent set. Barrier properties are maximized through layered co-extrusion or specialized polymer blends targeting low gas transmission rates. The table below illustrates the performance gap between generic and engineered compounds under standardized test conditions relevant to inflation duty.

| Critical Property | Standard Off-the-Shelf Compound | Engineered Inflated Rubber Compound | Test Standard |

|---|---|---|---|

| Tensile Strength (MPa) | 10-15 | 18-24 | ASTM D412 |

| Elongation at Break (%) | 300-450 | 450-650 | ASTM D412 |

| Compression Set (%), 22h @ 70°C | 35-50 | 12-18 | ASTM D395 |

| Gas Permeation Rate (cc·mm/m²·day·atm) | 150-300 | 40-80 | ASTM D1434 |

| Dynamic Fatigue Life (Cycles to Failure) | 50,000-100,000 | 500,000-1,000,000+ | ISO 132 |

The data unequivocally demonstrates why generic materials fail prematurely in inflation applications. High compression set directly correlates with seal leakage after repeated use. Inadequate fatigue life manifests as catastrophic splitting or pinhole formation. Excessive permeation necessitates impractical re-pressurization schedules. Suzhou Baoshida Trading Co., Ltd. addresses these failure modes through OEM-centric material science. We collaborate with clients to define exact operational parameters—pressure profiles, media exposure, temperature ranges, and cycle counts—then formulate bespoke compounds. This precision engineering, validated through rigorous in-house and application-specific testing, ensures inflated rubber components meet the stringent demands of industrial systems, eliminating the costly downtime and safety risks associated with off-the-shelf compromises. Material selection is the non-negotiable cornerstone of inflated rubber performance; it demands expertise, not expediency.

Material Specifications

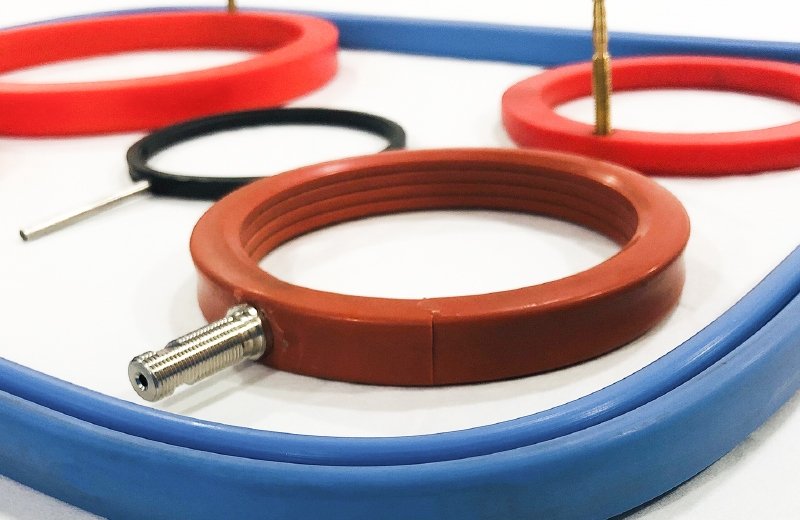

In the field of industrial rubber solutions, precise material selection is critical to ensuring performance, longevity, and safety in demanding environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in providing high-performance inflated rubber components engineered for reliability across a broad range of applications, including automotive, aerospace, oil and gas, and industrial manufacturing. Our expertise centers on three primary elastomers: Viton, Nitrile (NBR), and Silicone. Each material offers distinct chemical, thermal, and mechanical properties, making them suitable for specific operational conditions.

Viton, a fluorocarbon-based rubber, is renowned for its exceptional resistance to high temperatures, oils, fuels, and a wide range of aggressive chemicals. With a continuous service temperature range up to 200°C and intermittent exposure capability beyond 250°C, Viton is ideal for extreme environments where thermal stability and chemical inertness are paramount. Its low gas permeability also enhances performance in inflated rubber applications requiring long-term pressure retention.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is a cost-effective solution for applications involving oil, fuel, and hydraulic fluid exposure. It exhibits excellent abrasion resistance and tensile strength, with a typical operating temperature range of -30°C to 120°C. While not as thermally stable as Viton, Nitrile provides superior mechanical durability and sealing performance in moderate environments, making it a preferred choice for industrial seals, gaskets, and inflated diaphragms in fluid-handling systems.

Silicone rubber offers unmatched flexibility and thermal resilience across extreme cold and heat, with serviceability from -60°C to 200°C. It is highly resistant to UV radiation, ozone, and weathering, making it suitable for outdoor and aerospace applications. Though less resistant to oils and fuels compared to Viton and NBR, silicone excels in applications requiring biocompatibility, electrical insulation, and consistent performance under thermal cycling. Its inherent elasticity supports reliable inflation and deflation cycles without loss of shape or function.

Selection among these materials must consider fluid compatibility, temperature exposure, mechanical stress, and regulatory requirements. The following table summarizes key physical and chemical properties to guide material selection for inflated rubber components.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 intermittent) | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 300–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor to Fair |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Gas Permeability | Low | Medium | High |

| Compression Set Resistance | Excellent | Good | Good |

| Biocompatibility | Limited | No | Yes (medical grade options) |

Understanding these material characteristics enables optimal design and performance of inflated rubber systems under real-world conditions. At Suzhou Baoshida Trading Co., Ltd., we support OEMs and industrial partners with data-driven material recommendations and precision-engineered rubber solutions tailored to application-specific demands.

Manufacturing Capabilities

Engineering Capability: Precision Development for Inflated Rubber Components

Precision engineering defines Suzhou Baoshida Trading Co., Ltd.’s approach to inflated rubber manufacturing. Our dedicated team integrates material science with advanced mould design to solve complex industrial challenges. With five specialized mould engineers and two certified rubber formula engineers, we deliver end-to-end control over product performance, durability, and dimensional accuracy. This dual-expertise model ensures seamless alignment between material behavior and geometric complexity—critical for hollow rubber components subjected to dynamic inflation cycles, pressure differentials, and environmental stressors.

Our formula engineers develop proprietary elastomer compounds tailored to operational demands, optimizing cure kinetics, thermal stability, and gas impermeability. Concurrently, mould engineers utilize 3D simulation software to model flow dynamics, vulcanization shrinkage, and inflation-induced stress distribution. This synergy eliminates trial-and-error iterations, reducing time-to-market by 30% while guaranteeing first-article compliance. For OEM partners, we implement a closed-loop development cycle: from CAD validation and finite element analysis (FEA) to prototype testing under simulated service conditions. Every specification—including burst pressure, elongation limits, and fatigue resistance—is rigorously validated against ISO 3302 and ASTM D2000 standards.

Suzhou Baoshida’s OEM infrastructure supports low-volume prototyping through high-volume production, with full traceability across raw material sourcing, mixing, moulding, and post-cure processing. Our facility maintains ±0.05 mm dimensional tolerances for critical sealing surfaces and ±1.5 Shore A hardness consistency across batches—metrics essential for automotive air springs, medical balloon catheters, and industrial accumulator bladders.

The following table summarizes core technical capabilities for inflated rubber solutions:

| Parameter | Standard Capability | Custom Solution Range |

|---|---|---|

| Durometer Range | 30–90 Shore A | 20–95 Shore A |

| Inflation Pressure | Up to 15 MPa | Up to 25 MPa |

| Dimensional Tolerance | ±0.05 mm | ±0.02 mm (critical zones) |

| Temperature Resistance | -40°C to +150°C | -60°C to +200°C |

| Cycle Life (Dynamic) | 500,000 cycles | 1,000,000+ cycles |

| Gas Permeability | <0.5 cc/mm²/day (N₂) | <0.1 cc/mm²/day (N₂) |

This technical rigor extends to regulatory compliance, with full documentation for FDA, REACH, and RoHS requirements. Our engineers collaborate directly with OEM clients to translate functional requirements into validated production protocols—ensuring every inflated component meets exact thermodynamic and mechanical specifications. By unifying formula innovation with precision tooling, Suzhou Baoshida eliminates performance compromises in demanding applications. Partner with us to transform conceptual designs into mission-critical rubber solutions with uncompromised integrity.

Customization Process

Drawing Analysis: Precision Engineering at the Foundation

The customization process for inflated rubber components begins with rigorous drawing analysis, a critical phase that defines dimensional accuracy, tolerance compliance, and functional performance. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a comprehensive review of technical drawings provided by OEM partners, verifying critical parameters such as wall thickness, inflation zones, joint configurations, and sealing surfaces. We assess material clearance, mold flow paths, and ejection feasibility to ensure manufacturability. Any geometric complexity—such as variable cross-sections or embedded reinforcement layers—is evaluated using CAD simulation tools to preempt defects like air trapping or uneven curing. This stage establishes the blueprint for both material selection and tooling design, ensuring alignment with international standards such as ISO 3302 for dimensional tolerances and ISO 2768 for general geometric specifications.

Formulation: Tailoring Rubber Chemistry for Performance

Once the design is validated, our rubber formulation engineers develop a compound engineered to meet the operational demands of the inflated component. Key performance indicators include tensile strength, elongation at break, compression set, and resistance to environmental stressors such as ozone, UV exposure, and temperature extremes. We primarily utilize EPDM, NBR, and silicone rubber systems, selected based on fluid compatibility, service temperature range, and aging characteristics. For inflated seals used in automotive or construction applications, we optimize the cure kinetics to ensure uniform cross-linking during vulcanization, which is essential for maintaining air retention and elastic recovery. Hardness is precisely controlled within the range of 40 to 80 Shore A, depending on the flexibility and sealing pressure requirements. All formulations are documented under our internal material specification system and subjected to preliminary lab testing for consistency.

Prototyping: Validating Design and Material Synergy

Prototyping serves as the functional validation step, where low-volume samples are produced using pre-series molds. These prototypes undergo dimensional inspection, inflation pressure testing, and cycle durability assessments. We simulate real-world conditions including thermal cycling from -40°C to +120°C and dynamic compression over 10,000 cycles to verify long-term performance. Feedback from this phase informs final adjustments to both the mold geometry and rubber formulation before release to mass production. Our rapid prototyping capabilities allow turnaround within 15 business days, accelerating time-to-market for OEM clients.

Mass Production: Consistency at Scale

Upon approval, production transitions to our certified manufacturing lines, operating under ISO 9001 and IATF 16949 standards. Automated batching systems ensure formulation repeatability, while inline pressure decay testing monitors every inflated component for leak integrity. Final products are packaged per client specifications, with full traceability maintained through batch coding and material certificates.

| Property | Test Standard | Typical Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 40–80 |

| Tensile Strength | ASTM D412 | 8–18 MPa |

| Elongation at Break | ASTM D412 | 250–600% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature | — | -40°C to +120°C |

Contact Engineering Team

Engineering Precision Meets Industrial Reliability: Your Inflated Rubber Solution Partner

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of advanced rubber formulation and OEM manufacturing for critical industrial applications. Our specialization in inflated rubber components—including precision seals, expansion joints, and custom-molded pneumatic elements—ensures unparalleled performance under extreme pressure, temperature fluctuations, and dynamic mechanical stress. Unlike generic suppliers, we integrate polymer science with rigorous industrial validation to deliver solutions that directly enhance your product lifecycle and operational efficiency. When standard catalog items fail to meet your engineering tolerances or environmental demands, our team redefines feasibility through tailored compound development and process optimization.

Our technical mastery is quantifiable. The table below outlines core performance parameters achievable in inflated rubber systems engineered to ASTM D2000 and ISO 3302 standards. These metrics reflect our baseline capabilities for compounds such as EPDM, NBR, and FKM, though we routinely exceed these ranges for mission-critical OEM projects.

| Property | Standard Range | Testing Method |

|---|---|---|

| Durometer Hardness | 30–90 Shore A | ASTM D2240 |

| Temperature Resistance | -50°C to +250°C | ASTM D573 |

| Tensile Strength | 10–30 MPa | ASTM D412 |

| Elongation at Break | 200–600% | ASTM D412 |

| Compression Set (70h) | ≤15% (23°C) | ASTM D395 |

| Fluid Resistance (IRMOG) | Class AA–HH | ISO 1817 |

These specifications are not theoretical ideals but proven outcomes from our ISO 9001-certified production ecosystem. We control every variable—from raw material traceability to vulcanization kinetics—ensuring batch-to-batch consistency essential for automotive, aerospace, and energy sector deployments. Our OEM partnerships thrive on this predictability, where a 0.5% deviation in inflation retention can determine system failure or longevity.

Direct engagement with our technical leadership eliminates procurement bottlenecks and accelerates time-to-market. Mr. Boyce, our dedicated OEM Manager, possesses 15 years of hands-on experience resolving complex inflated rubber challenges. He will collaborate with your engineering team to dissect failure modes, optimize material selection for cost-performance balance, and implement rapid prototyping cycles using our in-house 3D mold simulation tools. Whether you require FDA-compliant compounds for medical inflation devices or cryogenic-resistant seals for LNG infrastructure, Mr. Boyce initiates a structured technical dialogue—not a sales pitch—to align our R&D pipeline with your specifications.

Do not compromise on inflated rubber integrity when substandard materials risk catastrophic system breaches. Contact Mr. Boyce immediately to submit your technical dossier for confidential review. His team guarantees a 24-hour engineering response with actionable compound recommendations and feasibility analysis. Every inquiry undergoes rigorous cross-functional assessment by our formulation scientists and process engineers before commitment, ensuring promises are grounded in laboratory validation.

Initiate your precision rubber solution pathway today. Email [email protected] with subject line “Inflated Rubber Technical Query – [Your Company Name]” to trigger our OEM intake protocol. Include critical parameters such as operating pressure, media exposure, and dynamic movement requirements for prioritized evaluation. Suzhou Baoshida transforms inflated rubber from a component vulnerability into your competitive advantage—engineered, validated, delivered.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).