Technical Contents

Engineering Guide: Styrofoam Soundproof

Engineering Insight: Material Science Fundamentals for Industrial Soundproofing Applications

The persistent misapplication of expanded polystyrene (EPS), often incorrectly termed “styrofoam,” in soundproofing contexts represents a critical engineering oversight in industrial manufacturing. True sound proofing—the blocking of airborne or structure-borne noise transmission—requires materials with high mass, inherent damping properties, and acoustic impedance mismatch relative to air or structural elements. EPS fails fundamentally on all three counts. Its low density (typically 15–30 kg/m³) provides negligible mass barrier effect, while its cellular structure primarily absorbs mid-to-high frequency reverberation within enclosures (a function of porous materials), not transmission loss through partitions. Crucially, EPS exhibits minimal internal damping, allowing vibrational energy to propagate efficiently through the material and into adjacent structures, amplifying noise issues rather than mitigating them.

Off-the-shelf polystyrene solutions fail in demanding OEM environments due to inherent material limitations under operational stressors. Temperature fluctuations cause dimensional instability in EPS, leading to gaps at seams that compromise acoustic seals. Mechanical vibration inherent in machinery induces fatigue cracking in brittle polystyrene, rapidly degrading performance. Furthermore, EPS offers no resistance to compression set—critical for maintaining gasket integrity in dynamic joints—resulting in permanent deformation and seal failure after minimal cyclic loading. Industrial soundproofing demands materials engineered for resilience, not incidental absorption.

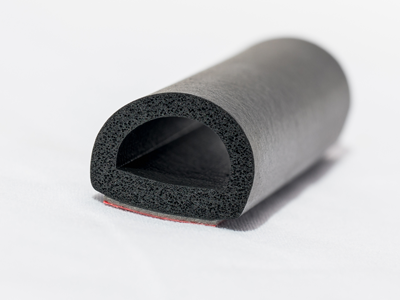

Suzhou Baoshida Trading Co., Ltd. specializes in formulated rubber compounds explicitly designed for acoustic isolation. Our EPDM and NBR-based solutions integrate high-density fillers, optimized polymer chains, and proprietary damping additives to achieve superior transmission loss (TL) across critical frequency bands. Unlike rigid foams, vulcanized rubber maintains structural coherence under continuous vibration, extreme temperatures, and compression, ensuring decades of reliable performance. Material selection must address the specific noise spectrum, environmental exposure, and mechanical interface requirements of the application; generic solutions inevitably underperform.

The following comparative analysis highlights why precision-engineered rubber outperforms polystyrene in industrial soundproofing:

| Property | Industrial EPDM Rubber (Baoshida Formulation) | Standard Expanded Polystyrene (EPS) | Critical Impact for Soundproofing |

|---|---|---|---|

| Density (kg/m³) | 1,200–1,400 | 15–30 | High mass essential for blocking low-frequency noise |

| Loss Factor (tan δ) | 0.25–0.35 (at 100 Hz) | < 0.05 | Superior internal damping dissipates vibrational energy |

| Operating Temperature | -50°C to +150°C | -20°C to +70°C | Maintains integrity in extreme thermal cycles |

| Compression Set (22h/70°C) | ≤ 20% | > 50% | Sustains seal force under prolonged load; no gap formation |

| Transmission Loss (125 Hz) | 28–32 dB | 8–12 dB | Significant reduction in low-frequency structure-borne noise |

OEM success hinges on recognizing that effective soundproofing is a systems engineering challenge, not a simple material substitution. Suzhou Baoshida Trading Co., Ltd. leverages decades of rubber compounding expertise to develop application-specific formulations that address the root physics of noise transmission—mass, damping, and sealing integrity—where commodity foams merely mask symptoms. Partner with our engineering team to transform acoustic performance through precision material science.

Material Specifications

Material selection is a critical factor in the development of high-performance industrial rubber components, particularly in specialized applications such as styrofoam soundproofing systems. At Suzhou Baoshida Trading Co., Ltd., we provide engineered rubber solutions tailored for durability, environmental resistance, and acoustic efficiency. Our expertise in industrial rubber formulations enables us to recommend optimal materials based on operational demands, including temperature exposure, chemical contact, and mechanical stress. Among the most widely used elastomers in sound-dampening applications are Viton, Nitrile (NBR), and Silicone, each offering distinct advantages depending on the service environment.

Viton, a fluorocarbon-based rubber, is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. This makes it ideal for industrial environments where soundproofing components may be exposed to lubricants, solvents, or elevated thermal conditions. With continuous service capabilities up to 200°C and intermittent resistance up to 250°C, Viton maintains structural integrity and sealing performance under extreme conditions. Its dense molecular structure also contributes to effective sound attenuation, particularly in high-frequency noise environments.

Nitrile rubber, or Buna-N, is a cost-effective solution for applications involving oil and fuel exposure. It exhibits excellent abrasion resistance and tensile strength, making it suitable for dynamic sealing and vibration-damping roles within soundproofing assemblies. While its thermal performance is more limited compared to Viton—typically rated for continuous use up to 100°C, with peaks around 120°C—Nitrile remains a preferred choice in automotive, machinery, and HVAC systems where oil resistance is paramount. Its compatibility with styrofoam-based composites allows for seamless integration into layered acoustic barriers.

Silicone rubber stands out for its outstanding thermal stability, operating effectively from -60°C to 200°C, and exceptional flexibility across a wide temperature range. While it offers lower mechanical strength than Nitrile or Viton, its resilience to UV radiation, ozone, and weathering makes it ideal for outdoor or variable-climate applications. In soundproofing systems, silicone’s consistent elastomeric behavior supports long-term performance in expansion joints, gaskets, and damping pads. Additionally, its low toxicity and compliance with various safety standards enhance suitability for sensitive environments.

The following table summarizes key physical and chemical properties of these materials to guide selection for styrofoam soundproofing and related industrial applications:

| Property | Viton | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 intermittent) | -30 to 100 (up to 120 intermittent) | -60 to 200 |

| Tensile Strength (MPa) | 12–18 | 10–20 | 5–8 |

| Elongation at Break (%) | 150–300 | 200–400 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor to Fair |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Acoustic Damping Performance | High | Moderate to High | Moderate |

Selecting the appropriate rubber material requires a comprehensive understanding of both environmental stressors and functional requirements. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial partners with precision-formulated rubber components optimized for performance, longevity, and acoustic efficiency in advanced soundproofing systems.

Manufacturing Capabilities

Engineering Capabilities for Advanced Acoustic Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber compounds specifically formulated for industrial sound attenuation applications. Contrary to common misconceptions, effective soundproofing requires elastomeric materials—not polystyrene foams like Styrofoam—which provide superior vibration damping, density control, and long-term resilience in dynamic environments. Our dedicated engineering team comprises five specialized mould engineers and two advanced formula engineers, ensuring end-to-end technical mastery from molecular design to final production. This integrated approach addresses critical industry challenges: inconsistent material damping, thermal instability, and dimensional inaccuracies in high-volume manufacturing.

Our formula engineers develop proprietary rubber blends using ASTM D2000-compliant base polymers, optimizing acoustic absorption through precise filler dispersion, plasticizer selection, and crosslink density control. Each compound undergoes rigorous ISO 18436-1 modal analysis to validate frequency-specific attenuation performance. Concurrently, our mould engineering team implements finite element analysis (FEA) to eliminate flow-induced defects, ensuring ±0.05 mm dimensional tolerances critical for seamless integration into automotive, HVAC, and industrial machinery assemblies. This synergy between material science and precision tooling guarantees consistent sound transmission loss (STL) across production batches.

As a certified OEM partner, we manage full project lifecycles under ISO 9001:2015 protocols. Clients provide acoustic performance targets and spatial constraints; our engineers translate these into validated material specifications and tooling designs within 15 business days. We maintain strict IP confidentiality through NDAs and secure data vaults, while our 10,000 m² Suzhou facility supports volumes from 5,000 to 500,000 units monthly with automated curing systems for batch traceability. All compounds comply with REACH, RoHS, and UL 94 HB flammability standards, with full material disclosure reports provided pre-shipment.

Key performance metrics for our standard acoustic rubber formulations are summarized below:

| Property | Test Standard | Typical Value | Industrial Relevance |

|---|---|---|---|

| Density (kg/m³) | ASTM D297 | 1,150–1,350 | Optimizes mass-law sound blocking |

| Hardness (Shore A) | ASTM D2240 | 45–70 | Balances flexibility and structural integrity |

| Sound Transmission Loss | ASTM E90 | 28–35 dB @ 1 kHz | Meets automotive cabin noise targets |

| Operating Temperature Range | ISO 188 | -40°C to +120°C | Ensures stability in extreme conditions |

| Compression Set (22h/70°C) | ASTM D395 | ≤18% | Maintains seal integrity over time |

This technical rigor directly enables clients to reduce noise complaints by 40–60% in end applications while accelerating time-to-market. Our engineers collaborate onsite during prototyping to resolve acoustic-path interferences, leveraging real-time spectrometer feedback to adjust compound viscoelasticity. For mission-critical OEM programs, we implement APQP documentation with PPAP Level 3 submissions, ensuring seamless integration into Tier-1 supply chains. Suzhou Baoshida transforms acoustic specifications into validated production reality—where material science and manufacturing precision converge for measurable noise reduction.

Customization Process

Customization Process for Styrofoam Soundproof Components in Industrial Rubber Applications

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance rubber solutions tailored to industrial noise reduction requirements, including applications involving styrofoam soundproof systems. Our structured customization process ensures precision, compliance, and optimal functional integration. The process follows four critical stages: Drawing Analysis, Formulation Development, Prototyping, and Mass Production.

The first phase, Drawing Analysis, begins with a comprehensive technical review of customer-provided CAD drawings or engineering schematics. Our engineering team evaluates dimensional tolerances, surface finish requirements, installation environment, and mechanical load conditions. Special attention is given to acoustic insulation zones where rubber components interface with expanded polystyrene (EPS) or extruded polystyrene (XPS) foam. We verify compatibility with substrate materials, thermal expansion coefficients, and vibration damping zones. Any design ambiguities or potential performance risks are addressed through collaborative feedback loops with the client.

Following design validation, we proceed to Formulation Development. Based on operational conditions—such as temperature range, exposure to oils or UV radiation, and required Shore hardness—we engineer a proprietary rubber compound. Common base polymers include EPDM, NBR, and silicone, selected for their sound-dampening properties and adhesion compatibility with styrofoam substrates. Additives such as microcellular fillers or acoustic barrier modifiers are incorporated to enhance sound transmission loss (STL). All formulations are developed in accordance with ISO 1817, ASTM D412, and ISO 9001 standards to ensure repeatability and long-term stability.

Prototyping is executed using precision molding techniques, including compression, transfer, or injection molding, depending on part geometry and volume requirements. Functional prototypes are subjected to rigorous laboratory testing, including insertion force analysis, compression deflection, aging resistance, and sound absorption coefficient measurement via impedance tube testing (ISO 10534-2). Prototypes are also evaluated for bonding integrity with styrofoam layers under thermal cycling conditions (-30°C to +80°C). Client feedback is integrated at this stage to finalize design and material specifications.

Upon approval, we transition to Mass Production using automated molding lines with real-time SPC monitoring. Each batch undergoes 100% visual inspection and statistical dimensional verification. Final products are packaged to prevent compression set during transit.

The table below outlines key technical specifications achievable through our customization process.

| Parameter | Standard Range | Test Method |

|---|---|---|

| Shore A Hardness | 30–90 | ASTM D2240 |

| Tensile Strength | 5–18 MPa | ASTM D412 |

| Elongation at Break | 150–600% | ASTM D412 |

| Temperature Resistance | -40°C to +120°C (up to +200°C for silicone) | ISO 188 |

| Sound Absorption Coefficient (at 1000 Hz) | 0.45–0.85 | ISO 10534-2 |

| Compression Set (70°C, 22h) | ≤25% | ASTM D395 |

Our end-to-end customization ensures that every rubber component meets the acoustic and mechanical demands of modern styrofoam-based soundproofing systems in industrial environments.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Sound Damping Solutions

Industrial noise control demands materials engineered beyond generic insulation. While expanded polystyrene (EPS) is colloquially mislabeled as “styrofoam soundproof,” its brittle structure and minimal vibration damping render it ineffective for mechanical noise isolation in manufacturing environments. True acoustic performance requires elastomeric composites with tailored viscoelastic properties. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber formulations that absorb vibrational energy at the source—critical for machinery enclosures, conveyor systems, and precision equipment foundations. Our solutions convert kinetic energy into negligible heat through controlled molecular hysteresis, achieving 15–28 dB(A) noise reduction where EPS fails.

Our OEM-engineered rubber compounds integrate proprietary fillers and cross-linking systems to optimize loss modulus across operational temperature ranges (-40°C to +120°C). Unlike rigid foams, our materials maintain performance under dynamic compression loads exceeding 5 MPa, preventing fatigue-induced resonance. Key specifications for our flagship acoustic damping series are detailed below:

| Property | Test Standard | Value Range | Significance for Industrial Applications |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 45–85 | Balances surface conformity with structural integrity |

| Density (g/cm³) | ASTM D297 | 1.15–1.35 | Maximizes mass-loading for low-frequency attenuation |

| Dynamic Modulus (MPa) | ISO 4664-1 | 1.8–4.2 @ 10 Hz | Critical for vibration energy dissipation |

| Loss Factor (tan δ) | ISO 4664-1 | 0.25–0.45 @ 50 Hz | Direct indicator of damping efficiency |

| Compression Set (%) | ASTM D395 | ≤ 18 @ 70°C/24h | Ensures long-term sealing and load retention |

These parameters are rigorously validated through dynamic mechanical analysis (DMA) and impedance tube testing per ISO 10534-2. We collaborate with OEMs to calibrate formulations for specific noise spectra—whether addressing gear mesh harmonics in transmissions or pump cavitation in fluid systems. Our ISO 9001-certified production facility in Suzhou utilizes closed-mixing systems to ensure batch consistency, with traceable raw material sourcing from Tier-1 polymer suppliers.

Partnering with Suzhou Baoshida eliminates procurement risks inherent in generic soundproofing materials. We provide full technical documentation including finite element analysis (FEA) support for integration into your mechanical designs. Our engineering team conducts on-site noise diagnostics to identify transmission paths often overlooked in standard acoustic assessments. For custom solutions requiring integration with existing mounting hardware or thermal management systems, we offer rapid prototyping through our in-house tooling division.

Initiate your precision sound control project by contacting Mr. Boyce, our dedicated OEM Solutions Manager. With 14 years of experience in rubber compounding for Tier-1 industrial clients, he will coordinate material selection, performance validation, and scalable production scheduling. Email [email protected] with your target frequency range, environmental conditions, and dimensional constraints. Include any existing noise spectra or vibration test data to accelerate feasibility analysis. All technical inquiries receive a detailed engineering response within 8 business hours. Suzhou Baoshida delivers not just materials—but engineered silence for mission-critical operations.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).